Professional Documents

Culture Documents

TAD1241GE: Volvo Penta Genset Engine

Uploaded by

Muhammad rizkiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TAD1241GE: Volvo Penta Genset Engine

Uploaded by

Muhammad rizkiCopyright:

Available Formats

VOLVO PENTA GENSET ENGINE

TAD1241GE

1500 rpm, 354 kW (481 hp) – 1800 rpm, 387 kW (526 hp)

The TAD1241GE is a powerful, reliable

and economical Generating Set Diesel

Engine built on the dependable in-line six

design.

Durability & low noise

Designed for easiest, fastest and most

economical installation. Well-balanced to

produce smooth and vibration-free opera-

tion with low noise level.

To maintain a controlled working tem-

perature in cylinders and combustion

chambers, the engine is equipped with

piston cooling. The engine is also fitted

with replaceable cylinder liners and valve

seats/guides to ensure maximum durabil-

ity and service life of the engine.

Low exhaust emission

The state of the art, high-tech injection

and charging system with low internal

losses contributes to excellent combus-

tion and low fuel consumption.

The TAD1241GE complies with EU

Features

– Maintained performance, air temp 40°C

Stage 2 and TA-Luft -50% exhaust emis- – Tropical cooling system (55°C)

sion regulations. – Fully electronic with Volvo Penta EDC III

– Dual frequency switch (between 1500 rpm and 1800 rpm)

Easy service & maintenance – High power density

Easily accessible service and mainte- – Emission compliant

nance points contribute to the ease of – Low noise levels

– Gen Pac configuration

service of the engine.

Technical description:

Engine and block Lubrication system – Efficient cooling with accurate coolant con-

– Optimized cast iron cylinder block with opti- – Full flow oil cooler trol through a water distribution duct in the

mum distribution of forces without the block – Full flow disposable spin-on oil filter, for ex- cylinder block. Reliable sleeve thermostat

being unnessarily heavy. tra high filtration with minimum pressure drop

– Wet, replaceable cylinder liners – The lubricating oil level can be measured

during operation

Turbo charger

– Piston cooling for low piston temperature – Efficient and reliable turbo charger

and reduced ring temperature – Gear type lubricating oil pump, gear driven

– Extra oil filter for the turbo charger

– Tapered connecting rods for reduce risk of by the transmission

piston cracking Fuel system Electrical system

– Crankshaft induction hardened bearing – Electronical Diesel Control III (EDCIII), an

– Non-return fuel valve

surfaces and fillets with seven bearings for electronically controlled processing system

– Electronic Unit Injectors

moderate load on main and high-end bear- which optimizes engine performance. It also

– Fuel prefilter with water separator and wa-

ings includes advanced facilities for diagnostics

ter-in-fuel indicator / alarm

– Case hardened and nitrocarburized trans- and fault tracing

– Gear driven low-pressure fuel pump

mission gears for heavy duty operation – Three different ways for the customer to

– Fine fuel filter with manual feed pump and

– Keystone top compression rings for long connect his controls and instrument to the

fuel pressure switch

service life engine. CAN SAE J1939 interface, CIU

– Fuel shut-off valve, electrically operated

– Viscous type crankshaft vibration dampers (Control interface unit) and Stand alone

to withstand single bearing alternator tor- Cooling system connections.

sional vibrations – Air to air intercooler – Sensors for oil pressure, oil temp, boost

– Replaceable valve guides and valve seats – Coolant filter as standard pressure, boost temp, coolant temp, fuel

– Over head camshaft and four valves per cyl- – Gear driven, maintenance-free coolant temp, water in fuel, fuel pressure and two

inder pump with high degree of efficiency speed sensors.

TAD1241GE

Technical Data

General Standard equipment Engine Gen Pac

Engine designation......................................................................... TAD1241GE Engine

No. of cylinders and configuration........................................................ in-line 6 Automatic belt tensioner • •

Method of operation................................................................................ 4-stroke Lift eyelets • •

Bore, mm (in.)...................................................................................... 131 (5.16) Flywheel

Stroke, mm (in.)................................................................................... 150 (5.91) Flywheel housing with conn. acc. to SAE 1 • •

Displacement, l (in3).................................................................... 12.13 (740.2) Flywheel for 14” flex. plate and flexible coupling • •

Compression ratio...................................................................................... 17.5:1 Vibration dampers • •

