Professional Documents

Culture Documents

Lesson Plan Subject Name-Theory Metal Cutting Branch - Production Engineering Subject Code - BPE 2504 Semester - 5

Uploaded by

Raja RamachandranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lesson Plan Subject Name-Theory Metal Cutting Branch - Production Engineering Subject Code - BPE 2504 Semester - 5

Uploaded by

Raja RamachandranCopyright:

Available Formats

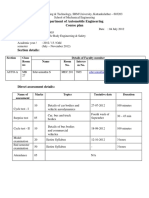

LESSON PLAN

Subject Name- Theory Metal Cutting Branch- Production Engineering

Subject Code- BPE 2504 Semester- 5th

Period/

S/N Module Topic(s)

Hours

1 I Basic shapes of machine tools 1

2 I Wedge action, function of different angles of cutting tools 2

3 I Tool geometry and Nomenclatures ASA,ORS system 3

Conversion of angles, geometry of twist drill & slab milling

4 I 4

cutter

5 I Grinding of single point cutting tool, Tool materials 5

6 I Tutorial 6

Mechanism of chip formation: Mode of failure under stress-

7 I 7

fracture & yielding mechanism

8 I Types of chips, Factor involved in chip formation, shear plane 8

Effect of cutting variable on chip reduction coefficient, chip

9 I 9

formation in Drilling and milling

10 I Tutorial 10

Force system in turning- Merchant circle diagram, velocity

11 II 11-12

relationship

12 II Stress in conventional shear plane, Energy of cutting process 13-14

13 II Tutorial 15

14 II Earnst& Merchant angle relationship 16-17

15 II Forces in drilling and plane slab milling 18-19

Measurement of forces-dynamometer for measuring turning &

16 II 20-21

drilling forces

Period/

S/N Module Topic(s)

Hours

17 II Tutorial 22

Thermodynamics of chip formation: The shear plane

18 III temperature-interference temperature from dimensional 23-27

analysis-Experimental determination of chip tool interface

19 III Tutorial 28

Coolants- Theory of cutting fluid action at the chip tool

20 III 29-30

interface

21 III Techniques for application of cutting fluids 31

22 III Tutorial 32

23 IV Tool wear: Criteria of wear 33

24 IV Machinability and tool life 34

25 IV Flank wear, Taylor’s tool life equation, Crater wear 35-36

26 IV Vibration & chatter in machining 37-38

27 IV Economics of metal machining 39

28 IV Tutorial 40

You might also like

- Lesson Plan Subject Name-Tool Design Branch - Production Engineering Subject Code - BPE 2604 Semester - 6Document2 pagesLesson Plan Subject Name-Tool Design Branch - Production Engineering Subject Code - BPE 2604 Semester - 6Raja RamachandranNo ratings yet

- Lesson Plan Subject Name-Advanced Casting and Welding Branch - Production Engineering Subject Code - BPE 2605 Semester - 8Document2 pagesLesson Plan Subject Name-Advanced Casting and Welding Branch - Production Engineering Subject Code - BPE 2605 Semester - 8Raja RamachandranNo ratings yet

- Lesson Plan Subject Name-Theory of Metal Forming Branch - Production Engineering Subject Code - BPE 2603 Semester - 6Document2 pagesLesson Plan Subject Name-Theory of Metal Forming Branch - Production Engineering Subject Code - BPE 2603 Semester - 6Raja RamachandranNo ratings yet

- ME6402 MT II by WWW - Learnengineering.inDocument102 pagesME6402 MT II by WWW - Learnengineering.inVikram C KNo ratings yet

- MEF 112 Course HandoutDocument4 pagesMEF 112 Course HandoutAR7 StudioNo ratings yet

- ME6402 SCAD MSM by EasyEngineering - Net 2Document101 pagesME6402 SCAD MSM by EasyEngineering - Net 2Akash PrasanthNo ratings yet

