Professional Documents

Culture Documents

Glass Concrete

Uploaded by

Fernando RosalesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glass Concrete

Uploaded by

Fernando RosalesCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/257938067

Recycled Glass Concrete

Article in Concrete International · January 2013

CITATIONS READS

3 2,530

3 authors, including:

Amirpasha Peyvandi Roz-Ud-Din Nassar

Jacobs Engineering Group Inc 16 PUBLICATIONS 213 CITATIONS

36 PUBLICATIONS 340 CITATIONS

SEE PROFILE

SEE PROFILE

All content following this page was uploaded by Amirpasha Peyvandi on 28 August 2014.

The user has requested enhancement of the downloaded file.

Recycled Glass

Concrete

Milled waste glass used in mixtures for flatwork construction on the campus

of Michigan State University

by Amirpasha Peyvandi, Parviz Soroushian, and Roz-Ud-Din Nassar

I

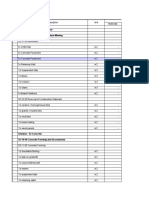

n the United States alone, about 9.4 million tons (8.5 million at 3.0 oz/yd3 [117 mL/m3]); and ASTM C260 air-entraining

tonnes) of mixed-color glass container waste (Fig. 1(a)) admixture (MB Micro Air at 1.0 oz/yd3 [39 mL/m3]). The

are generated annually, but only about a third of this mixture has an air content of 6.5%, a slump of 4 in. (102 mm),

waste stream is recycled.1 Laboratory studies and field trials and a unit weight (density) of 142.6 lb/ft3 (2284 kg/m3).

have verified the viability of waste glass powder (Fig. 1(b)) This mixture, modified with 20% cement replacement

as a supplementary cementitious material2 so, therefore, with milled mixed-color waste glass, has been used on a

mixed-color glass waste presents a significant opportunity trial basis for construction of walkways, driveways, and

for the concrete industry. curbs (Fig. 3) on the MSU campus since 2008.2,4,5 Visual

Since 2008, Michigan State University (MSU) in East field inspections and tests performed on core specimens

Lansing, MI, has been conducting evaluations of concrete

mixtures incorporating mixed-color waste glass. In September

2012, all of the concrete used for flatwork projects on the MSU

campus was produced using waste glass as a major component.

Laboratory Studies

Laboratory studies conducted at MSU and other

institutions have indicated that, when milled to about the

particle size of cement (15 µm), mixed-color waste glass can

react with cement hydrates and is therefore a pozzolan.2,3

When used as a cement replacement (at a dosage of about

20% by weight of cement), waste glass powder results in a

lower initial rate of hydration and strength development, yet

(a)

it improves long-term strength and reduces permeability.

And, although the sodium oxide content of mixed-color

waste glass is relatively high, its high reactivity allows it to

help mitigate the potential for alkali-silica reactions.3 Figure 2

provides an example of tests conducted per ASTM C1260,2

showing that a mixture comprising portland cement and

milled glass has significantly lower expansion than a control

mixture with portland cement alone.

Field Investigations

For construction projects at MSU, a typical concrete

mixture used in flatwork construction comprises Type I

portland cement (564 lb/yd3 [335 kg/m3]); ASTM C33 2NS

(b)

sand (1287 lb/yd3 [764 kg/m3]); ASTM C33 6AA limestone

(1772 lb/yd3 [1051 kg/m3]); water (256 lb/yd3 [152 kg/m3]); Fig. 1: Mixed-color waste glass: (a) as stored at the recycling

ASTM C494/C494M water-reducing admixture (MB 200N center; and (b) after milling

Concrete international january 2013 29

have indicated satisfactory performance of recycled glass

concrete in these applications after up to 4 years of

exposure to traffic loads and weather.