Dry weight, kg (lb)........................................................................... 1380 (3036) Engine suspension

With Gen Pac, kg (lb).................................................................... 1645 (3627)

Wet weight, kg (lb)......................................................................... 1455 (3201) Fixed front suspension • •

With Gen Pac, kg (lb).................................................................... 1720 (3792) Lubrication system

Oil dipstick • •

Performance Full-flow oil filter of spin-on type • •

with fan, kW (hp) 1500 rpm 1800 rpm By-pass oil filter of spin-on type • •

Prime Power 323 (439) 352 (479) Oil cooler, side mounted • •

Max Standby Power 354 (481) 387 (526) Low noise oil sump • •

Fuel system

Lubrication system Fuel filters of disposable type • •

Oil consumption, liter/h (US gal/h) 1500 rpm 1800 rpm Electronic unit injectors • •

Prime Power 0.11 (0.029) 0.12 (0.032) Pre-filter with water separator • •

Max Standby Power 0.12 (0.032) 0.13 (0.034) Intake and exhaust system

Oil system capacity incl filters, liter.................................................................35 Air filter without rain cover • •

Oil change intervals at specification Air filter with replaceable paper insert • •

VDS-2, h............................................................................................................ 600 Air restriction indicator • •

VDS, ACEA E3, h............................................................................................ 400 Air cooled exhaust manifold • •

ACEA E1, E2, API CD, CF, CF-4, CG-4, h............................................... 200 Connecting flange for exhaust pipe • •

Exhaust flange with v-clamp • •

Fuel system Turbo charger, low right side • •

Specific fuel consumption at Crankcase ventilation • •

Prime Power, g/kWh (lb/hph) 1500 rpm 1800 rpm Cooling system

25 % 216 (0.350) 231 (0.374) Tropical radiator incl intercooler •¹) •

50 % 199 (0.323) 208 (0.330) Gear driven coolant pump • •

75 % 195 (0.316) 200 (0.324) Fan hub • •

100 % 198 (0.321) 202 (0.327) Thrust fan – •

Max Standby Power, g/kWh (lb/hph) 1500 rpm 1800 rpm Fan guard – •

25 % 211 (0.347) 225 (0.365) Belt guard – •

50 % 197 (0.319) 203 (0.329) Control system

75 % 195 (0.316) 200 (0.324) Engine Management System (EMS) with • •

100 % 199 (0.323) 203 (0.329) CAN-bus interface SAE J1939 and stand alone

interface

Intake and exhaust system Alternator

Air consumption at 27°C, m³/min (cfm) 1500 rpm 1800 rpm Alternator 60A / 24 V • •

Prime Power 23.5 (830) 28.0 (989) Starting system

Max Standby Power 25.0 (883) 29.0 (1024) Starter motor, 6.0kW, 24 V • •

Max allowable air intake restriction, kPa (In wc)................................5 (20.1)

Heat rejection to exhaust, Connection facility for extra starter motor • •

kW (BTU/min) 1500 rpm 1800 rpm Instruments and senders

Prime Power 250 (14217) 272 (15468) Temp.- and oil pressure for automatic • •

Max Standby power 276 (15696) 306 (17402) stop/alarm 103°C

Exhaust gas temperature after turbine, Other equipment

°C (°F) 1500 rpm 1800 rpm Expandable base frame – •

Prime Power 490 (914) 465 (869) Engine Packing

Max Standby Power 505 (941) 490 (914) Plastic warpping • •

Max allowable back-pressure in exhaust line, kPa (In wc)............ 10 (40.2) ¹)must be ordered, se order specification - optional equipment

Exhaust gas flow, m³/min (cfm) 1500 rpm 1800 rpm − optional equipment or not applicable

Prime power 58 (2048) 66 (2331) • included in standard specification

Max Standby Power 63 (2225) 72 (2543)

Cooling system

Heat rejection radiation from engine,

kW (BTU/min) 1500 rpm 1800 rpm

Prime Power 17 (967) 18 (1024)

Max Standby Power 18 (1024) 20 (1137)

Heat rejection to coolant kW (BTU/min)

Prime Power 123 (6995) 139 (7905)

Max Standby Power 125 (7109) 143 (8132)

Fan power consumption, kW (hp) 9 (12) 15 (20)

English 12-2006. © 2006 AB Volvo Penta

Note! Not all models, standard equipment and accessories are available in all countries.

All specifications are subject to change without notice.