- ME8451-MT-II - by WWW - LearnEngineering.inDocument102 pagesME8451-MT-II - by WWW - LearnEngineering.inSundar GaneshNo ratings yet

- Manufacturing Processes PDFDocument6 pagesManufacturing Processes PDFAbhi GalandeNo ratings yet

- Me 8392 - Manufacturing Technology: 14. Course OutcomesDocument6 pagesMe 8392 - Manufacturing Technology: 14. Course OutcomesERKATHIRNo ratings yet

- BMP - RollingDocument46 pagesBMP - Rollingmantra2010No ratings yet

- MCMT Course File Doc 30th Juky2016 Unit 1 2 and 3,4Document91 pagesMCMT Course File Doc 30th Juky2016 Unit 1 2 and 3,4Pilla SireeshaNo ratings yet

- Ae2253 LPDocument2 pagesAe2253 LPசுஜித் குமார்No ratings yet

- Works T-IIIDocument3 pagesWorks T-IIITki NeweNo ratings yet

- Video PDFDocument2 pagesVideo PDFRaja RamachandranNo ratings yet

- Lesson Plan Subject Name-Basic Manufacturing Process Branch - Production Engineering Subject Code - BPE2301 Semester - 3Document2 pagesLesson Plan Subject Name-Basic Manufacturing Process Branch - Production Engineering Subject Code - BPE2301 Semester - 3Raja RamachandranNo ratings yet

- Dhanalakshmi Srinivasan Engineering College PERAMBALUR-621212Document8 pagesDhanalakshmi Srinivasan Engineering College PERAMBALUR-621212Kalai ArasanNo ratings yet

- BMP - DrawingDocument22 pagesBMP - Drawingmantra2010No ratings yet

- Me8361 - Manufacturing Technology Laboratory Syllabus Course ObjectivesDocument75 pagesMe8361 - Manufacturing Technology Laboratory Syllabus Course ObjectivesArumugam RNo ratings yet

- BMP PDFDocument17 pagesBMP PDFmantra2010No ratings yet

- BMP - Metal WorkingDocument17 pagesBMP - Metal Workingmantra2010No ratings yet

- BMP - ForgingDocument31 pagesBMP - Forgingmantra2010No ratings yet

- MDM Lab Manual OU Machine DrawingDocument41 pagesMDM Lab Manual OU Machine DrawingBandara EMNo ratings yet

- ME8451 Notes MT-II - by WWW - Easyengineering.net 4Document64 pagesME8451 Notes MT-II - by WWW - Easyengineering.net 4Praveena S.SundaramNo ratings yet

- B. Tech. Session: Odd, 2021-22 Sem V Lecture Plan: Department of Mechanical Engineering MEC-303Document3 pagesB. Tech. Session: Odd, 2021-22 Sem V Lecture Plan: Department of Mechanical Engineering MEC-303ME VideoNo ratings yet

- Question BankDocument48 pagesQuestion Banksanjai kumarNo ratings yet

- Presstool Design Tutorial - MisumiDocument166 pagesPresstool Design Tutorial - Misumiazadsingh1No ratings yet

- BMP - IntroductionDocument130 pagesBMP - Introductionmantra2010No ratings yet

- Manufacturing Technology IIDocument97 pagesManufacturing Technology IIPedro FernandesNo ratings yet

- Manufacturing TechDocument6 pagesManufacturing TechSachi MensiNo ratings yet

- BMP - ExtrusionDocument24 pagesBMP - Extrusionmantra2010No ratings yet

- BMP - Electric Arc WeldingDocument91 pagesBMP - Electric Arc Weldingsujay nayakNo ratings yet

- Me6302-Manufacturing Technology - I Ii /iii Mechanical EngineeringDocument46 pagesMe6302-Manufacturing Technology - I Ii /iii Mechanical EngineeringNandha Gopal SenthilnathanNo ratings yet

