Professional Documents

Culture Documents

Coming To Terms: M.F.F.T. Minimum Film Forming Temperature

Uploaded by

Raymond TanumiharjaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coming To Terms: M.F.F.T. Minimum Film Forming Temperature

Uploaded by

Raymond TanumiharjaCopyright:

Available Formats

Quelle/Publication: European Coatings Journal

Ausgabe/Issue: 03/2003

Seite/Page: 112

Coming to Terms: M.F.F.T. = Minimum Film

Forming Temperature

M.F.F.T. is the lowest temperature at which a polymer or

solid portion of an aqueous polymer dispersion (also called

latex or emulsion) self coalesces in the semi dry state to

form a continuous polymer film, which in turn acts as a

binder for the rest of the solids in the paint film.

At temperatures at and above the M.F.F.T. of the polymer

the film is formed. At temperatures below its M.F.F.T. the

polymer cannot coalesce to form a continuous film and thus

cannot bind together itself (or any pigments and extenders

that may be present) and a "cracked, crazed" powdery layer

results.

Practical Usage

M.F.F.T. is normally used as a guide by coatings formulators

as to how the polymer will affect the following parameters of

any coating in which it is used:

- Ease of low temperature film formation/Storage Stability:

the higher the M.F.F.T the lower the chance of unaided low

temperature film formation

- Flexibility:

As a rough rule of thumb, the lower the M.F.F.T. of a

polymer the more flexible and elastomeric it will be -

However, with modern polymer systems this rule may not

apply. Flexibility is very monomer dependent: For instance,

pure acrylic and a styrene acrylic copolymer emulsions may

have exactly the same M.F.F.T. but not have the same

flexibility/elasticity.

- Dirt retention/film thermoplasticity:

The higher the M.F.F.T. the harder the final polymer film

and the less thermoplastic the polymer will be, which in turn

means that the chance of dirt adhering to it will be lower.

As usual in coatings technology, we actually require a

balance between these properties, and so we tend to

manipulate these properties of the polymer either by adding

a temporary volatile plasticiser (coalescent) or by altering

the polymer backbone morphology (e.g. core/shell-systems)

to achieve the desired properties.

Practical Measurement/Determination

If you know the exact monomeric build-up of a polymer, it is

possible to roughly calculate the M.F.F.T. of a dispersion

polymer. However, it is also fairly easy to very accurately

determine the M.F.F.T. of a polymer with and without

coalescent, using fairly unsophisticated equipment - a

copper bar heater/ice and thermocouples/thermometers.

Properties like M.F.F.T. are very polymer composition

dependent. They will thus vary from batch to batch, even for

mixtures of the same ingredients. Therefore, most

dispersion polymer manufacturers indicate an

M.F.F.T.-range rather than a specific figure.

Philip Green,

Paint Technology consultant,

Philip@iccorp.co.za

Vincentz Network +++ Schiffgraben 43 +++ D-30175 Hannover +++ Tel.:+49(511)9910-000

You might also like

- Cit 1Document11 pagesCit 1Sebastian Segura AhumadaNo ratings yet

- Perfluoroelastomer and Fluoroelastomer Seals For Photovoltaic Cell Manufacturing ProcessesDocument12 pagesPerfluoroelastomer and Fluoroelastomer Seals For Photovoltaic Cell Manufacturing ProcessesJagdish PatelNo ratings yet

- MFDocument29 pagesMFRayhan AdhaNo ratings yet

- Slip Additives For films-CoFDocument4 pagesSlip Additives For films-CoFShivaranjani KuruparanNo ratings yet

- Fluro Silicone Dyanmic - FS 80Document1 pageFluro Silicone Dyanmic - FS 80Suryanshu KushwahaNo ratings yet

- Base Resistant FKM Technology in Oilfield SealsDocument15 pagesBase Resistant FKM Technology in Oilfield Sealspeach5No ratings yet

- Slip Agents Extended Performance Range For Polyolefin FilmsDocument2 pagesSlip Agents Extended Performance Range For Polyolefin Filmsanti blocking additiveNo ratings yet

- Thermoplastic Promises New Pultrusion SynergiesDocument6 pagesThermoplastic Promises New Pultrusion Synergiesabilio_j_vieiraNo ratings yet

- Polymers and Plastics PDFDocument90 pagesPolymers and Plastics PDFHarrah Jean GumawaNo ratings yet

- Assignment # 01 (TE-671) 10-NTU-6012Document12 pagesAssignment # 01 (TE-671) 10-NTU-6012Sajid FaheemNo ratings yet

- 1.1 Thermoplastic and Thermosetting PolymersDocument5 pages1.1 Thermoplastic and Thermosetting PolymerssumherilNo ratings yet

- MembranasDocument69 pagesMembranasCristina SilvaNo ratings yet

- FCP PropertiesDocument5 pagesFCP Propertiestedsimon1No ratings yet

- Article Co ExtrusionDocument1 pageArticle Co Extrusiondanibiz2No ratings yet

- Unit-Iv Part-ADocument7 pagesUnit-Iv Part-AParameswara RajaNo ratings yet

- SpecialChem - Coalescing Agents in Coatings - Definition, Types & PropertiesDocument5 pagesSpecialChem - Coalescing Agents in Coatings - Definition, Types & Propertiesichsan hakimNo ratings yet

