Professional Documents

Culture Documents

Six Laning of Shamlaji to Motachiloda GSB Trial Patch Report

Uploaded by

Md Yasin0 ratings0% found this document useful (0 votes)

192 views2 pagesOriginal Title

GSB TRIAL PATCH-3.doc

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

192 views2 pagesSix Laning of Shamlaji to Motachiloda GSB Trial Patch Report

Uploaded by

Md YasinCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

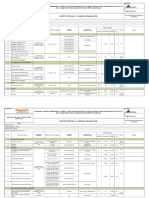

Name of the Project :Six Laning of Shamlaji to Motachiloda from Km. 401.

200 to

494.410(Length 93.210 Km) Section of NH-8 in the State of Gujarat Under

NHDP Phase-V (Package-VI) on Hybrid Annuity Mode

GSB TRIAL PATCH CARRIED ON 20 Dec-2018

Location : 479+500 (LHS)

Area : Length 150m x Width 7.05 m = 1058 Sqm

Source of Material : Padar Crusher

Job Mix Formula Reference:

Stock Pile of the Material:

Location : Padar Crusher, km 461+435 LHS

Material : Crushed GSB

GSB crusher

Location: Padar Crusher, km 461+435 LHS @ 4.0 km inside from ch.

Collection of GSB Samples from Plant for Gradation, Atterberg Limit Checking:

Test Format Enclosed

FDD test has been checked. Location map and test reports enclosed.

Preparation and Transportation of Mix:

GSB was prepared in Cone Crusher with suitable capacity having provision for

controlled addition of water. The mix was transported to the site by using

dumpers.

Spreading of Mix:

The Material was spread across the width of formation which has presently been

taken up for construction. Spreading of the mix has been done by using motor

grader.

Compaction:

After laying the mix to the required thickness, grade and camber the same was

uniformly compacted using Vibratory Roller of 8-10 Tons Capacity. The speed of

the roller was maintained up to 5 km per hour. Initial the rolling was one plain

pass followed by three High vibratory passes, then Two Low vibratory passes and

finally followed by one plain pass.

Rolling was commenced from lower edge and progressed towards the upper edge.

In each pass the roller was progressed parallel to the centre line of the road and

succeeding passes were given. Uniformly over lapping each proceeding track by

at least one third width of compacting drum until the entire surface had been

rolled An alternate trip of the roller was terminated in stops at least 1mt. away

from any proceeding stop.

After rolling & level checking compaction test was carried out to check its degree

of compaction by sand replacement method conforming to IS 2720 (Part 28). The

field density achieved is minimum of 98% of the Maximum dry density of the

mix as determined by the method outlined in IS: 2720 (Part-8). Test results are

enclosed herewith.

In-situ GSB Sample for Gradation Checking: Test reports Enclosed.

Contractor Concessionaire IE’s

Representative Representative Representative

You might also like

- Construction of Flyover at Km.77+750 on NH-44 in MaharashtraDocument1 pageConstruction of Flyover at Km.77+750 on NH-44 in MaharashtraMangeysh S. Chauhan100% (1)

- Tiki Tar's "AsphaltosealDocument41 pagesTiki Tar's "Asphaltosealnagaraj_qce3499100% (1)

- Schedule K (EPC) PDFDocument2 pagesSchedule K (EPC) PDFAkshay PendurkarNo ratings yet

- Concrete Pavement Sub-Base SpecificationsDocument9 pagesConcrete Pavement Sub-Base SpecificationsAmit AbhangNo ratings yet

- MBIU Report Gorakhpur BypassDocument167 pagesMBIU Report Gorakhpur BypassRaghav SharmaNo ratings yet

- Wet Mix Macadam (WMM) Quantity / Compaction Factor Value For WMMDocument31 pagesWet Mix Macadam (WMM) Quantity / Compaction Factor Value For WMMsuniljhilmilNo ratings yet

- Retro-Reflectivity TestDocument8 pagesRetro-Reflectivity Testjitendra100% (1)

- Morth Section 900Document256 pagesMorth Section 900VikasMauryaNo ratings yet

- 1304..mix Design m25 Dalmia Cement... Mes JorhatDocument16 pages1304..mix Design m25 Dalmia Cement... Mes JorhatAbhishek KumarNo ratings yet

