Professional Documents

Culture Documents

Engineering Frozen Desserts: Ice Cream or Frozen Dessert?

Uploaded by

Junior RoqueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Frozen Desserts: Ice Cream or Frozen Dessert?

Uploaded by

Junior RoqueCopyright:

Available Formats

Engineering

Frozen Desserts

The scraped-surface freezer is at the core

of ice cream production. Understanding and

controlling this operation and the storage conditions

of the final product are critical to creating

the smooth and creamy treat consumers expect.

Richard Hartel

Univ. of Wisconsin

I

ce cream is a multiphase soft solid composed of ice

crystals, casein micelles, air cells, and emulsion droplets

Ice Cream or Frozen Dessert?

(both individual and clustered), all embodied within

an unfrozen serum phase that contains dissolved compo- I n the U.S., ice cream has a Standard of Identity as

defined by the U.S. Food and Drug Administration (FDA)

in the Code of Federal Regulations. It must contain no

nents. These disparate parts interact as ice cream melts in other fat than milk fat, and the minimum fat content is

the consumer’s mouth, which defines the overall quality or 10%. There is also a maximum density requirement that

acceptability of the product. Controlling the formation of effectively caps the amount of air that can be incorpo-

these different phases as the ice cream freezes requires an rated at 100% overrun (air incorporation on a volume

understanding of advanced engineering principles. basis). If the requirements of the Standard of Identity are

Although frozen desserts have existed for centuries, not met, the product cannot be called ice cream on the

label, but instead must be called a frozen dessert.

modern manufacturing processes employ advanced control

to ensure efficient operation that creates products with

desirable attributes. Building on the rudimentary freezers of

yesteryears, the modern scraped-surface freezer (SSF) effi-

ciently creates the structures necessary for frozen desserts.

However, the inner workings of the freezer (i.e., a scraped-

surface heat exchanger) remain somewhat elusive. This is in

part because the inner workings are not visible for analyti-

cal measurement, but also because ice changes extremely

rapidly as temperature varies.

In particular, controlling the creation of the ice phase

is critical to product quality and shelf life. Numerous ice

crystals smaller than about 50 µm produce a desirable

smooth and creamy texture. The freezer must create these

Copyright © 2019 American Institute of Chemical Engineers (AIChE).

CEP May 2019 www.aiche.org/cep 39

Not for distribution without prior written permission.

SBE Special Section: Food Engineering

Flavors small ice crystals while also controlling the

and other phases (i.e., air and fat). The small ice

Colors

Packaging crystals created in the freezer, however, are

Pasteurization

and Freezing unstable; their high surface energy leads

Ice Homogenization Hardening

Cream

to recrystallization. To maintain the small

Mix ice crystals on the shelf, storage conditions

Storage must minimize recrystallization mecha-

Air and

Distribution

nisms, such as Ostwald ripening, in which

small crystals dissolve and redeposit onto

larger crystals.

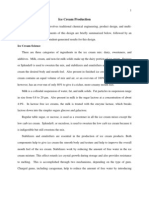

p Figure 1. This simplified flow diagram depicts the steps of a continuous ice cream Recent advances in the production

production process.

of frozen desserts include developments

of alternative processes and advances in

modeling of freezers. This article provides

a brief overview of ice cream production

Human/Machine Interface Refrigeration System and the operation of the SSF and details

the engineering behind these alternative

processes and models of existing freezers.

Freezing Barrel Air Inlet

The traditional ice cream process

The process of making ice cream starts

Power Source

Ice Cream Outlet

with creating a mix from the component

ingredients. Cream, or some other dairy

Ice Cream Mix Inlet ingredient, and sugar are the main com-

ponents that make up the bulk of the ice

cream mix. A variety of ingredients that

p Figure 2. This cutaway diagram reveals the interior of a modern ice cream freezer. Image enhance the product or reduce cost may

courtesy of Tetra Pak. also be added. Emulsifiers are generally

Refrigerant Scraper

needed to control the emulsion interface.

