Professional Documents

Culture Documents

A Textbook of Machine Design by R.S.khurMI and J.K.guptA (Tortuka)

Uploaded by

lastjohnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Textbook of Machine Design by R.S.khurMI and J.K.guptA (Tortuka)

Uploaded by

lastjohnCopyright:

Available Formats

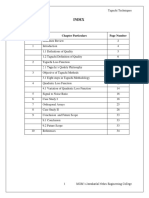

Contents

351

The following cases of fillet welded joints are important from the subject point of view.

1. Circular fillet weld subjected to torsion. Consider a circular rod connected to a rigid plate

by a fillet weld as shown in Fig. 10.9.

Let d = Diameter of rod,

r = Radius of rod,

T = Torque acting on the rod,

s = Size (or leg) of weld,

t = Throat thickness,

*J = Polar moment of inertia of the

t d3

weld section =

4

We know that shear stress for the material,

Fig. 10.9. Circular fillet weld

T .r T d / 2

= subjected to torsion.

J J

T d /2 2T T

= 3 2

...

td /4 td r J

This shear stress occurs in a horizontal plane along a leg of the fillet weld. The maximum shear

occurs on the throat of weld which is inclined at 45° to the horizontal plane.

Length of throat, t = s sin 45° = 0.707 s

and maximum shear stress,

2T 2.83 T

max = 2

0.707 s d s d2

2. Circular fillet weld subjected to bending moment. Consider a circular rod connected to a

rigid plate by a fillet weld as shown in Fig. 10.10.

Let d = Diameter of rod,

M = Bending moment acting on the rod,

s = Size (or leg) of weld,

t = Throat thickness,

**Z = Section modulus of the weld section

t d2

=

4

We know that the bending stress,

M M 4M

b = Z 2 Fig. 10.10. Circular fillet weld

td /4 t d2

This bending stress occurs in a horizontal plane along a leg of the subjected to bending moment.

fillet weld. The maximum bending stress occurs on the throat of the

weld which is inclined at 45° to the horizontal plane.

Length of throat, t = s sin 45° = 0.707 s

and maximum bending stress,

4M 5.66 M

b(max) = 0.707 s d 2

s d2

* See Art, 10.24.

** See Art, 10.24.

You might also like

- Strength of Materials Lecture NotesDocument272 pagesStrength of Materials Lecture NotesbookdigitNo ratings yet

- Mechanical Spring Design GuideDocument8 pagesMechanical Spring Design GuideJosafatNo ratings yet

- Gas Metal Arc Welding (MIG) Presented by N.Sankar/Ap /mechDocument50 pagesGas Metal Arc Welding (MIG) Presented by N.Sankar/Ap /mechlastjohnNo ratings yet

- Design of Rafter by LSD: Loading: Beam-9, Shelter-B, L/C: 214Document3 pagesDesign of Rafter by LSD: Loading: Beam-9, Shelter-B, L/C: 214Ayush GargNo ratings yet

- Design of Welded JointsDocument7 pagesDesign of Welded JointsmohammadNo ratings yet

- 30 Design of Welded JointsDocument8 pages30 Design of Welded JointsPRASAD326No ratings yet

- LIFTING BEAM STRESS ANALYSISDocument2 pagesLIFTING BEAM STRESS ANALYSISAnonymous BzGb2fnfE50% (2)

- SASMO 2020 Grade 6 + SolutionDocument24 pagesSASMO 2020 Grade 6 + SolutionBentley Leopold Halim94% (18)

- Abp Dynamics Multiple Choice 2016-02-24Document10 pagesAbp Dynamics Multiple Choice 2016-02-24artsidartsyNo ratings yet

- Shafts and BearingsDocument43 pagesShafts and BearingsMario AndrewNo ratings yet

- Design of underground water tankDocument4 pagesDesign of underground water tankDhayalan PalanisamyNo ratings yet

- Machine Drawing Detailed ContentsDocument6 pagesMachine Drawing Detailed ContentsTharun GNo ratings yet

- Session5 Automotive PackagingDocument72 pagesSession5 Automotive PackagingShivprasad Savadatti100% (1)

- Chemistry Notes for Class 12 Chapter 15 PolymersDocument17 pagesChemistry Notes for Class 12 Chapter 15 PolymersAsifNo ratings yet

- Chemistry Notes for Class 12 Chapter 15 PolymersDocument17 pagesChemistry Notes for Class 12 Chapter 15 PolymersAsifNo ratings yet

- Water Tank - Is 3370-Mbbr Tank - 1 & 2Document4 pagesWater Tank - Is 3370-Mbbr Tank - 1 & 2Dhayalan PalanisamyNo ratings yet