- Earthworks Construction GuideDocument9 pagesEarthworks Construction GuidePathankot MandiNo ratings yet

- Method Statement: Granular Sub Base (GSB) Layer Compaction ProcessDocument1 pageMethod Statement: Granular Sub Base (GSB) Layer Compaction ProcessjitendraNo ratings yet

- QAP For Bitumen JobDocument2 pagesQAP For Bitumen JobSasanka SekharNo ratings yet

- Ravi Sir DLC PresentationDocument13 pagesRavi Sir DLC Presentationসৌগত রায় ঘটকNo ratings yet

- WMM Calibration 05.01.2016Document8 pagesWMM Calibration 05.01.2016SRR QAQCNo ratings yet

- Casting Method for RE Wall Fascia PanelsDocument4 pagesCasting Method for RE Wall Fascia PanelsAkhilesh DwivediNo ratings yet

- MTC Fosroc Auramix 400Document2 pagesMTC Fosroc Auramix 400manish upadhyay0% (1)

- PQC Methodology - Nagpur MumbaiDocument14 pagesPQC Methodology - Nagpur MumbaiGanesh Kumar TulabandulaNo ratings yet

- Rap GSB and WMM PDFDocument4 pagesRap GSB and WMM PDFvenkateswara rao PothinaNo ratings yet

- Monthly Progress Report: Frischmannprabhu (India) Pvt. LTDDocument54 pagesMonthly Progress Report: Frischmannprabhu (India) Pvt. LTDshravan38No ratings yet

- Method Statement For Wet Mix MacadamDocument7 pagesMethod Statement For Wet Mix Macadammadhu arepelliNo ratings yet

- Construction of Road at BallabgarhDocument55 pagesConstruction of Road at BallabgarhAadil AhmadNo ratings yet

- Is 383 (1970) Grading ZonesDocument2 pagesIs 383 (1970) Grading ZonesAnonymous 2RduvkjgZNo ratings yet

- Combine Flakiness & Elongation TestDocument1 pageCombine Flakiness & Elongation TestFariha AzadNo ratings yet

- Mix Design For PQCDocument34 pagesMix Design For PQCSAMRADDHI PRAJAPATINo ratings yet

- WMM Design DataDocument42 pagesWMM Design DatapreranaNo ratings yet

- Letter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatDocument4 pagesLetter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatProf. Prithvi Singh Kandhal100% (1)

- Concrete dispatch slip quality planDocument1 pageConcrete dispatch slip quality planShesha ShayanNo ratings yet

- Sand Calibration FormetDocument2 pagesSand Calibration FormetAnish PanchalNo ratings yet

- (With Flyash) : M-20 KERBDocument8 pages(With Flyash) : M-20 KERBNaveen SinghNo ratings yet

- RE Wall Drawing For Structure 31+329 & 31+820Document25 pagesRE Wall Drawing For Structure 31+329 & 31+820Vibekananda MohantyNo ratings yet

- Compaction Test by Core Cutter (Is: 2720, Part 29)Document2 pagesCompaction Test by Core Cutter (Is: 2720, Part 29)Francis Aw Soon LeeNo ratings yet

- Draft Letter Permission For Casting Percast Girder PDFDocument2 pagesDraft Letter Permission For Casting Percast Girder PDFSachin RamaniNo ratings yet

- BLENDING of MSS Mix Design TypeDocument3 pagesBLENDING of MSS Mix Design TypeEnd EndNo ratings yet

- Water Bound Macadam-WbmDocument11 pagesWater Bound Macadam-WbmCheng EngiNo ratings yet

- Highway Material Testing & Quality Control, 1/e: G. Venkatappa Rao, D.V. Bhavanna Rao, K. Ramachandra Rao & Kausik PahariDocument2 pagesHighway Material Testing & Quality Control, 1/e: G. Venkatappa Rao, D.V. Bhavanna Rao, K. Ramachandra Rao & Kausik Paharisunil777tvpm100% (1)

- Section 400 - (Granular-Sub-Base) - Finally CorrectedDocument16 pagesSection 400 - (Granular-Sub-Base) - Finally CorrectedTousifAnwar MundaragiNo ratings yet