Blades Stabilizers (e.g., hydrocolloids such as

Ice Cream

gelatin, gums, or cellulose) are often

added to increase viscosity and extend

Ice Cream Mix shelf life. Other ingredients that may be

and Air added include corn syrup solids, skim milk

solids, and, of course, colors and flavors.

After freezing, variegates (e.g., caramel,

Dasher

Refrigerant

marshmallow, fudge) and particulates

(e.g., chocolate chips, cookie dough, nuts,

p Figure 3. A rotating dasher with scraper blades clears product from the inside surface of the fruits) may be added to provide unique

barrel, incorporating it into the bulk of the mixture.

characteristics.

Making ice cream commercially

involves a variety of unit operations

Ripening (Figure 1). All of the ingredients are first

Refrigerant

Dasher Ice Disks combined to form the liquid mix. This mix

Broken Floc

is pasteurized to destroy pathogenic bacte-

ria and then homogenized to ensure indi-

Ice Floc

sh vidual fat globules are about 1 µm. Colors

Scraper Blade Slu

and Support Freezer Wall and flavors are added to the liquid mix,

after which it is frozen into ice cream in a

continuous freezer. In the primary freezer,

p Figure 4. As ice crystals form, the scraper blade moves slush away from the freezer wall and often called the dynamic freezing step, ice

incorporates it back into the bulk. cream structures (e.g., ice crystals, air cells,

40 www.aiche.org/cep May 2019 CEP

Copyright © 2019 American Institute of Chemical Engineers (AIChE).

Not for distribution without prior written permission.

clustered fat globules) are formed. The semi-fluid product higher viscosity, which makes complete filling of containers

of the dynamic freezing step is packaged before it enters a problematic; an ice cream that is too stiff leaves air pockets

hardening tunnel or room, where secondary freezing takes as the product fills the container.

place. After exiting the hardening tunnel, the product is After packing, the containers of ice cream are sent to a

ready to be shipped for distribution to consumers. hardening tunnel, where the temperature is about –30°C;

The quality of ice cream is highest immediately after there the temperature within the container is quickly

manufacture, since storage conditions generally degrade reduced. Secondary freezing occurs as the ice crystals

product quality. Thus, controlling the dynamic freezing step created in the dynamic freezing step increase in size

is a key part of creating products with high quality and long based on the new phase equilibrium at the lower tempera-

shelf life. ture. Crystals grow to about 35–45 µm after hardening,

The dynamic freezing step occurs in a scraped-surface

heat exchanger (Figure 2). The liquid mix enters the con-

tinuous freezer at about 4°C, where it is partially frozen,

and exits as a semi-frozen slurry that resembles soft-serve

ice cream. Air is incorporated into the mix and broken

down into small air cells by shear forces within the freezer.

During this process, individual fat globules (≈1 µm) begin

to form clusters of partially coalesced fat globules of about

10–100 µm. These structures govern the ice cream’s quality

and shelf life.

Figure 3 details the freezing barrel of the SSF. Within

the cylindrical barrel, a rotating dasher with scraper blades

continually clears the inside surface of the barrel. Vaporiz-

ing refrigerant on the outside of the barrel cools the surface.

Ice cream mix that enters one end of the barrel encounters

this cold surface and begins to freeze at the wall. Ice con-

tinues to develop as the mix passes along the length of the

barrel until it exits as a soft-serve slurry. p Figure 5. The ice crystals that exit an ice cream freezer typically

measure 20–35 µm.

A dendritic ice slush forms on the inside of the barrel

(Figure 4) because of the high driving force for freezing Edy’s Full-Fat Vanilla

(i.e., large temperature difference between the mix freez- Cold Air Storage

Refrigerant

ing temperature and the wall temperature). The scraper and

–30°C Distribution

blades clear the barrel surface approximately every 0.1 sec,

depending on the dasher design and rotation speed. The 2°C –10°C to –20°C

Freezer

cold ice slush mixes into the center of the barrel where tem- Hardening

peratures are much warmer. The flow path is governed by

Packaging –18°C

the flow profile set by the interior dasher (or beater) design.

