Professional Documents

Culture Documents

Modern Marine Propulsion Gearing

Uploaded by

Merrel RossOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modern Marine Propulsion Gearing

Uploaded by

Merrel RossCopyright:

Available Formats

CAPTAIN R. E. W.

HARRISON, USNR, Retired

MODERN MARINE PROPuLsIolv GEARRVG

THE AUTHOR

was b m in Manchester, England, in 1893. Educated Manchester Cdlege of

Technology. With Royal Engineers, British Army 19141919, Egypt, GoUipdi,

Sinai, France, Belgium. lndwtrial Engineering experience includes special

apprenticeship and superviswy poeitions with Churchdl Machine Tod Com-

pany, England, in the building design and engineering seUing of precision

grinding machinery; in 1926 as Director of Engineering, Cincinnati crinhers,

Cineinnuti Milling Machine Company; 1934 Chief, Machinery Division, U . S .

Department of Commerce; 1935 Vice-President Chambetsburg Engineering

Company; in Wwld War 11, on staffof Assistant Secretuq, U.S.Navy, and later

as Special Assistant to the Under-Secretary; Registered Mechanical Engineer

in Ohio, New York,Pennsylvania, Marnland and District of Columbia. Felkm

ASME and Rogal Society of Arts; Member other Engineering Societies in

U. S . A . and Europe. A t present engaged in Engineering and Management

Consulting, Washington, D.C.

INTRODUCTION SOURCES OF REALLY FACTUAL DATA

A P E m m m N G L Y critical review of the engineering

progress achieved during the last fifty years in

As is customary in the development of most, if not

all, major mechanical units and power generation

the processes involved in converting the fuel aboard mechanisms, new elements in the power transmis-

ship into propulsion of that ship, for a given distance sion line are first put through shorebound laboratory

at required speed, clearly indicates that the progress, tests, designed to evaluate performance in terms of

while spectacular as a whole, is, without doubt, designed for and specified requirements measured

sketchy in spots. against actual results.

Marine boilers today are, sue for sue, many times Of necessity, laboratory tests are limited in time,

as efficient as they were fifty years back-likewise, and frequently are run under ideal conditions, and

the turbines for which the boilers provide the steam. while these tests are obviously necessary, it is nw-

Horsepower for horsepower they are also much ertheless true that the only really reliable engineer-

smaller and lighter. ing data are these forthcoming from “ndlcmn”

Shafting which transmits power to the propeller is operation at sea, year in-year out, on strict time

proportionately lighter in terms of pounds weight schedule and in accordance with a set of rigidly re-

ratio-wise to delivered shaft horsepower, and propel- quired conditions of operating economy.

lers, in turn, are much more efficient than they ever Possession of a powerful fleet of armed vessels

were before. seldom, if ever, provides “milkrun” type of engineer-

Right in the middle of this line of power transmis- ing experience data, for the very reason that mili-

sion sits the gear case, all too frequently the location tary operations by their essential nature are invari-

of deep seated troubles, and the only remaining major ably, even in peacetime, on a &run basis.

p i n t of weakness in a ship’s propulsion power trans- Fighting ships to win the fight must be capable of

mission line. extraordinarily fast maneuvering, plus bursts of

This paper discusses the reasons for the existence speed f a r beyond anything commercially obtainable

of the current propulsion gearing problem, and poses or even necessary. While every endeavor is made to

some suggested remedies. operate under standard speed conditions as frequent-

A.S.N.E. Journal. Yay IS7 263

MARINE PROPULSION GEARING R E.W.HARFUSON

ly and for as long as possible, tours of ship’s duty are reliability. Where, therefore, can the team of re-

necessarily erratic and relatively so short,that engi- searchers and design engineers turn with more con-

neering data which can be culled from the logs are fidence than to the tanker operator who makes or

so beset with special conditions and variables, that loses a profit on his operations in terms of total avail-

they cannot compare in operational validity with the able designed propeller turns per annum?

carefully kept records of, for example, the operation

RATIOS

of a fleet of tankers sailing between some port in the

Caribbean, and a destination in the Delaware River. It is just as simple as that. Seagoing experience

In other words-a “milkrun.” being what it is, cannot with impunity be ignored,

It could well be debated that a military ship and seawater being what it is, says that too much ro-

seldom, if ever, jeopardizes its ability to perform its tational speed on the wheel means cavitation and

designed mission by failing to achieve a proper all the evils which go with it.

economy of operation, because perhaps the propel- So-until there be developed an alternative to the

ler makes ten more or ten less turns per minute then 3, 4, 5 or 7 bladed propeller, to avoid cavitation and

called for as the designed operational speed (stand- uncontrollable vibration, we must use relatively

ard), but should a tanker on a “milkrun” be com- large diameter, relatively slow speed propellers (at

pelled for some machinery shortcoming to operate least as slow as we can operate them, consistent with

a t ten less RPM than deyigned, it will quickly be- performance of the required mission of the ship).

