Professional Documents

Culture Documents

Optimize SEO with Nestle Waters Fire Pump Relocation Project

Uploaded by

Ahmed Ayman HassaneenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimize SEO with Nestle Waters Fire Pump Relocation Project

Uploaded by

Ahmed Ayman HassaneenCopyright:

Available Formats

Nestle Waters RE-LOCATING FIRE PUMPS

Project

RE-LOCATION OF FIRE PUMP ASSEMBLY

NESTLE WATERS, EGYPT ABU-RAWASH

WAREHOUSE ABU-RAWASH, EGYPT

BILL OF QUANTITIES

FOR CIVIL & MECHANICAL WORKS

Prepared by

GRAPHCO ENGINEERING DESIGN

RV-00

MAY 2019

Price in L.E.

Item Description Unit Qty.

Unit Total

GRAPHCO Engineering Design Page-1-

Nestle Waters RE-LOCATING FIRE PUMPS

1 Prepare the underground tank compartment for acceptance of existing fire pump system. It will be made ready through the following:

Empty water from two compartments and dispose of site to authorized dump location. This will

1-a be done by tankers equipped with pumps for sucking water from underground tanks. Tank two No. 1

compartment capacity 300m3.

Close existing 3 openings in concrete wall between two compartments. This will be done by

casting a reinforced concrete wall in the other compartment. New wall height shall extend 40cm

above the openings and width shall be such that it extends by 50cm on either side of the

openings. Thickness of wall is 25cm with double reinforcement mesh of 5phi12/m’. Steel

dowels of phi12 (every 30cm) shall be placed to fix new wall to tank floor and wall. This in

2-a addition to closure of the three openings by a special Sika fast setting grout (or equivalent). No. 1

Opening closure has to be tested by filling one compartment with water for 1-2days and fixing

any leaks that will appear. The item includes the water proofing of the new wall with a strong

water proof from sika or equivalent.

Close existing 2 openings in ceiling of pump room compartment using galvanized steel wavy

3-a wire mesh. The mesh shall be placed over a galvanized steel frame fixed to the existing opening. No. 1

Frame shall be set so that it protects pedestrian from topping over of falling in tank.

Supply and place reinforced concrete base for pumps (fire, diesel and jockey) in the new room,

with mixing ratios of 0.4 cubic meter sand, 0.8 cubic meter gravel, and at least 250 kg ordinary

Portland cement (fcu=250kg/cm2). The footings shall be placed in correct locations similar to

4-a design drawings and according to final approved shop drawings of pump assembly layout. No. 1

Approximate dimensions of footings shall be 6.2m in length, 1m in width and 0.4m in thickness.

Upper double mesh of 6phi12/m shall be used in new bases.

Supply and place 40x40x1.2cm white ceramic tiles for flooring of the new pump room. The tiles

shall be laid and fixed to the ground using cement mortar. Approximate area is 55m2. The item

5-a includes placement of imported clean coarse sand (35cm) and compaction. Tiles are Cleopatra No. 1

or Rocca or equivalent.

Item Description Unit Qty. Price in L.E.

GRAPHCO Engineering Design Page-2-

Nestle Waters RE-LOCATING FIRE PUMPS

Unit Total

Supply and place drainage trench on one side of the new pump room beside the dividing existing

6-a wall. The item includes supply and placement of 10inch PVC half pipe fixed in a box of plain No. 1

concrete. Approximate length of 6m.

Supply and place new drainage sump at the corner of the new pump room. Dimensions of sump

are 1mx1mx0.6m. Side walls are reinforced concrete walls, 20cm 5phi12. Inside of sump to be

7-a painted with water proofing coating. The item includes the supply of small submersible pump No. 1

5lit/s, 20m and connection of pump discharge pipe to nearest manhole.

