Professional Documents

Culture Documents

StainTrode D

Uploaded by

Gyanaranjan2011Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

StainTrode D

Uploaded by

Gyanaranjan2011Copyright:

Available Formats

Premium Stainless Steel Maintenance and Repair Electrode

Enhanced Chromium-Nickel Stainless Steel Electrode.

StainTrode D ®

WELDING

• Welding dissimilar stainless steels

• Welding stainless steels to carbon steels

• Welding stainless steels of unknown composition

• High heat applications

DESCRIPTION TYPICAL ANTI-WEAR APPLICATIONS & INDUSTRIES

StainTrode D is an enhanced chromium-nickel electrode APPLICATIONS INDUSTRY

formulated to weld dissimilar stainless steels and stainless • Boiler Baffles Various Industries

steels of unknown composition. Its chemistry is enriched • Sponge Iron Kilns Iron and Steel Works

for use with AISI grade 310. This premium stainless steel • Radiant Tubes Iron and Steel Works

• Annealing Covers Iron and Steel Works

electrode is easily handled and has very good scaling and

• Refractory Anchor Bolts Cement Works

oxidation resistance up to 2100° F.

WELDING PROCEDURE & TECHNIQUE TeroMatD6t-up

STAINTRODE Information

D TECHNICAL DATA

Preparation: Clean weld area of scale and/or oxide. Make & SET-UP INFORMATION

sure all oily contaminants are removed with a suitable

Typical Tensile Strength: 95,000 psi (655 N/mm2)

VOC-free cleaner. Angle prepping normally involves close-

Typical Yield Strength: 64,000 psi (440 N/mm2)

butts and infrequently bevel preparations. If needed, a 60°

Typical Elongation: 35% at room temperature

V bevel is acceptable. Pre-heating of stainless steels is gen-

Typical Hardness: BHN: 190

erally not required.

Typical Impact Strength: Charpy V: 35 ft-lbs at -150°F

Typical Ferrite Content: Fully austenitic

Technique: A short, non-contact technique is recommend-

ed for both fillet and butt-welding. Use a slightly longer

arc-length for bead-on-plate welding. Deposit stringer

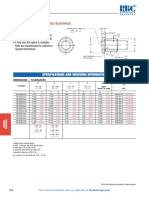

WELDING PARAMETERS

beads or 2 times to 3 times weave beads. Do not weave

more than three times the electrode diameter otherwise Current & Polarity: AC or DCEP (+)

excessive heat input will cause distortion. Diameters: 3/32" - 2.4mm 1/8" - 3.2mm 5/32" - 4.0mm

Post-Welding: Allow parts to cool naturally in still air. Amperage: 65 - 80 85 - 105 115 - 135

Note: When using StainTrode D, keep to the low-end of the amperage range for opti-

mized results.

YOUR RESOURCE FOR PROTECTION, REPAIR AND JOINING SOLUTIONS

Eutectic Corporation Eutectic Services

N94 W14355 Garwin Mace Drive 12300 Carmen Avenue

Menomonee Falls, WI 53051 USA Milwaukee, WI 53225 USA

P 800-558-8524 • F 262-255-5542 P 800-558-8524 • F 262-255-5542

www.eutectic.com

Statement of Liability: Due to variations inherent in specific applications, the technical information contained herein, including any information as to suggested product applications or results, is presented without

representation or warranty, expressed or implied. Without limitation, there are no warranties of merchantability or of fitness for a particular purpose. Each process and application must be fully evaluated by the user

in all respects, including suitability, compliance with applicable law and non-infringement of the rights of others, and Eutectic Corporation and its affiliates shall have no liability in respect thereof.

Dl 09-15 © 2008, Eutectic Corporation, ® Reg. T.M., Printed in the U.S.A.

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- AbraTec 6715Document2 pagesAbraTec 6715Luis MoriNo ratings yet

- Xuper 6804 XHD: WeldingDocument2 pagesXuper 6804 XHD: WeldingAravind rajNo ratings yet

- Chromcarb N6006: WeldingDocument2 pagesChromcarb N6006: WeldingCasa de Adoración ConcepciónNo ratings yet

- EnDOtec 310Document2 pagesEnDOtec 310EdwinNo ratings yet

- Abratec 6710 XHD: WeldingDocument2 pagesAbratec 6710 XHD: WeldingAravind rajNo ratings yet

- ChromCarb N6006Document2 pagesChromCarb N6006mohamed AdelNo ratings yet

- Xuper 680 CGS: WeldingDocument2 pagesXuper 680 CGS: WeldingSharad ShahNo ratings yet