come apparent that this ship so handicapped is un- Tanker, Destroyer, Passenger ship or Carrier, spin

profitable. There then comes into play the strong the wheel too fast and we have cavitation and loss

commercial urge-in fact the urgent necessity to of efficiency.

build up the efficiency of this “milkrun” performance The net result of this set of conditions and require-

to the point where profit is consistently assured (at ments is high ratio reduction gears, because turbines

an economic maximum). The alternative is to lay (steam and gas) work best at the higher RPMs and

her up. the wheels do best at the lower end of the scale.

The net of the discussion up to this point is that Relatively high RPMs at the turbine, and low

there is much to be learned for the benefit of des- RPMs at the wheel, mean high mechanical leverage

signers of military ships from the performance of on the wheel, all of which is used to the good except

vast tanker fleets, most if not nearly all of whch that 10 revs per minute lost on a 100 RPM wheel

operate on a “milkrun” basis, and thereby produce (maybe because the propulsion gearing has to be

some priceless engineering data for the discerning “nursed”) means 10 per cent extra time at sea with

designers of ships. The ferry boats in the North At- its accompanying dollar drain. Under such condi-

lantic, and Pacific ferry services also, yield excel- tions one full year’s operation is only equal to

lent engineering data, but passenger service persists eleven months at designed speed. In other words, on

and necessitates overdesigns which detract from the a non-military ship it is the ship operator’s profit

values, from the designers’ viewpoint. which has pone down the drain.

Only those Naval Architects, who sweat out all Net of the foregoing: slow turning propellers,

the numerous and always conAicting factors which while good in the engineering senae, make a n i f ; -

have to be accommodated to produce a given speed c a m e of a f e w lost RPM disproportionately costly in

at a predetermined fuel economy, can fully appre- terms of operational success.

ciate the complexity of the engineering problem, SIGNIFICANCE

when this problem relates to a strictly military ship O n the basis that it is the success, or otherwise, of

of the Destroyer class, where engine room cubic our domestic economy which determines the type

footage is always at a premium. and size of naval power we can exercise or afford, is

The burden of providmg a usable engineering it not logical that just as the “milkruns” of the air-

solution can, and already has been demonstratably lines give us exceptionally reliable data on plane

eased by the emergence of nuclear power, which designs, so the experience of civilian seagoing in-

largely removes the present overriding considera- dustry, in this case mercantile tanker shipping, can

ations of fuel economy. However, nucleonics as a automatically provide excellently reliable design and

source of power for a majority of units of the U.S , practice bases for the pamlleling factom in opera-

Fleet and its train is a long way off. tional requirements for a fighting fleet?

In the interim we can do none other than get all

the “dories” we can out of the fuel oil and provide ORIGIN AND PRECEPT FOR A BETLZR TECHNIQUE

a mechanism reaching all the way from the bunkers There are, of course, other commercial engineering

to propellers, which translates calories into reliable achievements which point like beckoning signposts

standard speed, a spectacular maximum speed, ma- to those who seek a superior engineering perform-

neuverability, and freedom from the apron-strings ance in ship propulsion gearing, and it is extremely

of a Naval Operating Base or a Naval Shipyard. significant that this superior performance has been

Any experienced researcher will testify at short developed in a country which possesses no fleet at

notice that the data he feeds to the design engineers all, military or mercantile, i.e., land-locked Switzer-

are most prized in proportion to their demonstrated land.

A.S.N.E. Journal. May 1957

R. E.W.HARRISON MARINE PROPULSION GEARING

STRANGE PROVING GROUND FOR A BETTER CONCEPT EVOLUTION AT WORK (ENGI"C TYPE)

The geographical and topographical features of It was partially recognition of these features which

Switzerland inevitably are such that railroading and led to the use of double helical gearing, with its

street-car services called for superlative perform- over-designed static strength and its very own built-

ances to enable power units to pull vehicles up very in, overdesigned, self-destructive forces (products of

steep grades, and necessity being forever the mother all the machining variables and metallurgical incon-

of invention, it was far from unnatural that Swiss sistencies).

machine tool engineers should devise a product and The dynamic destructiveness of a jack hammer is

a method of gear production adequate to deal with re!atively child's play when stacked against the dy-

their local situation. (The mountain goat may be namic hammering that the most minute inaccuracies

tough to eat-but his steel-spring muscles and vi- in a conventional double helical gear and pinion gen-

tality are the envy of the world). erate under all stages of work loading. During a