–5°C to –6°C

The average temperature decreases along the axial

length of the freezer, approximately following the freezing Avg. Crystal Size

point depression curve. Complex heat- and mass-transfer Edy’s Slow-Churned Vanilla = 54 µm

Storage

processes occur as ice melts and then recrystallizes, eventu- Refrigerant Refrigerant

and

ally creating a distribution of block-shaped ice crystals Distribution

with a mean crystal size at the freezer exit of 20–35 µm 2°C Extruder –10°C to –20°C

(Figure 5). Crystal size varies based on operating conditions Freezer

and mix formulation.

–5°C to –6°C

The ice cream slurry exits the freezer at about –6°C and Packaging

is dispensed into containers. The choice of draw tempera- –10°C to –12°C

ture weighs opposing goals: freezing as much as possible in

Avg. Crystal Size

the dynamic freezing step and ease of packaging. The more = 34 µm

ice frozen during dynamic freezing, generally the smaller

p Figure 6. Ice cream produced through cold extrusion has significantly

the ice crystals, since no other step in the process involves smaller ice crystals in the finished product (34 µm) than ice cream pro-

nucleation. However, a product with more ice will have a duced by traditional methods (54 µm).

CEP May 2019 www.aiche.org/cep 41

Copyright © 2019 American Institute of Chemical Engineers (AIChE).

Not for distribution without prior written permission.

SBE Special Section: Food Engineering

Coarsening of ice crystals during storage is the dynamic nature of the multiphase system.

one of the main issues for frozen foods. It Hernandez-Parra et al. (4) recently modeled heat

transfer and flow of sorbet in an SSF. Sorbet is a relatively

occurs due to slight differences between the simple model system because only ice forms, with no air

melting points of small and large crystals. incorporation or fat globule structuring. A key element in

modeling sorbet is the change in fluid properties as the

although this depends somewhat on the size and shape product transitions from a liquid mix to an ice slurry exiting

of the container. Product on the outside of the container the freezer. By assuming an ice phase equilibrium along the

freezes faster than that in the center, where there is a greater length of the freezer, they were able to develop correlations

opportunity for ice crystals to grow larger through recrystal- for viscosity (consistency coefficient for a shear-thinning

lization mechanisms. fluid), specific heat capacity, and thermal conductivity along

the length of the freezer. Assuming single-phase flow (i.e.,

Cold extrusion processing neglecting ice effects on flow properties), they predicted

Cold extrusion is one of the most creative recent innova- a wide range of parameters, including shear rate profile,

tions in ice cream processing (1, 2). Instead of packaging velocity profile (Figure 7), pressure profile, temperature

ice cream after it exits the SSF, the slurry is pumped into profile, enthalpy and ice fraction along the freezer, and

a low-temperature extruder to reduce the temperature. The viscous dissipation rate. To validate the model, they com-

extruder quickly cools the slurry to about –12°C. The slow pared measured temperature profiles to predicted values for

rotation of the extruder screw(s) provides uniform cooling a range of operating conditions, including dasher rotation

and minimizes recrystallization of ice crystals and coales- speed, throughput rate, and refrigerant temperature. In all

cence of air bubbles. The finished product has smaller ice cases, predicted values agreed well with the experimental

crystals and air cells and, interestingly, still maintains suf- data, suggesting the model was accurately predicting condi-

ficient fluidity to completely fill the package. tions within the freezer.