Test Results

Except for September 2012, when exclusively recycled

glass concrete was used for all flatwork and curb

construction on the MSU campus, control (normal)

concrete was placed parallel with recycled glass concrete in

the 2008 to 2012 time period. Occasionally, samples were

taken from both mixtures to evaluate compressive and

flexural strength (per ASTM C39 and ASTM C78,

respectively). Typical test results (Fig. 4) show that recycled

glass concrete has a slower initial rate of strength

Fig. 2: Example test results for concrete mixtures incorporating development than normal concrete, but it reaches higher

reactive aggregates. Partial replacement of cement with milled

long-term strength levels. Figure 5 presents typical

mixed-color waste glass results in lowered expansion values,

compressive strength test data obtained from recycled glass

indicating a reduction of deleterious alkali-silica reactions2

concrete cores extracted in the field at different ages. The

concrete shows a significant strength gain over time.

During field placements, samples of recycled glass and

normal concrete were also taken to evaluate drying

shrinkage (per ASTM C157), water absorption (per ASTM

C1585) at 28 days, and abrasion resistance (per ASTM

C944) after 28 days of moist curing. The drying shrinkage

test results (Fig. 6(a)) showed that the recycled glass

concrete exhibited lower drying shrinkage than normal

(a)

(a)

(b)

Fig. 4: Strength (mean and standard error) as a function of time

(b)

for moist-cured molded specimens produced using normal

Fig. 3: Examples of recycled glass concrete projects on the MSU concrete and recycled glass concrete: (a) compressive

campus: (a) walkway; and (b) curb strength; and (b) flexural strength (Note: 100 psi = 0.7 MPa)

30 january 2013 Concrete international

concrete; this effect was found to be statistically significant

(0.05 significance level). The reduced drying shrinkage of

recycled glass concrete could be attributed to its reduced

permeability relative to normal concrete, which is apparent in

the moisture absorption rate test results presented in Fig. 6(b).

The abrasion resistance of recycled glass concrete was also

found to be better than that of normal concrete (Fig. 6(c)).

Other Observations

The workability of freshly mixed concrete used in

flatwork and curb construction on the MSU campus

Fig. 5: Compressive strength (mean and standard error) as a

benefitted from partial (20% by weight) replacement of

function of time for recycled glass concrete cores extracted

cement with milled waste glass. This could be attributed to from field placements (Note: 100 psi = 0.7 MPa)

the relatively low absorption rate of milled waste glass

when compared with cement particles. The air content of

concrete required for resistance to freezing and thawing Fully Applied

was not disturbed with the addition of milled waste glass. After laboratory and field trials verified satisfactory

The water absorption capacity of concrete core performance, recycled glass concrete was used on a routine

specimens obtained from field projects at an age of 1 to basis for construction of all exterior concrete flatwork and

4 years was reduced by an average of 15% upon partial curbs placed on the MSU campus throughout the month of

replacement of cement with milled waste glass. This September 2012. For this purpose, mixed-color waste glass was

reduced water absorption could translate into improved collected from campus recycling bins in July and shipped to a

durability characteristics of recycled glass concrete in milling facility. Twenty tons (18.1 tonnes) of milled mixed-

comparison to normal concrete. color waste glass were delivered to a concrete plant near the

Weld-Crete®—The pale Simply brush, roll or spray Weld-Crete®

blue bonding agent with on to concrete or any structurally

sound surface. Then come back hours,

over 60 years of superior

days or a week later and finish with

performance in the field. new concrete, stucco, tile, terrazzo,

other cement mixes or portland cement

plaster. Plus Weld-Crete’s® low VOC

content significantly reduces airborne

pollutants that affect health and the

environment.

Originators of leading chemical bonding

agents… worldwide since 1952

800.633.6668

www.larsenproducts.com

Concrete international january 2013 31

Generation, Recycling, and Disposal in the United States: Facts and

Figures for 2010,” Washington, DC, Dec. 2011, 12 pp.

2. Nassar, R.U.D., “Synergistic Use of Milled Waste Glass and Re-

cycled Aggregate towards a Sustainable Concrete-Based Infrastructure,”

PhD thesis, Michigan State University, East Lansing, MI, 2010.

3. Hou, X.; Struble, L.J.; and Kirkpatrick, R.J., “Formation of ASR

Gel and the Roles of C-S-H and Portlandite,” Cement and Concrete

Research, V. 34, No. 9, Sept. 2004, pp. 1683-1696.

4. Nassar, R., and Soroushian, P., “Strength and Durability of Recycled

Aggregate Concrete Containing Milled Glass as Partial Replacement for

(a) Cement,” Construction and Building Materials, V. 29, Apr. 2012, pp. 368-377.

