Professional Documents

Culture Documents

Lembar Kerja 11 Garam Lampiran

Uploaded by

Frendy RianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lembar Kerja 11 Garam Lampiran

Uploaded by

Frendy RianCopyright:

Available Formats

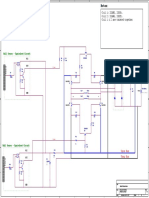

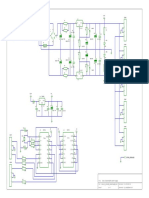

General Notes:

1. All Sharp Edge to be Rounced

2. Bolt holes orientation in nozzle flange shall be stradle to normal

center line of the equipment

N1b 3. Threaded connections must be re-tapped after welding

Electro Motor (Rotor) NP 4. All dimension are in mm unless otherwise noted

N5

2x Baffle

2HP = 1.5kW; 1400 rpm 30° BTM 5. All internal weld are to be ground smooth

Gear Box

N1a 15° N1c Surface Finishing:

Bonfiglioli Type AS20/F - Inside/contact product :

Mat'L CS : -

1:5.02; P90 B5

R300

Mat'L SS : Mirror

150

- Outside/non-contact product:

Mat'L CS : -

R260

N1d

Mat'L SS : Polish WL #220

N3 105°

N1d

947

R200 DESIGN DATA

N1c N0. REQ'D (Unit) 1

N1b 3

PART Tangki Penyimpanan (T-402)

R739 N2 5

CODE ASME Sec.VIII Div.1, 2013 Ed

N1a

VOLUME (Liter) 316

FLUID -

t= 4

2x Lifting Lug SPEC. GRAVITY -

DESIGN PRESS (Barg) 3

R74 N2 DESIGN TEMP ( C) 50

OPERATING PRESS (Kgf/cm2. C) -

160

N4 BTM

OPERATING TEMP ( C) -

APPROX. 2405

NAWP (Barg @ C) 3 @ 50

TOP VIEW

MONT -

HYD. TEST PRESSURE (Barg) 3.9

Scale 1:10 PNEUMA. TEST PRESSURE (Kgf/cm2. C)

N3 N2

POSTWELD HEAT TREATMENT NO

6 RADIOGRAPH NO

22°

1150 TO FLOOR

CORROSION ALLOWANCE (mm) -

1.5"

JOIN EFFICIENCY SHELL 0.7

739

HEAD 0.7

PAINTING (cs oNLY) -

INSULATION -

EMPTY WEIGHT (kgf/unit) -

OPERATING WEIGHT (kgf/unit) -

t=4

I.D 739 1 fULL WATER WEIGHT (kgf/unit) -

Spray Ball

N5 1 0.5" TUBE #1500 BSP SOCKET PRESS TRANS

245 N4 1 1.5" TUBE - CLAMP FERRULE OUTLET

R73,90 SEE

160

N3 1 4.0" TUBE - - - SIGHT GLASS

DWG

N2 1 1.0" TUBE - CLAMP FERRULE SPRAY BALL

t=4

R739

N1a-d 1 1.5" TUBE - CLAMP FERRULE INLET

WELDING JOINT NOZZLE

NO.

SIZE

SCH

RATING FACING TYPE

C.L. TO SERVICE &

2

REQ'D. THK'S FACE DESCRIPTION

3x 2" 150 OUTSIDE INSIDE

FLANGE

400

Sch.10S N5 N4 60° NOZZLE LIST

4 2 2 6 BUFFLE PL.4t SA 240-304 -

60°

2 5 LIFTING LUGS PL.14t SA 240-304 -

2" Sch

4 4 LEGS SA 312-TP 304 -

10S

2 2

1 3 TOP DISHEAD PL.4t SA 240-304 28 -

2

1 2 BOTTOM DISHEAD PL.4t SA 240-304 28 -

INSIDE OUTSIDE

1 1 SHELL PL.4t SA 240-304 28 -

SPARE QTY

DETAIL : LWL DETAIL : CWL PART

PART NAME SPEC. MATERIAL WEIGHT REMARK

Scale 1:1 Scale 1:1

NO. OF NO.

