Professional Documents

Culture Documents

MatSel SDR

Uploaded by

Matthew MiceliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MatSel SDR

Uploaded by

Matthew MiceliCopyright:

Available Formats

Matthew Miceli Senior Design Presentation Reviews 4/25/2019

SAE Aero Regular class

Team 25

4/23/2019

1:00 PM

The goal of the experiment was to create an airplane, under certain restrictions, that could

carry a specific load, simulating passengers and luggage. The plane would fly in a national

competition in which hit had to take off on a 200 ft runway and make a loop around a certain

area. The criterion for the competition included how many passengers the plane could hold and

how well the plane could take off among other things. Overall, the plane finished in 29th place

out of 37 with 2 successful flights attempts out of 5, carrying a total of 20 passengers.

The three main materials used in the creation of the airplane were balsa wood, foam,

and epoxy. For the wings, foam was used with a rod running though the length of the wings.

They did not specify the material of the rod; however, the rod should theoretically increase the

stiffness of the wings, allowing for a somewhat light and stiff structure. The body of the plane

was made with balsa wood, also light and rigid. Finally, epoxy was used an adhesive for the

materials of the plane.

Matthew Miceli Senior Design Presentation Reviews 4/25/2019

Chandler’s NASA Human Exploration Rover Challenge

Team 24

4/25/2019

3:00 PM

This project aimed at creating a man-powered rover for a competition held in Huntsville,

Alabama. The goal was to create a rover that was collapsible, light, and could complete

competition runs in a timely manner. Each team was allowed to perform two runs, the best of

which was kept and used for scoring. The LSU team experienced failure on the rear crankset

during the first run and fixed it for the second run.

In designing the wheels, a solid wheel design was chosen to increase strength. Each

wheel was composed of polyurethane with a 0.012” carbon fiber surrounding on each side. In

order to save on weight, they used a honeycomb polyurethane core for the wheels. The

driveshaft was composed Aluminum 6061-T6 in order to save weight, while the chains were

made of hardened carbon steel to increase strength in response to last year’s failures. Finally, a

trapezoidal configuration was used in the shape selection of the main frame in order to increase

its moment of inertia while reducing its cross-sectional area, and Aluminum 6061-T6 was used

due to its strength-to-weight ratio..

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- D6557Document16 pagesD6557moh_ichwanuddinNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Landing GearDocument6 pagesLanding GearMureithi SamNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- PhilosophyofTheism 10036021 PDFDocument354 pagesPhilosophyofTheism 10036021 PDFdydycookyNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Mullarney Sweeteners Used in Chewable TabletsDocument10 pagesMullarney Sweeteners Used in Chewable TabletsKatherine PosadaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Separation Assignment MembraneDocument4 pagesSeparation Assignment MembraneQilah KamarudinNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Stable Solid Deodorant Product Grape Fruit1Document15 pagesStable Solid Deodorant Product Grape Fruit1sabunbeningNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Chapter 24)Document10 pagesChapter 24)Hazel LopezNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Us 20130000370Document9 pagesUs 20130000370japerezle23No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Complete Physical Chemistry McqsDocument13 pagesComplete Physical Chemistry Mcqszafarchem_iqbalNo ratings yet

- Ipsita RoyDocument60 pagesIpsita RoyJohn F ServilleNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- K3Document5 pagesK3Dani SetiawanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Indian Standard For Industrial FlooringDocument10 pagesIndian Standard For Industrial FlooringRamprasad JeyaramNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- CHEM35.1 E2 Aromatic Side Chain OxidationDocument3 pagesCHEM35.1 E2 Aromatic Side Chain OxidationGlenn Vincent TumimbangNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Lec1 PDFDocument3 pagesLec1 PDFusmanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Advanced Packaging TechnologiesDocument5 pagesAdvanced Packaging TechnologiesSam HongNo ratings yet

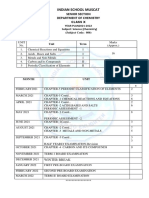

- Indian School Muscat: Senior Section Department of ChemistryDocument1 pageIndian School Muscat: Senior Section Department of ChemistryRitaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Fertilizer CompanyDocument5 pagesFertilizer CompanyParth Patel100% (1)

- Laser Cutting SystemDocument21 pagesLaser Cutting SystemSamo FelicijanNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Flexi Tech 60rg DataDocument2 pagesFlexi Tech 60rg DatadogankkuNo ratings yet

- 2 Introduction To XRPD Data AnalysisDocument25 pages2 Introduction To XRPD Data AnalysisMuthu KumarNo ratings yet

- The D 130 LeafletDocument2 pagesThe D 130 LeafletKenny Wong Choon HoonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MEFff 2Document97 pagesMEFff 2Bza ZaBugNo ratings yet

- FSD243eng ISC2 Series Broch LTR 2 PDFDocument6 pagesFSD243eng ISC2 Series Broch LTR 2 PDFDang XmanNo ratings yet

- Aic 10026Document15 pagesAic 10026Abril HerreraNo ratings yet

- Dielectric Properties of CoalDocument11 pagesDielectric Properties of CoalEsther BarrachinaNo ratings yet

- Renolit So-Gfb: Description AdvantagesDocument3 pagesRenolit So-Gfb: Description AdvantagesAhmed El TayebNo ratings yet

- Mechanical Properties of Carbon Fiber Composite MaterialsDocument2 pagesMechanical Properties of Carbon Fiber Composite MaterialsmehtabpathanNo ratings yet

- Assignment Solution Adv Single CorrectDocument31 pagesAssignment Solution Adv Single CorrectNonu RajputNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Rotogravure Printing Learn MoreDocument15 pagesRotogravure Printing Learn Moreumangashling100% (1)

- The Aqueous Geochemistry of Gallium, Germanium, Indium and ScandiumDocument46 pagesThe Aqueous Geochemistry of Gallium, Germanium, Indium and ScandiumLeon MutambalaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)