5. Nassar, R., and Soroushian, P., “Field Investigation of Concrete

Incorporating Milled Waste Glass,” The Journal of Solid Waste Technology

and Management, V. 37, No. 4, Nov. 2011, pp. 307-319.

Note: Additional information on the ASTM standards discussed in

this article can be found at www.astm.org.

Selected for reader interest by the editors.

(b) Amirpasha Peyvandi received his

BS and MS in civil and structural

engineering from the University of

Tehran, Iran. He is currently working

toward a PhD in civil and

environmental engineering at

Michigan State University. His research

interests include application of

nanotechnology in cementitious

material and development of environmentally friendly

and energy-efficient construction materials and systems.

He also has 4 years of experience in the design of bridge

infrastructures.

(c) Parviz Soroushian, FACI, FASCE,

received his PhD from Cornell

Fig. 6: Test results for normal and recycled glass concrete: (a) drying University. He is currently a Professor of

shrinkage; (b) water absorption at 28 days; and (c) abrasion civil and environmental engineering

resistance at 28 days (Note: 1 mm = 0.04 in., 1 g = 0.04 oz.) at Michigan State University. His

research focuses on advanced

campus in August 2012. Nearly 600 tons (544 tonnes) of structural, protective, and functional

recycled glass concrete was placed on the MSU campus during materials. His research interests include

September. The results show that if the university continues to materials science and engineering,

use waste glass as a cement replacement, a significant amount of and sustainable construction materials and systems. His

material can be diverted from landfills. background also includes research and development of

technologies concerning structural applications of

nanocomposites, reinforcing fibers for composites, and

Acknowledgments

smart materials and structural systems.

The authors are thankful to the MSU Physical Plant, MSU Office of

Sustainability, and the U.S. Environmental Protection Agency for their

Roz-Ud-Din Nassar received his PhD in civil engineering

financial support of the project. The continued guidance and support

from Michigan State University. He is currently working

provided by R. Ellerhorst and A. Lawver have been vital to successful

as an Associate Professor of civil engineering at the

implementation of the laboratory and field studies reported herein.

University of South Asia, Lahore, Pakistan. His research

focuses on environmentally friendly and energy-efficient

References construction materials.

1. U.S. Environmental Protection Agency, “Municipal Solid Waste

32 january 2013 Concrete international

Reproduced with permission of the copyright owner. Further reproduction prohibited without permission.

View publication stats

You might also like

- ACI MATERIALS JOURNAL Durability of Lightweight Concrete With Expanded GlassDocument8 pagesACI MATERIALS JOURNAL Durability of Lightweight Concrete With Expanded GlassMuchtar SufaatNo ratings yet

- A Review Paper On Strength and Durability Studies On Concrete Fine Aggregate Replaced With Recycled Crushed GlassDocument4 pagesA Review Paper On Strength and Durability Studies On Concrete Fine Aggregate Replaced With Recycled Crushed GlassIAEME PublicationNo ratings yet

- Sustainable Production of Concrete Containing Discarded Beverage GlassDocument9 pagesSustainable Production of Concrete Containing Discarded Beverage Glassyeison100% (1)

- Bom Mang Chay Dien Husky Hoat DongDocument72 pagesBom Mang Chay Dien Husky Hoat DongcabatoNo ratings yet

- COMPRESORASDocument78 pagesCOMPRESORASEduardo RiveraNo ratings yet

- Instructions For TC083 PER-CAST VACUUM CASTING MACHINE PDFDocument5 pagesInstructions For TC083 PER-CAST VACUUM CASTING MACHINE PDFMarciaNo ratings yet

- Glass Powder As Fine Aggregate in High Strength ConcreteDocument3 pagesGlass Powder As Fine Aggregate in High Strength ConcreteBhagwatNo ratings yet

- Cemfil Sprayguide WW 12 2008 Rev1Document32 pagesCemfil Sprayguide WW 12 2008 Rev1freidorNo ratings yet

- Kumpulan Soal Soal AnnoncementDocument10 pagesKumpulan Soal Soal AnnoncementCci SahabatNo ratings yet

