Professional Documents

Culture Documents

Galvanized Steel Grade Data Sheets

Uploaded by

Harendra kumar0 ratings0% found this document useful (0 votes)

220 views2 pagesSheet facts

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSheet facts

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

220 views2 pagesGalvanized Steel Grade Data Sheets

Uploaded by

Harendra kumarSheet facts

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

C a n a d i a n S h e e t S t e e l B u i l d i n g I n s t i t u t e

Sheet Steel Facts

May 2006

Sheet Steel Gauges

and Thicknesses

Within the construction industry there is often confusion Base Steel Thickness: The thickness of the sheet steel material

over gauges, gauge numbers and the actual thickness. The without any coatings.

industry has been trying to move away from gauge numbers,

without complete success. The following information will Coated Thickness: The thickness of the steel sheet including

show why sheet steel products should be specified to the any metallic coatings (i.e. zinc or 55% aluminum-zinc alloy)

decimal thickness. and paint coatings.

Design Thickness: The design thickness is the thickness of

Manufacturers’ Standard Gauge For the base steel only, and is used by the engineer to determine

Steel Sheets the structural properties of the cold formed product. This is

The most common gauge system used in Canada for the thickness that a manufacturer will list in their product

structural sheet steel products is the Manufacturers’ catalogues and load tables, where it could also be called the

Standard Gauge (MSG). The MSG for steel sheets was nominal base steel thickness.

developed having a DEFINITE THICKNESS equivalent for

each gauge number. In the standard gauge system the Minimum Thickness: The minimum thickness of structural

density of steel is taken as 489.6 lbs/ft3, or 40.80 lbs/ft2/in. sheet steel building products delivered to the job site will be

However, since sheet weights are calculated on the basis of the design thickness minus the maximum allowable under-

specified width and length, with all shearing on the over tolerance specified by the CSA-S136-2001 Standard or the

side, and also since sheets are somewhat thicker at the centre material specification, whichever is the more restrictive. The

than they are at the edges, a further adjustment was made minimum thickness allowed by the CSA-S136-2001 Standard

to obtain a closer approximation for inter-changeability is 95% of the design thickness.

between weight and thickness. Over a long period of time

this value for sheets has been found to be close to 2.5 per Gauge Number And Decimal Thickness

cent heavier than 40.80 lb/ft2/in. A figure of 41.820 lb/ft2/in Table 1 shows the relationship between the MSG numbers,

is the one commonly used to express the relationship the nominal or design thickness, and the minimum

between weight and thickness for steel sheet. thickness based on the CSA-S136-2001 Standard.

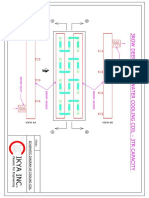

Table 1 - MSG Sheet Steel Gauge

The Galvanized Sheet Gauge Numbers and Thickness

The Galvanized Sheet Gauge is an older system used

primarily by the trades consuming non-structural galvanized Gauge Minimum Base Steel Design Thickness

steel and is a measure of the zinc coated sheet thickness. It Number Thickness (Nominal Base

was developed in the early days of galvanizing before (95% of Design Thickness) Steel Thickness)

sophisticated wipers were available and, consequently, zinc inches mm inches mm

thicknesses were thicker than today. The GSG system was 8 0.1562 3.967 0.1644 4.176

used on some of the older gauge charts published years ago 10 0.1278 3.245 0.1345 3.416

that unfortunately still seem to get used even today. 12 0.0994 2.524 0.1046 2.657

13 0.0852 2.164 0.0897 2.278

Thickness Definitions 14 0.0710 1.802 0.0747 1.897

There are a number of terms used for sheet steel products 15 0.0639 1.624 0.0673 1.709

that need to be explained because they will affect the 16 0.0568 1.443 0.0598 1.519

thickness of product that could be delivered to the job site. 18 0.0454 1.153 0.0478 1.214

20 0.0341 0.866 0.0359 0.912

Nominal Thickness: When sheet steel is produced by the 22 0.0284 0.721 0.0299 0.759

steel companies it is manufactured to a target or “nominal” 24 0.0227 0.577 0.0239 0.607

thickness. As with all manufacturing processes, variations in 26 0.0170 0.432 0.0179 0.455

the final thickness of the sheet are unavoidable. However, 28 0.0142 0.359 0.0149 0.378

the thickness is controlled very tightly to ensure that it does 29 0.0128 0.326 0.0135 0.343

not fall below the minimum thickness (as described below). 30 0.0114 0.290 0.0120 0.305

(Replaces February 2006)

C a n a d i a n S h e e t S t e e l B u i l d i n g I n s t i t u t e

Minimum Thickness Allowance Table 4 – Minimum Thickness for

for Coatings Prefinished(1) Sheet

Sheet steel products are normally coated with a metallic

coating (i.e. zinc or 55% aluminum-zinc alloy), and also may Minimum Base Steel

be painted. The minimum thicknesses of typical hot-dipped Gauge Thickness Minimum Coated

metallic coatings are given in Table 2. The metallic coating Number (95% of Design Thickness) Steel Thickness

thickness must be added to the minimum base sheet inches mm inches mm

thickness when determining the delivered sheet thickness. 20 0.0341 0.866 0.0369 0.939