- Strength of Materials For Technicians Chapter6Document110 pagesStrength of Materials For Technicians Chapter6MR150No ratings yet

- Shear Force & Bending MomentDocument17 pagesShear Force & Bending Momentnitin_johriNo ratings yet

- 06 Failure Theories Fatigue Criteria 2016-2Document22 pages06 Failure Theories Fatigue Criteria 2016-2William BohorquezNo ratings yet

- Mass Spectroscopy: Submitted by Reenu - Thankachan First Semester, M Pharm Pharmaceutical AnalysisDocument38 pagesMass Spectroscopy: Submitted by Reenu - Thankachan First Semester, M Pharm Pharmaceutical AnalysisReenu ThankachanNo ratings yet

- Anup Goel - Spur GearDocument72 pagesAnup Goel - Spur Gearalka sNo ratings yet

- Advisor Webcast Exadata Disk Management and Troubleshotting Tips FinalDocument84 pagesAdvisor Webcast Exadata Disk Management and Troubleshotting Tips FinalethenhuntNo ratings yet

- Fea Lab Manual 18mel68 July 2021Document49 pagesFea Lab Manual 18mel68 July 2021md bashirul haqueNo ratings yet

- XML JavascriptDocument62 pagesXML Javascriptanon-506495No ratings yet

- EG5096 Fatigue and Fracture Mechanics Exam PaperDocument4 pagesEG5096 Fatigue and Fracture Mechanics Exam PaperShanice McAlister-BishopNo ratings yet

- VolumesDocument4 pagesVolumesĐinh Nho BảoNo ratings yet

- Torsion Chapter: Stress Distribution and Angle of Twist CalculationDocument57 pagesTorsion Chapter: Stress Distribution and Angle of Twist CalculationShaktivell LetchumananNo ratings yet

- CmeDocument41 pagesCmekhalis@hotmail.com100% (1)

- Euler Column Theory PDFDocument2 pagesEuler Column Theory PDFDeeNo ratings yet

- Tutorial - 1-Design For Static and Fatigue StrengthDocument5 pagesTutorial - 1-Design For Static and Fatigue StrengthSouradeepBhattacharya50% (2)

- Unit 1 Steady & Variable Stresses in Machine Members: Design of Machine ElementsDocument30 pagesUnit 1 Steady & Variable Stresses in Machine Members: Design of Machine ElementsPrasanth YuviNo ratings yet

- ACD Lab Manual Spur Gear DesignDocument4 pagesACD Lab Manual Spur Gear Designbalaguru780% (1)

- Knuckle JointDocument15 pagesKnuckle JointKetanJShahNo ratings yet

- Bicycle Crank Arm Topology OptimizationDocument13 pagesBicycle Crank Arm Topology OptimizationMauricio Londoño MontoyaNo ratings yet

- Machine Design-II Question BankDocument9 pagesMachine Design-II Question BankProf. Avinash MahaleNo ratings yet

- ME703 Mechanical Vibrations Semester End Exam QuestionsDocument4 pagesME703 Mechanical Vibrations Semester End Exam QuestionsArun100% (1)

- ASM16-Torsion of Noncircular Shafts VI PDFDocument101 pagesASM16-Torsion of Noncircular Shafts VI PDFHusnain JabbarNo ratings yet

- KOM Unit 1Document100 pagesKOM Unit 1VPSureshKumar100% (23)

- To Investigate Band Study The Effect of Varying The Current and The Voltage On The Arc Welded SpecimenDocument5 pagesTo Investigate Band Study The Effect of Varying The Current and The Voltage On The Arc Welded SpecimenRao MaazNo ratings yet

- MosDocument42 pagesMosSajjan Kumar100% (2)

- Neral Notes On Engineering Hardware - FastenersDocument45 pagesNeral Notes On Engineering Hardware - Fastenersbrotaccristian100% (1)

- DampingDocument20 pagesDampingjudeekene_403330720100% (1)

- Worked Examples - Journal & Roller Bearing DesignDocument2 pagesWorked Examples - Journal & Roller Bearing Designsbusiso100% (1)

- Theory of Metal Cutting by Bhattacharya PDF: Mirror Link #1Document6 pagesTheory of Metal Cutting by Bhattacharya PDF: Mirror Link #1Debendra MeherNo ratings yet

- CH 19Document21 pagesCH 19Sanjay Kumar100% (1)

- Course Code Course Title: ME212 Machine Drawing 1 6 5Document4 pagesCourse Code Course Title: ME212 Machine Drawing 1 6 5Kantha RaoNo ratings yet

- J PPT Lecture 8 PDFDocument13 pagesJ PPT Lecture 8 PDFSchmetterling TraurigNo ratings yet