- An Electric Revolution - The Rise of Indonesia's E-Motorcycle (Deloitte X Foundry)Document25 pagesAn Electric Revolution - The Rise of Indonesia's E-Motorcycle (Deloitte X Foundry)muhamadilham ryankusumaNo ratings yet

- Utilization of Waste Glass in ConcreteDocument8 pagesUtilization of Waste Glass in ConcreteSamarNo ratings yet

- Haendle Extrution UnitsDocument0 pagesHaendle Extrution UnitsMohan ShanmugamNo ratings yet

- Aluminum Plate LithoDocument3 pagesAluminum Plate Lithotony_baker_31No ratings yet

- 5 E 2008 Properties of Self-Compacting Concrete Prepared With Recycled Glass AggregateDocument7 pages5 E 2008 Properties of Self-Compacting Concrete Prepared With Recycled Glass Aggregatemaverick ownadorNo ratings yet

- An Experimental Analysis of Partial Replacement of Coarse Aggregate by Waste Ceramic Tile in ConcreteDocument12 pagesAn Experimental Analysis of Partial Replacement of Coarse Aggregate by Waste Ceramic Tile in Concreteshivanand hippargaNo ratings yet

- Materials Today: Proceedings: Mycherla Chaitanya, G. RamakrishnaDocument4 pagesMaterials Today: Proceedings: Mycherla Chaitanya, G. Ramakrishnachaitanya mycherlaNo ratings yet

- Use of Glass Wastes As Fine Aggregate in Concrete: January 2012Document4 pagesUse of Glass Wastes As Fine Aggregate in Concrete: January 2012Yuri ValenciaNo ratings yet

- Effectiveness of Using Recycled Coarse Aggregates (Rca) in Making High Strength ConcreteDocument5 pagesEffectiveness of Using Recycled Coarse Aggregates (Rca) in Making High Strength ConcreteSelva PrakashNo ratings yet

- 4 E A Study On The Properties of Fresh Self-Consolidating Glass Concrete (SCGC)Document6 pages4 E A Study On The Properties of Fresh Self-Consolidating Glass Concrete (SCGC)maverick ownadorNo ratings yet

- Aggregates With GlassDocument4 pagesAggregates With Glasshoranlovely5No ratings yet

- Journal ReportDocument6 pagesJournal ReportmaruthiNo ratings yet

- Irjet V3i720Document6 pagesIrjet V3i720SHARAN PATILNo ratings yet

- Prediction of Early Age Shrinkage of Reinforced Cement ConcreteDocument4 pagesPrediction of Early Age Shrinkage of Reinforced Cement ConcreteSurabhiBhatNo ratings yet

- 2011-Effectiveness of Using Coarse Recycled Concrete Aggregate in Concrete PDFDocument7 pages2011-Effectiveness of Using Coarse Recycled Concrete Aggregate in Concrete PDF8790922772No ratings yet

- (Elias G. Abu-Saba Auth.) Design of Steel StrucDocument7 pages(Elias G. Abu-Saba Auth.) Design of Steel StrucAkhand AkhandNo ratings yet

- Construction and Building Materials: S.C. Kou, C.S. PoonDocument8 pagesConstruction and Building Materials: S.C. Kou, C.S. PoonsaratNo ratings yet

- Relation Between Density and Compressive Strength of Hardened ConcreteDocument9 pagesRelation Between Density and Compressive Strength of Hardened ConcreteMohd NasimNo ratings yet

- Influence of Self-Healing, Mixing Method and Adding Silica Fume On Mechanical Properties of Recycled Aggregates ConcreteDocument7 pagesInfluence of Self-Healing, Mixing Method and Adding Silica Fume On Mechanical Properties of Recycled Aggregates ConcreteRizal RifdoNo ratings yet

- Granulated Waste Tyres in Concrete Paving BlockDocument7 pagesGranulated Waste Tyres in Concrete Paving BlockAravind kumarNo ratings yet

- 9b2b PDFDocument5 pages9b2b PDFShaikKhanNo ratings yet

- An Experimental Investigation On Partial Replacement of Cement by Glass Powder in ConcreteDocument8 pagesAn Experimental Investigation On Partial Replacement of Cement by Glass Powder in ConcreteAnish PanchalNo ratings yet