The engine illustrated may not be entirely identical to production standard engines.

Power Standards Rating Guidelines

The engine performance corresponds to ISO 3046, BS PRIME POWER rating corresponds to ISO Standard Power for

5514 and DIN 6271. The technical data applies to an engine continuous operation. It is applicable for supplying electrical power

without cooling fan and operating on a fuel with calorific at variable load for an unlimited number of hours instead of com-

value of 42.7 MJ /kg (18360 BTU/lb) and a density of 0.84 mercially purchased power. A10 % overload capability for govering

kg/liter (7.01 lb/US gal), also where this involves a deviation purpose is available for this rating.

from the standards. Power output guaranteed within 0 to MAXIMUM STANDBY POWER rating corresponds to ISO

+2% att rated ambient conditions at delivery. Ratings are Standard Fuel Stop Power. It is applicable for supplying standby

based on ISO 8528. Engine speed governing in accordance electrical power at variable load in areas with well established

with ISO 3046/IV, class A1 and ISO 8528-5 class G3 electrical networks in the event of normal utility power failure. No

Exhaust emissions overload capability is available for this rating.

The engine complies with EU stage 2 emission legislation 1 hp = 1 kW x 1.36

according to the Non Road Directive EU 97/68/EEC. The Information

engine also complies with TA-luft -50% exhaust emission For more technical data and information, please look in the Gener- AB Volvo Penta

regulations. ating Set Engines Sales Guide. SE-405 08 Göteborg, Sweden

www.volvopenta.com

You might also like

- IAMI Revision Answers Motor and GeneralDocument26 pagesIAMI Revision Answers Motor and GeneralStewart LongNo ratings yet

- Diesel Engine Ajm Atj Avb Avf Awx Repair Manual EngDocument172 pagesDiesel Engine Ajm Atj Avb Avf Awx Repair Manual EngAndsanta 130% (1)

- (Troubleshooting) Caterpillar 320d Excavator Fault Code Fault Code - PDF Download - Factory Workshop Service Repair ManualDocument21 pages(Troubleshooting) Caterpillar 320d Excavator Fault Code Fault Code - PDF Download - Factory Workshop Service Repair Manualdhanysiregar88% (51)

- Kioti Daedong CK2610 (H), CK3510 (H), CK4010 (H) Tractors Service ManualDocument19 pagesKioti Daedong CK2610 (H), CK3510 (H), CK4010 (H) Tractors Service ManualLisakolyNo ratings yet

- Man MegiDocument66 pagesMan Megihoodyz_r_usNo ratings yet

- ZF85A Marine Propulsion SystemDocument9 pagesZF85A Marine Propulsion SystemJun AballeNo ratings yet

- Palfinger ETI 29/33/37Document2 pagesPalfinger ETI 29/33/37DarthCain0% (1)

- 2954 4960 01 - Branded EU Lighting Tower - ENDocument50 pages2954 4960 01 - Branded EU Lighting Tower - ENIlarion Ciobanu100% (1)

- G330 IntelysisDocument330 pagesG330 IntelysisLIBERTADNo ratings yet

- TAD870-873VE: Low Cost of OwnershipDocument2 pagesTAD870-873VE: Low Cost of OwnershipAaravGuptaNo ratings yet

- User's Guide: Group G Controller For Automatic & Non-Automatic Transfer SwitchesDocument40 pagesUser's Guide: Group G Controller For Automatic & Non-Automatic Transfer Switchesangel aguilarNo ratings yet

- Series 1163 TB73-TB93LDocument72 pagesSeries 1163 TB73-TB93LDimas SaputroNo ratings yet

- Fiat 8065 Iveco UseMaintanceManual 8060series Industrial L31022019E Jan05Document41 pagesFiat 8065 Iveco UseMaintanceManual 8060series Industrial L31022019E Jan05Dedy Cj100% (1)

- CO2 CompressorDocument23 pagesCO2 CompressorGaurav MishraNo ratings yet

- TAD1640GE: Volvo Penta Genset EngineDocument2 pagesTAD1640GE: Volvo Penta Genset EngineRenzo zuñiga ahon100% (1)

- Tad1641ge PDFDocument2 pagesTad1641ge PDFjuanNo ratings yet

- RM 100 Short Descirption HELPDocument62 pagesRM 100 Short Descirption HELPFrancys Mareco GodoyNo ratings yet