Supply and place steel ladder for access of the new pump room. Steel is prim-prepared and

8-a painted with 3 coats of anti-rust paint and fixed to new pump room floor. No. 1

8-a-

Option Paint existing steel ladder with 3 coats of anti-rust paint. No. 1

Make new openings (two 8 inch openings for supply of water to header, one 6inch for test drain,

one 6inch for the drain line) in the reinforced concrete divider wall. The item includes using the

core machine for making openings at correct location –depending on the approved shop drawing

of the fire assembly. The item includes the placement of black steel 8inch and 6inch puddle

9-a No. 1

pieces in the opening and the proper sealing around it by specialized sealants from sika or

equivalent. Opening closure has to be tested by filling one compartment with water for 1-2days

and fixing any leaks that will appear with proper procedure.

Make new opening in concrete ceiling for muffler of diesel engine. This item includes using the

core machine for making openings at correct location –depending on the approved shop drawing

10-a of the fire assembly. The item includes proper sealing around muffler pipe by specialized No. 1

sealants from sika or equivalent. Opening closure has to be tested by water hose on the ceiling

and fixing any leaks that will appear with proper procedure.

Make new opening (one 8 inch openings for discharge of pump to fire loop). In ceiling of new

11-a pump room. This item includes using the core machine for making openings at correct location No. 1

–depending on the approved shop drawing of the fire assembly. The item includes proper

GRAPHCO Engineering Design Page-3-

Nestle Waters RE-LOCATING FIRE PUMPS

Price in L.E.

Item Description Unit Qty.

Unit Total

sealing around pipe by specialized sealants from sika or equivalent. Opening closure has to be

tested by water hose on the ceiling and fixing any leaks that will appear with proper procedure.

2 Relocate fire pump assembly from top of tank to new pump room, commission and test. The item includes the following:

Dismantle all fire assembly, including: pumps, valves, pipes, fittings etc. in a good condition so

that they can be used in new pump room. The item includes repairing rusted pipes or accessories

2-a by sand plastering, prime painting with one coat, and paint with red color plastic paint for three No. 1

coats. The item includes the re-location of all fire assembly to the new pump room using suitable

crane.

Assemble all piping, fittings, accessories, pumps, and valves in the new pump room according

to final approved shop drawings. The item includes all required piping and mechanical

connections for operation of new fire pump assembly. Any needed accessories (not available on

site or from old assembly) such as: piped header, piping, elbows, reducers etc. are included in

this item. Pipes are Russian or Ukraine made. Valves are English of US made. No Chinese

2-b components shall be approved. The item includes required steel supports for valves and bends No. 1

(prime and 3 coat painted); all required connections for the fuel tank and batteries to the diesel

engine. The item includes the supply and installation of the muffler hood from the diesel engine

to the atmosphere. The item includes all required fittings such as elbows and vortex shedding

pieces inside the water tank

Supply and connect all required electrical connections between pumps and their electric panel

2-c inside pump room. All cables are installed on galvanized cable tray fixed on the walls of the No. 1

new pump room.

Supply and connect main feeding cable to pump control panel in new pump room. All cables are

2-d installed on galvanized cable tray fixed on the walls of the new pump room. No. 1

2- Re-connect existing main feeding cable to pump control panel in new pump room. All cables are

doption installed on galvanized cable tray fixed on the walls of the new pump room. No. 1

GRAPHCO Engineering Design Page-4-

Nestle Waters RE-LOCATING FIRE PUMPS

2-e Supply, install and commission analogue pressure gauges on various locations of new No. 4

Price in L.E.

Item Description Unit Qty.

Unit Total

assembly.

Total

Proposed time for completion of project in days

GRAPHCO Engineering Design Page-5-

Nestle Waters RE-LOCATING FIRE PUMPS

1- Openings in tank wall:

2- Openings in tank ceiling:

GRAPHCO Engineering Design Page-6-

Nestle Waters RE-LOCATING FIRE PUMPS

3- Assembly of fire pumps:

GRAPHCO Engineering Design Page-7-

Nestle Waters RE-LOCATING FIRE PUMPS

GRAPHCO Engineering Design Page-8-

You might also like

- Innovative Through-Tubing Cement Packer PDFDocument2 pagesInnovative Through-Tubing Cement Packer PDFFe Maligi100% (1)