- Gov. Pablo Borbon Campus II, Alangilan Batangas City, PhilippinesDocument49 pagesGov. Pablo Borbon Campus II, Alangilan Batangas City, PhilippinesRenee CruzNo ratings yet

- BMP - Other Welding ProcessesDocument76 pagesBMP - Other Welding Processessujay nayakNo ratings yet

- Martelli Tramac PDFDocument64 pagesMartelli Tramac PDFFastcross HondaNo ratings yet

- Manual AFIADORA UNIVERSAL 2020Document39 pagesManual AFIADORA UNIVERSAL 2020Marcus LopesNo ratings yet

- Research of CFRP Drill Hole Quality Based On Different Ply AngleDocument43 pagesResearch of CFRP Drill Hole Quality Based On Different Ply Angletpo482247No ratings yet

- Mould Tech 6Document70 pagesMould Tech 6Jagatheeswaran RNo ratings yet

- MT3493 Question Bank - MechDocument34 pagesMT3493 Question Bank - Mechmohan kumarNo ratings yet

- Esbm5a 1B310 S AaDocument28 pagesEsbm5a 1B310 S AaAlanevh AlanevhNo ratings yet

- BMP - CastingDocument217 pagesBMP - Castingmantra2010No ratings yet

- M3 - MFG Science and Tooling - Theory of Metal Cutting-4Document172 pagesM3 - MFG Science and Tooling - Theory of Metal Cutting-4Grishma BalgiNo ratings yet

- Me1302 LP ADocument3 pagesMe1302 LP ACKDinakarrajNo ratings yet

- Me1302 LP BDocument3 pagesMe1302 LP BCKDinakarrajNo ratings yet

- Me8361 Mech MTL Even Iiise LabmanualDocument80 pagesMe8361 Mech MTL Even Iiise Labmanualkannu19802550No ratings yet

- Abidi Me503 Mt-IIDocument98 pagesAbidi Me503 Mt-IIEr Syed Shauzab AbidiNo ratings yet

- Course Syllabus Manufacturing Processes (1) Metal CuttingDocument4 pagesCourse Syllabus Manufacturing Processes (1) Metal CuttingG. Dancer GhNo ratings yet

- New Workshop Charts... 01.Document7 pagesNew Workshop Charts... 01.upenderdhullNo ratings yet

- SCC - TB - Enu Scia - Esa PT Steel Code CheckDocument265 pagesSCC - TB - Enu Scia - Esa PT Steel Code CheckrwaidaabbasNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document4 pagesGujarat Technological University: W.E.F. AY 2018-19Divyeshkumar MorabiyaNo ratings yet

- Production Technology PDFDocument2 pagesProduction Technology PDFRamana Kumar NarsipuramNo ratings yet

- Abrasive Methods Engineering PDFDocument392 pagesAbrasive Methods Engineering PDFGautam Tyagi100% (2)

- Course ObjectivesDocument5 pagesCourse Objectives75Ujwal TDNo ratings yet

- Fabrication, Characteristics and Analysis of Drill Bits Made of High HRC MaterialsDocument6 pagesFabrication, Characteristics and Analysis of Drill Bits Made of High HRC MaterialsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- BMP - Powder MetallurgyDocument71 pagesBMP - Powder Metallurgymantra2010No ratings yet

- Design and Fabrication of Pneumatic Sheet Metal Cutting MachineDocument38 pagesDesign and Fabrication of Pneumatic Sheet Metal Cutting MachineSiva ForeviewNo ratings yet

- Reference Only: I Pus Pond StreetDocument132 pagesReference Only: I Pus Pond StreetJagdish ShindeNo ratings yet

- Esbm5a-B 1n261-s Aa RSWDocument37 pagesEsbm5a-B 1n261-s Aa RSWChandrajeet Shelke50% (2)

- Vehicle DynamicsDocument4 pagesVehicle DynamicsRaja RamachandranNo ratings yet

- Non Traditional Machining TechniquesDocument4 pagesNon Traditional Machining TechniquesRaja RamachandranNo ratings yet

