Professional Documents

Culture Documents

Fuel-Amm-Main Fuel Pump System - Description and Operation PDF

Uploaded by

Thanh QuangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel-Amm-Main Fuel Pump System - Description and Operation PDF

Uploaded by

Thanh QuangCopyright:

Available Formats

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

** ON A/C ALL

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP SYSTEM - DESCRIPTION AND OPERATION

1. General

The main fuel pump system supplies the fuel from the fuel tanks to the engines. The system has six main fuel

pumps (main pumps):

· two in each wing tank

· two in the center tank.

The main pumps in each wing operate together continuously to supply fuel to their related engine.

The Fuel Level Sensing Control Units (FLSCUs) (Ref. AMM D/O 28-46-00-00) normally control the main

pumps in the center tank automatically. They supply fuel to their related engine during flight when the fuel in

the wing tank is below a specified level. The wing tank pumps each have a sequence valve that makes sure the

center tank fuel is supplied to the engines first.

The crossfeed system (Ref. AMM D/O 28-23-00-00) , when closed, divides the main fuel pump system into

two parts, one part for each engine. If one wing tank main pump has a failure (or it is set to OFF) the other will

continue to supply fuel to its related engine.

When the crossfeed system is open, it is possible for one fuel pump to supply fuel to the two engines.

The system has valves that automatically bleed the air from the engine feed-pipes during fuel pump operation.

The Engine/Warning Display (EWD) (Ref. AMM D/O 31-66-00-00) and the System Display (SD) (which

together make the ECAM) give system data to the crew. If specified failures occur:

· a warning is given on the EWD

· the FUEL page shows on the SD.

When necessary the crew can make a selection on the ECAM control panel (Ref. AMM D/O 31-56-00-00) to

look at the FUEL page.

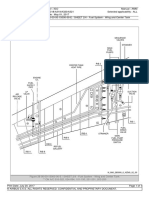

2. Component Location

(Ref. Fig. Main Fuel Pump System)

Print Date: August 12, 2017 Page 1 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

MAIN FUEL MAIN FUEL

PUMP PUMP

21QA

25QA

(26QA)

(22QA)

MAIN FUEL

PUMP CANISTER MAIN FUEL

PUMP CANISTER

1QM

2QM

TO MAIN FUEL

(4QM) PUMP SCAVENGE (3QM)

SYSTEM

STRAINER

ENGINE 5QM

C/L RIB2

(7QM)

LP

VALVE

(28-24-00)

SEQUENCE

FUEL VALVES

AIR

RELEASE SUPPLY

VALVE PIPE

86QM

(87QM)

SUCTION

MM VALVE

RIB1

CLACK

VALVES

RIB4

RIB6

RIB8 STRAINER

6QM

(8QM)

RIB11 RIB9

MAIN

FUEL PUMP

PRESSURE

SWITCH

23QA 27QA

(28QA) (24QA)

N_MM_282100_0_AUM0_01_01

Figure 28-21-00-12500-00-B / SHEET 1/2 - Main Fuel Pump System

** ON A/C ALL

Print Date: August 12, 2017 Page 2 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

MAIN FUEL PUMP MAIN FUEL PUMP

37QA C/L 38QA

MAIN FUEL PUMP MAIN FUEL PUMP

CANISTER CANISTER

84QM 85QM

STRAINER STRAINER

CENTER

TANK

FROM MAIN FROM MAIN

FUEL PUMP FUEL PUMP

SCAVENGE SCAVENGE

SYSTEM SYSTEM

M M M

TO MAIN TO MAIN

FUEL PUMP FUEL PUMP

SCAVENGE SCAVENGE

SYSTEM SYSTEM

DEFUEL

TRANSFER CENTER TANK

VALVE FUEL PUMP

CENTER TANK (28-25-00) PRESSURE

FUEL PUMP

SWITCH

PRESSURE SWITCH

39QA CROSSFEED 40QA

VALVE

(28-23-00)

TO APU

FUEL PUMP

SYSTEM

(28-22-00)

N_MM_282100_0_AUM0_02_00

Figure 28-21-00-12500-00-B / SHEET 2/2 - Main Fuel Pump System

** ON A/C ALL

Print Date: August 12, 2017 Page 3 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

(Ref. Fig. Main Fuel Pump Scavenge System)

Print Date: August 12, 2017 Page 4 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

RIB 15

JET PUMP

PICK-UP

PIPE

RIB 22

FROM THE

MAIN FUEL

PUMPS

INTERCELL

TRANSFER

VALVE

JET PUMP (28-15-00)

67QM

JET PUMP (68QM)

66QM

A (69QM)

CHECK VALVE

37QM

(38QM)

RIB 22

JET PUMP

PICK-UP PIPE

N_MM_282100_0_JCM0_01_00

Figure 28-21-00-12600-00-C / SHEET 1/3 - Main Fuel Pump Scavenge System

** ON A/C ALL

Print Date: August 12, 2017 Page 5 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

MAIN FUEL MAIN FUEL

PUMP PUMP

21QM 25QM

(26QM) (22QM)

CHECK VALVE

CHECK VALVE

34QM

33QM

RIB 2 (35QM)

(36QM)

STRAINER

JET PUMP

SUPPLY PIPE SEQUENCE

VALVES

RIB 1

RIB 4

RIB 6

RIB 8 STRAINER

RIB 11 RIB 9

MAIN FUEL PUMP

PRESSURE SWITCH

23QM 27QM

(28QM) (24QM)

N_MM_282100_0_JCM0_02_00

Figure 28-21-00-12600-00-C / SHEET 2/3 - Main Fuel Pump Scavenge System

** ON A/C ALL

Print Date: August 12, 2017 Page 6 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

C/L

MAIN FUEL PUMP MAIN FUEL PUMP

37QA 38QA

STRAINER STRAINER

CENTER

TANK

JET PUMP JET PUMP

PICK-UP PICK-UP

PIPES PIPES

JET PUMP JET PUMP

89QM 90QM

JET PUMP

SUPPLY

CENTER TANK PIPES CENTER TANK

FUEL PUMP FUEL PUMP

PRESSURE SWITCH PRESSURE SWITCH

39QA 40QA

N_MM_282100_0_JCM0_03_00

Figure 28-21-00-12600-00-C / SHEET 3/3 - Main Fuel Pump Scavenge System

** ON A/C ALL

Print Date: August 12, 2017 Page 7 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

FIN FUNCTIONAL DESIGNATION PANEL ZO AC- ATA REF

NE CESS

DOOR

21QA PUMP-FUEL NO 1, L WING TK 540AB 540 28-21-51

22QA PUMP-FUEL NO 1, R WING TK 640AB 640 28-21-51

25QA PUMP-FUEL NO 2, L WING TK 540AB 540 28-21-51

26QA PUMP-FUEL NO 2, R WING TK 640AB 640 28-21-51

23QA PRESS SW-FUEL PUMP NO 1, L WING 571AB 570 28-21-15

TK

24QA PRESS SW-FUEL PUMP NO 1, R WING 671AB 670 28-21-15

TK

27QA PRESS SW-FUEL PUMP NO 2, L WING 571AB 570 28-21-15

TK

28QA PRESS SW-FUEL PUMP NO 2, R WING 671AB 670 28-21-15

TK

1QM CANISTER-FUEL PUMP, L WING TK 540AB 540 28-21-52

OUTR

3QM CANISTER-FUEL PUMP, R WING TK INR 640AB 640 28-21-52

2QM CANISTER-FUEL PUMP, L WING TK INR 540AB 540 28-21-52

4QM CANISTER-FUEL PUMP, R WING TANK 640AB 640 28-21-52

OUTER

5QM STRAINER-PUMP INLET, L WING TK 540AB 540 28-21-54

OUTR

7QM STRAINER-PUMP INLET, R WING TK 640AB 640 28-21-54

INR

6QM STRAINER-PUMP INLET, L WING TK 540AB 540 28-21-54

INR

8QM STRAINER-PUMP INLET, R WING TK 640AB 640 28-21-54

OUTR

** ON A/C ALL

EMB SB 28-1123 for A/C 008-010

86QM VALVE-AIR RELEASE, L WING TK 540CB 540 28-21-41

87QM VALVE-AIR RELEASE, R WING TK 640CB 640 28-21-41

** ON A/C ALL

33QM CHECK VALVE-FUEL PUMP,L WING TK 540AB 540 28-21-43

OUTR

34QM CHECK VALVE-FUEL PUMP, L WING TK 540AB 540 28-21-43

INR

35QM CHECK VALVE-FUEL PUMP, R WING TK 640AB 640 28-21-43

INR

36QM CHECK VALVE-FUEL PUMP, R WING TK 640AB 640 28-21-43

OUTR

37QM CHECK VALVE-FUEL PUMP, L VENT 540AB 540 28-21-43

SURGE TK

38QM CHECK VALVE-FUEL PUMP, R VENT 640AB 640 28-21-43

SURGE TK

Print Date: August 12, 2017 Page 8 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