- T - Proc - Notices - Notices - 055 - K - Notice - Doc - 52645 - 617081917 PDFDocument5 pagesT - Proc - Notices - Notices - 055 - K - Notice - Doc - 52645 - 617081917 PDFMgciniwenkosi Masauso StoNo ratings yet

- A. Preliminaries: Optional OptionalDocument2 pagesA. Preliminaries: Optional OptionalHmNo ratings yet

- RE: Minor Civil Work and Architectural Alternation at VenetianDocument3 pagesRE: Minor Civil Work and Architectural Alternation at VenetianSheepdeeNo ratings yet

- URS Infrastructure and Utility NEW EC Line R0Document5 pagesURS Infrastructure and Utility NEW EC Line R0ICEDA HumNo ratings yet

- Special Specification 4582 Repair of Joints in Box CulvertDocument2 pagesSpecial Specification 4582 Repair of Joints in Box CulvertrenandNo ratings yet

- Actions For The Lighters Factory LPG InstallationDocument3 pagesActions For The Lighters Factory LPG InstallationKajubi EdrisNo ratings yet

- Comparitive of Waterproofing WorkDocument12 pagesComparitive of Waterproofing WorkReshik KannanNo ratings yet

- Hostel Block Renovation Cost Summary at NIPFPDocument16 pagesHostel Block Renovation Cost Summary at NIPFPrenjith p sNo ratings yet

- Constructing Mat SlabDocument4 pagesConstructing Mat SlabMrSamspartNo ratings yet

- SPE-184102-MS (2 Technology For Cementation)Document14 pagesSPE-184102-MS (2 Technology For Cementation)Randy SooknananNo ratings yet

- Dokumen - Tips - Hdpe Handbook Chapter 7 Underground InstallationDocument45 pagesDokumen - Tips - Hdpe Handbook Chapter 7 Underground Installationmai huy tânNo ratings yet

- Vibration-Free Rod-Baffle Design of TubeDocument5 pagesVibration-Free Rod-Baffle Design of Tubehwang2No ratings yet

- Section Four: Scope of Work, Underground Steam Line Repair (Revised) Buildings 2-267 and 2-246Document7 pagesSection Four: Scope of Work, Underground Steam Line Repair (Revised) Buildings 2-267 and 2-246Danny BoysieNo ratings yet

- NARRATIVE ON BEMONC Codon BHS-with QuantityDocument3 pagesNARRATIVE ON BEMONC Codon BHS-with QuantityjohnNo ratings yet

- Boq R2 - 290914Document25 pagesBoq R2 - 290914raviNo ratings yet

- Repair Underground Fire LineDocument10 pagesRepair Underground Fire LineBoj MingiNo ratings yet

- Annexure A Dwss Tor Dara Village TirahDocument3 pagesAnnexure A Dwss Tor Dara Village Tirahsajidali02020No ratings yet

- Cookstove Construction by The Terra-Ceta Method 1982 - PDF RoomDocument14 pagesCookstove Construction by The Terra-Ceta Method 1982 - PDF RoomRoland_DeschainNo ratings yet

- CAROL GARDENSDocument6 pagesCAROL GARDENSSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Quotation 1Document10 pagesQuotation 1Ankit VaswaniNo ratings yet

- L-861 FatoDocument15 pagesL-861 FatoSebastiánNo ratings yet

- 1 Repair Methodology Along With Cost Analis-SEPL LOW COSTDocument20 pages1 Repair Methodology Along With Cost Analis-SEPL LOW COSTDevinder Chawla100% (1)

- 123-Proposal For Joints Leakage TreatmentDocument5 pages123-Proposal For Joints Leakage TreatmentTariq MahmoodNo ratings yet

- Construction of Three Storied Building with Assembly Hall Balance Work Bill of QuantitiesDocument54 pagesConstruction of Three Storied Building with Assembly Hall Balance Work Bill of QuantitiesS A Y B JayasingheNo ratings yet

- 191 726359 2waterworks and Sewerage 713 EngDocument18 pages191 726359 2waterworks and Sewerage 713 Engredaey belachewNo ratings yet

