Professional Documents

Culture Documents

Lesson Plan Subject Name-Robotics and Flexible Manufacturing Systems Branch-Production Engineering Subject Code-BPE 2802 Semester - 8

Uploaded by

Raja RamachandranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lesson Plan Subject Name-Robotics and Flexible Manufacturing Systems Branch-Production Engineering Subject Code-BPE 2802 Semester - 8

Uploaded by

Raja RamachandranCopyright:

Available Formats

LESSON PLAN

Subject Name-Robotics And Flexible Branch- Production Engineering

Manufacturing Systems

Subject Code-BPE 2802 Semester- 8th

Period/

S/N Module Topic(s)

Hours

Robot fundamentals: definitions, history of robots, laws of

1. I 1

robots, robot specification, anatomy of robot

Robot classification, function line diagram representation of

2. I 2-3

robot arms, common types of arms.

Robot end effectors- Types, Tools as end

3. I 4

effectors,consideration in gripper selection and design.

Robot application in manufacturing-Material transfer-Material

4. I handling, loading and unloading, processing-spot and 5-6

continuous arc welding and spray painting.

Manipulator Kinematics- Homogenous coordinate

5. I transformation,D-H representation of kinematics linkages, 7-9

Forward and inverse kinematics of manipulators, Euler’s angle.

6. I Differential transformation and manipulators, Jacobians. 10

Robotics Dynamics: velocity kinematics, acceleration of rigid

7. II body, Lagrange Euler formulation. Robot actuators and sensors, 11-13

internal and external sensors.

Position –potentiometric, Optical sensors, Encoders-absolute,

8. II 14

incremental touch and slip sensors

Velocity acceleration sensors, Proximity sensors, force and

9. II 15

torque sensors.

Actuators- Hydraulic, Pneumatic and electrical, comparison of

10. II 16-18

actuating systems and their relative merits and demerits.

Robot Controllers: open and close loop control, manipulator

11. III 19

control problem, linear control

PD and PID control schemes, force and torque control in

12. III 20-23

robotic manipulators.

Robot Programming: Textual and lead through WAIT,

13. III 24

SIGNALand DELAY commands.

Capabilities and limitations of leadthrough programming, robot

14. III 25-27

language structure.

Motion, sensors and end efforts commands, Programming

15. III 28

examples.

Period/

S/N Module Topic(s)

Hours

Flexible manufacturing systems: types of production,

16. IV 29-31

characteristics, applications, Flexibility in machining systems.

Need for FMS, Flexible automation, where to apply FMS

17. IV 32

technology.

Components of FMS- FMS layout configuration, Planning the

18. IV FMS, workstations, Material Handling System, Automation 33-36

Guided Vehicle systems.

Automated storage and retrieval systems, FMS layout

19. IV 37-39

configurations.

Application and benefits of FMS, problems in implementing

20. IV 40

FMS.

You might also like

- ME8099 Notes QBDocument131 pagesME8099 Notes QBOnline EarnNo ratings yet

- RoboticsDocument2 pagesRoboticsvasanthsatNo ratings yet

- Unit 1Document5 pagesUnit 1N Dhanunjaya Rao BorraNo ratings yet

- Me 2028 Robotics With QBDocument141 pagesMe 2028 Robotics With QBCody LeeNo ratings yet

- CDM ME 464 Robotics and Automation-2022Document17 pagesCDM ME 464 Robotics and Automation-2022Tony K PaulNo ratings yet

- OIE751 Robotics SyllabusDocument1 pageOIE751 Robotics SyllabusmohanmzcetNo ratings yet

- IR SyllabusDocument1 pageIR Syllabusyallasanjay1No ratings yet

- Robotics NotesDocument61 pagesRobotics NotesMech HoD DAITNo ratings yet

- Syllabus - RobaticsDocument2 pagesSyllabus - RobaticsSatheesh KumarNo ratings yet

- Robotics SyllabusDocument1 pageRobotics SyllabusdsathiyaNo ratings yet

- Robotics SyllubusDocument1 pageRobotics SyllubusSubramaniyan MahendiranNo ratings yet