Figure 6 compares a traditional ice cream process to the The next step in modeling is to add modules that predict

cold extrusion process. Marketers often call this “slow- ice crystallization and air cell breakdown in the SSF. An

churned” ice cream to differentiate it from the tradition- early attempt to predict ice crystal size in an SSF by Arel-

ally made products. Unfortunately, the cost of adding an lano et al. (5) used a simple residence time distribution

extruder at the end of each SSF in commercial production model coupled with a population balance approach. One of

limits the application of this new technology, despite its the problems with this approach is identifying the appropri-

distinct advantages. ate crystallization kinetics. Nucleation occurs on the barrel

wall, followed by ripening and growth within the warmer

Modeling the freezer center of the barrel. Kinetic expressions for these complex

Although computational fluid dynamics (CFD) model- processes are generally not available. Thus, Arellano et al.

ing is widely used in other fields, its application to foods used literature values where they could and resorted to set-

has been slow (3). CFD can provide a window into the

0 weeks 1 week

complicated fluid dynamics within the enclosed SSF. The

complex structure development changes the nature of the

flow patterns, so CFD models must somehow account for

2 weeks 3 weeks

0 0.4 0.8 1.2 1.6 2

p Figure 7. CFD modeling shows the velocity profile of sorbet inside a p Figure 8. Ice crystals decrease in number and increase in mean size

scraped-surface heat exchanger, assuming single-phase flow. Source: (4). over a period of three weeks.

42 www.aiche.org/cep May 2019 CEP

Copyright © 2019 American Institute of Chemical Engineers (AIChE).

Not for distribution without prior written permission.

ting some variables for optimization to fit the experimental Closing thoughts

size data. More work is needed to improve this approach. Despite centuries of ice cream production, the engineer-

Similarly, Hernandez-Parra et al. (6) have attempted to ing principles have not yet been fully described, particularly

couple CFD modeling with a capillary number approach to those of the dynamic freezing step. The current drive for

predict maximum air bubble size. frozen dessert manufacturers to use fewer ingredients and

In the future, multiphase CFD modeling might be provide more health-conscious options has revealed this

coupled with population balance models for both ice crystal lack of understanding. Some new products have suffered

and air cell size distributions to predict the product output. from commercial issues, such as collapse of high overrun

Such a model could enable simulations that inform freezer products on the shelf. As a result, improving our under-

designs and predict operating conditions that produce standing of the science that underlies the production of ice

desirable ice cream structures. The current market, which cream and frozen desserts should be a high priority. CEP

is flooded with new styles of frozen desserts (high air, high

protein, low fat, low sugar, etc.) with little to no scientific

underpinning, could benefit from this type of model. Literature Cited

1. Windhab, E. J., and S. Bolliger, “Low Temperature Ice Cream

Shelf life stability Extrusion Technology and Related Ice Cream Properties,”

European Dairy Magazine, 10, pp. 24–28 (1998).

Coarsening of ice crystals during storage is one of the

2. Wildmoser, H., “Impact of Low Temperature Extrusion Process-

main issues for frozen foods. Coarsening occurs due to the ing on Disperse Microstructure in Ice Cream Systems,” PhD

Gibbs-Thomson effect, in which there is a slight difference Dissertation presented at the Swiss Federal Institute of Technol-

in melting point between small crystals and large crystals ogy (ETH), Zurich, Switzerland (2004).

(7, 8). True Ostwald ripening, however, is quite rare in fro- 3. Norton, T., and D. Sun, “CFD: An Innovative and Effective

Design Tool for the Food Industry,” Aguilera et al., eds., Food

zen desserts, mostly because other mechanisms of recrystal-

Engineering Interfaces, Springer, New York, NY, pp. 45–68

lization occur more rapidly (8, 9). The close proximity of (2011).

ice crystals in frozen desserts encourages rapid accretion, in 4. Hernández-Parra, O. D., et al., “Modeling Flow and Heat

which two adjacent crystals quickly form a neck and then Transfer in a Scraped Surface Heat Exchanger During the Pro-

gradually merge into one large spherical ice structure. duction of Sorbet,” Journal of Food Engineering, 221, pp. 54–69

(2018).