Metallic coatings are also subject to manufacturing 22 0.0284 0.721 0.0312 0.794

tolerances the same as the base steel. Therefore, the actual 24 0.0227 0.577 0.0255 0.650

thickness of the metallic coating will generally be greater 26 0.0170 0.432 0.0198 0.505

than the minimums listed in Table 2. This factor needs to 28 0.0142 0.359 0.0170 0.432

be considered when attempting to verify the base steel 29 0.0128 0.326 0.0156 0.399

thickness of a coated product. 30 0.0114 0.290 0.0142 0.363

(1) The sheet has a G90 (Z275) zinc coating (0.0015 in./0.040 mm), an

Table 2 - Minimum Metallic Coating 8000+ Series paint coating on the finish side (0.001 in./0.025 mm) and a

Thicknesses wash coat on the reverse side (0.0003 in./0.008 mm).

Minimum Minimum Additional Gauge Equivalents for

Coating Thickness Coating Thickness

Designation (inches) Designation (mm)

Steel Studs

The steel stud industry in Canada has in regular use additional

A01 0.0004 ZF001 0.010 gauge number equivalents that are different than shown in Table 1.

A25 0.0007 ZF075 0.018 Starting in June 2004, Canada will join the United States and adopt

G01 0.0004 Z001 0.010 a common set of standard base steel thicknesses for lightweight

G60 0.0010 Z180 0.025 steel framing components (e.g. studs and joists). These gauges are

G90 0.0015 Z275 0.038 unique to this industry and are shown in Table 5. The CSA-S136-

AZ50 0.0016 AZM150 0.041 2001 maximum under-tolerance also applies to these gauges as well

AZ55 0.0018 AZM165 0.046 as does the metallic coating allowances listed in Table 2.

AZ60 0.0020 AZM180 0.051 Table 5 – Standard Thicknesses for

Lightweight Steel Framing Components

A significant amount of sheet steel is also prefinished with

a paint system on top of the metallic coating. The thickness Designation Minimum Base Design Steel Framing

of these paint/primer layers must also be included when Thickness Steel Thickness(1) Thickness Gauge No. (for

(mils)(2) (in.) (mm) (in.) (mm) reference only)

measuring the thickness of the sheet. The thicknesses of

typical paint coatings vary from 0.0003 to 0.001 in. (0.008 18 0.0179 0.455 0.0188 0.478 25

to 0.025 mm) per side. Some thick film paint systems (e.g. 30 0.0296 0.752 0.0312 0.792 20 – Drywall

Barrier Series) have thicknesses of 0.004 to 0.012 in. (0.100 33 0.0329 0.836 0.0346 0.879 20 – Structural

to 0.300 mm). Listed in Table 3 are the thicknesses of 43 0.0428 1.087 0.0451 1.146 18

common prefinished paint systems used in Canada. 54 0.0538 1.367 0.0566 1.438 16

68 0.0677 1.720 0.0713 1.811 14

Table 3 - Thicknesses of Prefinished 97 0.0966 2.454 0.1017 2.583 12

Paint Systems 118 0.1180 2.997 0.1242 3.155 10

Paint Nominal Thickness(1) (1) Minimum thickness represents 95% of the design thickness. Metric (mm)

minimum thicknesses were calculated by converting the Imperial (in.) values.

System mm (2) A “mil” is 1/1000 of an inch (e.g. 30 mils is 0.030 inches).

inches

8000+ Series, HMP 0.001 0.025 Conclusion

10000 Series 0.001 0.025 An important thing to remember about gauge numbers is that

Elite and Metallic Series 0.002 0.051 they do not refer to only one thickness but instead represent a

Barrier Series – 4 mil 0.004 0.100 range of thicknesses within the allowable tolerances, or to

Barrier Series – 8 mil 0.008 0.200 different thicknesses for different products. Gauge numbers are

Barrier Series – 12 mil 0.012 0.300 not regulated and are generally used for convenience in sales

Washcoat 0.0003 0.008 literature. Decimal thickness is required for structural design

(1) The paint thicknesses listed are per coated side. and material ordering. The steel industry encourages everyone

to use decimal thicknesses in specifying sheet steel products

and avoid the potential problems inherent with gauges.