- MF Uf NFDocument69 pagesMF Uf NFShikha JaiswalNo ratings yet

- SSPC Tu 12 PDFDocument5 pagesSSPC Tu 12 PDFPrashant PandeyNo ratings yet

- 2004 Bucknal Nano LetterslDocument7 pages2004 Bucknal Nano Letterslnandini bhandaruNo ratings yet

- DDSP Introduction - Course Assignment: Diploma in Design and Specification of PlasticsDocument3 pagesDDSP Introduction - Course Assignment: Diploma in Design and Specification of PlasticsAnonymous fCp1HRwpNo ratings yet

- MITM12333Document3 pagesMITM12333anshul2106No ratings yet

- PCB ManufacturingDocument48 pagesPCB Manufacturingsathishkumar.vNo ratings yet

- ULTRADYN Hollow Fiber Modules FS10 FE10 User Manual PDFDocument20 pagesULTRADYN Hollow Fiber Modules FS10 FE10 User Manual PDFjpsingh75No ratings yet

- Polymer CompositeDocument8 pagesPolymer CompositeMuhammad AhmedNo ratings yet

- Thin FilmDocument3 pagesThin FilmNung NingNo ratings yet

- Tpe JadiDocument24 pagesTpe JadiMiraNo ratings yet

- Tailoring Pore Distribution in Polymer Films Via eDocument13 pagesTailoring Pore Distribution in Polymer Films Via eYOHANA KEDANGNo ratings yet

- F) Difference Between Thermoplastics & Thermo-Setting PlasticsDocument1 pageF) Difference Between Thermoplastics & Thermo-Setting PlasticsAsad kkNo ratings yet

- DOWANOL DPM POOR WETTING c5Document19 pagesDOWANOL DPM POOR WETTING c5Asit RayNo ratings yet

- DịchDocument30 pagesDịchKhánh Nguyễn NgHNo ratings yet

- Film Formation in Coatings - Properties, Mechanisms, and ApplicationsDocument10 pagesFilm Formation in Coatings - Properties, Mechanisms, and ApplicationsAadhi InnovativesNo ratings yet

- Polymers&CompoundingDocument80 pagesPolymers&CompoundingM PraveenNo ratings yet

- Crosslinking of WaterborneDocument11 pagesCrosslinking of WaterbornealpersakirmetinNo ratings yet

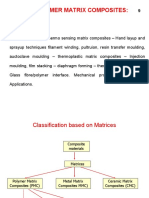

- 59a1polymer Matrix Composites PolymerDocument121 pages59a1polymer Matrix Composites PolymerMisgatesNo ratings yet

- Polymer Matrix CompositesDocument121 pagesPolymer Matrix CompositesHitesh Shah100% (6)

- Technical Articles: Film andDocument9 pagesTechnical Articles: Film andLong HoàngNo ratings yet

- Unit Ii Polymer Matrix CompositesDocument121 pagesUnit Ii Polymer Matrix CompositesKarthick PrasadNo ratings yet

- Unit Ii Polymer Matrix CompositesDocument121 pagesUnit Ii Polymer Matrix CompositesKarthick PrasadNo ratings yet

- Elective Course (2) - Composite Materials MET 443Document16 pagesElective Course (2) - Composite Materials MET 443يوسف عادل حسانينNo ratings yet

- FILE 20191029 153218 Mckeen2013Document72 pagesFILE 20191029 153218 Mckeen2013kiddprofessorNo ratings yet

- Thermoplastic OlefinDocument2 pagesThermoplastic OlefinpepeNo ratings yet

- 13 PolimerDocument54 pages13 PolimerJhonsonNo ratings yet

- Ptfe by Vapour DepositionDocument6 pagesPtfe by Vapour DepositionKarthikeyanNo ratings yet

- MEMSDocument21 pagesMEMSScientist SakthivelNo ratings yet

- Ptfe Ptfe Compounds Pfa Technical InformationDocument16 pagesPtfe Ptfe Compounds Pfa Technical InformationMulyanto MulyonoNo ratings yet

- Ureaformaldehyde 160616122919Document8 pagesUreaformaldehyde 160616122919mikaela05No ratings yet

- 4-Experiment 4-Handout PDFDocument5 pages4-Experiment 4-Handout PDFOğuz YavuzNo ratings yet

- PP Film ManufacturingDocument61 pagesPP Film ManufacturingMerve Ayvaz KöroğluNo ratings yet

- 1996 Ejwwp 0085Document4 pages1996 Ejwwp 0085AndreaAbdelLatifNo ratings yet

- Compression & Transfer Mould DesignDocument135 pagesCompression & Transfer Mould DesignShubham ChaudharyNo ratings yet

- History of PolypropyleneDocument3 pagesHistory of PolypropyleneMayank GuptaNo ratings yet

- Lecture - 4 Classification of PolymerDocument14 pagesLecture - 4 Classification of PolymerRoronoaNo ratings yet

