Professional Documents

Culture Documents

Plumbing Code Ans

Uploaded by

Helena May Isaac0 ratings0% found this document useful (0 votes)

13 views2 pagesanswer key

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentanswer key

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views2 pagesPlumbing Code Ans

Uploaded by

Helena May Isaacanswer key

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

PLUMBING CODE

1. c. Rain water 63. –

2. c. Plumbarius 64. b. Continuous vent

3. c. Common vent 65. d. Water tight

4. c. Solid waste 66. a. The vertical main soil, waste or vent

5. a. Main sewer piping

6. c. Back pressure 67. a. Plumbing system

7. d. Maximum demand 68. b. 3 working days

8. a. 3 in 69. b. Continuous waste

9. c. 10 ft head for 15 minutes 70. c. 15 psi

10. c. Pressure 71. a. 80 psi

11. b. 150% of used water pressure 72. d. Rough piping inspection

12. b. Water 73. b. Fixture

13. – 74. b. Full gate valve

14. b. 8.0 psi 75. c. ASTM

15. d. Water meter 76. c. Combination Y and 1/8 bend

16. b. Full way gate valve 77. c. Pressure relief valve

17. c. Aluminum 78. d. ½ inch

18. b. Building drain 79. c. January 28, 1959

19. d. Plumbing code 80. a. House sewer

20. b. Corporation stop 81. d. Two

21. c. Pump circuit system 82. b. Flanges

22. d. 10 ft head 83. c. Four

23. c. Water pump 84. –

24. c. 2 gallons 85. B. Will increase the venting efficiently,

thus preventing from backflow

25. a. Foot valve 86. a. 5 ft

26. b. Service pipe 87. a. 3 ½ inches

27. d. Globe valve 88. B. 12 inches

28. a. 1 89. b. 1 gallon

29. – 90. a. 0.60

30. c. Stand pipe 91. a. Blue

31. c. Lavatory 92. b. Seal

32. c. March 93. a. 3 ft

33. c. Fire Code 94. c. Blank drill

34. c. Fire hose 95. b. Clarifier

35. d. Water pipe 96. b. Gas and water

36. d. Ventilation 97. d. 200

37. a. Aeration 98. a. 3

38. a. 2” 99. a. AIPMO

39. a. 30 100. b. 16

40. b. 2% 101. c. 15

41. b. 30 liters 102. c. 1935

42. b. 3 inches 103. c. Terminated

43. b. 3 104. b. 75

44. d. 50 mm 105. c. 15

45. a. 32-38 mm 106. b. Atmospheric Vacuum Breaker

46. a. 32 mm 107. a. 25 mm

47. b. 2 108. b. Float valve

48. a. 1 109. b. 2

49. b. 4 110. a. 25.4

50. – 111. d. 0.008

51. b. 4 ft 112. b. Commercial Standards and

52. a. 7.5 gpm Product Standards

53. a. Vents 113. b. Corporation cock

54. d. Total fixture units 114. a. 1 meter

55. c. 3 115. d. 0.45

56. c. 10 ft for 15 mins 116. b. Ball cock

57. a. Plumbing Code 117. b. 57 mm

58. a. Ejector 118. b. 152

59. a. Force 119. b. 2

60. a. Reynolds number 120. b. Flood level

61. – 121. c. Caulking

62. d. ¼ inch per foot 122. d. Butterfly valve

PLUMBING CODE

123. d. Lateral 184. b. 3 ½ inches

124. a. Water main 185. b. Lowest to the highest point

125. d. Service pipe 186. c. Exposed fixture supply

126. a. Waste pipe 187. b. Sewer

127. a. Neoprene rubber sleeves 188. d. 8 percent

128. a. 0.90 189. b. No

129. – 190. c. One year

130. c. 3.00 191. b. Ball cock

131. a. 120 192. d. Soil pipe

132. b. 1.8 193. c. DWV system

133. a. 0.60 194. a. House sewer

134. c. 344.5 195. c. Regulating Equipment

135. – 196. a. 25 ga

136. b. 152 197. a. Insanitary

137. b. 80 198. b. Six

138. b. Air break 199. c. Control valve

139. a. 0.60 200. d. Horizontal pipe

140. c. 305 mm 201. –

141. d. Battery of fixtures 202. d. Drainage, waste and vent

142. b. RA 1364 203. d. 24 inches wide

143. a. ½ 204. d. Public or Private sewer

144. d. Tapped tee 205. b. 20 psi

145. c. Squat type 206. d. Infiltration

146. a. Privy 207. b. The inlet connection of the

147. c. PD 856 appliance

148. b. Soldering 208. b. Gallons per minutes

149. b. Ferrule 209. b. Sump

150. a. 100 / 102 AS PER RNPCP 210. a. May exceed the maximum horizontal

length limited by code

151. c. Continuous vent 211. a. P 5.00

152. a. Storm water drainage piping 212. b.House sewer

153. a. Fixture unit 213. a. 15 m

214. d.Dry standpipe

154. b. Lavatory 215. c. 6”