- RoboticsDocument1 pageRoboticstagoreboopathyNo ratings yet

- MME 1366: Robotics Credits: 3 LTP 300Document2 pagesMME 1366: Robotics Credits: 3 LTP 300virender gurauNo ratings yet

- ME MinDocument1 pageME Minvhema prasadNo ratings yet

- Me 2028 Robotics With QBDocument133 pagesMe 2028 Robotics With QBDharmendra Kumar0% (1)

- ME809 9 Robotics LT PC: Anna University, Chennai Affiliated Institutions B.E. Mechanical Engineering Regulations - 2017Document2 pagesME809 9 Robotics LT PC: Anna University, Chennai Affiliated Institutions B.E. Mechanical Engineering Regulations - 2017Mech HoD DAITNo ratings yet

- MEE3014 - ROBOTICS-AND-AUTOMATION - LT - 1.0 - 1 - Robotics and AutomationDocument3 pagesMEE3014 - ROBOTICS-AND-AUTOMATION - LT - 1.0 - 1 - Robotics and AutomationInzamam Ul HaqueNo ratings yet

- Robotics & Autotronics Course Code: 3361108Document8 pagesRobotics & Autotronics Course Code: 3361108venkatesh naniNo ratings yet

- Principles of RoboticsDocument13 pagesPrinciples of RoboticsMahendran MahiNo ratings yet

- Robotics and Automation - Question Bank EC6003Document18 pagesRobotics and Automation - Question Bank EC6003jaiganeshNo ratings yet

- X04-Industrial Robot Programming - Lab ManualDocument9 pagesX04-Industrial Robot Programming - Lab ManualMahesh Nvsr BNo ratings yet

- Intelligence, Mcgraw-Hill International Editions. Robotics: Technology, Programming, and Applications, Mcgraw-Hill InternationalDocument3 pagesIntelligence, Mcgraw-Hill International Editions. Robotics: Technology, Programming, and Applications, Mcgraw-Hill InternationalAKSHAY KRISHNA K RNo ratings yet

- 12p602 Robotics and Machine Vision System SyllabusDocument2 pages12p602 Robotics and Machine Vision System Syllabusmskumar_5540% (1)

- Industrial RobotDocument14 pagesIndustrial RobotAbdo HeshamNo ratings yet

- Sílabo Por Competencias Robotics & Control System 2019 - II: Universidad Nacional José Faustino Sánchez CarriónDocument11 pagesSílabo Por Competencias Robotics & Control System 2019 - II: Universidad Nacional José Faustino Sánchez CarriónJhonyNo ratings yet

- EC368 RoboticsDocument3 pagesEC368 RoboticsHello123No ratings yet

- EC368 RoboticsDocument3 pagesEC368 RoboticsKrishnakumar KattarakunnuNo ratings yet

- EC368 RoboticsDocument3 pagesEC368 RoboticsBonifus Parambaloth LeenusNo ratings yet

- rOBOTICS NOTESDocument14 pagesrOBOTICS NOTESdsathiya100% (4)

- Course Objectives:: RoboticsDocument2 pagesCourse Objectives:: RoboticsPRAVEeNo ratings yet

- Unit 1Document100 pagesUnit 1apakkiNo ratings yet

- Position Control of 3-DOF Articulated Robot Arm Using PID ControllerDocument7 pagesPosition Control of 3-DOF Articulated Robot Arm Using PID ControllerJoker JkNo ratings yet

- Subject: Metrology and Measurements Class: Iv B.Tech-Isem (R13) Name of The Staff: M.Nagakiran Department: M.EDocument2 pagesSubject: Metrology and Measurements Class: Iv B.Tech-Isem (R13) Name of The Staff: M.Nagakiran Department: M.EkannakumarNo ratings yet

- Robotics R19 Iv Year Sem-IDocument3 pagesRobotics R19 Iv Year Sem-IShubham SomwanshiNo ratings yet