- EnDOtec 358Document2 pagesEnDOtec 358Luis NarvaezNo ratings yet

- 224 XyronDocument1 page224 Xyrontabrizee nurNo ratings yet

- Xuper 1665 XFCDocument2 pagesXuper 1665 XFCAntonio CardosoNo ratings yet

- Cartridge Heaters FIRERODDocument34 pagesCartridge Heaters FIRERODEliasNo ratings yet

- TeroMatec OA 2020Document2 pagesTeroMatec OA 2020EdwinNo ratings yet

- Cable Heaters K-RINGDocument2 pagesCable Heaters K-RINGEliasNo ratings yet

- Paar-Tronic-Cy: Flexible, Screened, Colour Coded To DIN 47100, Meter Marking, EMC-preferred TypeDocument2 pagesPaar-Tronic-Cy: Flexible, Screened, Colour Coded To DIN 47100, Meter Marking, EMC-preferred TypeKelvin NgumbauNo ratings yet

- Abratec 6710 XHD: Multi-Carbide Hardfacing ElectrodeDocument2 pagesAbratec 6710 XHD: Multi-Carbide Hardfacing ElectrodeCasa de Adoración ConcepciónNo ratings yet

- TDS 351do enDocument1 pageTDS 351do enMumkoNo ratings yet

- Teromatec Oa 4601: Premium Open Arc Wearfacing Wire For Combating Extreme AbrasionDocument2 pagesTeromatec Oa 4601: Premium Open Arc Wearfacing Wire For Combating Extreme AbrasionJuan Carlos EspinozaNo ratings yet

- 21001en 17012Document2 pages21001en 17012Mahesh KumbharNo ratings yet

- Tronic-Cy (Liy-Cy) : Flexible, Colour Coded To DIN 47100, Screened, Meter Marking, EMC-preferred TypeDocument2 pagesTronic-Cy (Liy-Cy) : Flexible, Colour Coded To DIN 47100, Screened, Meter Marking, EMC-preferred TypealexorigamiNo ratings yet

- EutecRod 190Document2 pagesEutecRod 190Juan LondonoNo ratings yet

- H01N2-D Welding Cable: Special Cable For The Transmission of High Currents For Electrical Welding MachinesDocument1 pageH01N2-D Welding Cable: Special Cable For The Transmission of High Currents For Electrical Welding MachinesbxblntlwhloivajlmxNo ratings yet

- Eutalloy 11496Document2 pagesEutalloy 11496jorge_20120% (1)

- Xuper 646 XHDDocument2 pagesXuper 646 XHDJuan LondonoNo ratings yet

- 44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2Document6 pages44a0111-20-0 44a0111-20-9 44a0111-22-0 44a0111-22-9 44a0111-24-9 44a1121-22-0/9-9 44a0111-18-0 44a0111-26-2عبدالغني القباطيNo ratings yet

- 189 Prod SelectionDocument1 page189 Prod Selectionherysyam1980No ratings yet

- LF46 LED Flood LightDocument2 pagesLF46 LED Flood Lightkiên phạm trungNo ratings yet

- Weld RepireDocument91 pagesWeld RepireالGINIRAL FREE FIRENo ratings yet

- ISSF Applications For Stainless Steel Long ProductsDocument26 pagesISSF Applications For Stainless Steel Long ProductsVANDANA GLOBALNo ratings yet

- Catalog Code - Master Led Factory Sealed Luminaires Appleton en Us 7436896Document15 pagesCatalog Code - Master Led Factory Sealed Luminaires Appleton en Us 7436896Samuel VelizNo ratings yet

- TEFC Vertical Pump Motors: Innovation and QualityDocument2 pagesTEFC Vertical Pump Motors: Innovation and QualityDinalpinNo ratings yet

- Brochure HEFDocument12 pagesBrochure HEFsreedhar srinivasanNo ratings yet

- EuTronic Arc Spray 595ASDocument2 pagesEuTronic Arc Spray 595ASEdwinNo ratings yet

- 05 - WELD REPAIR PROCEDURES of BOILER COMPONENTS PDFDocument165 pages05 - WELD REPAIR PROCEDURES of BOILER COMPONENTS PDFLakshmi Narayan100% (2)

- Buddy Tig 160 Spec Sheet MW Murphy SonDocument2 pagesBuddy Tig 160 Spec Sheet MW Murphy SoncarlosNo ratings yet

- Abratec 6715: WeldingDocument2 pagesAbratec 6715: Weldingmohamed AdelNo ratings yet