155. c. Private sewage disposal system 216. b.80 psi

156. a. Excessive water pressure 217. b.85%

218. b.Flush valve

157. c. Back pressure 219. d.Invert

158. a. Health officer 220. d.4 ft

159. a. Health officer 221. a. Building

222. a. Header

160. a. Plumbing system 223. b.Durham System

161. c. 3/8 diameter 224. a. 4”

162. c. 36 hrs 225. b.Residual Pressure

163. b. Air gap (connection) 226. b.Offset

227. a. Court

164. a. Vertical distance 228. b.Cesspool

165. b. Continuous waste 229. b.Receptor

166. d. Bushing 230. d.Pressure

231. a. Pollution

167. - 232. c. PE or Polyethylene

168. a. Gutter 233. a. 1999

169. c. Fitting & Adapter 234. b.2

235. b.John F. Hass

170. a. Routine inspection 236. a. PVB or Pressure Vacuum Breaker Backflow

171. c. Installed without joints where Prevention Assembly

possible 237. c. 4

238. a. December 21,1999

172. d. 40 psi 239. c. City Ordinance 2411

173. – 240. a. 6

174. b. P 5.00 241. c. June 18, 1955

242. a. Flared joints

175. d. Storm sewer 243. c. January 28,1959

176. d. 10 ft 244. a. 1

177. a. Laminar flow 245. b.17th Century

246. c. 1954

178. b. 1 inch 247. a. 32 mm

179. a. Testing laboratory 248. d.51

180. d. Within a building 249. b.45 degree ; 1/8 bend

250. b.50%

181. a. Caulking 251. b.508 mm

182. a. Scupper 252. a. 14.4 kPa

183. b. Cast Iron

You might also like

- The Philippine Administrative System: (PAS) : Its Components and Power BaseDocument21 pagesThe Philippine Administrative System: (PAS) : Its Components and Power BaseHelena May IsaacNo ratings yet

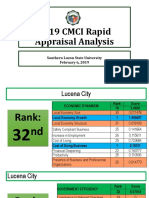

- 4a CMCI Strengths and Weaknesses (Cities, 1st and 2nd Class)Document77 pages4a CMCI Strengths and Weaknesses (Cities, 1st and 2nd Class)Helena May IsaacNo ratings yet

- RDO No. 61 - Gumaca, South QuezonDocument909 pagesRDO No. 61 - Gumaca, South QuezonHelena May Isaac100% (3)

- ELA Form 1Document1 pageELA Form 1Helena May IsaacNo ratings yet

- Pre-ELA Workshop MatrixDocument3 pagesPre-ELA Workshop MatrixHelena May IsaacNo ratings yet

- Updating of CDP MaputatDocument6 pagesUpdating of CDP MaputatHelena May IsaacNo ratings yet

- History of the Barangay - Understanding the Past and Present of Philippine CommunitiesDocument13 pagesHistory of the Barangay - Understanding the Past and Present of Philippine CommunitiesHelena May IsaacNo ratings yet

- Developing a Conceptual Framework for Construction Constraint ManagementDocument3 pagesDeveloping a Conceptual Framework for Construction Constraint ManagementramszlaiNo ratings yet

- Conceptual Industry Map of Negros Oriental Tourism Support ServicesDocument1 pageConceptual Industry Map of Negros Oriental Tourism Support ServicesHelena May IsaacNo ratings yet

- Project Development and Management TrainingDocument34 pagesProject Development and Management TrainingHelena May IsaacNo ratings yet

- Research Proposal TemplateDocument16 pagesResearch Proposal TemplatejacobnyandegaNo ratings yet

- Rationale Target Date Activities For October For 4th CallDocument8 pagesRationale Target Date Activities For October For 4th CallHelena May IsaacNo ratings yet

- Memo To CHs and MLGOOsDocument1 pageMemo To CHs and MLGOOsHelena May IsaacNo ratings yet

- Rationale Target Date Activities For October For 4th CallDocument8 pagesRationale Target Date Activities For October For 4th CallHelena May IsaacNo ratings yet

- MATH & ENG ECO GENERAL EVALUATION EXAMDocument22 pagesMATH & ENG ECO GENERAL EVALUATION EXAMJustinMendiolaNo ratings yet

- Action Plan Template - UMP QuezonDocument1 pageAction Plan Template - UMP QuezonHelena May IsaacNo ratings yet

- Plumbing Abbreviations, Definitions and SymbolsDocument15 pagesPlumbing Abbreviations, Definitions and SymbolsWahib Tannoury100% (1)