- A Report On Taguchi Methods (Techniques)Document35 pagesA Report On Taguchi Methods (Techniques)Kaustubh Babrekar100% (1)

- Som VivaDocument13 pagesSom VivaDoddaBasappaKNo ratings yet

- Chapter 07Document31 pagesChapter 07AmmarYasirNo ratings yet

- Elastic Constants and Strain EquationsDocument31 pagesElastic Constants and Strain EquationsTooling ganesh100% (2)

- 4 Stroke Petrol Lab 1Document3 pages4 Stroke Petrol Lab 1Eve GreenNo ratings yet

- Hydraulics and Pneumatics Question Bank Siraj PDFDocument9 pagesHydraulics and Pneumatics Question Bank Siraj PDFsirajudeen I100% (1)

- SM2-3 Chap3 Design Welded Joints Tutorial1Document7 pagesSM2-3 Chap3 Design Welded Joints Tutorial1AhmedNo ratings yet

- C-Clamp design guide under 40 charactersDocument10 pagesC-Clamp design guide under 40 charactersmadhu100% (1)

- DESIGN A COTTER JOINT FOR STATIC LOADDocument80 pagesDESIGN A COTTER JOINT FOR STATIC LOADDhruv PancholiNo ratings yet

- Lecture 4Document17 pagesLecture 4rajeshkumarmbcetNo ratings yet

- Design of CotterDocument37 pagesDesign of CotterAnnieMalikNo ratings yet

- 3.0 RIVETED JOINTS - Eccentric LoadingDocument9 pages3.0 RIVETED JOINTS - Eccentric Loadingbutukiprop68372No ratings yet

- 참고자료 11. Lifting Beam CalculationDocument2 pages참고자료 11. Lifting Beam Calculationaoaaoa1122No ratings yet

- Torsion Chapter SummaryDocument50 pagesTorsion Chapter SummaryIbnu Omar AlakiNo ratings yet

- Cushion The Effect of A Shock or Impact LoadingDocument39 pagesCushion The Effect of A Shock or Impact LoadingNAVEEN H V MENo ratings yet

- Lecture-3: Stresses Types and StrainsDocument15 pagesLecture-3: Stresses Types and StrainsAhmad NawazNo ratings yet

- Springs NotesDocument12 pagesSprings NotesKeith Tanaka MagakaNo ratings yet

- Session 08 Cotter Joints: Unit II-Design of Machine ElementsDocument16 pagesSession 08 Cotter Joints: Unit II-Design of Machine ElementsG.G. PRABHATH CHINTHAKANo ratings yet

- Aluminum Washer Blanking and Punching ProcessDocument8 pagesAluminum Washer Blanking and Punching Processprithvi shettyNo ratings yet

- Injection Molding: 2.810 Fall 2002 Professor Tim GutowskiDocument42 pagesInjection Molding: 2.810 Fall 2002 Professor Tim GutowskiSree Raj100% (1)

- DME Power Screw Dr. F. TauheedDocument13 pagesDME Power Screw Dr. F. TauheedDr Praveen KumarNo ratings yet

- FormulasDocument11 pagesFormulasAbdelrhman Essam AttiaNo ratings yet

- Torsional PendulumDocument6 pagesTorsional Pendulumdurairajgeetha318No ratings yet

- Brazing and Soldering Review QuestionsDocument2 pagesBrazing and Soldering Review QuestionslastjohnNo ratings yet

- Meles Zenawi Memorial Tvetc: - Choose The Best AnswerDocument1 pageMeles Zenawi Memorial Tvetc: - Choose The Best AnswerlastjohnNo ratings yet

- At The End of The Module The Learner Will Be Able ToDocument2 pagesAt The End of The Module The Learner Will Be Able TolastjohnNo ratings yet

- Quizzer-Cost-Behavior - Docx Regression Analysis Least SquaresDocument1 pageQuizzer-Cost-Behavior - Docx Regression Analysis Least SquareslastjohnNo ratings yet

- WorksheetDocument1 pageWorksheetlastjohnNo ratings yet

- 1506 ReadingDocument7 pages1506 ReadinglastjohnNo ratings yet

- Learning Outcomes and SamplesDocument9 pagesLearning Outcomes and SamplesakttripathiNo ratings yet

- Dire Dawa UniversityDocument1 pageDire Dawa UniversitylastjohnNo ratings yet

- Learning Outcomes and SamplesDocument9 pagesLearning Outcomes and SamplesakttripathiNo ratings yet

- Sa L 1Document10 pagesSa L 1lastjohnNo ratings yet

- Sophia Is Hanson RoboticsDocument1 pageSophia Is Hanson RoboticslastjohnNo ratings yet

- Jigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofDocument18 pagesJigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofazizmaarof100% (5)