MANUFAC

CONTRACT NO :

02-03.05/91.01/PPK.KP2-BLT/2017

BADAN PENGKAJIAN DAN

44/PKS/PB/BPPT/IV/2017

ISSUED FOR APPROVAL

PILOT PROJECT GARAM INDUSTRI DRAWING NO:

REVISIONS

MI SIS HSN

GD-TMB-T-402

C

PENERAPAN TEKNOLOGI

FRS

B ISSUED FOR REVIEW MI SIS HSN

REV:

FRS

A ISSUED FOR INTERNAL REVIEW FRS MI SIS HSN SCALE: 1:10

REFERENCE DWG NO DESCRIPTION REV DATE DESCRIPTION BY CHK APPD COMP MIXING TANK SHEET: C

You might also like

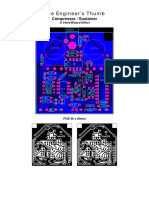

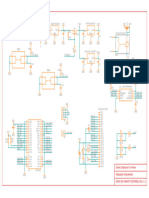

- The Engineer's Thumb: Compressor / SustainerDocument6 pagesThe Engineer's Thumb: Compressor / SustainerCarlos RuizNo ratings yet

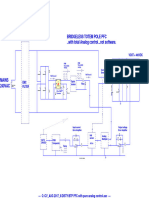

- Schematic - Inverter Egs HF - 2021!01!25.Document1 pageSchematic - Inverter Egs HF - 2021!01!25.INFORCEL ELETRÔNICA E MARCENARIANo ratings yet

- Schematic - Inverter Egs HF - 2021-01-25Document1 pageSchematic - Inverter Egs HF - 2021-01-25Ihya Ulumuddin100% (1)

- Schematic Inverter Egs HF 2021-01-25Document1 pageSchematic Inverter Egs HF 2021-01-25Penikmat Senja 6No ratings yet

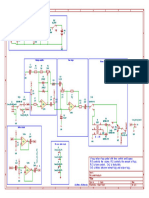

- R42 10K document titleDocument1 pageR42 10K document titleLuis ValerianoNo ratings yet

- NUCLEO-F767ZI - STM32 Nucleo-144 Development Board With STM32F767ZI MCU, Supports Arduino, ST Zio and Morpho Connectivity - STMiDocument1 pageNUCLEO-F767ZI - STM32 Nucleo-144 Development Board With STM32F767ZI MCU, Supports Arduino, ST Zio and Morpho Connectivity - STMijanespenicoNo ratings yet

- M30 Series AC/DC 2-Wire Inductive Sensors with 15mm Sensing RangeDocument1 pageM30 Series AC/DC 2-Wire Inductive Sensors with 15mm Sensing Rangeany3000No ratings yet

- M30 Series AC 2-Wire/AC-DC 2-Wire SN 15mm: Inductive Sensors FeaturesDocument1 pageM30 Series AC 2-Wire/AC-DC 2-Wire SN 15mm: Inductive Sensors Featuresany3000No ratings yet

- M30 Series AC/DC 2-Wire Inductive SensorsDocument1 pageM30 Series AC/DC 2-Wire Inductive Sensorsany3000No ratings yet

- Sde1 SeriesDocument6 pagesSde1 SeriesNelsonNo ratings yet

- Naocl Tank RwtpDocument2 pagesNaocl Tank RwtpAbu SuraisyNo ratings yet

- M30 Series AC 2-Wire/AC-DC 2-Wire SN 15/25mm: Inductive Sensors FeaturesDocument1 pageM30 Series AC 2-Wire/AC-DC 2-Wire SN 15/25mm: Inductive Sensors Featuresany3000No ratings yet

