Professional Documents

Culture Documents

UTS Testing of Material

Uploaded by

sreedhar0 ratings0% found this document useful (0 votes)

41 views1 pageThis document describes how to carry out the test on an Instron Universal Tensile Testing machine

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes how to carry out the test on an Instron Universal Tensile Testing machine

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

41 views1 pageUTS Testing of Material

Uploaded by

sreedharThis document describes how to carry out the test on an Instron Universal Tensile Testing machine

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

bd!NstRow

The difference is measurable

Metallic Materials for

sile Testing | ISO 6892-1:2009

Part 1: Method of Test at Ambient Temperature

Description of the Testing Requirements

The new ISO 6892-1:2009 (Metallic materials - Tensile

testing - Part 1: Method of Test at Room Temperature) is a

significant event for anyone performing tensile tests on

metallic materials. The new standard replaces both the

previous version of ISO 6892 and the widely-used EN

10002-1:2001 standard.

180 6892-1:2009 incorporates many detailed

improvements over the older version; however, the most,

significant changes are in the area of test control, where.

the new standard introduces a new test control criteria

“40.3 Testing Rate Based on Strain Rate Control (Method

A)". The aim of the new test control is to reduce the

variation on the mechanical properties by reducing the

variability in the testing conditions. The essential feature of

‘the new test control is the requirement to maintain the

strain rate applied to the test piece within 420% of the

specified rate. This contrasts with the test control

requirements of the EN10002-1:2001 and the older

version ISO 6802, which epecified a combination of stress

and strain rate control (stress rate in the elastic region

followed by strain rate) and allowed considerable variation

in the rates e.g. 2 1:10 variation in the strain rates when

determining Lower Yield (Ret) and only an upper limit an the

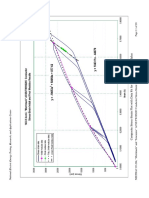

strain rate when determining Proof Strength (Ro) (Figure 1).

ice the mechanical properties of many metallic

materials, including commonly used steels, depend on

strain rate, reducing the variability in the strain rate will

increase the precision of the measured properties (Figure

2),

In addition to reducing the allowed variation in the strain

rate for al tests, the new standard also clarifies the test

conditions for the two types of yield behavior displayed by

‘metallic materials. For metals that demonstrate a smooth

transition from the elastic to plastic region (Figure 3), the

strain distribution in the gauge section of the material is

uniform through the offset yield (Rr) and up to the

‘maximum tensile stress (Rr). In this case, the definition of

strain rate can be, unambiguously, based on the strain

measured by the extensometer and the control of the strain

rate can be achieved using the signal from the

extensometer.

Re . a

= -

ii]| a ”

ri

“= | | ye

hy 1 Pt |

ron

Figure 1 ~ Test speeds at diferent calculation points for $0 6892-2

(Method & and Method B.

Figure 2 - Tests speeds at MPa and 60MPa to ISO 6892-1:2009

(Qulethedt 8)

Worldwide Headquarters | 825 University Avenue, Nerwood, MA 02062-2643 USA | 1.800 877 6674 | 1 781 575 5000 | www.instron.com Poge 1

You might also like

- 795 ACCR Polynomial DerivatDocument18 pages795 ACCR Polynomial DerivatsreedharNo ratings yet

- Ampacity Calculation - : Ac AcDocument1 pageAmpacity Calculation - : Ac AcsreedharNo ratings yet

- Tension and LoadDocument1 pageTension and LoadsreedharNo ratings yet

- Elevated Temperature Creep of AAC, AAAC, ACAR, AACSR, & ACSR ConductorsDocument8 pagesElevated Temperature Creep of AAC, AAAC, ACAR, AACSR, & ACSR ConductorssreedharNo ratings yet

- NEMA Class 2Document1 pageNEMA Class 2sreedharNo ratings yet

- NEMA Class 1Document1 pageNEMA Class 1sreedharNo ratings yet

- Hole Win Wire SectionDocument1 pageHole Win Wire SectionsreedharNo ratings yet

- Contributors and Revision ComDocument1 pageContributors and Revision ComsreedharNo ratings yet

- University - VIT APDocument1 pageUniversity - VIT APsreedharNo ratings yet

- Elevated Temperature CreepDocument2 pagesElevated Temperature CreepsreedharNo ratings yet

- Order ProcedureDocument1 pageOrder ProceduresreedharNo ratings yet

- Stress StrainDocument1 pageStress StrainsreedharNo ratings yet

- Creep Estimated IEEE 1283Document6 pagesCreep Estimated IEEE 1283sreedharNo ratings yet

- PrefaceDocument1 pagePrefacesreedharNo ratings yet

- Materials Groups in TablesDocument1 pageMaterials Groups in TablessreedharNo ratings yet

- Invar36 MechanicalDocument1 pageInvar36 MechanicalsreedharNo ratings yet

- ASM Reference TitleDocument1 pageASM Reference Titlesreedhar0% (1)

- MCL ACSR-MetricDocument1 pageMCL ACSR-MetricsreedharNo ratings yet

- Invar36 Char CurvesDocument1 pageInvar36 Char CurvessreedharNo ratings yet

- Gateway To Engg-VITDocument1 pageGateway To Engg-VITsreedharNo ratings yet

- C Users Sreedhar Downloads DASABrochureUG2021 18sep2021Document2 pagesC Users Sreedhar Downloads DASABrochureUG2021 18sep2021sreedharNo ratings yet

- MCL Acsr AstmDocument1 pageMCL Acsr AstmsreedharNo ratings yet

- Gateway To Engg-VIT - Progrms2Document1 pageGateway To Engg-VIT - Progrms2sreedharNo ratings yet

- Grain Refiner: The World'S Most EfficientDocument1 pageGrain Refiner: The World'S Most EfficientsreedharNo ratings yet

- Titanium Boron Aluminium Grain Refiners: Alloy Designation Color Code Ti B Si Fe V Others Each Total FormDocument1 pageTitanium Boron Aluminium Grain Refiners: Alloy Designation Color Code Ti B Si Fe V Others Each Total FormsreedharNo ratings yet

- Low Resistance Testing PDFDocument19 pagesLow Resistance Testing PDFAaqib MujtabaNo ratings yet

- Math Handout (Trigonometry) Trig Formulas Web PageDocument11 pagesMath Handout (Trigonometry) Trig Formulas Web PageAyushNo ratings yet

- Complexes Part2Document1 pageComplexes Part2sreedharNo ratings yet

- ComplexesDocument1 pageComplexessreedharNo ratings yet

- Titanium Aluminium and Titanium Carbon AluminiumDocument1 pageTitanium Aluminium and Titanium Carbon AluminiumsreedharNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)