- Underground Installation of PE Piping UnDocument39 pagesUnderground Installation of PE Piping UnGeorge_Wabag_2014No ratings yet

- Construction Studies Portfolio, Leaving Certificate 2010 - Layout of A Septic Tank.Document29 pagesConstruction Studies Portfolio, Leaving Certificate 2010 - Layout of A Septic Tank.Ciaran Henderson100% (12)

- Revised Quotation For Waterproofing Work To Basement, Superstructure & Terrace at MIT College, Kothrud, PuneDocument2 pagesRevised Quotation For Waterproofing Work To Basement, Superstructure & Terrace at MIT College, Kothrud, PuneRushi Kadgaonkar50% (2)

- GAW & GN BOQ SHEET for Preliminary Works at Asaba 8.5MVA Power PlantDocument2 pagesGAW & GN BOQ SHEET for Preliminary Works at Asaba 8.5MVA Power PlantGodwin IwekaNo ratings yet

- Checklist For Control Room Septic Tank & SoakpitDocument2 pagesChecklist For Control Room Septic Tank & SoakpitRupesh KhandekarNo ratings yet

- Waterproofing Techniques for Concrete StructuresDocument9 pagesWaterproofing Techniques for Concrete StructureshemantrulzNo ratings yet

- (Basic Emergency Maternal Obstetric and Neonatal Care) FacilityDocument3 pages(Basic Emergency Maternal Obstetric and Neonatal Care) FacilityjohnNo ratings yet

- Innovative Through-Tubing Cement Packer TechniqueDocument2 pagesInnovative Through-Tubing Cement Packer TechniquePak Rio100% (1)

- DBM OfficeDocument76 pagesDBM OfficeSrija RoyNo ratings yet

- Short FormDocument8 pagesShort Formravisingh26591No ratings yet

- Maternal Obstetric and Neonatal Care) FacilityDocument3 pagesMaternal Obstetric and Neonatal Care) FacilityjohnNo ratings yet

- Centrifugal Sprayed Concrete For Lining Horizontal Pipes Culverts and Vertical ShaftsDocument7 pagesCentrifugal Sprayed Concrete For Lining Horizontal Pipes Culverts and Vertical ShaftsFabiano MoraisNo ratings yet

- Special Applications of Chemical GroutsDocument14 pagesSpecial Applications of Chemical GroutsHồ ThắngNo ratings yet

- METHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The ViewsDocument6 pagesMETHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The Viewsaliengineer953No ratings yet

- 03 CPT Toilet Additional - Scope of Work Rev 1 - Aug21 2023Document21 pages03 CPT Toilet Additional - Scope of Work Rev 1 - Aug21 2023Wuttipong WangNo ratings yet

- 1 - Heating Coils85 - Heating Coils Cargo Tank1Document3 pages1 - Heating Coils85 - Heating Coils Cargo Tank1CHI-MING WENNo ratings yet

- BHARAT PETROLEUM CORPORATION LIMITED PRICE BID FORMAT FOR KANDLA INSTALLATIONDocument71 pagesBHARAT PETROLEUM CORPORATION LIMITED PRICE BID FORMAT FOR KANDLA INSTALLATIONPratik VermaNo ratings yet

- Facultad de Ingeniería Mecánica, Electrónica Y Biomédica: Taller 3Document2 pagesFacultad de Ingeniería Mecánica, Electrónica Y Biomédica: Taller 3DARIO FERNEY MARTINEZ RAMOSNo ratings yet

- Guidelines On Water ProofingDocument88 pagesGuidelines On Water ProofingViệt Đặng XuânNo ratings yet

- SPE 53955 Primary Cementing Optimisation: Well Conditioning Procedure and Foamed Spacer UseDocument13 pagesSPE 53955 Primary Cementing Optimisation: Well Conditioning Procedure and Foamed Spacer UseWaleed Barakat MariaNo ratings yet