Furthermore, storage conditions for frozen desserts

5. Arellano, M., et al., “Coupling Population Balance and Resi-

are not ideal. Temperatures fluctuate readily and rapidly, dence Time Distribution for the Ice Crystallization Modeling

which causes melting and refreezing as the ice attempts to in a Scraped Surface Heat Exchanger,” Chemical Engineering

maintain a phase equilibrium. Over time, smaller crystals Science, 102, pp. 502–513 (2013).

melt while larger ones grow. In general, this is the main 6. Hernández-Parra, O. D., et al., “Effect of Process Parameters

on Ice Crystals and Air Bubbles Size Distributions of Sorbets

mechanism for recrystallization since all freezers, especially in a Scraped Surface Heat Exchanger,” International Journal of

frost-free freezers, undergo significant thermal cycling. Refrigeration, 92, pp. 225–234 (2018).

Figure 8 illustrates the changes ice crystals undergo during 7. Mullin, J. W., “Crystallization, 4th Ed.,” Butterworth-

three weeks of accelerated storage. Heinemann, Oxford, U.K. (2001).

Although much work has been done to quantify the 8. Goff, H. D., and R. W. Hartel, “Ice Cream, 7th Ed.,” Springer,

New York, NY (2013).

rates of recrystallization and the general mechanisms

9. Hartel, R. W., “Mechanisms and Kinetics of Recrystallization

are well known, a comprehensive thermodynamic treat- in Ice Cream,” The Properties of Water in Foods: ISOPOW 6,

ment of frozen desserts has not yet been done. Recently, D. S. Reid, ed., Blackie, London, U.K., pp. 287–319 (1998).

van Westen and Groot (10) applied fundamental thermo 10. van Westen, T., and R. D. Groot, “Predicting the Kinetics of Ice

dynamic principles to model Ostwald ripening in frozen Recrystallization in Aqueous Sugar Solutions,” Crystal Growth

systems to predict ice crystal coarsening with time. Their & Design, 18, pp. 2405–2416 (2018).

results predicted experimental data reasonably well,

although some adjustment of parameters was necessary.

RICHARD HARTEL, PhD, is a professor of food

The model was then used to simulate the evolution of aver- engineering in the Food Science Dept. at

age ice crystal size with time. As models like these become the Univ. of Wisconsin-Madison. For over

30 years, he has focused his studies on ice

increasingly accurate, they will be able to predict shelf life cream and frozen desserts. He has authored

for a range of storage conditions, which could be tailored many publications, including coauthor-

ing Ice Cream, 7th ed. Hartel earned a BA

to extend shelf life. Such models could be expanded to in physics from the State Univ. College of

account for the effects of various additive ingredients, par- New York and MS and PhD in agricultural

engineering from Colorado State Univ.

ticularly stabilizers, that are added to ice cream to inhibit

recrystallization.

CEP May 2019 www.aiche.org/cep 43

Copyright © 2019 American Institute of Chemical Engineers (AIChE).

Not for distribution without prior written permission.

You might also like

- The Science of Ice CreamDocument3 pagesThe Science of Ice CreamFredericoAyestaran100% (1)

- Session 2 - Introduction To Ice-CreamDocument6 pagesSession 2 - Introduction To Ice-CreamApoorv_Agarwal90No ratings yet

- Mini Ice Plant ReportDocument40 pagesMini Ice Plant ReportCherry Obias100% (1)

- Butter ScienceDocument7 pagesButter ScienceAlisonNo ratings yet

- Vacuum DistillationDocument6 pagesVacuum DistillationnuclearengineerNo ratings yet

- Ice Morphology: Fundamentals and Technological Applications in FoodsDocument19 pagesIce Morphology: Fundamentals and Technological Applications in FoodsIsra RoblesNo ratings yet

- Mechanisms of Ice Crystallization IcecreamDocument10 pagesMechanisms of Ice Crystallization IcecreamJesusemiliozerpaNo ratings yet

- Mechanisms of Ice Crystallization in Ice Cream Production: K.L.K. Cook and R.W. HartelDocument10 pagesMechanisms of Ice Crystallization in Ice Cream Production: K.L.K. Cook and R.W. HartelMy Pham Thi DiemNo ratings yet

- Bridging The Cost BarrierDocument5 pagesBridging The Cost Barriercklcat1437No ratings yet