- Perkins New Diesel GeneratorsDocument3 pagesPerkins New Diesel GeneratorsReginald D. De GuzmanNo ratings yet

- Deep Sea Electronics: Complex Solutions Made SimpleDocument57 pagesDeep Sea Electronics: Complex Solutions Made SimpleRobertNo ratings yet

- 100series Hires 071113Document62 pages100series Hires 071113Souleymane BambaNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document17 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Jose Corcega britoNo ratings yet

- InstallationDocument156 pagesInstallationAkhir Widada100% (1)

- Kit NEXYS To APM303 - Install Procedure-EnglishDocument7 pagesKit NEXYS To APM303 - Install Procedure-Englishzawmintun zpeNo ratings yet

- Focs Plus Ldw1003 - GBDocument4 pagesFocs Plus Ldw1003 - GBRafael LopezNo ratings yet

- Use and Maintenance Manual MTU Diesel Engine 12V 4000 G20 12V 4000 G60 12V 4000 G80Document140 pagesUse and Maintenance Manual MTU Diesel Engine 12V 4000 G20 12V 4000 G60 12V 4000 G80Salah OsmanNo ratings yet

- Egcp1 (End User)Document160 pagesEgcp1 (End User)Dat Nguyen Cong100% (1)

- Ge W1001016 (TJK)Document118 pagesGe W1001016 (TJK)Ana Hernández MonterrubioNo ratings yet

- E 314C SpecalogDocument16 pagesE 314C SpecalogArmando Muñoz100% (1)

- DG8500SE - T: Diesel Generator Portable Soundproof TypeDocument1 pageDG8500SE - T: Diesel Generator Portable Soundproof TypeWilfried VISSIENNONNo ratings yet

- Identification of SAE J1939 DatalinksDocument3 pagesIdentification of SAE J1939 DatalinksMuhammad SohailNo ratings yet

- Aggreko Generator ManualDocument5 pagesAggreko Generator Manualmuzica cu versuriNo ratings yet

- General Information: HandsetDocument17 pagesGeneral Information: HandsetChristian BedoyaNo ratings yet

- DS ProductDataSheet EGT Denoxtronic5 en Lowres 150921Document2 pagesDS ProductDataSheet EGT Denoxtronic5 en Lowres 150921leandroNo ratings yet

- KDGC Control Panel Manual PDFDocument92 pagesKDGC Control Panel Manual PDFÁngel aguilarNo ratings yet

- S1 Thermostat Instruction Manual - 20222-08Document12 pagesS1 Thermostat Instruction Manual - 20222-08Владимир УшаковNo ratings yet

- Installation Manual & Technical Information Automatic Laser Control Control Box Model CB26 Model CB24+Document33 pagesInstallation Manual & Technical Information Automatic Laser Control Control Box Model CB26 Model CB24+magzigio100% (1)

- PQ1204 Double ActingDocument2 pagesPQ1204 Double Actingmkpasha55mpNo ratings yet

- Operator S Manual: Generating Set and Industrial EnginesDocument64 pagesOperator S Manual: Generating Set and Industrial EnginesAl Bima100% (1)

- Illustration 1 Schematic of The Circuit For The Shift LeverDocument8 pagesIllustration 1 Schematic of The Circuit For The Shift Leverlahcen boudaoudNo ratings yet

- 3b. Powertrain Cont PDFDocument921 pages3b. Powertrain Cont PDFDejan StojanovskiNo ratings yet

- Generator Auto Start ME-AGS-SDocument32 pagesGenerator Auto Start ME-AGS-SLonNo ratings yet

- Owner's Manual: Two-Stage Reciprocating Air CompressorsDocument24 pagesOwner's Manual: Two-Stage Reciprocating Air CompressorsmauricioNo ratings yet

- Fpo1 0010839Document28 pagesFpo1 0010839Sukesh EramangalamNo ratings yet

- Boom Extension Cylinder Assembly (Figure 9-35) : Unit Code B222 Europe 08/2007Document2 pagesBoom Extension Cylinder Assembly (Figure 9-35) : Unit Code B222 Europe 08/2007ncthanhckNo ratings yet

- Hypertherm 900 Manual PDFDocument107 pagesHypertherm 900 Manual PDFBradley BergNo ratings yet

- Fault Code 800142 J1939 Time OutDocument12 pagesFault Code 800142 J1939 Time OutJustice Machiwana100% (1)

