Professional Documents

Culture Documents

Steel Member Design

Uploaded by

Supun Aravinda Jayawardhane0 ratings0% found this document useful (0 votes)

14 views2 pagesOriginal Title

Steel member design.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pagesSteel Member Design

Uploaded by

Supun Aravinda JayawardhaneCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

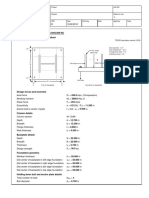

STEEL MEMBER DESIGN (AS4100)

In accordance with AS4100-1998 incorporating Amendment No.1 2012

TEDDS calculation version 3.0.09

Section details

Section type; 89x89x5 SHS (BHP 1999)

Steel grade; C350

From table 2.1: Strengths of steels

Thickness of material; t = 5.0 mm

Yield stress; fy = 350 N/mm2

Tensile strength; fu = 430 N/mm2

Modulus of elasticity; E = 200000 N/mm2

Capacity factors () for strength limit states - Table 3.4

Capacity factor; = 0.90

Lateral restraint

Distance between major axis restraints; Lx = 3000 mm

Distance between minor axis restraints; Ly = 3000 mm

Effective length factors

Effective length factor in major axis; kex= 1.000

Effective length factor in minor axis; key = 1.000

Section slenderness - Section 5.2.2

Flange slenderness; ef = (b - 2 t) / t [fy / 250 N/mm2] = 18.7

Flange yield slenderness limit - Table 5.2; eyf = 40; ef / eyf = 0.467

Web slenderness; ew = (d - 2 t) / (t) [fy / 250 N/mm2] = 18.7

Web yield slenderness limit - Table 5.2; eyw = 115; ew / eyw = 0.163

Section slenderness; s = 18.7

Section plasticity limit - Table 5.2; sp = 30

Yield slenderness limit - Table 5.2; sy = 40

s < sp - Section is compact

Members subject to axial compression - Section 6

Design compression force; N = 282 kN

Cross-sectional area of holes; Ah = 0 mm2

Net area of cross-section; An = Ag - Ah = 1594 mm2

Nominal section capacity - Section 6.2

Flange yield slenderness limit - Table 6.2.4; eyf = 40

Effective width of flanges - cl.6.2.4; bef = min(eyf / ef, 1) (b - 2 t) = 79.0 mm

Web yield slenderness limit - Table 6.2.4; eyw = 40

Effective width of web - cl.6.2.4; bew = min(eyw / ew, 1) (d - 2 t) = 79.0 mm

Effective area of section; Ae = Ag - 2 [(b - 2 t) - bef + (d - 2 t) - bew] t = 1594

mm2

Form factor - cl.6.2.2; kf = Ae / Ag = 1.000

Nominal section capacity in compression - cl.6.2.1; Ns = kf An fy = 557.9 kN

Design section capacity in compression; Nsc = Ns = 502.1 kN

Nominal member capacity in major (x-x) axis - Section 6.3

Effective length for buckling; lex = Lx kex = 3000 mm

Modified compression member slenderness; nx = lex / rx [kf] [fy / 250 N/mm2] = 105.112

Compression member factor; ax = 2100 (nx - 13.5) / (nx2 - 15.3 nx + 2050) = 16.743

Member section constant - Table 6.3.3(1); b = -0.5

Slenderness ratio; x = nx + ax b = 96.741

Compression member imperfection factor; x = 0.00326 (x - 13.5) = 0.271

Compression member factor; x = ((x / 90)2 + 1 + x) / (2 (x / 90)2) = 1.050

Member slenderness reduction factor; cx = x [1 - [1 - (90 / (x x))2]] = 0.563

Nominal member capacity in compression - cl.6.3.3; Ncx = cx Ns = 314.1 kN

Design member capacity in compression; Ncxc = Ncx = 282.7 kN

Nominal member capacity in minor (y-y) axis - Section 6.3

Effective length for buckling; ley = Ly key = 3000 mm

Modified compression member slenderness; ny = ley / ry [kf] [fy / 250 N/mm2] = 105.112

Compression member factor; ay = 2100 (ny - 13.5) / (ny2 - 15.3 ny + 2050) = 16.743