- 1 s2.0 S0008884600004762 MainDocument6 pages1 s2.0 S0008884600004762 MainAAMIRNo ratings yet

- Abdel Hay2015Document6 pagesAbdel Hay2015Lusman SulaimanNo ratings yet

- JETIR1903G72Document4 pagesJETIR1903G72Vikas SharmaNo ratings yet

- Usage of Sugarcane Bagasse Ash in Concrete: AbstractDocument7 pagesUsage of Sugarcane Bagasse Ash in Concrete: AbstractRadix CitizenNo ratings yet

- Cement & Concrete Composites: Shi-Cong Kou, Chi-Sun PoonDocument8 pagesCement & Concrete Composites: Shi-Cong Kou, Chi-Sun PoonsaratNo ratings yet

- Partial Replacement of Cement and Fine Aggregate byDocument5 pagesPartial Replacement of Cement and Fine Aggregate byInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Anderson2016 - Mechanical Properties of Concrete Utilising Waste Ceramic As Coarse Ag PDFDocument9 pagesAnderson2016 - Mechanical Properties of Concrete Utilising Waste Ceramic As Coarse Ag PDFFábio FriolNo ratings yet

- SCC 2Document4 pagesSCC 2Arunkumar BnNo ratings yet

- Chatveera 2006Document10 pagesChatveera 2006MD. MUSHFIQUE -US-SALEHEEN, 180051234No ratings yet

- Full Theises 22222Document41 pagesFull Theises 22222kazim khanNo ratings yet

- Characteristics of Concrete With Waste Glass As Fine Aggregate ReplacementDocument8 pagesCharacteristics of Concrete With Waste Glass As Fine Aggregate Replacementtaramalik07No ratings yet

- Study On Geopolymer Concrete Used For Paving BlocksDocument5 pagesStudy On Geopolymer Concrete Used For Paving BlocksIJIRAE- International Journal of Innovative Research in Advanced Engineering100% (1)

- Surface Absorption Characteristics of Recycled Concrete: Roshni John, A. A. BageDocument4 pagesSurface Absorption Characteristics of Recycled Concrete: Roshni John, A. A. BageDarth FrootLoopsNo ratings yet

- PARTIALLY REPLACEMENT IN CONCRETE BLOCK THE USE OF WASTE GLASS AS FINE AGGREGATE - Anthony Barrera, Rechell Rocha, and April Rose TiuDocument70 pagesPARTIALLY REPLACEMENT IN CONCRETE BLOCK THE USE OF WASTE GLASS AS FINE AGGREGATE - Anthony Barrera, Rechell Rocha, and April Rose TiuNacel AltizonNo ratings yet

- Influence of Recycled Aggregate On Slump and Bleeding of Fresh ConcreteDocument8 pagesInfluence of Recycled Aggregate On Slump and Bleeding of Fresh ConcreteAlfredo Landaverde GarcíaNo ratings yet

- Long Term Durability Properties of Field Concretes With Glass Sand and Glass PowderDocument9 pagesLong Term Durability Properties of Field Concretes With Glass Sand and Glass PowderRaviranjan Kumar SinghNo ratings yet

- TARP Assessment - IIDocument23 pagesTARP Assessment - IISyed Noor AkhtarNo ratings yet

- Pridiction of Compressive Strength of Cement by Using Regression Technique With Partial Replacement of Hylam Powder in Cement MortarDocument8 pagesPridiction of Compressive Strength of Cement by Using Regression Technique With Partial Replacement of Hylam Powder in Cement MortarMatthew JohnsonNo ratings yet

- Mechanical Properties of Eco-Friendly Cements-Based Glass Powder in Aggressive MediumDocument6 pagesMechanical Properties of Eco-Friendly Cements-Based Glass Powder in Aggressive MediumShaker QaidiNo ratings yet

- A Study On Slump and Compressive Strength of Recycled Aggregates Embedded ConcreteDocument5 pagesA Study On Slump and Compressive Strength of Recycled Aggregates Embedded ConcreteMalak ShatiNo ratings yet