- Parts/Components of Manual Transmission 1. Clutch 2. Clutch Pedal 3. Gearbox 4. Shift Fork 5. Shift Rod 6. Hydraulic SystemDocument7 pagesParts/Components of Manual Transmission 1. Clutch 2. Clutch Pedal 3. Gearbox 4. Shift Fork 5. Shift Rod 6. Hydraulic SystemVJ CarbonellNo ratings yet

- Engine Brakes PDFDocument18 pagesEngine Brakes PDFMitchelle GonouyaNo ratings yet

- Forklift Linde 18 52t CapacityDocument2 pagesForklift Linde 18 52t CapacityPavlovstefan6187No ratings yet

- h40 500 45 500 50 500 50 600evo en (Ed2) PDFDocument2 pagesh40 500 45 500 50 500 50 600evo en (Ed2) PDFAdmir BašićNo ratings yet

- Etectric Generating Ptants: Operator'S Manuat AND Parts CatalogDocument54 pagesEtectric Generating Ptants: Operator'S Manuat AND Parts CatalogBruce EgglestonNo ratings yet

- Eaton 93e Ups 40kva 60kva Generation 3 ManualDocument120 pagesEaton 93e Ups 40kva 60kva Generation 3 ManualInot KecilNo ratings yet

- 1078-HysterH16-19-t5p.00-18.00XM-12, H16.00-18.00XMS-12Document16 pages1078-HysterH16-19-t5p.00-18.00XM-12, H16.00-18.00XMS-12Darwin Yarleque FloresNo ratings yet

- Data Download HGM1770 V1.6 enDocument19 pagesData Download HGM1770 V1.6 enJohn GarnetNo ratings yet

- Dana Spicer Steer Axles: Service Manual AXSM-0038 September 2005Document44 pagesDana Spicer Steer Axles: Service Manual AXSM-0038 September 2005wadalla100100% (1)

- Genie Lift PartsDocument172 pagesGenie Lift PartsLarry JenningsNo ratings yet

- Deep Sea Electronics PLC: DSE7110 MKII & DSE7120 MKII Operator ManualDocument100 pagesDeep Sea Electronics PLC: DSE7110 MKII & DSE7120 MKII Operator ManualKelvinNo ratings yet

- TD1469-01 Service Manual TT-Axle 60-0xDocument72 pagesTD1469-01 Service Manual TT-Axle 60-0xabdelhadi houssinNo ratings yet

- QSK19 CM850 MCRS Wiring DiagramDocument11 pagesQSK19 CM850 MCRS Wiring DiagramMussardNo ratings yet

- Drum Brake Adjustment PDFDocument2 pagesDrum Brake Adjustment PDFY. VásquezNo ratings yet

- Hdi DL06PDocument246 pagesHdi DL06Pq26n65hvfsNo ratings yet

- Onan Genset HDKCA HDKCB Operators ManualDocument39 pagesOnan Genset HDKCA HDKCB Operators ManualEli Marsee100% (1)

- DTSC-200 ATS Controller: InstallationDocument41 pagesDTSC-200 ATS Controller: InstallationRafael FernandoNo ratings yet

- Detroit Engine Service Manual DD S in Line71Document17 pagesDetroit Engine Service Manual DD S in Line71reynaldo galvisNo ratings yet

- 4001e Control Panel (GB)Document2 pages4001e Control Panel (GB)RameshNo ratings yet

- 2013CatalogCompressed PDFDocument408 pages2013CatalogCompressed PDFSergiSerranoNo ratings yet

- Cat 3304 Inyeccion Directa Scroll Fuel System PDFDocument36 pagesCat 3304 Inyeccion Directa Scroll Fuel System PDFMuhammad rizki100% (5)

- Attachment 2690Document30 pagesAttachment 2690Muhammad rizkiNo ratings yet

- Subaru Electronic Fuel Injection Manual PDFDocument1 pageSubaru Electronic Fuel Injection Manual PDFMuhammad rizkiNo ratings yet

- 3306 Cat Dita Gp4 Engine Service ManualDocument1 page3306 Cat Dita Gp4 Engine Service ManualMuhammad rizkiNo ratings yet

- Acs 6t UsermanualDocument4 pagesAcs 6t UsermanualMuhammad rizkiNo ratings yet

- 4 Wheel Electric Forklift SpecsDocument4 pages4 Wheel Electric Forklift SpecsMuhammad rizkiNo ratings yet