- 04-400. Sub-Bases, (Non-Bituminous) and ShouldersDocument29 pages04-400. Sub-Bases, (Non-Bituminous) and ShouldersAnonymous g1LSaANo ratings yet

- WMM Mix DesignDocument57 pagesWMM Mix Designp. kiran kuamrNo ratings yet

- A Report On: Sub-Soil Investigation For The Proposed Construction of Minor Bridge Over Chora Nala at Ch. KM 4.000Document30 pagesA Report On: Sub-Soil Investigation For The Proposed Construction of Minor Bridge Over Chora Nala at Ch. KM 4.000Manvendra NigamNo ratings yet

- CC Road PDFDocument222 pagesCC Road PDFPhani PitchikaNo ratings yet

- Mix Design of Stone Matrix Asphalt With Othwad Quarry Aggregate and Bitumen VG 40Document109 pagesMix Design of Stone Matrix Asphalt With Othwad Quarry Aggregate and Bitumen VG 40ਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟNo ratings yet

- Irc 097-1987Document10 pagesIrc 097-1987kruttika_apNo ratings yet

- PROFILE CORRECTION WITH DENSE-BITUMINOUS MACADAMDocument7 pagesPROFILE CORRECTION WITH DENSE-BITUMINOUS MACADAMmadhu arepelliNo ratings yet

- Aggregate Impact Value (Is: 2386 (Part-Iv) )Document19 pagesAggregate Impact Value (Is: 2386 (Part-Iv) )ajit karandikarNo ratings yet

- 14a Prime CoatDocument3 pages14a Prime CoatAkhilesh DwivediNo ratings yet

- Developing rural roads agency in BiharDocument2 pagesDeveloping rural roads agency in Biharvijay kumarNo ratings yet

- Ultrasonic Pulse Velocity Test: Observation SheetDocument1 pageUltrasonic Pulse Velocity Test: Observation SheetAhteshaam MullaNo ratings yet

- Method Statement For Construction of Mastic Asphalt (As Per Clause 515 of MORTH Specification)Document4 pagesMethod Statement For Construction of Mastic Asphalt (As Per Clause 515 of MORTH Specification)DeepakNo ratings yet

- Frequency of TestsDocument5 pagesFrequency of TestsRayees Ahmad100% (1)

- Noida Metro Rail Project Cec-Sam-Jv.: Presentation On U-Girder Casting by L.K.PrasadDocument116 pagesNoida Metro Rail Project Cec-Sam-Jv.: Presentation On U-Girder Casting by L.K.PrasadLOHITH N100% (1)

- Methods For Testing Tar and Bituminous Materials - Determination of PenetrationDocument10 pagesMethods For Testing Tar and Bituminous Materials - Determination of PenetrationDevesh Kumar PandeyNo ratings yet

- NP4 Pipe Installation and Backfill - MethodologyDocument4 pagesNP4 Pipe Installation and Backfill - MethodologyRabnawaz Imam100% (1)

- Job Mix For BM 50 MMDocument3 pagesJob Mix For BM 50 MMSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- Cover Block Method StaDocument1 pageCover Block Method StaRavi kumarNo ratings yet

- Mix Design Using RAP 30Document4 pagesMix Design Using RAP 30Raghav100% (2)

- Thin Bituminous Surfacing AND Open Graded Premix CarpetDocument26 pagesThin Bituminous Surfacing AND Open Graded Premix CarpetCCT18-20 NMAMITNo ratings yet

- Highway Skid ResistanceDocument20 pagesHighway Skid ResistanceMohamed Al FahlNo ratings yet

- Analysis and Execution of Road Work - PPTDocument41 pagesAnalysis and Execution of Road Work - PPTengrarzooNo ratings yet

- Projet FRCDocument20 pagesProjet FRCHARSH KUMARNo ratings yet

- Road Stabilization With Bituminous MaterialsDocument10 pagesRoad Stabilization With Bituminous MaterialsBeth MawiaNo ratings yet

- Lab Rotary EvaporatorDocument7 pagesLab Rotary EvaporatorAnna Yunita SitompulNo ratings yet

- PRACTICE - Free Time-ActivitiesDocument2 pagesPRACTICE - Free Time-ActivitiesErica RemacheNo ratings yet