Member section constant - Table 6.3.3(1); b = -0.5

Slenderness ratio; y = ny + ay b = 96.741

Compression member imperfection factor; y = 0.00326 (y - 13.5) = 0.271

Compression member factor; y = ((y / 90)2 + 1 + y) / (2 (y / 90)2) = 1.050

Member slenderness reduction factor; cy = y [1 - [1 - (90 / (y y))2]] = 0.563

Nominal member capacity in compression - cl.6.3.3; Ncy = cy Ns = 314.1 kN

Design member capacity in compression; Ncyc = Ncy = 282.7 kN

PASS - Design capacity in compression exceeds design compression force

You might also like

- Steel Member Analysis & Design - Sample Calculation (As 4100)Document9 pagesSteel Member Analysis & Design - Sample Calculation (As 4100)Tiam MarapeNo ratings yet

- Section Is Class 2 CompactDocument2 pagesSection Is Class 2 CompactAmmar AzmiNo ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- 111Document3 pages111郑 凯伦 Tey Kai LoonNo ratings yet

- Design of Builtup SectionDocument4 pagesDesign of Builtup SectiondsanandaNo ratings yet

- EN WalerDocument8 pagesEN WalervsnsfbNo ratings yet

- Steel Member Design - Sample Calculation (AS4100)Document5 pagesSteel Member Design - Sample Calculation (AS4100)Tiam MarapeNo ratings yet

- EC2 Beam Section DesignDocument3 pagesEC2 Beam Section Designikanyu79100% (1)

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDDocument4 pagesDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghNo ratings yet

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- Rafter To Column Top Connection Design Given DataDocument10 pagesRafter To Column Top Connection Design Given DataSafi Zabihullah SafiNo ratings yet

- T3701a DFEDocument10 pagesT3701a DFEAnca SimaNo ratings yet

- EC2 Continuous Beam DesignDocument14 pagesEC2 Continuous Beam Designikanyu79No ratings yet

- EC2 Beam DesignDocument4 pagesEC2 Beam Designikanyu79No ratings yet

- Tedds RC Beam Design 2Document3 pagesTedds RC Beam Design 2Hor Ka WaiNo ratings yet

- 1200x800 Column DesignDocument4 pages1200x800 Column DesignrameshkaaNo ratings yet

- Design Compressive Stength For Channel With or Without Plate (As Per Is:800 2007)Document2 pagesDesign Compressive Stength For Channel With or Without Plate (As Per Is:800 2007)K SrikanthNo ratings yet

- Manual Beam DesignDocument14 pagesManual Beam DesignRonald Kaaku50% (2)

- Pile Cap Design - ColumnsDocument6 pagesPile Cap Design - ColumnsSadatcharaMoorthi N100% (1)

- RC Column Design (ACI318-05)Document5 pagesRC Column Design (ACI318-05)Rizwan MirzaNo ratings yet

- 5.15 Swing Barrier v.1.0Document190 pages5.15 Swing Barrier v.1.0rfvz6sNo ratings yet

- RC Rectangular Column DesignDocument12 pagesRC Rectangular Column DesignSachin AgarwalNo ratings yet

- Case Study ppt11Document25 pagesCase Study ppt11WHATS APP STATUSNo ratings yet

- Plan de Détails 2: Assemblage Poteau HEA 280-Traverse 360Document9 pagesPlan de Détails 2: Assemblage Poteau HEA 280-Traverse 360FrancklinMeunierM'ondoNo ratings yet

- End-Plate - Beam To Beam Connection Design 3Document8 pagesEnd-Plate - Beam To Beam Connection Design 3gianniorlatiNo ratings yet

- Mechanical Calculation - Inspection Port NeckDocument18 pagesMechanical Calculation - Inspection Port Neckfaizal rizkiNo ratings yet

- Pile Cap Design - ColumnsDocument6 pagesPile Cap Design - Columnsntah8450% (2)

- Pile Cap Design - ColumnsDocument6 pagesPile Cap Design - Columnssssmou100% (1)

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- Column Base Plate DesignDocument5 pagesColumn Base Plate Design_jessecaNo ratings yet

- Column DesignDocument68 pagesColumn DesignPiyush Tiwari100% (1)

- Section Properties and CapacitiesDocument19 pagesSection Properties and CapacitiesRufus ChengNo ratings yet

- Reinforced Concrete Section PropertiesDocument10 pagesReinforced Concrete Section PropertiesJose MLNo ratings yet

- Built Up Column - ChannelDocument18 pagesBuilt Up Column - ChannelSambhav PoddarNo ratings yet