- Robotic Arm Dynamic and Simulation With Virtual Re PDFDocument7 pagesRobotic Arm Dynamic and Simulation With Virtual Re PDFALA SOUISSINo ratings yet

- R&A Module 1ADocument78 pagesR&A Module 1ANagaraj BhatNo ratings yet

- 01 Robotics Applications, Components and SpecificationsDocument25 pages01 Robotics Applications, Components and SpecificationsAbdallah AkrabNo ratings yet

- Question Bank RoboticsDocument4 pagesQuestion Bank RoboticslakshmigsrNo ratings yet

- Me Robotics With QB - by Civildatas - Com 1Document61 pagesMe Robotics With QB - by Civildatas - Com 1Pavan KumarNo ratings yet

- Robot ArmDocument13 pagesRobot ArmDevvrat DixitNo ratings yet

- Industrial Robotics MCT 455Document39 pagesIndustrial Robotics MCT 455mohameed ahmedNo ratings yet

- Mechanical Engineering Department Subject - (Code - Semester - Vi Credit-5 Periods/week (L+T+P) 4-1-0 Total Marks in End Semester-70Document1 pageMechanical Engineering Department Subject - (Code - Semester - Vi Credit-5 Periods/week (L+T+P) 4-1-0 Total Marks in End Semester-70Dr Shubhashis SnyalNo ratings yet

- FRM Course Syllabus IPDownloadDocument2 pagesFRM Course Syllabus IPDownloadVivek KumarNo ratings yet

- Ee429 Programmable Logic Controllers (Dept. Elective - IV) : Course Description & ObjectivesDocument1 pageEe429 Programmable Logic Controllers (Dept. Elective - IV) : Course Description & Objectivespilotvivek1087No ratings yet

- Robotics - PresentationDocument57 pagesRobotics - PresentationAnonymous YkDJkSqNo ratings yet

- Department of Technical EducationDocument10 pagesDepartment of Technical EducationNIKHIL ASNo ratings yet

- Robotics MainDocument2 pagesRobotics MainrijuNo ratings yet

- A Review of Application Industrial RoboticDocument8 pagesA Review of Application Industrial RoboticHafidz AkbarNo ratings yet

- RoboticsDocument394 pagesRoboticsPeter Nomikos100% (5)

- IC6003-Principles of RoboticsDocument15 pagesIC6003-Principles of Roboticsrajemtech100% (1)

- ScaraDocument9 pagesScaraSalvatore VillaniNo ratings yet

- Color Based 6 DOF Sorting Robot With Real-Time Object DetectionDocument3 pagesColor Based 6 DOF Sorting Robot With Real-Time Object DetectionAli AzharNo ratings yet

- Robotics and Automation Notes NewDocument117 pagesRobotics and Automation Notes NewKALAIVANINo ratings yet

- Robotics Lesson PlanDocument2 pagesRobotics Lesson PlanMonica CarrollNo ratings yet

- Robotics - Automation-Question BankDocument10 pagesRobotics - Automation-Question BankMansi PatelNo ratings yet

- Advances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFrom EverandAdvances in Motion Sensing and Control for Robotic Applications: Selected Papers from the Symposium on Mechatronics, Robotics, and Control (SMRC’18)- CSME International Congress 2018, May 27-30, 2018 Toronto, CanadaFarrokh Janabi-SharifiNo ratings yet

- Industrial Process Automation Systems: Design and ImplementationFrom EverandIndustrial Process Automation Systems: Design and ImplementationRating: 4 out of 5 stars4/5 (10)

- Thermodynamics - Sunil PDFDocument5 pagesThermodynamics - Sunil PDFRaja RamachandranNo ratings yet

- Vehicle Body EnggDocument6 pagesVehicle Body EnggRaja RamachandranNo ratings yet

- Vehicle DynamicsDocument4 pagesVehicle DynamicsRaja RamachandranNo ratings yet

- Thermodynamics - SunilDocument5 pagesThermodynamics - SunilRaja RamachandranNo ratings yet

- Theory of Automotive EnginesDocument7 pagesTheory of Automotive EnginesRaja RamachandranNo ratings yet