- Performance of High-Strength Concrete Made With Recycled Ceramic AggregatesDocument10 pagesPerformance of High-Strength Concrete Made With Recycled Ceramic AggregatesJoão Felipe João F.No ratings yet

- Use of Recycled Plastic Water Bottles in Concrete Blocks PDFDocument8 pagesUse of Recycled Plastic Water Bottles in Concrete Blocks PDFAniel DiasNo ratings yet

- Using of Waste Glass As Fine Aggregate in Concrete: Civil EngineeringDocument9 pagesUsing of Waste Glass As Fine Aggregate in Concrete: Civil EngineeringaliNo ratings yet

- Study of Strength Characteristics of Crushed Glass Used As Fine Aggregate in ConcreteDocument4 pagesStudy of Strength Characteristics of Crushed Glass Used As Fine Aggregate in ConcreteNarasimha ReddyNo ratings yet

- An Experimental Investigation On Effect of Ggbs and Glass Fibre in High PerfDocument7 pagesAn Experimental Investigation On Effect of Ggbs and Glass Fibre in High PerfIAEME PublicationNo ratings yet

- 3 E Recycled Glass As A Partial Replacement For Fine Aggregate in Self Compacting ConcreteDocument7 pages3 E Recycled Glass As A Partial Replacement For Fine Aggregate in Self Compacting Concretemaverick ownadorNo ratings yet

- Research Related Literature v2 CitationsDocument3 pagesResearch Related Literature v2 CitationsJuntri HSRNo ratings yet

- Guide: Mr. Sumit Patil: Group Member NameDocument20 pagesGuide: Mr. Sumit Patil: Group Member NameMr.Bhaskar WabhitkarNo ratings yet

- Kamal Et Al-ICACE-2018 Full Paper-FinalDocument6 pagesKamal Et Al-ICACE-2018 Full Paper-Finalska51No ratings yet

- Mit PDFDocument62 pagesMit PDFFernando RosalesNo ratings yet

- Materials: Variation in Compressive Strength of Concrete Aross Thickness of Placed LayerDocument14 pagesMaterials: Variation in Compressive Strength of Concrete Aross Thickness of Placed LayerFernando RosalesNo ratings yet

- MyOrdersProductInvoice PDFDocument1 pageMyOrdersProductInvoice PDFFernando RosalesNo ratings yet

- Concrete Made With Recycled Glass Aggregates: Mechanical PerformanceDocument11 pagesConcrete Made With Recycled Glass Aggregates: Mechanical PerformanceFernando RosalesNo ratings yet

- Sarja Extenedlimitstatedesign MS43 2010Document12 pagesSarja Extenedlimitstatedesign MS43 2010Fernando RosalesNo ratings yet

- Calibration of Force-Measuring Instruments For Verifying The Force Indication of Testing MachinesDocument12 pagesCalibration of Force-Measuring Instruments For Verifying The Force Indication of Testing MachinesFernando RosalesNo ratings yet

- Life-365 Service Life Prediction Model Version 2.0Document2 pagesLife-365 Service Life Prediction Model Version 2.0Fernando RosalesNo ratings yet

- 5 Life-365™ Background Information: End of Service LifeDocument23 pages5 Life-365™ Background Information: End of Service LifeFernando RosalesNo ratings yet

- Life-365 - v2.2.3 - Users - Manual (1) - 66-88Document12 pagesLife-365 - v2.2.3 - Users - Manual (1) - 66-88Fernando RosalesNo ratings yet

- Life-365 - v2.2.3 - Users - Manual (1) - 26-53Document28 pagesLife-365 - v2.2.3 - Users - Manual (1) - 26-53Fernando RosalesNo ratings yet

- VERSICO TPO Over Concrete DeckDocument17 pagesVERSICO TPO Over Concrete DeckRafael Ramirez CasateNo ratings yet

- Drying Shinkage DilemmaDocument3 pagesDrying Shinkage DilemmaCristian MeloNo ratings yet

- Unit Rates and Cost Per ItemDocument213 pagesUnit Rates and Cost Per ItemDesiree Vera GrauelNo ratings yet

- Standards and Tolerances Guide 0Document72 pagesStandards and Tolerances Guide 0Damien TanNo ratings yet