- Vehicle Body EnggDocument6 pagesVehicle Body EnggRaja RamachandranNo ratings yet

- Thermodynamics - SunilDocument5 pagesThermodynamics - SunilRaja RamachandranNo ratings yet

- Theory of Automotive EnginesDocument7 pagesTheory of Automotive EnginesRaja RamachandranNo ratings yet

- Mechanics of SolidsDocument2 pagesMechanics of SolidsRaja RamachandranNo ratings yet

- Thermodynamics - Sunil PDFDocument5 pagesThermodynamics - Sunil PDFRaja RamachandranNo ratings yet

- Thermodynamics - SunilDocument5 pagesThermodynamics - SunilRaja RamachandranNo ratings yet

- CE1206 Lesson PlanDocument2 pagesCE1206 Lesson PlanRaja RamachandranNo ratings yet

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course PlanRaja RamachandranNo ratings yet

- Machines and MechanismDocument3 pagesMachines and MechanismRaja RamachandranNo ratings yet

- Manufacturing TechnologyDocument7 pagesManufacturing TechnologyRaja RamachandranNo ratings yet

- CE1136 Lesson Plan88Document3 pagesCE1136 Lesson Plan88Raja RamachandranNo ratings yet

- CE1205 Lesson PlanDocument2 pagesCE1205 Lesson PlanRaja RamachandranNo ratings yet

- CE1017 Lesson PlanDocument5 pagesCE1017 Lesson PlanRaja RamachandranNo ratings yet

- CE1017 Lesson PlanDocument5 pagesCE1017 Lesson PlanRaja RamachandranNo ratings yet

- CE1020 Lesson Plan333Document2 pagesCE1020 Lesson Plan333zaidNo ratings yet

- Sources and Types of Municipal Solid WastesDocument2 pagesSources and Types of Municipal Solid WastesRaja RamachandranNo ratings yet

- Sources and Types of Municipal Solid WastesDocument2 pagesSources and Types of Municipal Solid WastesRaja RamachandranNo ratings yet

- CE1017 Lesson Plan18Document3 pagesCE1017 Lesson Plan18Raja RamachandranNo ratings yet

- CE1006 Lesson Plan7Document2 pagesCE1006 Lesson Plan7Raja RamachandranNo ratings yet

- Lesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Document3 pagesLesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Raja RamachandranNo ratings yet

- CE1008 Lesson PlanDocument3 pagesCE1008 Lesson PlanRaja RamachandranNo ratings yet

- CE1006 Lesson PlanDocument2 pagesCE1006 Lesson PlanRaja RamachandranNo ratings yet

- Lesson 1493762094Document1 pageLesson 1493762094Raja RamachandranNo ratings yet

- CE1008 Lesson PlanDocument3 pagesCE1008 Lesson PlanRaja RamachandranNo ratings yet

- Faculty Name: Sucheta Panda: Total Number of Hours 48Document1 pageFaculty Name: Sucheta Panda: Total Number of Hours 48Raja RamachandranNo ratings yet

- CE1006 Lesson PlanDocument2 pagesCE1006 Lesson PlanRaja RamachandranNo ratings yet

- Lesson 1493761977Document1 pageLesson 1493761977santhi saranyaNo ratings yet

- Lesson Plan Branch-Mca 3 Semester Operating SystemDocument1 pageLesson Plan Branch-Mca 3 Semester Operating Systemsanthi saranyaNo ratings yet

- Is 402 Pipe BuoyancyDocument3 pagesIs 402 Pipe BuoyancyDGWNo ratings yet

- 1.2 Statement of ProblemDocument1 page1.2 Statement of Problemyonas DestaNo ratings yet

- Separator 01dyDocument44 pagesSeparator 01dyFadhil KhalidNo ratings yet

- Evaporation EvaporatorsDocument11 pagesEvaporation EvaporatorsOhad CazesNo ratings yet