FIN FUNCTIONAL DESIGNATION PANEL ZO AC- ATA REF

NE CESS

DOOR

66QM JET PUMP-WATER SCAVENGE, L VENT 540KB 540 28-21-53

SURGE TK

67QM JET PUMP-WATER SCAVENGE, L WING 540KB 540 28-21-53

TK

68QM JET PUMP-WATER SCAVENGE, R 640KB 640 28-21-53

WING TK

69QM JET PUMP-WATER SCAVENGE, R VENT 640KB 640 28-21-53

SURGE TK

37QA PUMP-FUEL NO 1, CTR TK 195AB 195 28-21-51

38QA PUMP-FUEL NO 2, CTR TK 196AB 196 28-21-51

84QM CANISTER-FUEL PUMP, L CTR TK 147AZ 141 28-21-52

85QM CANISTER-FUEL PUMP, R CTR TK 148AZ 142 28-21-52

39QA PRESS SW-FUEL PUMP NO 1, CTR TK 147 28-21-15

40QA PRESS SW-FUEL PUMP NO 2, CTR TK 148 28-21-15

89QM JET PUMP-WATER SCAVENGE, L CTR 147AZ 141 28-21-53

TK

90QM JET PUMP-WATER SCAVENGE, R CTR 148AZ 142 28-21-53

TK

3. System Description

The main fuel pump system has these components:

· the fuel strainers 5QM(7QM), 6QM(8QM)

· the fuel pumps 21QA(22QA), 25QA(26QA), 37QA(38QA)

· the fuel pump canisters 1QM(3QM), 2QM(4QM), 84QM(85QM)

· the fuel pump pressure switches 23QA(24QA), 27QA(28QA), 39QA(40QA)

· the check valves 33QM(36QM), 34QM(35QM), 37QM(38QM)

· the scavenge jet pumps 66QM(68QM), 66QM(69QM), 89QM(90QM)

· the engine fuel-feed air-release valves 86QM(87QM).

When it is in operation, each main pump supplies the fuel to:

· its related engine

· the crossfeed system (Ref. AMM D/O 28-23-00-00)

· the refuel/defuel system (Ref. AMM D/O 28-25-00-00) (for pressure defuel).

Each wing tank has a closed area which is a collector cell. The collector cell is made between RIB1 and RIB2,

the front and the rear spars and the top and bottom skins. Clack valves, in the bottom of RIB2, let the fuel go

into the collector cells but do not let the fuel go out. The collector cells make sure that the main pumps are

always fully in fuel during all flight manoeuvres. In the collector cells are:

· two fuel pump canisters and their related fuel pump elements (which together make the main pumps)

· two fuel strainers

· a suction valve

· two check valves.

The canisters 1QM(3QM) 2QM(4QM) are attached to the wing bottom skin and fully contain the fuel pump

element. Each canister has:

· an upper outlet that connects to the engine feed line

· an upper outlet that connects to a sequence valve

· a (smaller) outlet that connects to the scavenge jet pumps 66QM(69QM), 67QM(68QM) and the fuel pump

pressure switches 23QA(28QA), 27QA(24QA)

· a vent valve installed on the top of the canister

· a lower inlet that connects to the fuel strainers 6QM(8QM), 5QM(7QM).

The engine feed outlet from each canister has an internal check valve.

Print Date: August 12, 2017 Page 9 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

The check valves 33QM(36QM), 34QM(35QM) are in the line to the scavenge jet pumps.

The vent valve is installed in a flametrap at the top of the canister. Gas or air that is removed from the fuel by

the pump, is sent back to the fuel tank through the vent valve. The valve prevents fuel flow in the opposite

direction and is opened by a probe in the related fuel pump.

When the fuel pump is not in operation the check valves prevent a flow of fuel back through the pump.

The canisters 84QM(85QM) are attached to the center tank bottom skin and fully contain the fuel pump

element. Each canister has:

· an upper outlet that connects to the engine feed line

· a (smaller) outlet that connects to the scavenge jet pumps 89QM(90QM), and the fuel pump pressure

switches 39QA(40QA)

· a vent valve installed on the top of the canister

· a lower inlet that connects to a fuel strainer.

The vent valve is installed in a flametrap at the top of the canister. Gas or air that is removed from the fuel by

the pump, is sent back to the fuel tank through the vent valve. The valve prevents fuel flow in the opposite

direction and is opened by a probe in the related fuel pump.

When the fuel pump is not in operation the check valves prevent a flow of fuel back through the pump.

The canister makes it possible to replace the fuel pump element when there is fuel in the fuel tank. When the

fuel pump element is replaced, the internal check valve, the second check valve and a slide valve seal the

canister.

The pressure switches 23QA(28QA), 27QA(24QA) and 39QA(40QA) monitor the output pressure of the fuel

pumps. They are installed on the rear face of the wing and center tank rear spar. A banjo-connection and

pressure pipe connect the pressure switch to the fuel pump. If the pressure from the main pump decreases to

less than 0.41 bar (6 psi) the pressure switch:

· puts on the amber FAULT light in the related main pump P/BSW

· sends a signal to the Fuel Level Sensing Control Unit (FLSCU) (Ref. AMM D/O 28-46-00-00)

· sends a signal to the ECAM system.

The air release valve 86QM(87QM) releases the air caught in the engine fuel feed-line. The valve is installed at

the high point between the pump and the LP valve (Ref. AMM D/O 28-24-00-00) .

A suction valve is in the engine feed line in each of the collector cells. If all the main pumps fail the engines can

use suction pressure to remove the fuel from the applicable tank through the suction valves.

The suction valve includes drain paths that transfer excess fluid into the collector cell from the tank which

pressurizes the engine feed line.

(Ref. Fig. Fuel Pump System - Cockpit Indications SHEET 1)

Print Date: August 12, 2017 Page 10 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

X FEED

ENG 1 APU ENG 2

F OPEN F

U ON U

E L TK PUMPS CTR TK CTR TK R TK PUMPS E

1 2 PUMP 1 MODE SEL PUMP 2 1 2

L FAULT A FAULT FAULT

L

FAULT FAULT FAULT U FAULT

T

OFF OFF OFF MAN O OFF OFF OFF

13QA 33QA 34QA 14QA

15QA 48QA 16QA

FUEL CONTROL

PANEL

40VU

ECAM DISPLAY

FUEL KG

F.USED 1 F.USED 2

3100 FOB 3100

14260

APU

LEFT CTR RIGHT

700 5030 2800 5030 700

-11 °C +10 +10 °C -11

SYSTEM PAGE

N_MM_282100_0_JGM0_01_00

Figure 28-21-00-12700-00-C / SHEET 1/1 - Fuel Pump System - Cockpit Indications

** ON A/C ALL

Print Date: August 12, 2017 Page 11 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

Each fuel pump has a related control and indication circuit. These circuits have a P/BSW on the fuel control

panel 40VU (which is part of the overhead panel). Each circuit also has an interface with the two System Data-

Aquisition Concentrators (SDAC1 and SDAC2) (Ref. AMM D/O 31-54-00-00) .

The P/BSWs are identified as:

· L TK PUMP 1, 13QA

· L TK PUMP 2, 15QA

· R TK PUMP 1, 14QA

· R TK PUMP 2, 16QA

· CTR TK PUMP 1, 33QA

· CTR TK PUMP 2, 34QA

· CTR TK MODE SEL, 48QA.

The scavenge jet pumps 66QM(69QM), 67QM(68QM) are in the wing tank on the rear spar between RIB15 and

RIB16.

Fuel can enter the surge tank (Ref. AMM D/O 28-11-00-00) through the venting system (Ref. AMM D/O 28-

12-00-00) when this occurs, the scavenge jet pumps 66QM(69QM) move fuel to the rear intercell transfer

valves 28QM(30QM) (Ref. AMM D/O 28-15-00-00) .

The check valves 37QM(38QM) are in the fuel line between the surge tank and the related jet pump. They

make sure that fuel cannot enter the surge tank through the related jet pump if the main pumps fail or are set to

off.

The scavenge jet pumps 67QM(68QM) move fuel caught in the wing tank outer cell to the rear intercell transfer

valve.

The scavenge jet pumps 89QM(90QM) are in the center tank on the rear spar. They move fuel caught in the

center tank to the related center tank main pump inlet.