- Ice-Cream Processing: Amanda Bruno and Thulasi ThirugnanamDocument28 pagesIce-Cream Processing: Amanda Bruno and Thulasi ThirugnanamJonathan OnoniwuNo ratings yet

- Cristalizacion EnfriamientoDocument9 pagesCristalizacion EnfriamientoHector Joel Chaname RodriguezNo ratings yet

- LiofilizaciónDocument7 pagesLiofilizaciónEr'el ARNo ratings yet

- 4 Stages Complete Drying Process - Primarily From Freeze Drying Process-20190416023134-1 PDFDocument2 pages4 Stages Complete Drying Process - Primarily From Freeze Drying Process-20190416023134-1 PDFAzzwa ZubairiNo ratings yet

- Freeze Concentration 1Document13 pagesFreeze Concentration 1A PNo ratings yet

- Pawelec2015 Article AlteringCrystalGrowthAndAnnealDocument7 pagesPawelec2015 Article AlteringCrystalGrowthAndAnnealnatalia devia quinteroNo ratings yet

- 332 13 059 US Food Freezing Equipment Quality Safety Efficiency Cold FactsDocument4 pages332 13 059 US Food Freezing Equipment Quality Safety Efficiency Cold FactsDaniel NedelcuNo ratings yet

- Ijfs 2326 3350 11 502Document12 pagesIjfs 2326 3350 11 502ksangee2005No ratings yet

- Ice Cream StructureDocument11 pagesIce Cream StructureHon Le VanNo ratings yet

- A0044forehearttermalcondition DesbloqueadoDocument5 pagesA0044forehearttermalcondition DesbloqueadoReinaldo Nicolas PalacioNo ratings yet

- General Principles of Freeze Drying (The Lyophilization Process)Document9 pagesGeneral Principles of Freeze Drying (The Lyophilization Process)Shefali PawarNo ratings yet

- 20223-Share Pembukaan Refri THPDocument56 pages20223-Share Pembukaan Refri THPSyofiah FikriyahNo ratings yet

- Science of Ice CreamDocument5 pagesScience of Ice Creamacad1993No ratings yet

- Ministory Of: EducationDocument20 pagesMinistory Of: EducationThaungShanHtet PalatarNo ratings yet

- Thaung Shan HtetDocument19 pagesThaung Shan HtetThaungShanHtet PalatarNo ratings yet

- Ice Slurry Applications PDFDocument15 pagesIce Slurry Applications PDFmattiturboNo ratings yet

- DTC C35C UkDocument34 pagesDTC C35C UkJUAN ALBERTO HIDDALGONo ratings yet

- M14 - Jurnal Prof KauffeldDocument15 pagesM14 - Jurnal Prof KauffeldMark SandyNo ratings yet

- Ice Cream Formation and Stabilization A ReviewDocument17 pagesIce Cream Formation and Stabilization A Reviewhergofra100% (1)

- Freeze-Drying: The Basic Process: Ã 2016 Elsevier Ltd. All Rights ReservedDocument6 pagesFreeze-Drying: The Basic Process: Ã 2016 Elsevier Ltd. All Rights ReservedYashinta PutriNo ratings yet

- Informe 2Document3 pagesInforme 2Hector VillalobosNo ratings yet

- Bab 7Document33 pagesBab 7Yustin TriayuNo ratings yet

- Din DinDocument20 pagesDin DinThaungShanHtet PalatarNo ratings yet

- Din DinDocument20 pagesDin DinThaungShanHtet PalatarNo ratings yet

- Eastern Visayas State University Tacloban CityDocument7 pagesEastern Visayas State University Tacloban CityRonaldNo ratings yet

- A Clearer View of CrystallizersDocument5 pagesA Clearer View of Crystallizersfawmer61No ratings yet

- Clearer View of CrystilizerDocument5 pagesClearer View of CrystilizerChem.EnggNo ratings yet