- BTP PFC with pure analog controlDocument1 pageBTP PFC with pure analog controlgpNo ratings yet

- TI-7 SchematicsDocument4 pagesTI-7 SchematicsdddieguezdNo ratings yet

- Mainboard RSAG7.820.4302 2010Document10 pagesMainboard RSAG7.820.4302 2010pedroNo ratings yet

- Shop Fox ManualDocument67 pagesShop Fox Manualpr8No ratings yet

- Bedini Cole Window Motor v1.0Document1 pageBedini Cole Window Motor v1.0mklimesh2600No ratings yet

- 24V to 12V power conversion circuitDocument7 pages24V to 12V power conversion circuitPrint ImageNo ratings yet

- You Have Mail!: Robert EdlingerDocument1 pageYou Have Mail!: Robert EdlingerEdward SlametNo ratings yet

- 9101.220LED (298NEW-S14-D5730) SchematicDocument1 page9101.220LED (298NEW-S14-D5730) Schematicluis palominoNo ratings yet

- Schematic - Bi Directional Visitor Counter - 2022!05!15Document1 pageSchematic - Bi Directional Visitor Counter - 2022!05!15Mochamad NurulNo ratings yet

- Kot King of Tone Schematic BoardDocument2 pagesKot King of Tone Schematic BoardTia WilliamsNo ratings yet

- Vazzen 2009 Fuente regulable 0-19Document1 pageVazzen 2009 Fuente regulable 0-19juanchfNo ratings yet

- Pedal - PCBWay CommunityDocument1 pagePedal - PCBWay Communityheric fernandesNo ratings yet

- MCN ماکسDocument1 pageMCN ماکسabstco1400No ratings yet

- Binh Nen Khi 3000 Lit-Rk Project-23122015Document1 pageBinh Nen Khi 3000 Lit-Rk Project-23122015Van DiepNo ratings yet

- Kit Osciloscopio DIY UserManual 138 NewDocument4 pagesKit Osciloscopio DIY UserManual 138 NewHelder MotaNo ratings yet

- Power supply circuit diagramDocument1 pagePower supply circuit diagramFrancisco Chavez VzzNo ratings yet

- 3.chint Adjustable MCCB (NM8) PDFDocument4 pages3.chint Adjustable MCCB (NM8) PDFYamendra GurungNo ratings yet

- Eltek FP2 48V 15kW 400V+N BD LD SPD (GA - 2321483 - 1 - 1) - 1 PDFDocument1 pageEltek FP2 48V 15kW 400V+N BD LD SPD (GA - 2321483 - 1 - 1) - 1 PDFDmiNo ratings yet

- N2 N3 N3 N2: Ver Nota 1Document1 pageN2 N3 N3 N2: Ver Nota 1Juan ArcosNo ratings yet

- B.6.9 NKE-1130 (AC220V) : JMA-9100 Instruction Manual B.Drawings B.6 Interconnection Diagram of Scanner UnitDocument1 pageB.6.9 NKE-1130 (AC220V) : JMA-9100 Instruction Manual B.Drawings B.6 Interconnection Diagram of Scanner UnitNguyen Phuoc HoNo ratings yet

- Tube Phono Amp Passive RIAA Hard Wired VersionDocument3 pagesTube Phono Amp Passive RIAA Hard Wired VersiondatjblNo ratings yet

- ss4h-sd SchematicDocument1 pagess4h-sd Schematic003454No ratings yet

- Power input options and standby voltagesDocument10 pagesPower input options and standby voltagesautrera100% (1)

- Power input options and standby voltagesDocument10 pagesPower input options and standby voltagesDario EzequielNo ratings yet

- Coal LG Assy With Valves & Instrum - E0688 - HAE2663Document1 pageCoal LG Assy With Valves & Instrum - E0688 - HAE2663MEHDINo ratings yet