4. Power Supply

** ON A/C 008-008

PRE SB 28-1188 for A/C 008-008

(Ref. Fig. Wing Tank Pump 2 and Center Tank Manual Control - Electrical Schematic)

Print Date: August 12, 2017 Page 12 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

FAULT

115V A

AC OFF A

W

36LP XFMR-SYS 2 B

33-14-00

OFF

103PP ON

28VDC

BUS 1 31QA C/B-FUEL/CENTER TK

/PUMPS 1 AND 2/CTL AND IND

C

204PP 1

28VDC D

BUS 2 32QA C/B-FUEL/CENTER TK

/PUMPS 1 AND 2/CTL AND IND

33QA P/BSW-FUEL

/CENTER TK/PUMP 1 2

103XP

115VAC E

BUS 1

A F

B G

29QA C/B-FUEL

C /CENTER TK

/PUMP 1 SPLY H

35QA CNTOR-CENTER TK

PUMP 1 SPLY

FAULT

115V A

AC OFF

W

36LP XFMR-SYS 2

33-14-00

OFF J

202PP

28VDC ON

BUS 2 10QA C/B-FUEL/PUMPS 2/

/R CTL/AND L IND K

204PP L

28VDC 1

BUS 2 9QA C/B-FUEL/PUMPS/2

/L CTL AND R IND

15QA P/BSW-FUEL

/L TK PUMPS/2

204XP

115VAC M

BUS 2

A N

B P

7QA C/B-FUEL/L WING TK NOTE: L SYSTEM SHOWN

C /PUMP 2 SPLY R SYSTEM ALMOST

1 POSITION DATA TO SDACS 31-54-00 THE SAME

2 REFER TO AUTOMATIC CONTROL OF 19QA CNTOR-L WING

THE CENTER TANK FUEL PUMP SYSTEM TK PUMP 2 SPLY

N_MM_282100_0_JRM0_01_00

Figure 28-21-00-17000-00-B / SHEET 1/2 - Wing Tank Pump

2 and Center Tank Manual Control - Electrical Schematic

** ON A/C 008-008 | PRE SB 28-1188 for A/C 008-008

Print Date: August 12, 2017 Page 13 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

FILAMENT TEST

SYS FAULT

RLY

18LP BOARD-ANN LT TEST & INTERFACE

C 33-14-00

D

20LP BOARD-ANN LT

TEST & INTERFACE

33-14-00

F M

G Y

H 37QA PUMP-

FUEL NO. 1,

1 CTR TK

LO

HI

P 2

2

39QA PRESS SW- 41QA RELAY-CTR TK

FUEL PUMP NO. 1, AUTO CTL, 49QA RELAY-CTR TK

CENTER TK PUMP 1 FAULT UNHIBIT,

PUMP 1

J FILAMENT TEST

K

1 LO

L HI

P

SYS FAULT

RLY

27QA PRESS SW-

FUEL PUMP NO. 2

20LP BOARD-ANN LT TEST & INTERFACE L WING TK

M 33-14-00

N M

P Y

25QA PUMP-

FUEL NO. 2,

L WING TK

N_MM_282100_0_JRM0_02_00

Figure 28-21-00-17000-00-B / SHEET 2/2 - Wing Tank Pump

2 and Center Tank Manual Control - Electrical Schematic

** ON A/C 008-008 | PRE SB 28-1188 for A/C 008-008

** ON A/C 009-999

POST SB 28-1188 for A/C 008-008

EMB SB 28-1188 for A/C 009-010

(Ref. Fig. Wing Tank Pump 2 and Center Tank Manual Control - Electrical Schematic)

Print Date: August 12, 2017 Page 14 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

FAULT

115V A

AC A

OFF

W

B

36LP XFHR-SYS 2

33-14-00

OFF

103PP

28VDC ON

BUS 1 31QA C/B-FUEL/CENTER TK

/PIMPS 1 AND 2/CTL AND IND

C

204PP 1

28VDC D

BUS 2 32QA C/B-FUEL/CENTER TK

/PIMPS 1 AND 2/CTL AND IND

33QA P/BSW-FUEL

/CENTER TK/PUMP 1

2

103XP E

115VAC

BUS 1 D F

A E

T G

B

H

29QA C/B-FUEL G F I

C /CENTER TK

/PUMP 1 SPLY

69QA GF1 CENTER TK

PUMP 1 SPLY

115V FAULT

A

AC

OFF

W

36LP XFHR-SYS 2

33-14-00

J

202PP OFF

28VDC ON

BUS 2 10QA C/B-FUEL/PUMPS 2/ K

/R CTL/AND L IND

204PP L

28VDC 1

BUS 2 9QA C/B-FUEL/PUMPS 2/

/L CTL AND R IND

15QA P/BSW-FUEL

/L TK PUMPS/2

204XP M

115VAC

BUS 2 N

A

P

B

7QA C/B-FUEL/L WING TK

C /PUMP 2 SPLY

NOTE: L SYSTEM SHOWN, R SYSTEM SIMILIAR.

1 POSITION DATA TO SOACS 31-54-00. 19QA CNTOR-L WING

TK PUMP 2 SPLY

2 REFER TO AUTOMATIC CONTROL OF

THE CENTER TANK FUEL PUMP SYSTEM.

N_MM_282100_0_JRM1_01_00

Figure 28-21-00-17000-00-C / SHEET 1/2 - Wing Tank Pump

2 and Center Tank Manual Control - Electrical Schematic

** ON A/C 009-999 | EMB SB 28-1188 for A/C 009-010 | POST SB 28-1188 for A/C 008-008

Print Date: August 12, 2017 Page 15 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

FILAMENT TEST

SYS FAULT

RLY

C 18LP BOARD-ANN LT TEST & INTERFACE

33-14-00

D

20LP BOARD-ANN LT

TEST & INTERFACE

33-14-00

F M

G Y

H 47QA PUMP-

FUEL No.1

1 CTR TK

LO

HI

2

P

2

39QA PRESS SW- 41QA RELAY-CTR TK

FUEL PUMP NO.1 AUTO CONTROL 49QA RELAY-CTR TK

CENTER TK PUMP 1 FAULT INHIBIT

PUMP 1

J FILAMENT TEST

K

1 LO

L HI

P

SYS FAULT

RLY

27QA PRESS SW-

FUEL PUMP No.2

20LP BOARD-ANN LT TEST & INTERFACE L WING TK

M 33-14-00

N M

P Y

25QA PUMP-

FUEL PUMP No.2

L WING TK

N_MM_282100_0_JRM1_02_00

Figure 28-21-00-17000-00-C / SHEET 2/2 - Wing Tank Pump

2 and Center Tank Manual Control - Electrical Schematic

** ON A/C 009-999 | EMB SB 28-1188 for A/C 009-010 | POST SB 28-1188 for A/C 008-008

Print Date: August 12, 2017 Page 16 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

** ON A/C ALL

(Ref. Fig. Wing Tank Pump 1 Emergency Operation - Electrical Schematic)

Print Date: August 12, 2017 Page 17 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

115V

AC ESS

31LP XFMR-ESS

33-14-00

FILAMENT TEST

FAULT

A

LO

HI OFF

W

P SYS FAULT RLY OFF

1 ON

6LP BOARD-ANN

23QA PRESS SW- LT TEST & INTFC

FUEL PUMP NO 1, 33-14-00

L WING TK

FILAMENT TEST

13QA P/BSW-FUEL

/L TK PUMPS/1

45LP RLY-TEST, A

SYS 1 & ESS

33-14-00

101PP

28VDC

BUS 1 4QA C/B-FUEL

/PUMPS/1

/R CTL AND L IND

64QA RELAY-

BUS 1/ESS.

401PP R TK PUMP 1

28VDC

ESS 55QA C/B-FUEL/

BUS SMOKE/CONFIG SMOKE

/PUMP CTL OFF

TD-1s

103PP 13XU P/BSW-

28VDC 63QA RELAY- EMER ELEC PWR

BUS 1 3QA C/B-FUEL BUS 1/ESS. /SMOKE DRILL

/PUMPS/1 L TK PUMP 1

/L CTL AND R IND 24-22-00

NOTE: 1 POSITION DATA TO SDAC 31-54-00

N_MM_282100_0_SGM0_01_00

Figure 28-21-00-17100-00-A / SHEET 1/2 - Wing Tank Pump 1 Emergency Operation - Electrical Schematic

** ON A/C ALL

Print Date: August 12, 2017 Page 18 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

T1 L1

AC MAIN M

T2 L2

GENER

-ATION Y

T3 L3

11QA C/B-

L WING TK 21QA PUMP-

/PUMP 1 42XU3 1 FUEL No 1,

/STBY SPLY CURRENT L WING TK

9XU1 GLC-1

24-22-00 XFMR

53QA CNTOR-

L WING TK

STBY SPLY,

PUMP 1

103XP A

115VAC

BUS 1 B

A

1QA C/B-FUEL

C /L WING TK 1

/PUMP 1 SPLY

B

17QA CNTOR-

L WING TK

PUMP 1 SPLY

N_MM_282100_0_SGM0_02_00

Figure 28-21-00-17100-00-A / SHEET 2/2 - Wing Tank Pump 1 Emergency Operation - Electrical Schematic

** ON A/C ALL

Print Date: August 12, 2017 Page 19 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

** ON A/C ALL

EMB SB 28-1059 for A/C 008-010

(Ref. Fig. Center Tank Pumps Automatic Control - Electrical Schematic)

Print Date: August 12, 2017 Page 20 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

45LP RELAY-TEST,

SYS 1 & ESS

33-14-00

FAULT A

1

MAN W

115V

AC A

2

2

B

37LP XFMR-SYS 1

33-14-00

41QA RELAY-

AUTO CONTROL,

No 1 CTR

1

46LP RELAY-TEST,

SYS 1 & ESS 33-14-00

2

NOT REFUEL & 2

CTR TK >250Kg.