- Rigmaster 304 Stainless Steel Fluorescent LuminairesDocument2 pagesRigmaster 304 Stainless Steel Fluorescent LuminairesErikaGaitanGonzalezNo ratings yet

- GMAW Welding ParametersDocument32 pagesGMAW Welding Parametersnarutothunderjet216No ratings yet

- Features and Benefits: End of Life ProtectionDocument2 pagesFeatures and Benefits: End of Life ProtectionjambomillerNo ratings yet

- SHD-GC - 2019Document2 pagesSHD-GC - 2019S Adriano CiriacoNo ratings yet

- AMECA - Insert CoilDocument20 pagesAMECA - Insert CoilHector MartinezNo ratings yet

- Jz-604 TC Tray Cable: PVC Power Cable, Open Installation TC-ER, NFPA 79, 90°C, 600 V, Meter MarkingDocument2 pagesJz-604 TC Tray Cable: PVC Power Cable, Open Installation TC-ER, NFPA 79, 90°C, 600 V, Meter MarkingAlejandro MoralesNo ratings yet

- Eutectic Eutronic Arc Spray 4 HFDocument4 pagesEutectic Eutronic Arc Spray 4 HFjhonatan VBNo ratings yet

- Tubular and Process Assemblies: W A T L O WDocument26 pagesTubular and Process Assemblies: W A T L O WEliasNo ratings yet

- Invar 36Document5 pagesInvar 36Yoni BenshaharNo ratings yet

- Welding Consumable DSMW-0024.1 - WokaDur - S80-Ni-TIG - ElectrodeDocument3 pagesWelding Consumable DSMW-0024.1 - WokaDur - S80-Ni-TIG - ElectrodeJOLLY JAYA SENTOSANo ratings yet

- JZ 500Document3 pagesJZ 500maxlnw888888No ratings yet

- Cartridge HeatersDocument48 pagesCartridge Heatersprsking187No ratings yet

- Cartridge 0124Document48 pagesCartridge 0124estampados25032020No ratings yet

- 1DB - 49821 - enDocument1 page1DB - 49821 - enFreddy MormontoyNo ratings yet

- Bolted Aluminium Terminal Connectors For Substations: Material of CastingsDocument5 pagesBolted Aluminium Terminal Connectors For Substations: Material of CastingsTravis WoodNo ratings yet

- Photovoltaic CablesDocument12 pagesPhotovoltaic CablesAMARENDRA SINo ratings yet

- MC1081 Ranger Selection GuideDocument2 pagesMC1081 Ranger Selection GuideMiguel AngelNo ratings yet

- PG 00188 HK1819 ÖLFLEX HEAT 180 EWKF CDocument1 pagePG 00188 HK1819 ÖLFLEX HEAT 180 EWKF CRamesh RautNo ratings yet

- Export Product Hand BookDocument94 pagesExport Product Hand Bookamit singhNo ratings yet

- Anexo 1ADocument6 pagesAnexo 1APatricio Felipe Cortes CortesNo ratings yet

- Cable Heluflon PDFDocument2 pagesCable Heluflon PDFEugenioNo ratings yet

- Weld RepireDocument91 pagesWeld RepireKapil ManloiNo ratings yet

- Scotch: Super 33+ Vinyl Electrical TapeDocument2 pagesScotch: Super 33+ Vinyl Electrical TapeDonato PirroNo ratings yet

- Immersion Heaters Square FlangeDocument4 pagesImmersion Heaters Square FlangeEliasNo ratings yet

- KHD Roller PressDocument4 pagesKHD Roller PressAli MendozaNo ratings yet

- Hydraulic Roller Press - HRP PDFDocument12 pagesHydraulic Roller Press - HRP PDFGyanaranjan20110% (1)

- Hydraulic Roller Press - HRP PDFDocument12 pagesHydraulic Roller Press - HRP PDFGyanaranjan20110% (1)

- Butt Press Crusher SegmentDocument1 pageButt Press Crusher SegmentGyanaranjan2011No ratings yet

- Lotherme 464Document1 pageLotherme 464Gyanaranjan2011No ratings yet

- Diffusaloy 910Document1 pageDiffusaloy 910Gyanaranjan2011No ratings yet

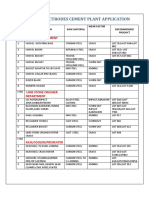

- D&H Secheron in Cement ApplicationDocument1 pageD&H Secheron in Cement ApplicationGyanaranjan2011No ratings yet