- JVCDocument26 pagesJVCDaniel CharlesNo ratings yet

- DVP SA DatasheetDocument2 pagesDVP SA DatasheetsamitosuNo ratings yet

- D D D D D D D D D D: DescriptionDocument25 pagesD D D D D D D D D D: DescriptionSofywka SofaNo ratings yet

- Power Supply LW6.194Document1 pagePower Supply LW6.194Vehid ParićNo ratings yet

- FUEL PUMP CONTROL CIRCUIT PT CrusierDocument5 pagesFUEL PUMP CONTROL CIRCUIT PT CrusierbelesferonteNo ratings yet

- 6.1.3 Netzsch NM031 01LDocument2 pages6.1.3 Netzsch NM031 01LDavid Quirilao100% (1)

- Xotic Soul Driven - SchematicDocument1 pageXotic Soul Driven - SchematicDavid BrownNo ratings yet

- Masterpact Electrical Diagrams GuideDocument10 pagesMasterpact Electrical Diagrams GuideMario Basurto VilledaNo ratings yet

- Sharp CD-M5000W CP-M5000Document6 pagesSharp CD-M5000W CP-M5000Unsk Vocesmuertas AsperNo ratings yet

- Nevera Samsung ConversionDocument1 pageNevera Samsung ConversionJuan Pablo Montero CarmonaNo ratings yet

- Dimensions: NBB5-18GM50-E0-V1Document1 pageDimensions: NBB5-18GM50-E0-V1Aditya ShankarNo ratings yet

- Arduino UNO optocoupler circuitDocument1 pageArduino UNO optocoupler circuitindoramaNo ratings yet

- Overall Electrical Wiring DiagramDocument144 pagesOverall Electrical Wiring DiagramArnuphap SudwaiyonNo ratings yet

- Specification: App. Leng Mark Size Service Rat Ing Remark Design Data For VesselDocument1 pageSpecification: App. Leng Mark Size Service Rat Ing Remark Design Data For VesselcayovinNo ratings yet

- IVQM说明书(20220312) PDFDocument15 pagesIVQM说明书(20220312) PDFGatheru Kamanja StephenNo ratings yet

- Mesa Boogie Dual Rectifier 2 Channel Preamp Emulator: Circuit by Trueval, PCB Layout by TemolDocument7 pagesMesa Boogie Dual Rectifier 2 Channel Preamp Emulator: Circuit by Trueval, PCB Layout by TemolСергей АндрияновNo ratings yet

- Mic Preamplifier A008Document1 pageMic Preamplifier A008Freddy Peters100% (1)

- SS4H-SD Schematic v. 1.1Document1 pageSS4H-SD Schematic v. 1.1gigioNo ratings yet

- FL Series Lighting For Image Processing Lighting Controller Instruction SheetDocument2 pagesFL Series Lighting For Image Processing Lighting Controller Instruction SheetFernando Rosales jardonNo ratings yet

- 1,8 TFT ScematicsDocument1 page1,8 TFT Scematicsnguyen van ANNo ratings yet

- FmradioDocument1 pageFmradiosiucarlos66No ratings yet

- Heat Loss Calculations and Heater Selection Air and GasDocument7 pagesHeat Loss Calculations and Heater Selection Air and GastgimranNo ratings yet

- Critical valve repair kits and sealsDocument30 pagesCritical valve repair kits and sealsFrendy RianNo ratings yet

- Instructions For Flowmeter Data Sheet - NE-ENG-83 PDFDocument3 pagesInstructions For Flowmeter Data Sheet - NE-ENG-83 PDFFrendy RianNo ratings yet

- DesignGuide PDFDocument24 pagesDesignGuide PDFFrendy RianNo ratings yet

- Typical Centrifugal Pump DatasheetDocument7 pagesTypical Centrifugal Pump DatasheetFabioSalaNo ratings yet

- Pressure Gauge SelectionDocument2 pagesPressure Gauge SelectiondjendraHeniNo ratings yet