- Practical Prob AnsDocument2 pagesPractical Prob AnsHelena May IsaacNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Green Accounting 1Document41 pagesGreen Accounting 1Rahul AroraNo ratings yet

- Benefits of HobbiesDocument13 pagesBenefits of HobbiesKiruthik VarshanNo ratings yet

- 2013 Trane Tall Floor CN r22Document4 pages2013 Trane Tall Floor CN r22Juanjo GarcíaNo ratings yet

- Specification For Highway Works - Series 600 EarthworksDocument75 pagesSpecification For Highway Works - Series 600 EarthworksMark CampbellNo ratings yet

- Ministry of Environment, Forest and Climate ChangeDocument25 pagesMinistry of Environment, Forest and Climate ChangeKuhu DhingraNo ratings yet

- Global Pollution AssignmentDocument5 pagesGlobal Pollution AssignmentAthirah ShafiqueNo ratings yet

- Unit Test 4: Answer All Thirty Questions. There Is One Mark Per QuestionDocument3 pagesUnit Test 4: Answer All Thirty Questions. There Is One Mark Per QuestionNguyên Nguyễn0% (1)

- Osram SylvaniaDocument212 pagesOsram SylvaniaAlejandro Márquez100% (1)

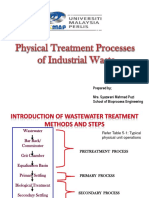

- Chapter 3 - Physical Treatment Processes of Industrial Waste-1Document65 pagesChapter 3 - Physical Treatment Processes of Industrial Waste-1Nasirah RadziNo ratings yet

- Belt Conveyor by Alok VardhanDocument30 pagesBelt Conveyor by Alok VardhanLOKENDRA9150% (2)

- List of Mining Books PDFDocument34 pagesList of Mining Books PDFkumar mandeoNo ratings yet

- Maintain and test UPS batteriesDocument2 pagesMaintain and test UPS batteriesAnas MemonNo ratings yet

- Gas Chlorine StationsDocument46 pagesGas Chlorine StationsakramhomriNo ratings yet

- MarchDocument70 pagesMarchdexter1850No ratings yet

- Maintain Training Facilities Comcok NC IiiDocument21 pagesMaintain Training Facilities Comcok NC IiiMylina FabiNo ratings yet

- Syllabus-PULP & PAPER TECHNOLOGYDocument5 pagesSyllabus-PULP & PAPER TECHNOLOGYVijai B RaghavanNo ratings yet

- BERDE+FOR+EXISTING+BUILDINGS+V1 0dfDocument127 pagesBERDE+FOR+EXISTING+BUILDINGS+V1 0dfpatNo ratings yet

- Appendix A Generic Checklist For GLP/G P Inspections/AuditsDocument9 pagesAppendix A Generic Checklist For GLP/G P Inspections/AuditsCaecilia Jessica UnarsoNo ratings yet

- Carlito RRLSDocument10 pagesCarlito RRLSCarlito SatsatinNo ratings yet

- Liberty Dining Scholarship Paper Suggests Composting and Employee EventsDocument2 pagesLiberty Dining Scholarship Paper Suggests Composting and Employee EventsLayna WebbNo ratings yet

- Effective Classroom Seating Arrangements: Search by Keyword or SKUDocument11 pagesEffective Classroom Seating Arrangements: Search by Keyword or SKUJoseph villatoroNo ratings yet

- Design of Sewage Treatment Plants CourseDocument56 pagesDesign of Sewage Treatment Plants CourseChanel100% (1)

- PWA Personnel Policies and Procedures ManualDocument31 pagesPWA Personnel Policies and Procedures ManualRecordTrac - City of OaklandNo ratings yet

- Tokyo 2020 Olympics impacts on city planning, economy, society and environmentDocument2 pagesTokyo 2020 Olympics impacts on city planning, economy, society and environmentF1sh YuNo ratings yet

- 12 Biology ImpQ CH10 Microbes in Human WelfareDocument7 pages12 Biology ImpQ CH10 Microbes in Human WelfarekeerthyNo ratings yet

- Pharmaceuticals As Pollutants: A Threat For Pharmacy ProfessionDocument9 pagesPharmaceuticals As Pollutants: A Threat For Pharmacy ProfessionAndrei BohotineanuNo ratings yet

- Rio de Janeiro Climate Change Case StudyDocument22 pagesRio de Janeiro Climate Change Case StudyCharlesLaffiteauNo ratings yet

- Procedures - Sharps Management and Injury ProtocolDocument6 pagesProcedures - Sharps Management and Injury ProtocolMarwan GamaleldinNo ratings yet

- COOKERY 11, W1, Module 3Document12 pagesCOOKERY 11, W1, Module 3Lea Lee BaudingNo ratings yet