- Ice Focus Issue 1Document12 pagesIce Focus Issue 1mariodalNo ratings yet

- Icemaking PlantDocument10 pagesIcemaking PlantAshokNo ratings yet

- Glass Ceramic: Fatima Shaker Supervision Dr. Elham AlaliDocument12 pagesGlass Ceramic: Fatima Shaker Supervision Dr. Elham Alaliمحمد المعموريNo ratings yet

- Ice CreamDocument6 pagesIce CreamAndres Tellez RochaNo ratings yet

- Extending Ice Longevity With SaltDocument7 pagesExtending Ice Longevity With Saltmuthukumaran TanujNo ratings yet

- Labconco Guide To Freeze DryingDocument12 pagesLabconco Guide To Freeze DryingHector Pacheco AhumadaNo ratings yet

- 34 1 105 OcrDocument6 pages34 1 105 OcrPhung Vo Hung PhatNo ratings yet

- Frrezing and DryinDocument3 pagesFrrezing and DryinFaisal AwanNo ratings yet

- Ice BlastingDocument22 pagesIce BlastingAbigith Baby100% (1)

- En Cryogenic Tunnel Freezers Do More Then FreezeDocument4 pagesEn Cryogenic Tunnel Freezers Do More Then Freezesamekh80No ratings yet

- Corso Di Laurea in Chimica e Tecnologia Farmaceutiche Fabbricazione Industriale Dei Medicinali - 8 CfuDocument120 pagesCorso Di Laurea in Chimica e Tecnologia Farmaceutiche Fabbricazione Industriale Dei Medicinali - 8 Cfuఝాన్సీ పుత్ర సతీష్No ratings yet

- Curso de Fabricadores de Hielo de NeveraDocument42 pagesCurso de Fabricadores de Hielo de NeveraJOSE CAMPOSNo ratings yet

- Freeze Concentration of Citrus and Other Fruit Juices: High Product Quality As A Result Of: ApplicationDocument2 pagesFreeze Concentration of Citrus and Other Fruit Juices: High Product Quality As A Result Of: ApplicationFabio Bottari100% (1)

- Clarification of Frost Damage Mechanism Based On Meso Scale Deformation and Temperature and Moisture ChangeDocument16 pagesClarification of Frost Damage Mechanism Based On Meso Scale Deformation and Temperature and Moisture ChangeLuthfian DaryonoNo ratings yet

- Buyers Guide Cooling Options For Rotary EvaporatorsDocument8 pagesBuyers Guide Cooling Options For Rotary EvaporatorsAla AzeezNo ratings yet

- Mini Ice Plant ReportDocument40 pagesMini Ice Plant ReportLeyzer MalumayNo ratings yet

- Growth Control of Ice Crystals by Poly (Vinyl Alcohol) and Antifreeze Protein in Ice SlurriesDocument10 pagesGrowth Control of Ice Crystals by Poly (Vinyl Alcohol) and Antifreeze Protein in Ice SlurriesShivam KhannaNo ratings yet

- CrystallizationDocument6 pagesCrystallizationbala saiNo ratings yet

- Thesis Pumpless Ice Thermal StorageDocument55 pagesThesis Pumpless Ice Thermal StorageMoiz TinwalaNo ratings yet

- 5 Common Misconceptions Lyo1Document3 pages5 Common Misconceptions Lyo1Apar DholakiaNo ratings yet

- Tran 2007Document10 pagesTran 2007Ngọc LànhNo ratings yet

- Lyophilization: Heat and Mass TransferDocument5 pagesLyophilization: Heat and Mass Transfertwintwin91No ratings yet

- Freeze Drying Guide Vol2Document49 pagesFreeze Drying Guide Vol2Keval PatelNo ratings yet

- Ice CreamDocument10 pagesIce Creamarchusaran7313No ratings yet

- Chem 120.1 Laboratory Report No. 7Document4 pagesChem 120.1 Laboratory Report No. 7JM BoylesNo ratings yet

- PX LW 75 - AkzoNDocument4 pagesPX LW 75 - AkzoNelbadelcarmensegoviaNo ratings yet

- United States Patent (191: Schweier Et A)Document5 pagesUnited States Patent (191: Schweier Et A)Maya RamlahNo ratings yet