Hardened and ground precision gearing has been properly instrumented test these minute but deadly

an accomplished necessary practice on Switzerland's hammer blows always show up as high and dominant

railroads and street car routes for at least thirty peaks on the recording oscillograph and tape.

years, and out of the failures and refinements of this Single helical gears as produced today are a nec-

experience has grown a gearing technique, proven essity, but with small helix angle, narrow face, fine

throughout the civilized engineering world, never pitch, small diameters, it is possible to provide proper

adequately copied and still supreme after many tooth engagement and overlap, super-accurate tooth

years as the best performer. This is the Swiss type spacing, torsional wind-up compensation, tooth flank

gear train, case-hardened and ground throughout, surfaces with fine micro-inch finish and tip and root

with superlatively, accurately spaced gear teeth, relief. We have in the modern, relatively narrow

true tooth form, and above all complete uniformity faced, case-hardened and ground gear, the quintes-

of mating surfaces automatically guaranteed by a sence of hard won experience of those+ who make

unique system of grinding wheel wear compensation, gears by the million, as against the relatively few

which guarantees that the last shall be like the first units required by the shipbuilding industry.

-something which is unique in gear teeth. It must be conceded that this hard won efficiency

carries a superlatively high commercial reward for

RIGIDITY EXISTS ONLY IN MEN'S MINDS success in the solving of the problem, and while the

The amateur engineer invariably starts out with competition in this particular commercial race is such

the supposition that the structures he designs are that there are today but three survivors out of a field

rigid. The facts of life say that no greater delusion of thirty-those same three survivors rank pretty

exists, and none is responsible for quite so many close to the top of the scale as the Nation's great

errors. This shibboleth has wrecked more mechan- profit earners.

isms and engineering reputations than almost any INERTIAS CAN BE COMMERCIAL AS WELL AS M S C H A N I C U

other cause.

The astute designer of machinery knows that ab- W h y then do we perpetuate the gear trains of

solutely nothing on this planet is rigid, and every World War I and continue to insert costly, oversized

element in the basic design must, of necessity, be as- monumental units of low efficiency in a power train

sumed to distort under load. Furthermore, if the which reaches from the oil bunkers with vastly im-

mechanism is to function properly and survive, dis- proved efficiency all the way down the shaft tunnel

tortions must be calculated, checked by practice, to the propeller?

and adequately compensated for under all operating As one might expect, the answer is simple. Com-

conditions. pare the specialized automobile industry profit ex-

Competent machinery designers must be experi- perience with the widerange financial ups and

enced physicists as well as mechanical engineers, downs and relatively meager profits of the m e r -

and the best injrariably design load distortion com- cid gear industry, and we have the one most im-

pensators into their mechanisms, so that under load, portant and r e v e a h g key to the answer.

all distortions h e catered for to the point where Technological progrem thrive8 on profit, and it is

their evils are eliminated. the promise of reliable profit which motivates prog-

Even though propulsion gear trains and their gear ress The few hardy souls who persist at the inven-

carrying shafts be drawn and specified in accordance tion game simply because they love it, are few

with best machine shop practices, as well as best ma- indeed, and mostly financially short-handed.

terials and heat treatments available today, under THE RUB

torsional loads shafts will inevitably bend away We cannot, of course, drop the subject at this point

from the point of maximum load to greater or lesser

and accept the marine gearing industry which is

degree. Furthermore, the gear teeth will wind up weighted down by its oversized, double, helical bull

and, unless these deformations are catered to in the gears as held fast on a lee shore for the simple but

machining as well as in basic design, the gears will all important fact that US.national survival depends

never function as the designer hoped they would ___-

perform. "he automobile industry.

A.S.N.E. J a r u l , MDI 1767 265

MARINE PROPULSION GEARJNG RE.W.HARRISON

not only on command of the sea lanes, but also on through Gethsemane up and onto its eventual tri-

better performance than the submarines of our near- umph.

est military competitor, the USSR Long life, highly efficient, economically priced,

It is significant that the US. Government is cur- propulsion gearing i s no exception, and if in this day

rently spending @-billion per year on research and and age we have prototype C a r r i e r s in dock with

development f o r the simple, single reason that com- broken gearing, Oilers limping along at 90 RPM on

mercial successes come too slowly and too erratical- the wheel instead of 110, and industrial machinery,

ly, to insure continuity of design progress in the such 8s highly expensive rolling mills, down for one

military equipment field. Costly experience has week out of four because of inadequate gearing, this

shown that miIitary invention, while patriotically then is the mechanical engineer’s Cethsemane and

stimulated during wartime, langudes in peacetime he may rejoice that he has been privileged to live

and all too frequently dies of that right common through a time when an approvable solution to a

disease known as profit anemia. great problem can be generated.