- Non Traditional Machining TechniquesDocument4 pagesNon Traditional Machining TechniquesRaja RamachandranNo ratings yet

- Thermodynamics - SunilDocument5 pagesThermodynamics - SunilRaja RamachandranNo ratings yet

- CE1136 Lesson Plan88Document3 pagesCE1136 Lesson Plan88Raja RamachandranNo ratings yet

- Lesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Document3 pagesLesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Raja RamachandranNo ratings yet

- Manufacturing TechnologyDocument7 pagesManufacturing TechnologyRaja RamachandranNo ratings yet

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course PlanRaja RamachandranNo ratings yet

- Machines and MechanismDocument3 pagesMachines and MechanismRaja RamachandranNo ratings yet

- Mechanics of SolidsDocument2 pagesMechanics of SolidsRaja RamachandranNo ratings yet

- CE1205 Lesson PlanDocument2 pagesCE1205 Lesson PlanRaja RamachandranNo ratings yet

- CE1206 Lesson PlanDocument2 pagesCE1206 Lesson PlanRaja RamachandranNo ratings yet

- Sources and Types of Municipal Solid WastesDocument2 pagesSources and Types of Municipal Solid WastesRaja RamachandranNo ratings yet

- Sources and Types of Municipal Solid WastesDocument2 pagesSources and Types of Municipal Solid WastesRaja RamachandranNo ratings yet

- CE1017 Lesson PlanDocument5 pagesCE1017 Lesson PlanRaja RamachandranNo ratings yet

- CE1020 Lesson Plan333Document2 pagesCE1020 Lesson Plan333zaidNo ratings yet

- CE1008 Lesson PlanDocument3 pagesCE1008 Lesson PlanRaja RamachandranNo ratings yet

- CE1017 Lesson PlanDocument5 pagesCE1017 Lesson PlanRaja RamachandranNo ratings yet

- CE1017 Lesson Plan18Document3 pagesCE1017 Lesson Plan18Raja RamachandranNo ratings yet

- CE1008 Lesson PlanDocument3 pagesCE1008 Lesson PlanRaja RamachandranNo ratings yet

- Lesson 1493762094Document1 pageLesson 1493762094Raja RamachandranNo ratings yet

- Lesson 1493761977Document1 pageLesson 1493761977santhi saranyaNo ratings yet

- CE1006 Lesson PlanDocument2 pagesCE1006 Lesson PlanRaja RamachandranNo ratings yet

- CE1006 Lesson Plan7Document2 pagesCE1006 Lesson Plan7Raja RamachandranNo ratings yet

- CE1006 Lesson PlanDocument2 pagesCE1006 Lesson PlanRaja RamachandranNo ratings yet

- Faculty Name: Sucheta Panda: Total Number of Hours 48Document1 pageFaculty Name: Sucheta Panda: Total Number of Hours 48Raja RamachandranNo ratings yet

- Lesson Plan Branch-Mca 3 Semester Operating SystemDocument1 pageLesson Plan Branch-Mca 3 Semester Operating Systemsanthi saranyaNo ratings yet

- Rediscovery' Revised - The Cooperation of Erich and Armin Von Tschermak-Seysenegg in The Context of The Rediscovery' of Mendel's Laws in 1899-1901Document7 pagesRediscovery' Revised - The Cooperation of Erich and Armin Von Tschermak-Seysenegg in The Context of The Rediscovery' of Mendel's Laws in 1899-1901lacisagNo ratings yet

- Calibrating Images TutorialDocument14 pagesCalibrating Images TutorialtrujillomadrigalNo ratings yet

- A Guide To Maintenance Metrics-ProgramDocument5 pagesA Guide To Maintenance Metrics-ProgramLy QuanNo ratings yet

- Chemistry Lab ReportDocument9 pagesChemistry Lab Reportapi-327824087No ratings yet

- DP16B Bench Drill PressDocument20 pagesDP16B Bench Drill Pressalfri7370% (1)