- E 205 11 PDFDocument60 pagesE 205 11 PDFWan Ah-LunNo ratings yet

- DesignGuide PDFDocument24 pagesDesignGuide PDFFrendy RianNo ratings yet

- Gas MixingDocument16 pagesGas MixingFrendy RianNo ratings yet

- Burst Disc Relief Valve Application Data Sheet PDFDocument4 pagesBurst Disc Relief Valve Application Data Sheet PDFFrendy RianNo ratings yet

- Pipe Rough ValuesDocument1 pagePipe Rough ValuesSpoonful BurnsideNo ratings yet

- Media FilterDocument12 pagesMedia FilterFrendy RianNo ratings yet

- Fs Pri 004 Lamella Settling A20160220Document30 pagesFs Pri 004 Lamella Settling A20160220bkkbrazil100% (1)

- Safety Pattern Pressure Gauges PGDocument2 pagesSafety Pattern Pressure Gauges PGSrinivas VenkatramanNo ratings yet

- Relief Valve Application Data SheetDocument4 pagesRelief Valve Application Data SheetFrendy RianNo ratings yet

- Arita KatalogDocument58 pagesArita KatalogAhmed Beaet83% (6)

- ScheduleDocument1 pageScheduleFrendy RianNo ratings yet

- Pid Legend PDFDocument1 pagePid Legend PDFSocMed Dtk UI0% (1)

- NO TAG Ukuran NO TAG Ukuran NO TAG: Valve ListDocument3 pagesNO TAG Ukuran NO TAG Ukuran NO TAG: Valve ListFrendy RianNo ratings yet

- Comparison FBD Vs Rotary DryerDocument1 pageComparison FBD Vs Rotary DryerFrendy RianNo ratings yet

- Control Valve P1 P2 Flow RangeDocument7 pagesControl Valve P1 P2 Flow RangeramkrishnaNo ratings yet

- Forbil Ebook Series Okt-II Basic Income Then and NowDocument24 pagesForbil Ebook Series Okt-II Basic Income Then and NowFrendy RianNo ratings yet

- 13 Envitec Biogas AG Co-Digestion of Solid and Effluent Waste As Optimum Solution For Energy GenerationDocument15 pages13 Envitec Biogas AG Co-Digestion of Solid and Effluent Waste As Optimum Solution For Energy GenerationFrendy RianNo ratings yet

- MCQ Gas Blender 6000Document4 pagesMCQ Gas Blender 6000Frendy RianNo ratings yet

- SwagelokDocument1 pageSwagelokFrendy RianNo ratings yet

- Haskel GasBoostersDocument36 pagesHaskel GasBoosterskammoNo ratings yet

- Logo EmbossDocument1 pageLogo EmbossFrendy RianNo ratings yet

- Engineering Fundamentals of The Internal Combustion Engine - Willard W. PulkrabekDocument425 pagesEngineering Fundamentals of The Internal Combustion Engine - Willard W. Pulkrabekmi2jaca100% (2)

- Catalog TMD TrundeanDocument12 pagesCatalog TMD TrundeanFrendy RianNo ratings yet

- LR Mate100iDocument7 pagesLR Mate100iFrancisco RojasNo ratings yet

- Toyota Celica GT4 ST165 ECU Pin Out and Wiring DiagramDocument3 pagesToyota Celica GT4 ST165 ECU Pin Out and Wiring DiagramSirleh SalehNo ratings yet

- Technical Specifications For The Supply, Installation, and Commissioning of Electro-Mechanical and Information and Communications Technology (Ict) System InstallationDocument252 pagesTechnical Specifications For The Supply, Installation, and Commissioning of Electro-Mechanical and Information and Communications Technology (Ict) System InstallationAF Dowell MirinNo ratings yet

- IEC Standards for Power CablesDocument1 pageIEC Standards for Power CablesLucian2001No ratings yet