Generally, during both war and peace, there is an

eager seeking by manufacturers and commercial PHILosoPmc CONTEMPLATION IS OUT

laboratories for US.Government Research and De- (THRU IS “00 MUCH H U T ON)

velopment contracts, even though those who take There is too great difference in real values b e

them know that any profit for manufacturers is well tween philasoph~ccontemplation of a situation which

in the future. Research and Development, as such, means only loss of dollars if voyage delay is pro-

is a costly experience in the immediate profit column. longed beyond reasonable limits as against physical

This applies with particular sig&cance to the gen- and moral loss in seamen’s lives and sinking of val-

eration of new and better military equipment designs uable ships and cargoes during a war.

(which includes propulsion gearing for fighting Two long World Wars within one short lifetime,

ships). plus valuable lessons in how to transport seaborne

Where the desired improvement is a matter of a loads during the Korean Police Action, prompt the

superior processing only, the experience is generally thought that handicapping of naval ships and their

less costly to both the government and its research- trains by the use of gearing other than that which

ing contractor. Procedure is relatively simple. Gov- is best in design and materials, is, indeed, costly

ernment buys equipment and selected contractors do folly, even though the peacetime commercial prdit

the work. When the new process is deemed of proven solution to the problem is still not in sight.

merit, the equipment is either mothballed or sold All of this definitely takes both naval combatant

or rented to the user. In any case,the US.Govern- and auxiliary ships out of the strictly competitive

ment can chalk up an advance in production tech- commercial gearing field, and puts them in the same

nology and for the time being satdy itself that. as class as projectiles, guided missiles, torpedoes, and

far as that particular item is concerned, “M”Day aerial bombs as f a r as required engineering quali-

is well taken care of. ties are concerned. Lets have a competitive commer-

cial solution, if one is available now-but a solution

FORKICN N A M 8 SOMETIMES TAKZ TM LEAD is overdue and mandatory.

Governments of Britain, Canada, France and

Germany have long remgmzd * the commercially FORCE MAJEUR

non-profit-feasible angle to military marine propul- Equally important, a sagacious military must, of

sion gearing, and of their own farseeing volition necessity, generate in its suppliers’ plants that tech-

have equipped their principal gearing suppliers with nique and productive capacity which a normal com-

special machine tools and collateral equipment need- petitive situation has been totally unable to produce.

ed to produce the type of gcaring which is militarily The current international crisis brought on by

necesstvy in ships of war and their trains, as well as seizure by Egypt of the Suez Canal properties seems

commercially desirable in the mercantile marine, likely to increase time at sea of all ships in the

which, when war comes, automatically becomes the Eastern trade by 30 to 50 per c e n t 4 of which adds

largest part of the supply train. up NOW to increased emphasis on higher practic-

able standard speed and need for superior reliability

CONCLUSIONS in the propulsion gear train.

Most engineering progress is evolutionary and

very seldom, indeed, revolutionary, notwithstanding A POSSIBLE SOLUTION

claims of some professional advertisers whose main Triple, in lieu of double, reduction gearing will

stock in trade is adjectives of superlativity. demonstrably greatly expand the procurement po-

A propulsion gearing problem, when licked, al- tential and can promptly remove one of the greatest

ways seems a simple, logical, soundly professional of our national hazards in the event of another major

piece of engineering reasoning, and most everyone conflict. Great emphasis is today placed op the dis-

figures that the solution was easy (after the event) persal of important production facilities, 3f we were

and never stops to inquire as to how many profes- irrevocably tied to double helical gearing designs, it

sional casualties occurred as the problem walked would be found that the few manufacturers who

266 A.S.N.6. J o u u l . Mar 1-51

R.E. W. HARRISON MARINE PROPULSION GEARING

could make the large diameter gearing involved em automotive and aircraft gears are designed for limited

would all be within a 30 minute flying radius in a life. This is sheer nonsense and merely reflects an affect of

their cloistered life. Other “can’t-be-done” arguments are

modem jet propelled enemy bomber. Obviously this equally invalid.

represents the quintessence of wartime procurement Prognss in the development of amall, light and relatively

vulnerability. inexpensive ship pt‘opulsion gears cannot be expected as long

On the other hand with gear sizes limited to a as the development programs are baaed upon competitive

designs prepared by the old, regular suppliera because thew

maximum of 60” diameter, the dispersing of facilities organizations know only the long outmoded way to deqign

would be trebled and the avadability of manufac- and manufacture g e a a Better gears w i l l not be available

turers increased tenfold. unless and until the job is entrusted to gear manufacturers

who know the facts of gear life. Only such o g p n i u t i ~can

~

Equally obviously, such broader basis of procure- think and produce in turns of modem h u d surface, nurow

ment would improve the competitive position in both faced geam It b up to the lnrge purchuMto n y han long

war and peacetime to the point where the cost to the we must plod doog with outdated geua w h i b the r u d d e r

government of the mechanisms under discussion can of the Ehip, puti&ly in the N8vy. b M modern a# yater-

be greatly reduced. &Y.