- Connection No.: 66: Load Ver. Brace L120X120X10 AxialDocument5 pagesConnection No.: 66: Load Ver. Brace L120X120X10 Axialrts123No ratings yet

- C1 - DeSIGN TEMPLATE - Shear ConnectionDocument3 pagesC1 - DeSIGN TEMPLATE - Shear ConnectionkalpanaadhiNo ratings yet

- Task 2.2Document15 pagesTask 2.2Mordecai de ValoisNo ratings yet

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- AISC Design ChecksDocument22 pagesAISC Design ChecksYogeshUndeNo ratings yet

- RC Stair Design 25Document6 pagesRC Stair Design 25Abel MulugetaNo ratings yet

- Towerwind Analysis - Anchoragebolt - Base PlateDocument14 pagesTowerwind Analysis - Anchoragebolt - Base PlateJoy lauriaNo ratings yet

- 6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3Document8 pages6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3abdulNo ratings yet

- Slab Full Report (Span) - GBDocument182 pagesSlab Full Report (Span) - GBbce20090001No ratings yet

- Kathmandu University Design of Column Section Designed By:: Er. Sudip ShresthaDocument9 pagesKathmandu University Design of Column Section Designed By:: Er. Sudip ShresthaSudip ShresthaNo ratings yet

- Design of Beam-Aci-11-01-05Document23 pagesDesign of Beam-Aci-11-01-05aomareltayeb100% (1)

- Channel Design AISCDocument9 pagesChannel Design AISCRajveer SinghNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Structural Calculations: PER IBC 2018, ASCE 7-16, CBC 2019, NDS 2018, AISC 360-16, ACI 318-14 TMS 402-16 (Former ACI 530)Document15 pagesStructural Calculations: PER IBC 2018, ASCE 7-16, CBC 2019, NDS 2018, AISC 360-16, ACI 318-14 TMS 402-16 (Former ACI 530)Supun Aravinda JayawardhaneNo ratings yet

- Structural Calculations: PER IBC 2018, ASCE 7-16, CBC 2019, NDS 2018, AISC 360-16, ACI 318-14 TMS 402-16 (Former ACI 530)Document8 pagesStructural Calculations: PER IBC 2018, ASCE 7-16, CBC 2019, NDS 2018, AISC 360-16, ACI 318-14 TMS 402-16 (Former ACI 530)Supun Aravinda JayawardhaneNo ratings yet

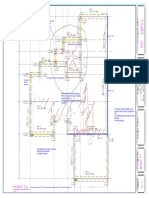

- Foundation Plan Draft 2Document1 pageFoundation Plan Draft 2Supun Aravinda JayawardhaneNo ratings yet

- Wall Footing: Code ReferencesDocument4 pagesWall Footing: Code ReferencesSupun Aravinda JayawardhaneNo ratings yet

- Fiverr Fast Cash PDFDocument27 pagesFiverr Fast Cash PDFSupun Aravinda JayawardhaneNo ratings yet

- Structural Assessment of Roof Trusses: 145 South Main, Mendon, UtahDocument23 pagesStructural Assessment of Roof Trusses: 145 South Main, Mendon, UtahSupun Aravinda JayawardhaneNo ratings yet

- Proposed Capitol Twinpeaks Condominium Development, Colombo 2Document11 pagesProposed Capitol Twinpeaks Condominium Development, Colombo 2Supun Aravinda JayawardhaneNo ratings yet

- Draft Report PDFDocument10 pagesDraft Report PDFSupun Aravinda JayawardhaneNo ratings yet

- Final Design ReportDocument95 pagesFinal Design ReportSupun Aravinda JayawardhaneNo ratings yet

- RET. WALL OriginalDocument15 pagesRET. WALL OriginalSupun Aravinda JayawardhaneNo ratings yet

- 200x200x9 Steel Beam AnalysisDocument5 pages200x200x9 Steel Beam AnalysisSupun Aravinda JayawardhaneNo ratings yet

- RET. WALL OriginalDocument54 pagesRET. WALL OriginalSupun Aravinda JayawardhaneNo ratings yet

- Tedds Calculation Version 1.0.04: I I I 1 I I 2Document2 pagesTedds Calculation Version 1.0.04: I I I 1 I I 2Supun Aravinda JayawardhaneNo ratings yet

- 200x200x9 Steel Beam AnalysisDocument5 pages200x200x9 Steel Beam AnalysisSupun Aravinda JayawardhaneNo ratings yet