- CTB - ADocument8 pagesCTB - ANathania RandyNo ratings yet

- ssss03-520-3-PA-304 A/B: Pumps FoundationDocument13 pagesssss03-520-3-PA-304 A/B: Pumps FoundationGrave moeletNo ratings yet

- Upgrading Gigmoto RHU to BEMONC FacilityDocument3 pagesUpgrading Gigmoto RHU to BEMONC FacilityjohnNo ratings yet

- Specifications 1. Tubewell: 1.1 Scope of WorkDocument7 pagesSpecifications 1. Tubewell: 1.1 Scope of WorkanwarNo ratings yet

- Trenchless Ducts Installation and Thermal Grouting For The Hackensack River ProjectDocument11 pagesTrenchless Ducts Installation and Thermal Grouting For The Hackensack River ProjectMarko IstenicNo ratings yet

- Flexible PipeDocument17 pagesFlexible PipeAnonymous dSFbLxc9100% (1)

- Dividing Wall Column Revamp Optimises Mixed Xylenes ProductionDocument14 pagesDividing Wall Column Revamp Optimises Mixed Xylenes ProductionMaria Alejandra Colonia MoyaNo ratings yet

- TENDER CLARIFICATION NO. 1 - Answer - Part 1Document5 pagesTENDER CLARIFICATION NO. 1 - Answer - Part 1Sathya SeelanNo ratings yet

- Grey Water Management Resource Book GoIDocument38 pagesGrey Water Management Resource Book GoIsalilNo ratings yet

- Concrete Construction Article PDF - Ice Rink Floor Placed in One PourDocument2 pagesConcrete Construction Article PDF - Ice Rink Floor Placed in One PourHasim AbdulNo ratings yet

- Xypex Patch'n Plug EN PDFDocument2 pagesXypex Patch'n Plug EN PDFQuốcQuắtQueoNo ratings yet

- P 1 HLF 03Document3 pagesP 1 HLF 03obaidullah.dsuNo ratings yet

- Scope of Work-BAMDocument21 pagesScope of Work-BAMShabeer Shaarim Abdul Jabbar100% (1)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Engineering Home 2019 25yrsDocument12 pagesEngineering Home 2019 25yrsAhmed Ayman HassaneenNo ratings yet

- Fittings and Supports MTO-Rev.1Document2 pagesFittings and Supports MTO-Rev.1Ahmed Ayman HassaneenNo ratings yet

- HFC-227ea/CO2 Engineered System Consist of 4 Main Elements:: Cylinder AssembliesDocument1 pageHFC-227ea/CO2 Engineered System Consist of 4 Main Elements:: Cylinder AssembliesAhmed Ayman HassaneenNo ratings yet

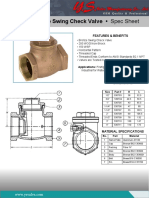

- YS-1905 Bronze Swing Check Valve - Spec Sheet: Features & BenefitsDocument1 pageYS-1905 Bronze Swing Check Valve - Spec Sheet: Features & BenefitsAhmed Ayman HassaneenNo ratings yet

- How Doenload PDF Books Part 1Document1 pageHow Doenload PDF Books Part 1Ahmed Ayman HassaneenNo ratings yet

- Honeywell SensePoint XCDDocument8 pagesHoneywell SensePoint XCDAhmed Ayman HassaneenNo ratings yet

- Taktis Flyer 2018Document6 pagesTaktis Flyer 2018Ahmed Ayman HassaneenNo ratings yet

- I 9602LW CGDocument12 pagesI 9602LW CGAhmed Ayman HassaneenNo ratings yet

- Structural Steel Design SpecificationDocument8 pagesStructural Steel Design SpecificationNassim SabriNo ratings yet

- Remodelling and Restructuring of Koyli Creek Including Vehicle Track in Surat. (Ch. 9500 To 10850)Document8 pagesRemodelling and Restructuring of Koyli Creek Including Vehicle Track in Surat. (Ch. 9500 To 10850)kkodgeNo ratings yet

- List of ACI Symposium VolumesDocument8 pagesList of ACI Symposium VolumesMymoon MoghulNo ratings yet