WING TK <5000Kg.

MAN

AUTO

3QT FQIC

28-42-00

49QA RELAY-

48QA P/BSW-FUEL/ FAULT INHIBIT

CTR TK/MODE PUMP 1

SELECT/AUTO

1

300s

204PP

28VDC

BUS 2 47QA C/B-FUEL/ D

CTR TK/AUTO CTL 45QA RELAY-

CTR TK CTL LOW LVL,

LOGIC 2 ON

No 1 CTR E

OFF

103PP

28VDC CTR TK

BUS 1 WET

31QA C/B- LO LVL DRY

FUEL/CTR TK/

PUMPS 1 AND 2/

CTL AND IND

7QJ FLSCU-1

1 POSITION DATA TO SDAC 31-54-00 28-46-00

2 REFER TO CENTER TANK MANUAL CONTROL NOTE: L SYSTEM SHOWN

R SYSTEM ALMOST THE SAME

N_MM_282100_0_JUP0_01_00

Figure 28-21-00-17200-00-D / SHEET 1/2 - Center Tank Pumps Automatic Control - Electrical Schematic

** ON A/C ALL | EMB SB 28-1059 for A/C 008-010

Print Date: August 12, 2017 Page 21 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

120S TDO

51QA RELAY-

ENGINE START

A ON CTR TK CTL

B

APU BOOST

INDICATION

APU ELECTRONIC

CONTROL BOX

49-61-00

IGNITION

N2<IDLE

1KS2 ENGINE

INTERFACE UNIT

73-25-00

IGNITION

N2<IDLE

14QU RELAY-

1KS1 ENGINE

REFUEL/DEFUEL CTL INTERFACE UNIT

PNL DOOR POSITION 73-25-00

28-25-00

o

SLATS>16

22CV SFCC-2

C 27-81-00

67QA RELAY-

CENTER TK

PUMP 1, o

SLATS>16

LATCHED OFF

D 21CV SFCC-1

27-81-00

N_MM_282100_0_JUP0_02_00

Figure 28-21-00-17200-00-D / SHEET 2/2 - Center Tank Pumps Automatic Control - Electrical Schematic

** ON A/C ALL | EMB SB 28-1059 for A/C 008-010

Print Date: August 12, 2017 Page 22 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

** ON A/C ALL

5. Interface

(Ref. Fig. Main Fuel Pump System - Interfaces SHEET 1)

Print Date: August 12, 2017 Page 23 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

ENGINE/

WARNING

DISPLAY

31-66-00

SYSTEM

DISPLAY MASTER

CAUTION

31-67-00

ECAM

CENTRAL APU/FUEL

WARNING PUMP

SYSTEM SYSTEM

31-50-00 28-22-00

MAIN

FUEL-PUMP FUEL

SYSTEM CROSSFEED

SYSTEM

28-21-00 28-23-00

REFUEL/

ANNUNCIATOR

DEFUEL

LIGHT TEST

SYSTEM

AND DIMMING

28-25-00

33-14-00

N_MM_282100_0_JLM0_01_00

Figure 28-21-00-20600-00-B / SHEET 1/1 - Main Fuel Pump System - Interfaces

** ON A/C ALL

Print Date: August 12, 2017 Page 24 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

6. Component Description

A. Fuel Pump Canister 1QM , 2QM , 3QM , 4QM , 84QM , 85QM

1QM(3QM), 2QM(4QM), 84QM(85QM)

(Ref. Fig. Fuel Pump Canister and Strainer)

Print Date: August 12, 2017 Page 25 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

RIB 2

5QM (7QM)

2QM (3QM)

1QM (4QM)

6QM (8QM)

FROM THE

FUEL PUMP

STRAINER

TYPICAL ENGINE PUMP

CANISTER

2QM (3QM)

N_MM_282100_0_BFM0_01_00

Figure 28-21-00-19700-00-D / SHEET 1/2 - Fuel Pump Canister and Strainer

** ON A/C ALL

Print Date: August 12, 2017 Page 26 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

TO THE MAIN

FUEL PUMP

CANNISTER B

SECTION

B B

SUPPORT

BRACKET

FUEL PUMP

STRAINER

5 QM 6 QM

(7QM) (8QM)

N_MM_282100_0_BFM0_02_00

Figure 28-21-00-19700-00-D / SHEET 2/2 - Fuel Pump Canister and Strainer

** ON A/C ALL

Print Date: August 12, 2017 Page 27 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

(Ref. Fig. Fuel Pump and Canister - Details)

Print Date: August 12, 2017 Page 28 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

VENT VALVE

OUTLET VALVE

FUEL PUMP

37QA (38QA)

OUTLET

CANNISTER

84QM (85QM)

INLET

SLIDE VALVE

ELECTRICAL

CONNECTION

RETAINER

DRAIN PLUG

N_MM_282100_0_BNM0_01_00

Figure 28-21-00-19800-00-C / SHEET 1/2 - Fuel Pump and Canister - Details

** ON A/C ALL

Print Date: August 12, 2017 Page 29 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

SEQUENCE VALVE

FUEL PUMP

21QA 25QA

(26QA) (22QA)

VENT VALVE

OUTLET VALVE

OUTLET

CANNISTER

1QM 2QM

(4QM) (3QM)

INLET

SLIDE

VALVE

IMPELLER

ASSEMBLY

SHAFT

INDUCER

ASSEMBLY

N_MM_282100_0_BNM0_02_00

Figure 28-21-00-19800-00-C / SHEET 2/2 - Fuel Pump and Canister - Details

** ON A/C ALL

Print Date: August 12, 2017 Page 30 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

The fuel pump canister has:

· a body

· an outlet valve

· a slide valve.

The body is hollow to contain the fuel pump. A mounting flange at the bottom of the body attaches the

canister to the fuel tank. The fuel entrance to the canister is immediately above the mounting flange and a

wire mesh strainer protects it. The slide valve closes to seal the fuel entrance to the canister when the fuel

pump is removed. When the pump is installed it holds the slide valve in the open position.

The canister has two primary fuel outlets. One outlet contains the outlet valve and is the fuel supply to

the engine feed pipe. The other outlet has a sequence valve. A small opening in the side of the canister

connects the fuel pump to:

· the pressure switch

· the jet pumps.

The primary components of the outlet valve are:

· the inlet body

· the outlet body

· the valve seat

· the valve assembly.

The inlet body of the outlet valve connects to the fuel pump canister outlet and an O-ring seals it. The inlet

body includes the valve seat which seals the poppet-type valve assembly (installed in the outlet body). The

valve assembly has:

· the spider assembly

· the valve head

· the spring.

The spider assembly has four legs with a spindle through the center. Each leg contains a steel ball which is

held in place with a small spring. When the valve is closed, the four balls locate in a recess on the spindle.

When there is no fuel pressure, the spring holds the valve head against the valve seat. If the fuel pressure

increases (but is less than a specified value) the force of the spring on the valve head (plus the force of the

balls on the spindle) does not let the valve open. When the fuel pressure is more than 0.17 bar (2.5 psi) it

pushes the valve head off its seat. The fuel then flows through the valve.

B. Fuel Pump Element

21QA(22QA) 25QA(26QA) 37QA(38QA)

(Ref. Fig. Fuel Pump and Canister - Details)

The fuel pump element has:

· a rotor assembly

· an impeller assembly

· an inducer assembly

· a shaft

· three thermal switches.

The pump element is assembled vertically. The rotor assembly is at the top. The impeller assembly is in the

center and the inducer assembly is at the bottom. The shaft connects the three assemblies together.

The rotor assembly is a 3 phase 115VAC electrical motor. When energized it turns the shaft and the

impeller and inducer assemblies. The inducer makes a suction that causes fuel to come through the

impeller assembly. The impeller assembly pressurizes and pushes the fuel out of the canister.

Print Date: August 12, 2017 Page 31 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

The three thermal switches are in the electrical circuit of the fuel pump element. If the temperature of the

pump element increases to more than 175 deg.C (347 deg.F) the switches operate. This causes the pump

element to stop. It cannot operate again and must be replaced.