- 25 K Spec PSCD1100712spec DoosanDocument4 pages25 K Spec PSCD1100712spec DoosanMuhammad rizkiNo ratings yet

- Vacuum Pump Mercedes Benz Diesel Damage Due To Wear On The Cam Disk 54389Document2 pagesVacuum Pump Mercedes Benz Diesel Damage Due To Wear On The Cam Disk 54389Muhammad rizkiNo ratings yet

- Donaldson FilterDocument6 pagesDonaldson FilterMuhammad rizkiNo ratings yet

- MAN Biogas EngineDocument16 pagesMAN Biogas EngineMuhammad rizkiNo ratings yet

- Mercedes-Maybach S 600 Guard VR10Document15 pagesMercedes-Maybach S 600 Guard VR10Muhammad rizkiNo ratings yet

- E SD XX 0460Document2 pagesE SD XX 0460Muhammad rizkiNo ratings yet

- DS Ecm XC2 24Document2 pagesDS Ecm XC2 24Muhammad rizkiNo ratings yet

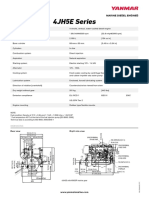

- Yanmar-Datasheet 4JH5EDocument2 pagesYanmar-Datasheet 4JH5EMuhammad rizkiNo ratings yet

- Advanced Test Equipment Rentals: Endocal RTE-Series Refrigerated Bath/CirculatorDocument26 pagesAdvanced Test Equipment Rentals: Endocal RTE-Series Refrigerated Bath/Circulatormario3312No ratings yet

- Air To The Ground: Samsung Turbo Air CompressorDocument8 pagesAir To The Ground: Samsung Turbo Air CompressorSharad KokateNo ratings yet

- Napier Series 7 BrochureDocument16 pagesNapier Series 7 BrochureZinwoo BaeNo ratings yet

- 08ATS2Document16 pages08ATS2jorgeroa111No ratings yet

- Tata Spacio Gold PlusDocument96 pagesTata Spacio Gold Plusxtemp100% (1)

- Super ChargingDocument23 pagesSuper Charginghirenbabaji100% (2)

- Sample LM6000Document26 pagesSample LM6000Eliyanto E BudiartoNo ratings yet

- C11, C13&C15Document60 pagesC11, C13&C15jaimeNo ratings yet

- Xas 400 JD It4Document2 pagesXas 400 JD It4FOXX AHMNo ratings yet

- Sa4d102e 1ab S N 21240928 UpDocument120 pagesSa4d102e 1ab S N 21240928 UpRAMON TEIXIDORNo ratings yet

- 6284 1 15 PDFDocument31 pages6284 1 15 PDFnpsNo ratings yet

- MT500209 PSRPT 2023-07-10 21.18.53Document26 pagesMT500209 PSRPT 2023-07-10 21.18.53gleidsongp182No ratings yet

- These W AttardDocument590 pagesThese W Attardmbassi81No ratings yet

- An A-Z of Aviation Terms and DefinitionsDocument5 pagesAn A-Z of Aviation Terms and DefinitionsAlej GonzálezNo ratings yet

- 854e-E34ta Engine Pn1956Document4 pages854e-E34ta Engine Pn1956Paulo AzañeroNo ratings yet

- Compressor-Spares (2019 - 04 - 18 23 - 15 - 39 UTC)Document20 pagesCompressor-Spares (2019 - 04 - 18 23 - 15 - 39 UTC)LOUI BERRIOSNo ratings yet

- Brochure 23Document4 pagesBrochure 23brujula24100% (1)

- ABB Turbocharging VTCDocument8 pagesABB Turbocharging VTCSrijith M MenonNo ratings yet

- B8 TFSI Catch Can Kit Installation 034-101-1000Document7 pagesB8 TFSI Catch Can Kit Installation 034-101-1000DedelNo ratings yet

- Instruction Fuel Limit AdjustmentDocument12 pagesInstruction Fuel Limit AdjustmentSergei KurpishNo ratings yet

- SpecSheetCFP11E F20Document2 pagesSpecSheetCFP11E F20abdelrhmangbr86No ratings yet

- Mtu 6r1500-EsiteDocument2 pagesMtu 6r1500-EsiteYew LimNo ratings yet

- Aerospace Inventics Visual GuideDocument178 pagesAerospace Inventics Visual GuideValeriu Dragan100% (1)