- Dave Graham Literature CatalogDocument640 pagesDave Graham Literature CatalogPierce PetersonNo ratings yet

- Required Obstacle ClearanceDocument14 pagesRequired Obstacle ClearancePero PericNo ratings yet

- 10 To 11-ClassDocument111 pages10 To 11-ClassVikaas SagerNo ratings yet

- CP Lithium Ion BatteriesDocument4 pagesCP Lithium Ion BatteriesvaseemalikhanNo ratings yet

- Flood RateDocument367 pagesFlood RatetpktpkNo ratings yet

- PIANC SMART Rivers Proceedings OkDocument190 pagesPIANC SMART Rivers Proceedings OkMartin PrietoNo ratings yet

- Infant of A Diabetic MotherDocument17 pagesInfant of A Diabetic MotherLovina Falendini AndriNo ratings yet

- Vivo X5Pro Smartphone Specifications: Brand and ModelDocument4 pagesVivo X5Pro Smartphone Specifications: Brand and ModelEric AndriantoNo ratings yet

- KIN-CN-STU-NW-0001 Puerto Real Towing Study of Kincardine 04Document44 pagesKIN-CN-STU-NW-0001 Puerto Real Towing Study of Kincardine 04RUBEN BARTOLOME GARCIA100% (1)

- Cbse Class 6 Science Notes Chapter 13Document4 pagesCbse Class 6 Science Notes Chapter 13rohinimr007No ratings yet

- Lake Superior RoadmapDocument2 pagesLake Superior RoadmapWDIV/ClickOnDetroitNo ratings yet

- AdsfatreewerwertgdsfDocument1 pageAdsfatreewerwertgdsfJhonel AguilarNo ratings yet

- C-81-9903-17-82 Halal 100g 2024-06-08Document1 pageC-81-9903-17-82 Halal 100g 2024-06-08NURUL FAUZANY BINTI MOHD BASARUDDINNo ratings yet

- Journal of Environmental Management: Ajay Singh TDocument7 pagesJournal of Environmental Management: Ajay Singh TNestor Garay CahuanaNo ratings yet

- Aspirating Smoke Detector: Technical DescriptionDocument115 pagesAspirating Smoke Detector: Technical DescriptionSecuriton ArgentinaNo ratings yet

- Review of Henry Vyverberg, Historical Pessimism in The French EnlightenmentDocument4 pagesReview of Henry Vyverberg, Historical Pessimism in The French EnlightenmentRalph EllectualNo ratings yet

- Measuring Salinity in Crude Oils Evaluation of MetDocument9 pagesMeasuring Salinity in Crude Oils Evaluation of Metarmando fuentesNo ratings yet

- Renal New Growth - NCM 103 - or CaseDocument19 pagesRenal New Growth - NCM 103 - or CasePat EnriquezNo ratings yet

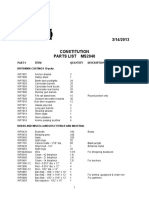

- MS2040 Constitution Parts ListDocument6 pagesMS2040 Constitution Parts ListTemptationNo ratings yet

- StringTokenizer in JavaDocument11 pagesStringTokenizer in JavaNeha saxena Neha saxenaNo ratings yet

- Unit-3: Grid FrameworkDocument44 pagesUnit-3: Grid FrameworkMUKESH KUMAR P 2019-2023 CSENo ratings yet

- Comparative Superlative With Key PDFDocument1 pageComparative Superlative With Key PDFAnonymous 8AHCMsPuNo ratings yet

- Annals of The New York Academy of Sciences - 2023 - Hess - Accelerating Action To Reduce Anemia Review of Causes and RiskDocument13 pagesAnnals of The New York Academy of Sciences - 2023 - Hess - Accelerating Action To Reduce Anemia Review of Causes and RiskIdmNo ratings yet

- Smart City Scheme GuidelinesDocument48 pagesSmart City Scheme GuidelinesKarishma Juttun100% (1)

- Part PabrikDocument2 pagesPart PabrikNaldy NaldyNo ratings yet