C. Fuel-Pump Pressure Switch

23QA(24QA), 27QA(28QA), 39QA(40QA)

(Ref. Fig. Main Pump Pressure Switches SHEET 1)

Print Date: August 12, 2017 Page 32 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

Z147

(Z148)

27QA

A

39QA

40QA

STA0

RIB 1

28QA

B

STA700/

RIB 2

23QA

STA0

RIB 1

24QA

STA700/

RIB 2

B

TYPICAL INSTALLATION

BANJO

ADAPTER

REAR SPAR

PRESSURE

SWITCH

N_MM_282100_0_BWM0_01_00

Figure 28-21-00-21000-00-B / SHEET 1/1 - Main Pump Pressure Switches

** ON A/C ALL

Print Date: August 12, 2017 Page 33 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

The primary components of the fuel-pump pressure switch are the body and the banjo adapter. The body

contains:

· a flexible diaphragm

· a switch mechanism

· an electrical microswitch.

The flexible diaphragm isolates the switch mechanism and the microswitch from the fuel. When the fuel

pressure increases to 0.55 bar (8 psi), the flexible diaphragm moves to operate the switch mechanism

(which opens the contacts of the microswitch). When the fuel pressure decreases to 0.41 bar (6 psi),

the flexible diaphragm moves (in the opposite direction) to operate the switch mechanism and close the

contacts of the microswitch.

D. Scavenge Jet Pumps

66QM(69QM), 67QM(68QM), 89QM(90QM)

(Ref. Fig. Jet Pump 66QM(69QM) 67QM(68QM) 89QM(90QM) SHEET 1)

Print Date: August 12, 2017 Page 34 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

A A

89QM 90QM

67QM

(68QM)

66QM

(69QM) A

JET PUMP

JET

ADAPTOR

ASSEMBLY FLANGE

JET PUMP NON RETURN

BODY VALVE (NRV) O - RING

OUTLET

Z

JET NOZZLE

VALVE ASSEMBLY

SPRING

NOTE: FOR THE JET PUMPS 89QM (90QM)

Y X

THE OPENINGS X AND Y ARE AT THE TOP

N_MM_282100_0_BUM0_01_00

Figure 28-21-00-21700-00-C / SHEET 1/1 - Jet Pump 66QM(69QM) 67QM(68QM) 89QM(90QM)

** ON A/C ALL

Print Date: August 12, 2017 Page 35 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

The jet pump has:

· a jet pump body

· a jet adaptor assembly.

The jet pump body fully contains the jet adaptor assembly. The jet pump body has a flange at one end for

installation to the tank rear spar. The jet pump body also has three threaded openings. These openings are

as follows:

· Z is the outlet from the jet pump

· Y is the inlet from the fuel tank

· X is the inlet from the related main pump.

The jet adaptor assembly has:

· a Non-Return Valve (NRV)

· a jet nozzle.

The NRV has a spring and a valve assembly. If the related main pump has a failure, or is set to off, the

spring closes the NRV. Thus fuel cannot enter a main pump that is set to off.

When the related main pump is on, fuel goes into the jet pump through the opening X. The fuel moves

through the NRV and the jet nozzle. The jet nozzle decreases the pressure and increases the velocity of the

fuel that goes through it. This decrease in pressure and increase in velocity causes a suction pressure at

the inlet Y. The fuel at the inlet Y is moved through the jet pump, with the fuel from the main pump, and out

at the opening Z.

E. Check Valve

33QM(36QM), 34QM(35QM), 37QM(38QM)

(Ref. Fig. Check Valve 33QM(36QM) 34QM(35QM) 37QM(38QM) SHEET 1)

Print Date: August 12, 2017 Page 36 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

STA700/ RIB2

A

RIB 22

SPECIAL

WASHER

A

SPINDLE

INLET

37QM 33QM 34QM

(38QM) (36QM) (35QM)

'O' RING

OUTLET

SPRING

HALF

BODY

SPINDLE HALF

GUIDE BODY

N_MM_282100_0_JXM0_01_00

Figure 28-21-00-22300-00-A / SHEET 1/1 - Check Valve 33QM(36QM) 34QM(35QM) 37QM(38QM)

** ON A/C ALL

Print Date: August 12, 2017 Page 37 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

The check valve has:

· two half bodies (inlet and outlet)

· a spindle and a special washer

· a spring

· a spindle guide.

Three countersunk bolts and three screws connect the two half bodies. An O-ring seal, between the two half

bodies, stops fuel leaks. The special washer, the spindle, the spring and the spindle guide are installed in

the two half bodies to make the valve. The shank of the spindle goes through the spindle guide. The spring

is installed between the spindle and the spindle guide to keep the valve in the closed position.

F. Sequence Valve

(Ref. Fig. Sequence Valve SHEET 1)

Print Date: August 12, 2017 Page 38 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

A SEQUENCE VALVE

PUMP AND

CANNISTER

VALVE GUIDE

UPPER COVER

SPRING

LOWER COVER POPPET

VALVE

VALVE BODY

N_MM_282100_0_BQM0_01_00

Figure 28-21-00-22800-00-A / SHEET 1/1 - Sequence Valve

** ON A/C ALL

Print Date: August 12, 2017 Page 39 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

The sequence valve has:

· a valve body

· a poppet valve

· a spring

· a valve guide

· an upper and a lower cover.

The valve body contains the poppet valve, the spring and the valve guide. The poppet valve closes the

valve body inlet and a spring keeps it in this position. The valve guide is in the top end of the valve body.

The shank of the poppet valve goes through the valve guide, this makes sure that the valve is kept in

position during its operation.

The valve body has four openings to let the fuel out and back into its related fuel tank.

The covers prevent damage to the valve and make sure that the fuel enters the tank smoothly.

When the fuel pressure at the valve inlet is more than 1.74 bar (25.2 psi), the valve opens. The fuel

then moves from the valve inlet back into its related fuel tank. When the fuel pressure at the valve inlet

decreases to a specified value, the valve closes.

G. Air Release Valve 86QM(87QM)

(Ref. Fig. Air Release Valve SHEET 1)

Print Date: August 12, 2017 Page 40 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

RIB 8

AIR RELEASE VALVE

86 QM 87 QM

CHECK DIAPHRAGM

VALVE

FUEL

FLOAT LEVEL

FUEL

STABLE OR AIR IN FUEL BLED-OF-AIR

SUCTION CONDITION CONDITION

CONDITION

N_MM_282100_0_SXM0_01_00

Figure 28-21-00-23200-00-A / SHEET 1/1 - Air Release Valve

** ON A/C ALL

Print Date: August 12, 2017 Page 41 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

The air release valve has:

· a valve body

· a diaphragm and vent valve assembly

· a rubber check valve

· an annular float.

The body of the air release valve has a mounting flange at the bottom and the rubber check valve at the top.

Internally the valve has three chambers, which are:

· a vent chamber

· a diaphragm chamber

· a float chamber.

The float chamber contains an annular float. The openings in the bottom of the chamber let in the fuel and

the air. A small opening at the top of the float chamber connects to the diaphragm-chamber. The vent valve

(attached to the center of the diaphragm) closes the vent port between the float chamber and the vent

chamber. The valve has these conditions of operation:

· the stable or suction condition

· the air in fuel condition

· the bled-of-air condition.

Stable or suction condition.

When the pressure in the valve is equal to (or less than) the pressure in the fuel tank, the rubber check

valve closes (to seal the valve).

Air-in-fuel condition.

If air (which is caught in the fuel pipe) goes into the float chamber, the float falls. This opens the opening to

the diaphragm chamber. During the fuel pump operation this air becomes pressurized which causes:

(1) the diaphragm/vent valve assembly to move to the open position

(2) the rubber check valve to open

(3) the air to bleed from the valve (and thus from the fuel pipe).

Bled-of-air condition.

When the fuel goes into the float chamber:

(1) the float lifts and seals the opening to the diaphragm chamber

(2) the diaphragm/vent valve assembly moves to the closed position

(3) the rubber check valve closes to seal the valve.

H. Ground Fault Interrupter 69QA(70QA)

** ON A/C 009-999

POST SB 28-1188 for A/C 008-008

EMB SB 28-1188 for A/C 009-010

(Ref. Fig. GFI - Component Location SHEET 1)

Print Date: August 12, 2017 Page 42 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

A

822

FR24

69QA

Z120

70QA

FR1 B

A

VIEW LOOKING AFT ON

TEST BUTTON CONTACTOR BOX 107VU

TRIP/RESET INDICATOR

(TRIPPED POSITION)

TRIPPED POSITION

TEST BUTTON

TRIP/RESET INDICATOR

(RESET POSITION)

RESET POSITION

B

N_MM_282100_0_AAA0_01_01

Figure 28-21-00-23900-00-A / SHEET 1/1 - GFI - Component Location

** ON A/C 009-999 | EMB SB 28-1188 for A/C 009-010 | POST SB 28-1188 for A/C 008-008

Print Date: August 12, 2017 Page 43 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

The primary components of the Ground Fault Interrupter (GFI) are:

· a 3 Pole Single Throw relay and

· an auxiliary Single Pole Double Throw contact.