- Content 1 BalaDocument1 pageContent 1 BalalastjohnNo ratings yet

- Jigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofDocument18 pagesJigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofazizmaarof100% (5)

- Jigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofDocument18 pagesJigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofazizmaarof100% (5)

- Jigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofDocument18 pagesJigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofazizmaarof100% (5)

- Jigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofDocument18 pagesJigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofazizmaarof100% (5)

- Sophia Is Hanson RoboticsDocument1 pageSophia Is Hanson RoboticslastjohnNo ratings yet

- Engineering Metrology and Measurements ..Document1 pageEngineering Metrology and Measurements ..lastjohnNo ratings yet

- Jigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofDocument18 pagesJigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofazizmaarof100% (5)

- DefectsDocument32 pagesDefectsrysul12No ratings yet

- Home WQ-POMDocument2 pagesHome WQ-POMlastjohnNo ratings yet

- SAFE Technical Note 1: How SAFE Calculates Punching Shear For The ACI 318-95 CodeDocument33 pagesSAFE Technical Note 1: How SAFE Calculates Punching Shear For The ACI 318-95 CodeGaby FloresNo ratings yet

- TIG Welding Guide for BeginnersDocument17 pagesTIG Welding Guide for BeginnerslastjohnNo ratings yet

- Grade 6 MathDocument12 pagesGrade 6 Mathapi-264682510No ratings yet

- Mos PDFDocument194 pagesMos PDFChoon Ewe LimNo ratings yet

- NORSOK M-601 Annex C Weld Inspection GuideDocument1 pageNORSOK M-601 Annex C Weld Inspection Guidehalim abas100% (1)

- SVCE Seminar Report Format (FINAL)Document6 pagesSVCE Seminar Report Format (FINAL)Vinod KumarNo ratings yet

- Beyond SVGFDocument66 pagesBeyond SVGFLiliana QueiroloNo ratings yet

- Surge Current Protection Using SuperconductorDocument25 pagesSurge Current Protection Using SuperconductorAbhishek Walter PaulNo ratings yet

- CH-2 Earth DamsDocument18 pagesCH-2 Earth DamssidNo ratings yet

- Hierarchical Routing AlgorithmsDocument26 pagesHierarchical Routing AlgorithmsMuhammad HassanNo ratings yet

- Coefficient of Linear Expansion: 1) IntroductionDocument10 pagesCoefficient of Linear Expansion: 1) IntroductionCynthia PeterNo ratings yet

- IGCSE Chemistry TEST YOUR SELF CHAPTER 4Document12 pagesIGCSE Chemistry TEST YOUR SELF CHAPTER 4Nguyễn Việt Huy RoyNo ratings yet

- Tapered Vector Spiral in InkscapeDocument5 pagesTapered Vector Spiral in InkscapejeanNo ratings yet

- The Importance of Calculators in Math ClassDocument6 pagesThe Importance of Calculators in Math Classchloe shanice bordiosNo ratings yet

- Command Line Basics - Everything CurlDocument2 pagesCommand Line Basics - Everything Curlnot hereNo ratings yet

- American Journal of Sociology Volume 46 Issue 3 1940 (Doi 10.2307/2769572) C. Wright Mills - Methodological Consequences of The Sociology of KnowledgeDocument16 pagesAmerican Journal of Sociology Volume 46 Issue 3 1940 (Doi 10.2307/2769572) C. Wright Mills - Methodological Consequences of The Sociology of KnowledgeBobi BadarevskiNo ratings yet

- B1698Document23 pagesB1698Esteban OrtegaNo ratings yet

- Lab 2 ECADocument7 pagesLab 2 ECAAizan AhmedNo ratings yet

- Experimental Noize Guitar Set 1 Effects PedalDocument2 pagesExperimental Noize Guitar Set 1 Effects PedalSingani Titicaca100% (1)

- Delphi Temp SensorDocument2 pagesDelphi Temp SensorAlways Super Gaming vatsal GehlotNo ratings yet

- Hitachi ZW550Document12 pagesHitachi ZW550ForomaquinasNo ratings yet

- A Short Guide To Arrows in ChemistryDocument1 pageA Short Guide To Arrows in ChemistryJefferson RibeiroNo ratings yet

- Manual F700GS 2013Document164 pagesManual F700GS 2013j gfatggNo ratings yet

- Statistical Properties of Population Stability IndexDocument60 pagesStatistical Properties of Population Stability IndexВячеславNo ratings yet

- ContentServer PDFDocument16 pagesContentServer PDFdaniel leon marinNo ratings yet

- Solution To Solved Problems: 1.S1 Make or BuyDocument3 pagesSolution To Solved Problems: 1.S1 Make or BuyHIEN TRAN THENo ratings yet