A similar dtuntion conirontcd our rpilrodr a few years

ago. The remedy in that as in m y d e r static in-

GXPHIIGNCE (THERE IS NO mseuAm s u ~ s m v l . r ) durtria, b fantYrr to dl of you. In a few yeara the anti-

It seems proper to conclude this article with the quated, in&cht rtum bcaamtlva are beaning museum

pi- becaumetb. job wast.tQIoverby a dynamic organiza-

remarks of a famous gear engineer,. who has d c tion. It is, of EOUL~C,unforhuurte that the old static loanno-

voted many years of intensive study to this subject. tive buildem m w e hurt in the trondtion, but it wan a result

In his own particular field (gearing) he has a repu- Ofthcirownrcdaurccto~

tation for hardheaded engineering logic, which has There are m y gear manufacturers who are competent

spelled success and profit to his Corporation (the and ready to do for ship propuLiasl gears what h~ already

bees done for locuinotivea T)MII) 4 h o m e r . an import.nt

hugest in the world). difFuenec. The pobntirl locomotive market WM great enough

The designers ond builderr, of conventional ship proplkioa to anmnt private expendltuma for the wcclpry nrarch

gmn, whether intended for warahiw, cargo .hipa amst

and development period prior to 0P.rtatjLLg the new pmduct.

guard or tugs are quick to defend their products .eJNt It b doubtful t h t the p0tCnti.l market for rhip amplldaa

attack. One favorite argument is their supposition that mad-

geam M justify prlvate remarch uul devdapncnt Thk

iuitial outlay murt be d by a m e n t agency

* J. 0.Mncn through a Contrrcc to an up-to-d.te gear muda&ud-

The 200 inch gear hobbers at 6eneral Etoctric’s Lynn hob gears of

up to 200 inch dimetar, 88 inch face width, and woighimg up to I44,OOO

pounds. Despite the enormous rim and weight invdvod, tooth-bhth

spacing variations of leu than 0.0002 inch are maintained. An ebctrid

device sets off an alarm if the gear should shift as l i i e as one millionth

of an inch during hobbing.

A.S.N.P. JOU~WI.UW im 267

You might also like

- Naval: The Cost of SpeedDocument3 pagesNaval: The Cost of SpeedebyNo ratings yet

- Merlin XX EngineDocument6 pagesMerlin XX EngineIvan Kopić100% (2)

- The Shore Testing of Marine Gas Turbine Ship PropulsionDocument6 pagesThe Shore Testing of Marine Gas Turbine Ship PropulsionMarkNo ratings yet

- How To Design A Big New WinchDocument4 pagesHow To Design A Big New WinchMahdiNo ratings yet

- The Application and Advantages of Catamarans For Coastal Patrol Vessels, SNAME, May 1995 (Missing Figures)Document27 pagesThe Application and Advantages of Catamarans For Coastal Patrol Vessels, SNAME, May 1995 (Missing Figures)Matheus Ferri100% (1)

- Marine PropulsionDocument8 pagesMarine PropulsionThomas StNo ratings yet

- Hydraulics in Flight-Deck Machinery: Paper 2Document12 pagesHydraulics in Flight-Deck Machinery: Paper 2Jeff ShellenbergerNo ratings yet

- Barge Structure SSCDocument8 pagesBarge Structure SSCLenin ValerioNo ratings yet

- Eve Men Advanced: Ac With CraftDocument11 pagesEve Men Advanced: Ac With CraftsrhthhtNo ratings yet

- Propeller Selection and Optimizacion PDFDocument102 pagesPropeller Selection and Optimizacion PDFMerrel RossNo ratings yet

- ENIRAM - Guide To Dynamic Trim Optimization 280611 PDFDocument14 pagesENIRAM - Guide To Dynamic Trim Optimization 280611 PDFPhineas MagellanNo ratings yet

- BMTDSL The Advanced Waterjet Confpaper INEC May10 PDFDocument13 pagesBMTDSL The Advanced Waterjet Confpaper INEC May10 PDFhieuhuech1No ratings yet

- The Propulsion & Manoeuvring Concept of The BCF-Super C - Class Double End FerriesDocument8 pagesThe Propulsion & Manoeuvring Concept of The BCF-Super C - Class Double End FerriesLelosPinelos123No ratings yet