Operational functions of the GFI are as follows:

If a ground fault occurs in the load or on the wiring, downstream of the GFI:

· the GFI micro-contactor will operate to isolate the load and ground fault from the power supply

· the GFI will trip and the RESET P/BSW's metallic shaft will be visible.

The GFI will operate to close the main contacts when the load is selected to ON (relay coil

supplied with 28 VDC or 100 VDC). When the load is selected to OFF the main contacts of the

GFI will open.

When the RESET P/BSW is in the normal position, the RESET P/BSW's metallic shaft is not

visible.

The GFI micro-contactor can be tripped when the auto-test P/BSW is pushed. If the RESET

P/BSW is in the normal position, the GFI function is defective. The GFI micro-contactor can

be unlatched when the RESET P/BSW is pushed. The pins connection A1 and C1 must be

energized to perform the auto-test of the GFI.

The GFI will trip when the:

· maximum differential current is between 1.35 A and 1.65A

· detection time of the GFI is between 2.9 and 3.1 milli seconds

· total reaction time of the GFI (detection time and the opening time of the contactor to isolate the system)

is more than 20 milli seconds.

** ON A/C ALL

7. Operation/Control and Indicating

(Ref. Fig. Main Fuel Pump Scavenge System)

** ON A/C 008-008

PRE SB 28-1188 for A/C 008-008

(Ref. Fig. Wing Tank Pump 2 and Center Tank Manual Control - Electrical Schematic)

** ON A/C 009-999

POST SB 28-1188 for A/C 008-008

EMB SB 28-1188 for A/C 009-010

(Ref. Fig. Wing Tank Pump 2 and Center Tank Manual Control - Electrical Schematic)

** ON A/C ALL

(Ref. Fig. Wing Tank Pump 1 Emergency Operation - Electrical Schematic)

** ON A/C ALL

EMB SB 28-1059 for A/C 008-010

(Ref. Fig. Center Tank Pumps Automatic Control - Electrical Schematic)

** ON A/C ALL

The wing tank pumps of the main fuel pump system are manually controlled. The FLSCUs normally control the

center tank pumps automatically. For the system to operate it is necessary to:

· energize the 115AC BUS (101XP), (103XP), (202XP) and (204XP), and the 28VDC BUS (101PP), (103PP),

(202PP), (204PP) and (401PP)

· close the circuit breakers 1QA, 2QA, 3QA, 4QA, 7QA, 8QA, 9QA, 10QA, 11QA, 12QA, 29QA, 30QA, 31QA,

32QA, 47QA and 55QA.

The main fuel pump system has six main pumps. The main fuel pump system is divided into two sub-systems

(LH/RH). Each sub-system has three main pumps that supply fuel to their related engine. The circuit for each

Print Date: August 12, 2017 Page 44 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

sub-system contains (and connects to) the same type of equipment. As the other sub-system is the same, only

the operation of the No. 1 sub-system/circuit (LH) is given here.

A. Operation

In normal conditions the two pumps in the wing tank or the related pump in the center tank supply an

engine. But, one pump can supply the necessary fuel for an engine.

The fuel supply to one engine is controlled independently of the other. Thus, the wing tank pumps can

supply the fuel for one of the engines and the opposite center tank pump can supply the other engine.

The center tank pumps are set to give a higher pressure of fuel than the related wing tank pumps. A

sequence valve (installed on each wing tank pump canister) reduces the output pressure of the related wing

tank pump. When all the pumps operate, the center tank pump will supply fuel to its related engine.

When the wing tank pumps are set to ON, the pumps will operate continuously during the flight until

switched off manually.

The center tank pumps have two modes of operation, manual and automatic. The MODE SEL P/BSW

(48QA), on the FUEL panel (40VU), controls these modes of operation.

In manual mode (MODE SEL P/BSW released out), the operation of the center tank pumps is controlled by

the CTR TK PUMPS 1 and 2 P/BSWs (33QA and 34QA).

In automatic mode (MODE SEL P/BSW pushed in), and with the CTR TK PUMPS 1 and 2 P/BSWs set to

ON:

· the center tank pumps are set to on and off automatically during specified flight phases

· the center tank pumps will supply fuel to the engines, as required, when the fuel is at specified levels

(Ref. AMM D/O 28-46-00-00) .

At engine start-up, the automatic fuel feed system operates as follows:

· a signal from the interface units (1KS1 and 1KS2) energizes the center tank control relays (51QA, 52QA)

· the AUTO CTL relays (41QA, 42QA) are de-energized

· if the center tank LOW LVL sensors are wet with fuel the two center tank pumps operate

· two minutes after the first engine reaches idle speed, the center tank pumps stop

· if the second engine is started during the two minutes, the center tank pumps will operate for two more

minutes. They will operate for two more minutes from when the second engine reaches idle speed and

then stop

· if the second engine is started after the two minutes are over, the center tank pumps will operate again for

two minutes. They will operate from the time that the second engine reaches idle speed

· the position of the slats now controls the operation of the center tank pumps

· the center tank pumps will not operate again until the slats are retracted

· until then the wing tank pumps supply fuel to the engines.

** ON A/C 008-008

PRE SB 28-1188 for A/C 008-008

EMB SB 28-1059 for A/C 008-008

After take-off, the automatic fuel feed system operates as follows:

· the AUTO CTL relays (41QA and 42QA) de-energize when the slats retract

· the center tank pump control relays (35QA and 36QA) energize and the center tank pumps are given

signals to operate, independently of each other

· a center tank pump will stop when the two FULL LVL sensors in the related wing tank are wet. The pump

will not operate again until at least one UNDERFULL LVL sensor in the related wing tank is dry. The

related center tank LOW LVL sensor must also be wet for the pump to restart

· a signal is given to the time delay relays (45QA and 46QA) when a center tank LOW LVL sensor

becomes dry. When the LOW LVL sensor has been dry for five minutes, the related center tank pump is

latched off

Print Date: August 12, 2017 Page 45 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

· the latch is released and the related pump(s) come on when MANUAL mode is selected or when the

refuel panel access door is opened

· FAULT INHIBIT relays do not let the FAULT annunciators come ON during the five minute cycle

· when a center tank pump stops, an engine is supplied with fuel from the related wing tank pumps.

** ON A/C 009-999

POST SB 28-1188 for A/C 008-008

EMB SB 28-1059 for A/C 008-010

EMB SB 28-1188 for A/C 009-010

After take-off, the automatic fuel feed system operates as follows:

· the AUTO CTL relays (41QA and 42QA) de-energize when the slats retract

· the center tank pump control Ground Fault Interrupters (GFIs) (69QA and 70QA) energize and the center

tank pumps are given signals to operate, independently of each other

· a center tank pump will stop when the two FULL LVL sensors in the related wing tank are wet. The pump

will not operate again until at least one UNDERFULL LVL sensor in the related wing tank is dry. The

related center tank LOW LVL sensor must also be wet for the pump to restart

· a signal is given to the time delay relays (45QA and 46QA) when a center tank LOW LVL sensor

becomes dry. When the LOW LVL sensor has been dry for five minutes, the related center tank pump is

latched off

· the latch is released and the related pump(s) come on when MANUAL mode is selected or when the

refuel panel access door is opened

· FAULT INHIBIT relays do not let the FAULT annunciators come ON during the five minute cycle

· when a center tank pump stops, an engine is supplied with fuel from the related wing tank pumps.

** ON A/C ALL

In the electrical smoke configuration (Ref. AMM D/O 24-24-00-00) the contactor 17QA is de-energized.

The L (R) TK PUMP 1 P/BSW then connects a 28VDC supply to the contactor 53QA (No. 1 fuel pump

emergency contactor-control). The contactor 53QA connects a 115VAC supply to energize the fuel pump

21QA (22QA).

The pumps get their fuel supply from the lowest part of the collector cell. When they are in operation each

pump gives two outputs. One output is to the engine feed pipe, one to the related scavenge jet pump.

B. Cockpit Indications

If specified failures or system configurations occur in the main fuel pump system:

· the Flight Warning Computer (FWC) (Ref. AMM D/O 31-52-00-00) gives an aural and visual warning

· the ECAM shows a failure message on the EWD, and the FUEL page on the SD.

If necessary, a procedure to correct the effects of the failure is also given with the warning message.

(1) EWD Messages

The warning messages given are:

(a) FUEL L TK PUMP 1 LO PR

The No. 1 main pump is set to on, but low pressure has occurred (equivalent warning messages are

given for the R TK PUMP 1).

(b) FUEL L TK PUMP 2 LO PR

The No. 2 main pump is set to on, but low pressure has occurred (equivalent warning messages are

given for the R TK PUMP 2).

(c) FUEL L TK PUMPS 1+2 LO PR

Both the fuel pumps in the LH wing are set to on, but low pressure has occurred (an equivalent

warning message is given for the R TK PUMPS 1+2).