- Lecture - 5 Thermoset - IPNDocument18 pagesLecture - 5 Thermoset - IPNRoronoaNo ratings yet

- Thermoplastic ElastomerDocument4 pagesThermoplastic ElastomerpepeNo ratings yet

- Mckeen2014 PDFDocument28 pagesMckeen2014 PDFashok_abclNo ratings yet

- Applications of Fluoropolymer Films: Properties, Processing, and ProductsFrom EverandApplications of Fluoropolymer Films: Properties, Processing, and ProductsNo ratings yet

- 12th Grade Chemical Kinetics WorhshhetDocument1 page12th Grade Chemical Kinetics WorhshhetAmen RaipurNo ratings yet

- Physical Science 1 1Document58 pagesPhysical Science 1 1Anonymous N0FZEkrSaeNo ratings yet

- BLISKDocument24 pagesBLISKRachmat Miftakhul HudaNo ratings yet

- Project Work On Water Tank Cleaning MachineDocument2 pagesProject Work On Water Tank Cleaning MachinePrakash Pokhrel100% (1)

- Periodic Table Sig Fig B WDocument1 pagePeriodic Table Sig Fig B WRicardo VelozNo ratings yet

- Unit 2 - Chemical ReactionsDocument9 pagesUnit 2 - Chemical ReactionsNobukhosi NdlovuNo ratings yet

- Elvis 4Document9 pagesElvis 4Azhar Ali Zafar0% (1)

- 9701 w05 QP 4Document12 pages9701 w05 QP 4Hubbak KhanNo ratings yet

- ReportDocument20 pagesReportAidaFarzanaNanaNo ratings yet

- Silver Clusters in Zeolites: Structure, Stability and PhotoactivityDocument1 pageSilver Clusters in Zeolites: Structure, Stability and PhotoactivityJan HermannNo ratings yet

- Composite Leaf SpringDocument23 pagesComposite Leaf SpringVijay AnandNo ratings yet

- Model Paper Engg - Chemistry 1 1 r16Document1 pageModel Paper Engg - Chemistry 1 1 r16vrkoradaNo ratings yet

- Análisis de Textura en Frutas CongeladasDocument9 pagesAnálisis de Textura en Frutas CongeladasJORGENo ratings yet

- Analytical Concepts of Errors, Accuracy and Precision: Group: 2 Eman Fatima Fajar Eman Khadija LubainaDocument12 pagesAnalytical Concepts of Errors, Accuracy and Precision: Group: 2 Eman Fatima Fajar Eman Khadija LubainaAzhan HassanNo ratings yet

- Crystal Structure Refinement and Hydration Behaviour of Doped Tricalcium AluminateDocument10 pagesCrystal Structure Refinement and Hydration Behaviour of Doped Tricalcium AluminateJuliano. PQMNo ratings yet

- Ray OpticsDocument52 pagesRay OpticsJack LupinoNo ratings yet

- Solar and Stellar Magnetic Activity - ISBN0521582865 PDFDocument402 pagesSolar and Stellar Magnetic Activity - ISBN0521582865 PDFOmar Musalem100% (1)

- Urt 2Document3 pagesUrt 2Reham HishamNo ratings yet

- Ls Series Washer Extractors: Designed To LastDocument4 pagesLs Series Washer Extractors: Designed To LastTom DavidcsNo ratings yet

- Disclosure To Promote The Right To InformationDocument19 pagesDisclosure To Promote The Right To Informationjoaoaugusto79No ratings yet

- 20-1-16 LS Dyna - SHPB Analysis FinalDocument7 pages20-1-16 LS Dyna - SHPB Analysis FinalJayDeep KhajureNo ratings yet

- RSM 2008 RevisionDocument51 pagesRSM 2008 RevisionphanthanhhungNo ratings yet

- Physics Progect On Led As Light SensorDocument10 pagesPhysics Progect On Led As Light SensorShubham KumarNo ratings yet

- Ladle Furnace Refractory Lining: A Review: Dashrath Singh KathaitDocument8 pagesLadle Furnace Refractory Lining: A Review: Dashrath Singh KathaitHameedNo ratings yet

- Service Boom Inspection and Repair PDFDocument60 pagesService Boom Inspection and Repair PDFYadi Kusmayadi100% (1)

- Maharashtra HSC Chemistry Paper 2-Target PublicationDocument45 pagesMaharashtra HSC Chemistry Paper 2-Target PublicationKhanAbdullah100% (1)

- Experiment 2 - Study of Packed Column DistillationDocument7 pagesExperiment 2 - Study of Packed Column DistillationAdawiyah Az-zahra100% (1)

- Baicapil™Document26 pagesBaicapil™HarmonyLife100% (6)

- A Reviewof Studies On Central Receiver Solar Thermal Power PlantsDocument28 pagesA Reviewof Studies On Central Receiver Solar Thermal Power PlantsValeria Rueda100% (1)

- The Latent Heat of Fusion of IceDocument4 pagesThe Latent Heat of Fusion of Iceeid elsayedNo ratings yet