- 5044 Ships and SubmarinesDocument36 pages5044 Ships and Submarinesmohamedalfi51No ratings yet

- Marine Use of Gas Turbines PDFDocument8 pagesMarine Use of Gas Turbines PDFVenu MadhavNo ratings yet

- Effects of Propeller Design-Point Definition On The PerformanceDocument30 pagesEffects of Propeller Design-Point Definition On The PerformanceDaniel Riveros100% (1)

- PID Marine Engine Speed Regulation Under Full Load Conditions For Sensitivity H Norm Specifications Against Propeller DisturbanceDocument10 pagesPID Marine Engine Speed Regulation Under Full Load Conditions For Sensitivity H Norm Specifications Against Propeller DisturbanceHa Di KhNo ratings yet

- JAN2015 MT GrunditzDocument8 pagesJAN2015 MT GrunditzSahil Jawa100% (1)

- Fast Attack Combatant For Near-Shore OperationDocument11 pagesFast Attack Combatant For Near-Shore OperationVokramNo ratings yet

- Book Marine Propellers and Propulsion (CARLTON)Document18 pagesBook Marine Propellers and Propulsion (CARLTON)Jhason ChristNo ratings yet

- Research Paper On Kaplan TurbineDocument7 pagesResearch Paper On Kaplan Turbinengqcodbkf100% (1)

- Design of Propulsion Systems For High-Speed CraftDocument17 pagesDesign of Propulsion Systems For High-Speed Craftaeromexpower2009No ratings yet

- Electric Drive For Battle Ship, by Nikola Tesla, New York Herald, 1917Document5 pagesElectric Drive For Battle Ship, by Nikola Tesla, New York Herald, 1917dag57No ratings yet

- Electric Drive For Battle Ship, by Nikola Tesla, New York Herald, 1917Document5 pagesElectric Drive For Battle Ship, by Nikola Tesla, New York Herald, 1917dag57No ratings yet

- Electric Drive For Battle Ship, by Nikola Tesla, New York Herald, 1917Document5 pagesElectric Drive For Battle Ship, by Nikola Tesla, New York Herald, 1917dag57No ratings yet

- Operating Experience With Modern High Speed Diesel Engine in Ship Assist Tugs and Related Requirements For Future Engine DevelopmentDocument18 pagesOperating Experience With Modern High Speed Diesel Engine in Ship Assist Tugs and Related Requirements For Future Engine DevelopmentYao WeiNo ratings yet

- Electric Drive For Battle Ship, by Nikola Tesla, New York Herald, 1917Document5 pagesElectric Drive For Battle Ship, by Nikola Tesla, New York Herald, 1917dag57No ratings yet

- CHAPTER 2 PROPULSION SYSTEM - Marine Propellers and Propulsion - JOHN CARLTONDocument20 pagesCHAPTER 2 PROPULSION SYSTEM - Marine Propellers and Propulsion - JOHN CARLTONNur Salim100% (1)

- R90 - p6 - Full Block ShipsDocument2 pagesR90 - p6 - Full Block ShipsBozidar SaricNo ratings yet

- Design of Propulsion Systems For High-Speed Craft - Blount, Bartee 1997Document17 pagesDesign of Propulsion Systems For High-Speed Craft - Blount, Bartee 1997Leandro MeiliNo ratings yet

- Refri RSWDocument11 pagesRefri RSWCah Ndeso KlutukNo ratings yet

- Russo V L.submarine Tankers.1960.TRANSDocument50 pagesRusso V L.submarine Tankers.1960.TRANSLe Anh Tuan100% (1)

- Modern Tug DesignDocument83 pagesModern Tug DesignJohn Angelo Tuliao100% (1)

- Abstract-Fully Enhanced Gas Turbine For Surface Ships PDFDocument12 pagesAbstract-Fully Enhanced Gas Turbine For Surface Ships PDFABHIRAM RNo ratings yet

- The Propulsion of A 12 500TEU Container Ship: JS Carlton, Lloyd's Register, LondonDocument15 pagesThe Propulsion of A 12 500TEU Container Ship: JS Carlton, Lloyd's Register, LondonŞansal DikmenerNo ratings yet

- 2012chennai SubmarineDesignDocument27 pages2012chennai SubmarineDesignPericlesleiteNo ratings yet

- Deconstructing The Propulsion ConundrumDocument13 pagesDeconstructing The Propulsion ConundrumNajmul Puda PappadamNo ratings yet

- Journal of Marine Science and Application November 2019Document20 pagesJournal of Marine Science and Application November 2019ikusumaNo ratings yet