(d) FUEL CTR TK PUMP 1 LO PR

Print Date: August 12, 2017 Page 46 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

The center tank pump 1 (LH) is set to on, but low pressure has occurred (Equivalent warning

message for center tank pump 2 (RH)).

(e) FUEL CTR TK PUMPS LO PR

The center tank pumps 1 and 2 are set to on, but low pressure has occurred.

(f) FUEL CTR TK PUMPS OFF

The center tank pumps are set to OFF, but no failure has occurred.

(g) FUEL AUTO FEED FAULT

The fuel pumps are set to on with the fuel condition as follows:

· left or right wing tank contains less than 5000 kg (11023 lb) of fuel

· center tank contains more than 250 kg (551 lb) of fuel.

The center tank pumps do not stop after the slats are extended.

The center tank pumps do not stop 5 minutes after the related low level sensors are dry.

(2) SD (FUEL Page) Indications

(Ref. Fig. ECAM (FUEL Page) Display - Main Fuel Pump System Indication SHEET 1)

Print Date: August 12, 2017 Page 47 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

ECAM DISPLAY

FUEL KG

F.USED 1 F.USED 2

3100 FOB 3100

14260

APU

A

LEFT CTR RIGHT

A A

700 5030 2800 5030 700

-11 °C 10 10 °C -11

SYSTEM PAGE

INDICATION COLOR FUEL-PUMP INDICATION

GREEN FUEL-PUMP

IN OPERATION

AMBER FUEL-PUMP OFF

XX NO FUEL-PUMP

AMBER

DATA AVAILABLE

LO AMBER

FUEL-PUMP

LOW PRESSURE

A

FUEL-PUMP SET

TO ON BUT NOT

GREEN IN OPERATION

(CENTER TANK

AUTO MODE ONLY)

N_MM_282100_0_LAM0_01_00

Figure 28-21-00-26700-00-C / SHEET 1/1 - ECAM (FUEL

Page) Display - Main Fuel Pump System Indication

** ON A/C ALL

Print Date: August 12, 2017 Page 48 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

(3) Fuel Control Panel 40VU

(Ref. Fig. Fuel Pump System - Cockpit Indications SHEET 1)

(a) Each fuel pump P/BSW shows:

· OFF (white) when the fuel pump is not set to on

· FAULT (amber) if a failure occurs (pump low pressure).

(b) The MODE SEL P/BSW shows:

· MAN (white) when the center tank pumps are in manual control

· FAULT (amber) if a failure has occurred whilst the center tank pumps are in auto mode.

8. BITE Test

Not applicable

Figure 28-21-00-12500-00-B / SHEET 1/2 - Main Fuel Pump System

Figure 28-21-00-12500-00-B / SHEET 2/2 - Main Fuel Pump System

Figure 28-21-00-12600-00-C / SHEET 1/3 - Main Fuel Pump Scavenge System

Figure 28-21-00-12600-00-C / SHEET 2/3 - Main Fuel Pump Scavenge System

Figure 28-21-00-12600-00-C / SHEET 3/3 - Main Fuel Pump Scavenge System

Figure 28-21-00-12700-00-C / SHEET 1/1 - Fuel Pump System - Cockpit Indications

** ON A/C 008-008

PRE SB 28-1188 for A/C 008-008

Figure 28-21-00-17000-00-B / SHEET 1/2 - Wing Tank Pump 2 and Center Tank Manual Control - Electrical

Schematic

Figure 28-21-00-17000-00-B / SHEET 2/2 - Wing Tank Pump 2 and Center Tank Manual Control - Electrical

Schematic

** ON A/C 009-999

POST SB 28-1188 for A/C 008-008

EMB SB 28-1188 for A/C 009-010

Figure 28-21-00-17000-00-C / SHEET 1/2 - Wing Tank Pump 2 and Center Tank Manual Control - Electrical

Schematic

Figure 28-21-00-17000-00-C / SHEET 2/2 - Wing Tank Pump 2 and Center Tank Manual Control - Electrical

Schematic

** ON A/C ALL

Figure 28-21-00-17100-00-A / SHEET 1/2 - Wing Tank Pump 1 Emergency Operation - Electrical Schematic

Figure 28-21-00-17100-00-A / SHEET 2/2 - Wing Tank Pump 1 Emergency Operation - Electrical Schematic

** ON A/C ALL

EMB SB 28-1059 for A/C 008-010

Figure 28-21-00-17200-00-D / SHEET 1/2 - Center Tank Pumps Automatic Control - Electrical Schematic

Figure 28-21-00-17200-00-D / SHEET 2/2 - Center Tank Pumps Automatic Control - Electrical Schematic

** ON A/C ALL

Figure 28-21-00-19700-00-D / SHEET 1/2 - Fuel Pump Canister and Strainer

Print Date: August 12, 2017 Page 49 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : RGA Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : ALL

Rev. Date : May 01, 2017

28-21-00 PB 001 CONF 00 - MAIN FUEL PUMP

SYSTEM - DESCRIPTION AND OPERATION

Figure 28-21-00-19700-00-D / SHEET 2/2 - Fuel Pump Canister and Strainer

Figure 28-21-00-19800-00-C / SHEET 1/2 - Fuel Pump and Canister - Details

Figure 28-21-00-19800-00-C / SHEET 2/2 - Fuel Pump and Canister - Details

Figure 28-21-00-20600-00-B / SHEET 1/1 - Main Fuel Pump System - Interfaces

Figure 28-21-00-21000-00-B / SHEET 1/1 - Main Pump Pressure Switches

Figure 28-21-00-21700-00-C / SHEET 1/1 - Jet Pump 66QM(69QM) 67QM(68QM) 89QM(90QM)

Figure 28-21-00-22300-00-A / SHEET 1/1 - Check Valve 33QM(36QM) 34QM(35QM) 37QM(38QM)

Figure 28-21-00-22800-00-A / SHEET 1/1 - Sequence Valve

Figure 28-21-00-23200-00-A / SHEET 1/1 - Air Release Valve

** ON A/C 009-999

POST SB 28-1188 for A/C 008-008

EMB SB 28-1188 for A/C 009-010

Figure 28-21-00-23900-00-A / SHEET 1/1 - GFI - Component Location

** ON A/C ALL

Figure 28-21-00-26700-00-C / SHEET 1/1 - ECAM (FUEL Page) Display - Main Fuel Pump System Indication

End of document

Print Date: August 12, 2017 Page 50 of 50

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

You might also like

- TASK 12!32!28 281 001 A Drain Water ContentDocument13 pagesTASK 12!32!28 281 001 A Drain Water ContentSatishReddyNo ratings yet

- Leaflet FCPCDocument2 pagesLeaflet FCPCAshraf BadawiNo ratings yet

- A320 ATA 24 Electrical PowerDocument474 pagesA320 ATA 24 Electrical PowerDavid MF CocNo ratings yet

- 23 CommunicationsDocument238 pages23 CommunicationsMaher Abu-ElolaNo ratings yet

- Engineering SupportDocument8 pagesEngineering SupportJivendra KumarNo ratings yet

- 36 PneumaticDocument50 pages36 PneumaticduythienddtNo ratings yet

- EASA Mod 4 BK 3 ServosDocument75 pagesEASA Mod 4 BK 3 ServosPriyanka ShresthaNo ratings yet

- 36 Pneumatic - 1Document54 pages36 Pneumatic - 1Nunu Zarnuji100% (2)

- 71-00-00-710-009-B - Vibration Check PDFDocument3 pages71-00-00-710-009-B - Vibration Check PDFEder Luciano100% (1)

- ATA 30 - Ice & Rain 09-04-18 PDFDocument143 pagesATA 30 - Ice & Rain 09-04-18 PDFDavid OwenNo ratings yet

- Single Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) Information SystemsDocument40 pagesSingle Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) Information Systemssan2inNo ratings yet

- Basic AerodynamicsDocument57 pagesBasic Aerodynamicsmuhammad al afiqNo ratings yet

- DGCA Module 11 June 2019 QuestionsDocument4 pagesDGCA Module 11 June 2019 QuestionsMC ManojNo ratings yet

- ATA Chapters, ReferenceDocument89 pagesATA Chapters, Reference张海林No ratings yet

- Notes A 320 Neo LightDocument44 pagesNotes A 320 Neo LightAnurag MishraNo ratings yet

- Aircraft Engine Types and APU InstallationsDocument13 pagesAircraft Engine Types and APU InstallationsAbdul MuizzNo ratings yet

- Inert Gas System OverviewDocument46 pagesInert Gas System Overviewange100% (1)

- A320 Technical Training Manual Mechanics / Electrics & Avionics Course 49 Apu (Apic)Document174 pagesA320 Technical Training Manual Mechanics / Electrics & Avionics Course 49 Apu (Apic)BahadorNo ratings yet

- CFM Doc Leap 1b Co Nac 3 v2.0Document19 pagesCFM Doc Leap 1b Co Nac 3 v2.0Paulo Sanz100% (1)