- Field and Potential - BDocument4 pagesField and Potential - BParth ChandrayanNo ratings yet

- The Eight Parts of SpeechDocument70 pagesThe Eight Parts of Speechibrahim mohammedNo ratings yet

- APUNG GUIDANG MAPEH Daily Lesson LogDocument4 pagesAPUNG GUIDANG MAPEH Daily Lesson LogJeinel Catahan GuiaoNo ratings yet

- Lesson Plan Science Primary 5 Diana (08B0529) & Nurul Khairunnisa (08B0534)Document11 pagesLesson Plan Science Primary 5 Diana (08B0529) & Nurul Khairunnisa (08B0534)dyanedianaNo ratings yet

- Dance in the Philippines: A Cultural TraditionDocument13 pagesDance in the Philippines: A Cultural TraditionSTEPHEN C. PASTEDIONo ratings yet

- Little Red Riding HoodDocument4 pagesLittle Red Riding HoodRoxana Quispe CuadrosNo ratings yet

- Online Stocks User Guide IDocument22 pagesOnline Stocks User Guide ITan Teck HweeNo ratings yet

- Matildas Morning AdventuresDocument22 pagesMatildas Morning AdventuresViviana Dovald LuxenNo ratings yet

- Worksheet Bart SimpsonDocument2 pagesWorksheet Bart Simpsonmartatoledo100% (1)

- VDP Technical Drawings RealDocument12 pagesVDP Technical Drawings Realapi-331456896No ratings yet

- Bill Statement: Previous Charges Amount (RM) Current Charges Amount (RM)Document11 pagesBill Statement: Previous Charges Amount (RM) Current Charges Amount (RM)Vaishnavi ManoharanNo ratings yet

- JBL Sound Bar ManualDocument8 pagesJBL Sound Bar ManualJorge MarroquinNo ratings yet

- Autocad en 3 Dimensiones: Terminología para Cad en 3-DDocument20 pagesAutocad en 3 Dimensiones: Terminología para Cad en 3-DlalalaNo ratings yet

- Sash PlanesDocument5 pagesSash PlanesBlakdawg15100% (1)

- Cardiac Output SnA Catalog Jan2023 Low ResDocument2 pagesCardiac Output SnA Catalog Jan2023 Low ResKatia DominguezNo ratings yet

- RAB BAHAN BAKU Kopi ShopDocument3 pagesRAB BAHAN BAKU Kopi ShopapotekcimanukNo ratings yet

- Cloth Habit 1001 Ladyshorts InstructionsDocument4 pagesCloth Habit 1001 Ladyshorts InstructionsNathalie GaillardNo ratings yet

- Hotel Restaurant Data All IndiaDocument3 pagesHotel Restaurant Data All IndiaNeha Bansal100% (1)

- LTM201M1 L01 SamsungDocument36 pagesLTM201M1 L01 SamsungGeorge AdrianNo ratings yet

- Set B QuizDocument1 pageSet B QuizBeyoung GamefightNo ratings yet

- "When Reality Strikes" (Grade 9)Document4 pages"When Reality Strikes" (Grade 9)Jeffrey De ChavezNo ratings yet

- Digitech RP350 ManualDocument40 pagesDigitech RP350 Manualbarfine100% (1)

- Types of Mice and Their ComponentsDocument18 pagesTypes of Mice and Their ComponentsMinecraft VillagerNo ratings yet

- Tortle 7-11Document5 pagesTortle 7-11Jonathan GomezNo ratings yet

- Diode: Tube Diode (Now Rarely Used Except in Some High-Power Technologies) IsDocument16 pagesDiode: Tube Diode (Now Rarely Used Except in Some High-Power Technologies) IsGorishsharmaNo ratings yet

- Week 1 - Grammar-Practice-Adjectives-WorksheetDocument2 pagesWeek 1 - Grammar-Practice-Adjectives-WorksheetJakmensar Dewantara SiagianNo ratings yet

- Article 8 Reflective Paper 2Document11 pagesArticle 8 Reflective Paper 2Nur Amira NadiaNo ratings yet

- The Gold WatchDocument1 pageThe Gold Watchabhijit8sarkar-3No ratings yet