- Lotherme Electrodes Cement Plant Application: Mining DepartmentDocument2 pagesLotherme Electrodes Cement Plant Application: Mining DepartmentGyanaranjan2011No ratings yet

- Lotherme Electrodes Cement Plant Application: Mining DepartmentDocument2 pagesLotherme Electrodes Cement Plant Application: Mining DepartmentGyanaranjan2011No ratings yet

- Full Plate Patterns or Custom Flame Cut Shapes and Parts.: Characteristics/specificationsDocument7 pagesFull Plate Patterns or Custom Flame Cut Shapes and Parts.: Characteristics/specificationsrcaletaNo ratings yet

- Boilers and Furnaces Refractory and InsulationDocument56 pagesBoilers and Furnaces Refractory and InsulationKhaled BOUALINo ratings yet

- Solid State Chemistry IITDocument22 pagesSolid State Chemistry IITAdiChemAdi100% (23)

- NC-559-ASM, No-Clean Solder Paste: Product Data SheetDocument2 pagesNC-559-ASM, No-Clean Solder Paste: Product Data SheetAkhmad MukhsinNo ratings yet

- Sandvik SteelDocument16 pagesSandvik Steeljohn9999_502754No ratings yet

- Ladle Metallurgy - Steelpedia - IrDocument171 pagesLadle Metallurgy - Steelpedia - IrAuri Rico MartinezNo ratings yet

- Brochure SouthpartnersDocument19 pagesBrochure SouthpartnersStanislau Felix Garcia RomeroNo ratings yet

- Gear Materials and Heat TreatmentsDocument2 pagesGear Materials and Heat TreatmentsLazaras Benny INo ratings yet

- UNS N08367 Welded Tube: Standard Specification ForDocument2 pagesUNS N08367 Welded Tube: Standard Specification ForROHITNo ratings yet

- ICSG Factbook 2021Document68 pagesICSG Factbook 2021Juan Manuel PardalNo ratings yet

- European Steel and Alloy Grades: About Us EN 10025-2Document2 pagesEuropean Steel and Alloy Grades: About Us EN 10025-2farshid KarpasandNo ratings yet

- QC General NotesDocument21 pagesQC General NotesBilly Kurniawan100% (2)

- ASTM A570 Steel Grade 50 PDFDocument1 pageASTM A570 Steel Grade 50 PDFranjitNo ratings yet

- Eyv 5031 - Chapter 1Document18 pagesEyv 5031 - Chapter 1Aziz AdamNo ratings yet

- Flanged Bushings: Specifications and Ordering InformationDocument1 pageFlanged Bushings: Specifications and Ordering Informationrodryguo74No ratings yet

- Lecture Note 152311150152550Document33 pagesLecture Note 152311150152550Sadu GajiNo ratings yet

- 11 Astm A320 A320m-2018Document8 pages11 Astm A320 A320m-2018FYNo ratings yet

- Rohtak Chain CatalogueDocument32 pagesRohtak Chain CatalogueBhavya OswalNo ratings yet

- Jis g3101 Ss 400 SteelDocument1 pageJis g3101 Ss 400 SteelTerry Gunawan100% (2)

- Question BankDocument27 pagesQuestion BankselvaNo ratings yet

- RoastingDocument2 pagesRoastingRon Estolano0% (1)

- Corrosion: Prepared By: Engr Derik R de CastroDocument22 pagesCorrosion: Prepared By: Engr Derik R de CastroMatthew SilabNo ratings yet

- Zinc PlatingDocument4 pagesZinc Platingrohitpatil330% (1)

- Outokumpu Machining Guidelines For Forta LDX2404Document2 pagesOutokumpu Machining Guidelines For Forta LDX2404chavico113No ratings yet

- Influence Analysis of Different Tempering Temperature On 4330V Steel Plates - SHEW-E STEELDocument3 pagesInfluence Analysis of Different Tempering Temperature On 4330V Steel Plates - SHEW-E STEELnagaraj patilNo ratings yet

- Bab 03 Pemilihan Material PipaDocument30 pagesBab 03 Pemilihan Material PipaMohammad Zaki UsmanNo ratings yet

- Gold SilverDocument2 pagesGold SilverAnonymous O27ezjcNo ratings yet

- CorrosionDocument29 pagesCorrosionHarshaNo ratings yet

- Modification of Molten Steelmaking Slag For Cement ApplicationDocument16 pagesModification of Molten Steelmaking Slag For Cement Applicationlahcen essNo ratings yet

- MAKINO U Series Doc ButtonDocument12 pagesMAKINO U Series Doc ButtonBharath SaravananNo ratings yet