- E190 Type Traing Fuel Review QuestionsDocument5 pagesE190 Type Traing Fuel Review QuestionscollinsNo ratings yet

- Single Aisle Pneumatic Training ManualDocument34 pagesSingle Aisle Pneumatic Training ManualAnh NguyenXuanNo ratings yet

- Certification privileges of Aircraft Maintenance EngineersDocument141 pagesCertification privileges of Aircraft Maintenance EngineersKshitiz RastogiNo ratings yet

- Single Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) CommunicationsDocument238 pagesSingle Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) CommunicationsHark DarkNo ratings yet

- APU PresentationDocument8 pagesAPU PresentationIsmail mhailNo ratings yet

- Task 46!21!00-710-002-A VHF 3 Link Test of The AtsuDocument8 pagesTask 46!21!00-710-002-A VHF 3 Link Test of The AtsuSatishReddyNo ratings yet

- APU 320 FinishedDocument38 pagesAPU 320 FinishedGalaxy A32No ratings yet

- AC 20-154 Incoming InspectionDocument24 pagesAC 20-154 Incoming Inspectionyvesandrade100% (1)

- Scribd Download - Com A320 Computer Reset Nov11Document18 pagesScribd Download - Com A320 Computer Reset Nov11hayri yilmazNo ratings yet

- Single Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) APUDocument216 pagesSingle Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) APUAnonymous 298xlo3uUNo ratings yet

- A320 Family Fire Protection and ExtinguishingDocument192 pagesA320 Family Fire Protection and ExtinguishingBahadorNo ratings yet

- On The GroundDocument3 pagesOn The Groundroyalairmaroc737No ratings yet

- Ata 30Document23 pagesAta 30Dũng NguyễnNo ratings yet

- TTM Single Aisle Line & Base Ata 31Document512 pagesTTM Single Aisle Line & Base Ata 31林至伟No ratings yet

- A320 Cockpit Lights Training ManualDocument40 pagesA320 Cockpit Lights Training ManualAhmad ZakwanNo ratings yet

- Ice and Rain System PresentationDocument16 pagesIce and Rain System Presentationmansooor1234100% (1)

- A330-200/300 Technical Training Manual Ramp & Servicing Course - M02 (Ge Cf6) Aircraft General PracticesDocument16 pagesA330-200/300 Technical Training Manual Ramp & Servicing Course - M02 (Ge Cf6) Aircraft General PracticesWilliam Jaldin CorralesNo ratings yet

- Atr Pec Trimming ProcedureDocument5 pagesAtr Pec Trimming ProcedureKhaqan AliNo ratings yet

- SJI Air Conditioning Training ManualDocument42 pagesSJI Air Conditioning Training Manualsvyat_kNo ratings yet

- Mil e 7016FDocument48 pagesMil e 7016FnicolasNo ratings yet

- Idg 1 Low Oil Pressure or Idg 1 Oil Overheat: GeneralDocument4 pagesIdg 1 Low Oil Pressure or Idg 1 Oil Overheat: Generaljontis jasoliyaNo ratings yet

- A300B4 Refrsher Course Exam: C-A Servo Control Sliding Valve JamDocument7 pagesA300B4 Refrsher Course Exam: C-A Servo Control Sliding Valve JamMohammad Faraz AkhterNo ratings yet

- Ata 36Document11 pagesAta 36jontis jasoliyaNo ratings yet

- 47 Inert Gas SystemDocument46 pages47 Inert Gas Systemdheerajdorlikar100% (1)

- 13.11 - Air ConditioningDocument40 pages13.11 - Air ConditioningTheo kl100% (2)

- Hydraulic SystemDocument59 pagesHydraulic SystemMerselinne FeriaNo ratings yet

- CFM Doc Leap 1B Cid Eng Eb 3 V1Document41 pagesCFM Doc Leap 1B Cid Eng Eb 3 V1Paulo SanzNo ratings yet

- SR Technics: 28 Fuel SafetyDocument154 pagesSR Technics: 28 Fuel SafetyTam Ho100% (1)

- Airbus A330 ATA 46 INFORMATION SYSTEMS B2 PrintDocument29 pagesAirbus A330 ATA 46 INFORMATION SYSTEMS B2 PrintMeysam530100% (1)

- List of Abbreviations: Training Publication PMC-39-A0126-AF001-00Document10 pagesList of Abbreviations: Training Publication PMC-39-A0126-AF001-00Alexander Goez100% (1)

- Ata 38 Water and WasteDocument38 pagesAta 38 Water and WasteSantiago MolinaNo ratings yet

- A330-Fire ProtectionDocument25 pagesA330-Fire ProtectionShifu Chip100% (1)

- V2500 Engine Maintenance Manual ExcerptDocument70 pagesV2500 Engine Maintenance Manual ExcerptHellovnAZNo ratings yet

- British Airways CFM56 Training ManualDocument86 pagesBritish Airways CFM56 Training ManualZbor ZborNo ratings yet

- Single Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) GeneralDocument8 pagesSingle Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) Generalripan thakurNo ratings yet

- CFM56 Technical Training Manual Chapter on Aircraft Information SystemsDocument30 pagesCFM56 Technical Training Manual Chapter on Aircraft Information SystemsarunNo ratings yet

- ATA 24 24.06.2008 - B2 L3 Ready To PrintDocument103 pagesATA 24 24.06.2008 - B2 L3 Ready To PrintDmitryNo ratings yet

- Fuel DescriptionDocument32 pagesFuel Descriptionsiti fatimatuzzahraNo ratings yet

- Ata - 28 (Nov-19)Document2,663 pagesAta - 28 (Nov-19)saradeepsNo ratings yet

- Fuel System - Wing and Center Tank 2Document1 pageFuel System - Wing and Center Tank 2chinna_jetNo ratings yet

- Aerospace Engineering Services JSCDocument76 pagesAerospace Engineering Services JSCThanh QuangNo ratings yet

- Module 1Document41 pagesModule 1Thanh Quang100% (4)

- Aircraft Maintenance Manual Diamond Da201-c1-Rev-22Document1,372 pagesAircraft Maintenance Manual Diamond Da201-c1-Rev-22Edwin Garay100% (3)

- Dong Ho Thoi Gian ThucDocument1 pageDong Ho Thoi Gian ThucTrimen PhanNo ratings yet

- SY155WDocument4 pagesSY155WLutfi DstrNo ratings yet

- Senior Aerospace Defense Engineer in Orlando FL Resume Ken WebbDocument3 pagesSenior Aerospace Defense Engineer in Orlando FL Resume Ken WebbKenWebbNo ratings yet

- Volvo FMX: Product Guide - Euro 3-5Document24 pagesVolvo FMX: Product Guide - Euro 3-5HiT Dayat100% (2)

- 6338d1285569848 Task Alfa 300ci SB Toner PDFDocument3 pages6338d1285569848 Task Alfa 300ci SB Toner PDFjosealcudiacastellas100% (1)

- CalibrationDocument7 pagesCalibrationstolen mechieducNo ratings yet

- Gas Stop HTDocument1 pageGas Stop HTbagus918No ratings yet

- FiberHome Introduction (07.12.2015)Document13 pagesFiberHome Introduction (07.12.2015)Sandeep SheetalNo ratings yet

- Accuret-A20: Electrical SpecificationsDocument2 pagesAccuret-A20: Electrical SpecificationsClaudio CalabreseNo ratings yet

- Sa2009-001608 en Rel670 CT Calculation ExampleDocument7 pagesSa2009-001608 en Rel670 CT Calculation ExampleinsanazizNo ratings yet

- Engineering Data Ip5-3600Document2 pagesEngineering Data Ip5-3600CESAR SEGURANo ratings yet

- MAP Demo ExercisesDocument34 pagesMAP Demo ExercisesNancy HernandezNo ratings yet

- Xbox 14260984 Ssc2802 TX 4 A DatasheetDocument5 pagesXbox 14260984 Ssc2802 TX 4 A DatasheetBaye Dame DIOPNo ratings yet

- If Steam Drum Under Vacuum Then What Will HappenDocument2 pagesIf Steam Drum Under Vacuum Then What Will HappenyogacruiseNo ratings yet

- Stability Data BookletDocument18 pagesStability Data BookletPaul Ashton25% (4)

- PackagesDocument2 pagesPackagesSteven MirandaNo ratings yet

- VW T-Cross 2019+ - Connector ViewsDocument220 pagesVW T-Cross 2019+ - Connector ViewsMucowera AshaNo ratings yet

- Mechanics of A Diesel Fuel Injection SystemDocument8 pagesMechanics of A Diesel Fuel Injection Systemekitriandi0% (1)

- Revue Des Études Juives. 1880. Volumes 71-73.Document706 pagesRevue Des Études Juives. 1880. Volumes 71-73.Patrologia Latina, Graeca et OrientalisNo ratings yet