- Foundation Check DraftDocument13 pagesFoundation Check DraftSupun Aravinda JayawardhaneNo ratings yet

- Structural Assessment of Transportation Facility: North Kitsap School DistrictDocument8 pagesStructural Assessment of Transportation Facility: North Kitsap School DistrictSupun Aravinda JayawardhaneNo ratings yet

- Free Manual Solution PDF PDFDocument19 pagesFree Manual Solution PDF PDFSon Le Minh50% (2)

- Top Gun I-ARC 130Document9 pagesTop Gun I-ARC 130Tom PleysierNo ratings yet

- ODAA Support LetterDocument2 pagesODAA Support LetterStatesman JournalNo ratings yet

- Technical FeasibilityDocument5 pagesTechnical FeasibilityMelody ArgenteraNo ratings yet

- Instrument Transformer Fuses Types WBP and BRT: Catalogue B12/06/01/EDocument8 pagesInstrument Transformer Fuses Types WBP and BRT: Catalogue B12/06/01/EivanramljakNo ratings yet

- Carrier SelectionDocument13 pagesCarrier SelectionRanesh SinglaNo ratings yet

- LiliaGutnik Resume 2013Document2 pagesLiliaGutnik Resume 2013Lilia GutnikNo ratings yet

- Specification For Piping MaterialDocument9 pagesSpecification For Piping MaterialAgus SupriadiNo ratings yet

- Voice Recognition Using MatlabDocument10 pagesVoice Recognition Using MatlabSneha Muralidharan100% (1)

- FB131Document7 pagesFB131Hoangvinh DuongNo ratings yet

- Layanan Dan Pelayanan Perpustakaan: Menjawab Tantangan Era Teknologi InformasiDocument6 pagesLayanan Dan Pelayanan Perpustakaan: Menjawab Tantangan Era Teknologi InformasiLailatur RahmiNo ratings yet

- Schneider ElectricCahier Technique No. 199Document36 pagesSchneider ElectricCahier Technique No. 199Alda EnglandNo ratings yet

- Cmus Cheat SheetDocument1 pageCmus Cheat Sheetvoll macuserNo ratings yet

- Water Filtration System - Method StatementDocument7 pagesWater Filtration System - Method Statementsunil_v575% (4)

- Jeppesen Charts LegendsDocument34 pagesJeppesen Charts LegendsFatih OguzNo ratings yet

- Instalación Zapata Case 9010Document5 pagesInstalación Zapata Case 9010Miguel Angel Herrera MartinezNo ratings yet

- DJJ10022 Report (Sir Amri)Document6 pagesDJJ10022 Report (Sir Amri)Muhd Imran Kasyidi OmarNo ratings yet

- Lab 31Document8 pagesLab 31net fliNo ratings yet

- Sony Walkman GuideDocument39 pagesSony Walkman Guideapi-3797085No ratings yet

- Alternative Sources of EnergyDocument6 pagesAlternative Sources of EnergykageNo ratings yet

- Wireless Local Loop: A Seminar Report OnDocument12 pagesWireless Local Loop: A Seminar Report OnYesh DamaniaNo ratings yet

- Mycom TecnicaDocument21 pagesMycom TecnicaTeuku Mukhriza100% (1)

- Alien Legacy-Manual PDFDocument93 pagesAlien Legacy-Manual PDFMark BallingerNo ratings yet

- PipeDocument30 pagesPipepudumai100% (1)

- Partner Colibri II O2010 Euenapen 545196762Document13 pagesPartner Colibri II O2010 Euenapen 545196762Popescu OvidiuNo ratings yet

- R05411101 ImageprocessingandpatternrecognitionDocument4 pagesR05411101 ImageprocessingandpatternrecognitionSamiullah MohammedNo ratings yet

- How To Start Building With CobDocument16 pagesHow To Start Building With CobRoy Huntley100% (3)

- Zener DiodeDocument3 pagesZener DiodeAde MurtalaNo ratings yet

- Fisher™ FIELDVUE™ DVC6200 SIS Digital Valve ControllerDocument116 pagesFisher™ FIELDVUE™ DVC6200 SIS Digital Valve ControllerMohsen HeidariNo ratings yet

- Example Pump CalcsDocument4 pagesExample Pump CalcsSourav ChattopadhyayNo ratings yet