- Solved SAILMT Exam Paper For Mechanical EngineerDocument12 pagesSolved SAILMT Exam Paper For Mechanical EngineerSudeesh BabuNo ratings yet

- 50 MCQ Engineering Mechanics PDFDocument8 pages50 MCQ Engineering Mechanics PDFAntonette LimNo ratings yet

- TALAT Lecture 3501: Alloys and PropertiesDocument8 pagesTALAT Lecture 3501: Alloys and PropertiesCORE MaterialsNo ratings yet

- 09 - Telecommunication CablesDocument45 pages09 - Telecommunication CablesmlutfimaNo ratings yet

- MIL-PRF-81309 REV. H - Part17Document1 pageMIL-PRF-81309 REV. H - Part17David WongNo ratings yet

- TL - 52337 (2015)Document8 pagesTL - 52337 (2015)Chloe ReyesNo ratings yet

- Ratliperl: The Modern Solution For Energy Efficient BuildingDocument18 pagesRatliperl: The Modern Solution For Energy Efficient BuildingAdhil Ramsurup100% (1)

- SFSP Profile Catalogue 2019Document45 pagesSFSP Profile Catalogue 2019imranNo ratings yet

- DD Folio p01170 CC TuxpanDocument102 pagesDD Folio p01170 CC TuxpanErnesto VazquezNo ratings yet

- Canpolat 2004 PDFDocument5 pagesCanpolat 2004 PDFIsha PatelNo ratings yet

- Mapefloor FC 200 ME: High Build Epoxy Resin Floor CoatingDocument4 pagesMapefloor FC 200 ME: High Build Epoxy Resin Floor Coatingdiv_bamaniaNo ratings yet

- YALE (C878) GDP155VX LIFT TRUCK Service Repair Manual PDFDocument20 pagesYALE (C878) GDP155VX LIFT TRUCK Service Repair Manual PDFfjskekdmmemNo ratings yet

- Alfa Laval Unique RV P Pneumatic Regulating Valve Instruction Manual Ese02801enDocument32 pagesAlfa Laval Unique RV P Pneumatic Regulating Valve Instruction Manual Ese02801enRobert MoreiraNo ratings yet

- Manual Gavita Pro 750e - 1000e de EU V15-51 HRDocument8 pagesManual Gavita Pro 750e - 1000e de EU V15-51 HRwhazzup6367No ratings yet

- Asme GT2005-68799 PDFDocument9 pagesAsme GT2005-68799 PDFJeeEianYannNo ratings yet

- BS 709Document17 pagesBS 709vuthuy94No ratings yet

- RODocument10 pagesROShahrooz Leo QureshiNo ratings yet

- US5518537Document5 pagesUS5518537Marm246247 AlloyNo ratings yet

- 141 000 Mi CN MST 0089Document33 pages141 000 Mi CN MST 0089Mehmet AtabayNo ratings yet

- EIA923 Schedules 2 3 4 5 M 12 2016 Early ReleaseDocument31 pagesEIA923 Schedules 2 3 4 5 M 12 2016 Early ReleaseMaria Saucedo SanchezNo ratings yet

- GUS Trash Feasibility StudyDocument504 pagesGUS Trash Feasibility StudyDaily FreemanNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocument20 pagesUniversity of Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456No ratings yet

- Flexpipe PDS FlexCord EnglishDocument2 pagesFlexpipe PDS FlexCord EnglishpsycopaulNo ratings yet

- RPCP PDFDocument2 pagesRPCP PDFmhafizanNo ratings yet

- K-PRIX Means The Combination of Quality, Cost and Service..Document10 pagesK-PRIX Means The Combination of Quality, Cost and Service..M. AguiarNo ratings yet

- Eaton 91PS and 93PS UPSDocument2 pagesEaton 91PS and 93PS UPSALEXNo ratings yet