- World Refining-Rocket ScienceDocument3 pagesWorld Refining-Rocket ScienceIndunil WarnasooriyaNo ratings yet

- Archmaterials Vol 03Document52 pagesArchmaterials Vol 03turuceluNo ratings yet

- Guniting MethodologyDocument3 pagesGuniting MethodologykishanNo ratings yet

- MasterEmaco - S650 v1 PDFDocument2 pagesMasterEmaco - S650 v1 PDFPuneet AggarwalNo ratings yet

- Piping Design InfoDocument273 pagesPiping Design InfoFerry SiswantoNo ratings yet

- Piping Support Detail Training Session (Day-Iii)Document24 pagesPiping Support Detail Training Session (Day-Iii)Zahoor Ahmed100% (1)

- Ceilcote Secondary Containment July 2013Document51 pagesCeilcote Secondary Containment July 2013Jaime Andres Perez Alvarado100% (1)

- Comparing Quality & Yield Performance in January 2019Document7 pagesComparing Quality & Yield Performance in January 2019Aris SusantoNo ratings yet

- SERIES 7000/8000: 3 Piece Full Port " - 12"Document8 pagesSERIES 7000/8000: 3 Piece Full Port " - 12"ErickNo ratings yet

- Sheet Metal Gauge Size Chart-Stainless SteelDocument2 pagesSheet Metal Gauge Size Chart-Stainless Steellorenzinho290No ratings yet

- Estimate 29 - 11Document19 pagesEstimate 29 - 11Ositha WarunaNo ratings yet

- 04 - Stock Out CardDocument11 pages04 - Stock Out CardShirley AngNo ratings yet

- Conduit Wiring: Section I. Rigid Conduit Uses and AdvantagesDocument13 pagesConduit Wiring: Section I. Rigid Conduit Uses and AdvantagesElujekwute BenjaminNo ratings yet

- SJS - DHT-Downhole Oil ToolsDocument156 pagesSJS - DHT-Downhole Oil ToolsTHUNDER KESAR1000No ratings yet

- Dram & Sample Storage VialsDocument4 pagesDram & Sample Storage VialsSavioNo ratings yet

- Estimation and PlanningDocument151 pagesEstimation and Planningfirojji panchtilakNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- Steel Material ScienceDocument15 pagesSteel Material Science04352No ratings yet

- S1239 Epoxy Primer: DescriptionDocument2 pagesS1239 Epoxy Primer: DescriptionELEJONDO Pablo - VCNo ratings yet

- Din en Iso - 10684Document27 pagesDin en Iso - 10684Guillermo Torres100% (1)

- Ut Velocity Table: Material L-Wave Velocity M/s S-Wave Velocity In/ms S-Wave Velocity M/sDocument1 pageUt Velocity Table: Material L-Wave Velocity M/s S-Wave Velocity In/ms S-Wave Velocity M/sprakashNo ratings yet

- Wear Characterization of LM29 Alloy With40 Micron Sized B4C Reinforced Metal CompositesDocument9 pagesWear Characterization of LM29 Alloy With40 Micron Sized B4C Reinforced Metal CompositesIJAR JOURNALNo ratings yet

- RCD 1Document25 pagesRCD 1Niña Amethyst AlivioNo ratings yet

- Uns Aceros InglesDocument5 pagesUns Aceros InglesEdgar Ivan DavilaNo ratings yet

- Catch Up Plan Nha Format r.0001Document2 pagesCatch Up Plan Nha Format r.0001Anthony Alvarez50% (6)

- High Nitrogen Martensitic Steels A New Family of Martensitic Corrosion Resistant Steels For Improved Aerospace Bearing PerformanceDocument5 pagesHigh Nitrogen Martensitic Steels A New Family of Martensitic Corrosion Resistant Steels For Improved Aerospace Bearing PerformanceJim SmithNo ratings yet

- Satish Lele: Codes and StandardsDocument10 pagesSatish Lele: Codes and StandardsAamerMAhmadNo ratings yet