- DA0X81MB6E0Document66 pagesDA0X81MB6E0Asterman SaidiNo ratings yet

- An 4137SCDocument13 pagesAn 4137SCYung SangNo ratings yet

- Xerox DocuColor 2006 - SparePartsListDocument7 pagesXerox DocuColor 2006 - SparePartsListJonathan LongNo ratings yet

- Sterner Infranor Polaris-12 Series Brochure 2006Document20 pagesSterner Infranor Polaris-12 Series Brochure 2006Alan MastersNo ratings yet

- Instruction Manual: Fuel Valve Test Device MODEL: HDFD-1100Document16 pagesInstruction Manual: Fuel Valve Test Device MODEL: HDFD-1100Vlad KorzhovNo ratings yet

- Project BOMDocument22 pagesProject BOMellaNo ratings yet

- History of The Australian - Assembled MGB - MGBs Made in AustraliaDocument2 pagesHistory of The Australian - Assembled MGB - MGBs Made in AustraliaOmiNo ratings yet

- Ba Bfk458 enDocument52 pagesBa Bfk458 enWalterLlenqueTrellesNo ratings yet

- ISOLATION TRANSFORMERS FOR MEDICAL EQUIPMENT SAFETYDocument3 pagesISOLATION TRANSFORMERS FOR MEDICAL EQUIPMENT SAFETYAnwar BasheerNo ratings yet

- 1.load Test On DC Shut MotorDocument5 pages1.load Test On DC Shut Motorg3v5No ratings yet

- Philips - Decorative LightingDocument9 pagesPhilips - Decorative LightingrumahsketchNo ratings yet

- NV-A4S-DC /NV-A4S-UK Simplese Audio Distribution System: Installation GuideDocument32 pagesNV-A4S-DC /NV-A4S-UK Simplese Audio Distribution System: Installation GuideMarian PNo ratings yet

- Daikin Altherma 3 H EPGA-D 11-14-16 KW: Product Catalogue 2020Document40 pagesDaikin Altherma 3 H EPGA-D 11-14-16 KW: Product Catalogue 2020wiwiNo ratings yet

- Testing Aircraft Pitot-Static SystemsDocument13 pagesTesting Aircraft Pitot-Static SystemsMedaNo ratings yet

- Digital I/O multiplexing techniques drive LED displays with fewer pinsDocument2 pagesDigital I/O multiplexing techniques drive LED displays with fewer pinsabba123No ratings yet

- BOSCH Vikakoodit Maalampopumppu 7001i 7800i LW LWMDocument32 pagesBOSCH Vikakoodit Maalampopumppu 7001i 7800i LW LWMHeikki SyrjämäkiNo ratings yet

- Aspire l3600 ManualDocument87 pagesAspire l3600 ManualYishaq ElNo ratings yet

- IxawDocument4 pagesIxawyuvaraja 2219No ratings yet

- ABB TransformersDocument18 pagesABB TransformersEng HamiedNo ratings yet

- CV FormatDocument2 pagesCV FormatTehmas KamranNo ratings yet

- Digital Laser MFP SCX-6322DN Service ManualDocument185 pagesDigital Laser MFP SCX-6322DN Service ManualjaimecamoNo ratings yet

- Trane Engineers Newsletter - Mar2021Document8 pagesTrane Engineers Newsletter - Mar2021Raheem_kaNo ratings yet

- HL510-HL 560 Technical ManualDocument61 pagesHL510-HL 560 Technical ManualAJAYKUMAR PUND83% (6)

- GST200-2 1/2-Loop Addressable Fire Panel OverviewDocument82 pagesGST200-2 1/2-Loop Addressable Fire Panel OverviewgpuonlineNo ratings yet

- 02 Diagrams 5258 1Document6 pages02 Diagrams 5258 1Regis Consultec100% (1)

- Brother 3550-4550-6550-7550-9000-9500 Service ManualDocument171 pagesBrother 3550-4550-6550-7550-9000-9500 Service ManualRandy_Engesett_2494No ratings yet