- Ote 4543 Topside Facilities For Floating Production Systems Require Engineering ThinkingDocument10 pagesOte 4543 Topside Facilities For Floating Production Systems Require Engineering Thinkingthlim19078656No ratings yet

- 1959 5 EngDocument14 pages1959 5 EngTateNo ratings yet

- A Ship For Research in Naval Architecture - Robert Taggart 1957Document7 pagesA Ship For Research in Naval Architecture - Robert Taggart 1957Fernando Raúl LADINONo ratings yet

- Marine EnginesDocument12 pagesMarine EnginesSyukry MaulidyNo ratings yet

- Auricula.: NotesDocument9 pagesAuricula.: NotesAditya RaoNo ratings yet

- Propulsion Control Strategies For SHip Emergency ManoeuvresDocument11 pagesPropulsion Control Strategies For SHip Emergency Manoeuvresinfo sme india100% (1)

- Flying-Boats:: The Form and Dimensions of Their HullDocument1 pageFlying-Boats:: The Form and Dimensions of Their HullMark Evan SalutinNo ratings yet

- 5 Propeller DesignDocument50 pages5 Propeller DesignAnca GeaninaNo ratings yet

- Lankford 1968Document7 pagesLankford 1968pidutNo ratings yet

- Fix Pitch PropellerDocument7 pagesFix Pitch PropellerRisandi Dwirama PutraNo ratings yet

- FAQ Propeller Modification ShipcareDocument6 pagesFAQ Propeller Modification ShipcareJayjay TabuzoNo ratings yet

- 09-Hl47 Trim Optimisation - Sustainable SavingsDocument2 pages09-Hl47 Trim Optimisation - Sustainable SavingspothirajkalyanNo ratings yet

- John Et Al, 2011Document9 pagesJohn Et Al, 2011Muhamad Nazren Mohamed ZaidiNo ratings yet

- 2 193 Suryo Adji ch07Document47 pages2 193 Suryo Adji ch07Jón Ingvar PálssonNo ratings yet

- Matching Propulsion Engine With PropulsorDocument9 pagesMatching Propulsion Engine With PropulsorAnonymous gxAd4liNo ratings yet

- The Aircraft Engineer May 29, 1931Document8 pagesThe Aircraft Engineer May 29, 1931Mark Evan SalutinNo ratings yet

- FPSO-Design-to-Minimize-Operational-Downtime Refer For Limiting Conditions in Operations PDFDocument15 pagesFPSO-Design-to-Minimize-Operational-Downtime Refer For Limiting Conditions in Operations PDFRini MathewNo ratings yet

- INEC 2020 Paper 29Document16 pagesINEC 2020 Paper 29TasnikNo ratings yet

- Propeller Selection and Optimizacion PDFDocument102 pagesPropeller Selection and Optimizacion PDFMerrel RossNo ratings yet

- Guide For Supplementary Ventilation in A Ship S Cargo Hold When Using Internal Combustion EnginesDocument30 pagesGuide For Supplementary Ventilation in A Ship S Cargo Hold When Using Internal Combustion EnginesMerrel RossNo ratings yet

- Medium and Highspeed Diesel Engines For Marine Service 1938Document11 pagesMedium and Highspeed Diesel Engines For Marine Service 1938Merrel RossNo ratings yet

- Ch1 Hvac System Analysis and Selection PDFDocument10 pagesCh1 Hvac System Analysis and Selection PDFMerrel RossNo ratings yet

- Metodo de Holtrop y Mennem - ch50Document17 pagesMetodo de Holtrop y Mennem - ch50Merrel RossNo ratings yet

- Interpretations of The MODU SDocument41 pagesInterpretations of The MODU SMerrel RossNo ratings yet

- Diesel and Gas Turbine WorldwideDocument78 pagesDiesel and Gas Turbine WorldwideMerrel RossNo ratings yet

- Marine Machinery CourseDocument452 pagesMarine Machinery CourseMerrel Ross100% (1)

- Cicloidal Propulsion and Control For Ship Handling TugsDocument18 pagesCicloidal Propulsion and Control For Ship Handling TugsMerrel RossNo ratings yet

- Second Generation Gas TurbinaDocument5 pagesSecond Generation Gas TurbinaMerrel RossNo ratings yet

- SD OverviewDocument85 pagesSD OverviewSamatha GantaNo ratings yet

- Sindhudurg Kokan All Tourism Spot Information WWW - Marathimann.inDocument54 pagesSindhudurg Kokan All Tourism Spot Information WWW - Marathimann.inMarathi Mann92% (12)

- Photosynthesis 9700 CieDocument8 pagesPhotosynthesis 9700 CietrinhcloverNo ratings yet