- Experimental Study of Confined Low-, Medium - and High-Strength Concrete Subjected To Concentric CompressionDocument18 pagesExperimental Study of Confined Low-, Medium - and High-Strength Concrete Subjected To Concentric CompressionranawaqasahmedNo ratings yet

- PAES 419 - 2015 Warehouse For Bagged Storage For GrainDocument16 pagesPAES 419 - 2015 Warehouse For Bagged Storage For GrainFarouk PagsNo ratings yet

- Sika Concrete HandbookDocument151 pagesSika Concrete HandbookFatjon ShahaNo ratings yet

- TECHNICAL INSTRUCTION 1D-2013-MAy PDFDocument65 pagesTECHNICAL INSTRUCTION 1D-2013-MAy PDFStelian ConstantinescuNo ratings yet

- Construction Issue: (SA) EF 3 (SA) EF 4Document1 pageConstruction Issue: (SA) EF 3 (SA) EF 4Хөгжилтэй ЗугаатайNo ratings yet

- Materials Engineer Test ReviewerDocument63 pagesMaterials Engineer Test ReviewerMariel ColladoNo ratings yet

- RC Detailing To Eurocode 2Document39 pagesRC Detailing To Eurocode 2Sandipan DharNo ratings yet

- Supply of Precast Concrete Columns: StandardDocument12 pagesSupply of Precast Concrete Columns: Standardparallax1957No ratings yet

- 5-Aci 8855Document10 pages5-Aci 8855aliNo ratings yet

- 3-8 - CRACK WIDTHS - PART 2 - AtkinsonDocument18 pages3-8 - CRACK WIDTHS - PART 2 - AtkinsonForbes KambaNo ratings yet

- Division 4 MasonryDocument39 pagesDivision 4 MasonryLynette CabantingNo ratings yet

- A Low-Cost Vernacular Improved Housing DesignDocument8 pagesA Low-Cost Vernacular Improved Housing DesignsfhousingsearchNo ratings yet

- Analysis of Rates 8Document1 pageAnalysis of Rates 8Aman ThakurNo ratings yet

- FRC PDFDocument9 pagesFRC PDFHammad SalahuddinNo ratings yet

- Design of Hydroelectric Power PlantsDocument54 pagesDesign of Hydroelectric Power Plantsbagus adi saputraNo ratings yet

- Building Design-PWD GuidelinesDocument71 pagesBuilding Design-PWD GuidelinesPrayas SubediNo ratings yet

- Module 8 SAHITA ConcreteDocument11 pagesModule 8 SAHITA ConcreteHarrybfnNo ratings yet

- Design Recommendations For Precast Concrete Structures: Reported by ACI-ASCE Committee 550Document8 pagesDesign Recommendations For Precast Concrete Structures: Reported by ACI-ASCE Committee 550nathanNo ratings yet

- Method Statement EpoxyDocument43 pagesMethod Statement EpoxyMohd Syaril Mohd Ali0% (1)

- Composite Beam ChartsDocument8 pagesComposite Beam ChartsAnonymous 1sJXK1DKZNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument24 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- TCVN 3105.1993 Heavyweight Concrete Compound and Heavyweight Concrete - Samling, Making and Curing of Test SpecimensDocument6 pagesTCVN 3105.1993 Heavyweight Concrete Compound and Heavyweight Concrete - Samling, Making and Curing of Test SpecimensNgo Tien VinhNo ratings yet

- WRD 12 (653) IS 5620 Recommendation For Structural Design Criteria For Low Head Slide Gates (Third Revision)Document32 pagesWRD 12 (653) IS 5620 Recommendation For Structural Design Criteria For Low Head Slide Gates (Third Revision)Anup MitraNo ratings yet

- Sika WT-200 P - Brochure PDFDocument4 pagesSika WT-200 P - Brochure PDFΜιχάλης ΧατζημιχαήλNo ratings yet

- 12-Cross Drainage StructuresDocument49 pages12-Cross Drainage StructuresAsadullah DhilooNo ratings yet

- Siva2015 PDFDocument9 pagesSiva2015 PDFmekalaNo ratings yet