- Adsorption of Oxalic AcidDocument2 pagesAdsorption of Oxalic AcidDebadyuti SarkarNo ratings yet

- Langmuir Adsorption Isotherm PracticalDocument3 pagesLangmuir Adsorption Isotherm PracticalUsman GhaniNo ratings yet

- Process Heat TransferDocument327 pagesProcess Heat TransferMartin ZaballaNo ratings yet

- The Dense Plasma Focus: A Versatile Dense Pinch For Diverse ApplicationsDocument33 pagesThe Dense Plasma Focus: A Versatile Dense Pinch For Diverse ApplicationsGuilherme BiancarelliNo ratings yet

- Adenine, Adenosine, Ribose and 5'-Amp Adsorption To AllophaneDocument7 pagesAdenine, Adenosine, Ribose and 5'-Amp Adsorption To AllophaneAngelita DelgadoNo ratings yet

- 5 Internal Energy and First Law of ThermodynamicsDocument7 pages5 Internal Energy and First Law of Thermodynamicsstuart3390No ratings yet

- 2.2 Chemical EquationsDocument8 pages2.2 Chemical EquationsPBL MOMOSNo ratings yet

- Filtro SecadorDocument10 pagesFiltro SecadorGuilherme GomesNo ratings yet

- Dynamic Modelling of Margarine Manufacturing: Peter Bongers, Cristhian Almeida, Hans HooglandDocument5 pagesDynamic Modelling of Margarine Manufacturing: Peter Bongers, Cristhian Almeida, Hans HooglandNicolas BenavidezNo ratings yet

- Tide Load InstrDocument13 pagesTide Load InstrLilo17xiNo ratings yet

- Raman EffectDocument20 pagesRaman EffectUtkarshPatelNo ratings yet

- UOP Extending Molecular Sieve Life Tech PaperDocument7 pagesUOP Extending Molecular Sieve Life Tech PaperOmar EzzatNo ratings yet

- 2 Ig (Q&a)Document17 pages2 Ig (Q&a)EaintNo ratings yet

- DKK1413 Chapter 04-2Document31 pagesDKK1413 Chapter 04-2Salini ShaNo ratings yet

- Ecosystems ThermodynamicsDocument27 pagesEcosystems Thermodynamicsapi-326805662No ratings yet

- Physics 08-02 Coulomb's LawDocument2 pagesPhysics 08-02 Coulomb's LawGene CagzNo ratings yet

- Assignment 2Document2 pagesAssignment 2Ryan CarrollNo ratings yet

- Exhaust Base Vam Tonnage CalculationDocument9 pagesExhaust Base Vam Tonnage CalculationMagical RiyaNo ratings yet

- Analysis of Intensive Evaporation and Condensation: 4 K 59 X, Y, Z, P? M II, PS? PITDocument14 pagesAnalysis of Intensive Evaporation and Condensation: 4 K 59 X, Y, Z, P? M II, PS? PITSamuel HartonoNo ratings yet

- Experiment 4Document8 pagesExperiment 4Maelyn Nicole Tan RominNo ratings yet

- Canute - Hydrostatics and Hydraulic CalculationsDocument4 pagesCanute - Hydrostatics and Hydraulic CalculationsEdgardo EscobarNo ratings yet

- 8462 1H MS Chemistry Specimen (Set 2) v1.1Document21 pages8462 1H MS Chemistry Specimen (Set 2) v1.1humbee0404No ratings yet

- The Building Blocks of Matter - AtomsDocument29 pagesThe Building Blocks of Matter - AtomsROSHAN_25No ratings yet

- Large Improvement of The Lower Detection Limit of Ion-Selective Polymer Membrane ElectrodesDocument2 pagesLarge Improvement of The Lower Detection Limit of Ion-Selective Polymer Membrane ElectrodesSahidahIrawanNo ratings yet

- Izzah 1Document9 pagesIzzah 1Nur Ilham ArifuddinNo ratings yet