- Edgardo Macabulos - FS1-Activity-1Document8 pagesEdgardo Macabulos - FS1-Activity-1Macabulos Edgardo SableNo ratings yet

- Jacob Boehme Bibliography 6 August LatestDocument20 pagesJacob Boehme Bibliography 6 August Latestuli20No ratings yet

- Canine HyperlipidaemiaDocument11 pagesCanine Hyperlipidaemiaheidy acostaNo ratings yet

- Jackson Et Al 2019 Using The Analytical Target Profile To Drive The Analytical Method LifecycleDocument9 pagesJackson Et Al 2019 Using The Analytical Target Profile To Drive The Analytical Method LifecyclerbmoureNo ratings yet

- DBI Setup Steps For Procurement IntelligenceDocument4 pagesDBI Setup Steps For Procurement IntelligenceAnubhav.MittalNo ratings yet

- Lolita Enrico Vs Heirs of Spouses Eulogio Medinaceli and Trinidad MedinaceliDocument3 pagesLolita Enrico Vs Heirs of Spouses Eulogio Medinaceli and Trinidad Medinacelichatmche-06No ratings yet

- 7 Critical Reading StrategiesDocument1 page7 Critical Reading StrategiesWilliam Holt100% (2)

- Si493b 1Document3 pagesSi493b 1Sunil KhadkaNo ratings yet

- D78846GC20 sg2Document356 pagesD78846GC20 sg2hilordNo ratings yet

- Tate J. Hedtke SPED 608 Assignment #6 Standard # 8 Cross Categorical Special Education/ Learning Disabilities Artifact SummaryDocument5 pagesTate J. Hedtke SPED 608 Assignment #6 Standard # 8 Cross Categorical Special Education/ Learning Disabilities Artifact Summaryapi-344731850No ratings yet

- Transportation Research Part F: Andreas Lieberoth, Niels Holm Jensen, Thomas BredahlDocument16 pagesTransportation Research Part F: Andreas Lieberoth, Niels Holm Jensen, Thomas BredahlSayani MandalNo ratings yet

- The Christian Life ProgramDocument28 pagesThe Christian Life ProgramRalph Christer MaderazoNo ratings yet

- Electronic Check ProcessingDocument1 pageElectronic Check Processingaaes2No ratings yet

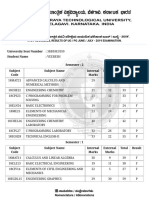

- VTU Result PDFDocument2 pagesVTU Result PDFVaibhavNo ratings yet

- Dribssa Beyene Security Sector Reform Paradox Somalia PublishedDocument29 pagesDribssa Beyene Security Sector Reform Paradox Somalia PublishedNanny KebedeNo ratings yet

- Jain Gayatri MantraDocument3 pagesJain Gayatri MantraShil9No ratings yet

- Superscope, Inc. v. Brookline Corp., Etc., Robert E. Lockwood, 715 F.2d 701, 1st Cir. (1983)Document3 pagesSuperscope, Inc. v. Brookline Corp., Etc., Robert E. Lockwood, 715 F.2d 701, 1st Cir. (1983)Scribd Government DocsNo ratings yet

- Sally Mann Hold Still - A Memoir With Photographs (PDFDrive)Document470 pagesSally Mann Hold Still - A Memoir With Photographs (PDFDrive)danitawea100% (1)

- Eco - Module 1 - Unit 3Document8 pagesEco - Module 1 - Unit 3Kartik PuranikNo ratings yet

- GEHealthcare Brochure - Discovery CT590 RT PDFDocument12 pagesGEHealthcare Brochure - Discovery CT590 RT PDFAnonymous ArdclHUONo ratings yet

- Adjective Clauses: Relative Pronouns & Relative ClausesDocument4 pagesAdjective Clauses: Relative Pronouns & Relative ClausesJaypee MelendezNo ratings yet

- Why The Sea Is SaltDocument3 pagesWhy The Sea Is SaltVictor CiobanNo ratings yet

- Post-Stroke Rehabilitation: Kazan State Medical UniversityDocument11 pagesPost-Stroke Rehabilitation: Kazan State Medical UniversityAigulNo ratings yet

- MODULE 13 Ethics Through Thick and ThinDocument7 pagesMODULE 13 Ethics Through Thick and ThinCristobal M. CantorNo ratings yet

- Unit 5 - Simulation of HVDC SystemDocument24 pagesUnit 5 - Simulation of HVDC Systemkarthik60% (10)

- Pplied Hysics-Ii: Vayu Education of IndiaDocument16 pagesPplied Hysics-Ii: Vayu Education of Indiagharib mahmoudNo ratings yet

- PPH CasestudyDocument45 pagesPPH CasestudyRona Mae PangilinanNo ratings yet