Minimum Thickness for Common

Prefinished Material For More Information

Table 4 shows the minimum thickness for a galvanized sheet For more information on sheet steel building products, or

with a common paint system. to order any CSSBI publications, contact the CSSBI at the

address shown below or visit the web site at www.cssbi.ca

652 Bishop St. N., Unit 2A, Cambridge, Ontario N3H 4V6 • Tel.: (519) 650-1285 • Fax: (519) 650-8081

You might also like

- FFFFDocument4 pagesFFFFChaudhary Hassan AliNo ratings yet

- Supertec Galvanized Steel SpecsDocument6 pagesSupertec Galvanized Steel Specszineil BlackwoodNo ratings yet

- Detailing of Reinforcement in Concrete Structures Volume 1Document244 pagesDetailing of Reinforcement in Concrete Structures Volume 1Ahmed Refaey100% (4)

- Light Steel Framing Members General Informa On: General Notes For All TablesDocument9 pagesLight Steel Framing Members General Informa On: General Notes For All TablesrobertofortNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- TSN Cold Formed Steel Framing Standard Stud Technical CatalogDocument56 pagesTSN Cold Formed Steel Framing Standard Stud Technical Catalogjoledil592No ratings yet

- Metallic Coated Sheet Steel For Structural Building ProductsDocument3 pagesMetallic Coated Sheet Steel For Structural Building Productsdaha333No ratings yet

- Technical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingDocument3 pagesTechnical Differences Between General or Batch Type and Continues Sheet Hot Dip GalvanizingNestramiNo ratings yet

- Cold Rolling MillDocument4 pagesCold Rolling MillArslan BohioNo ratings yet

- Hot Dip GalvanisedDocument20 pagesHot Dip Galvanisedepsa333100% (1)

- En 10143Document3 pagesEn 10143Anonymous JoB5ZxgNo ratings yet

- ISL G.I SheetDocument3 pagesISL G.I Sheetmalik hafeezNo ratings yet

- ISL G.I SheetDocument3 pagesISL G.I Sheetmalik hafeez0% (1)

- Rectangular-K27 Duct and Fittings Dimensions: Table 1Document31 pagesRectangular-K27 Duct and Fittings Dimensions: Table 1Shaun SullivanNo ratings yet

- CSSBI-Steel Roof Deck Floor DeckDocument13 pagesCSSBI-Steel Roof Deck Floor Deckizia_2100% (1)

- SECTION 09 22 16 Non-Structural Metal FramingDocument11 pagesSECTION 09 22 16 Non-Structural Metal FramingRima Baz FadousNo ratings yet

- Ingal - As NZS 4680 2006 - Ingalsm3Document6 pagesIngal - As NZS 4680 2006 - Ingalsm3Ramiro RivasNo ratings yet

- C 955 - 01 Qzk1ns1sruqDocument6 pagesC 955 - 01 Qzk1ns1sruqHumberto GutierrezNo ratings yet

- Decking and Roofing BrochureDocument4 pagesDecking and Roofing BrochurejsbharadwajNo ratings yet

- Design Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyDocument5 pagesDesign Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanypuneethudupiNo ratings yet

- Ttha 115Document17 pagesTtha 115san moedanoNo ratings yet

- Basic Sheet and Coil Training Edit VersionDocument35 pagesBasic Sheet and Coil Training Edit VersioncuongdcNo ratings yet

- Cssbi B13-19Document81 pagesCssbi B13-19Jose L MexiaNo ratings yet

- C1.1.0 Ajiya - 2018 - Roofing Catalogue Clip Lock ProfileDocument8 pagesC1.1.0 Ajiya - 2018 - Roofing Catalogue Clip Lock ProfileFahmi YusoffNo ratings yet

- AN 02.6 Thicker Galvanized Coatings For Specialised ApplicationsDocument10 pagesAN 02.6 Thicker Galvanized Coatings For Specialised Applicationsseii.chenNo ratings yet

- Hot Dip GalvanizDocument3 pagesHot Dip GalvanizRyan Adriadi NNo ratings yet

- Hot Dip Galvanizing For FastenersDocument3 pagesHot Dip Galvanizing For FastenersIrwin CastroNo ratings yet

- Design Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyDocument5 pagesDesign Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyVikram BorkhediyaNo ratings yet

- 0 Sa-263Document23 pages0 Sa-263avazcNo ratings yet

- Sheet Metal Design1Document57 pagesSheet Metal Design1Mohamed ZeinNo ratings yet

- 01.1 GalvInfoNote-1-1-Rev-4-0Document11 pages01.1 GalvInfoNote-1-1-Rev-4-0Silverio AcuñaNo ratings yet

- Amendment No. 1 Hot-Dip Zinc Coatings On Steel and Cast Iron ProductsDocument2 pagesAmendment No. 1 Hot-Dip Zinc Coatings On Steel and Cast Iron ProductsGMSNo ratings yet

- Appendix A (Wei-Wen Yu)Document2 pagesAppendix A (Wei-Wen Yu)Flynn RiderNo ratings yet

- Sheet Metal: Navigation SearchDocument10 pagesSheet Metal: Navigation SearchAnonymous rYZyQQot55No ratings yet

- Sheet Metal Design Guide 1Document13 pagesSheet Metal Design Guide 1Hydra JagguNo ratings yet

- E449 AnjestDocument8 pagesE449 AnjestMuhammad El-FahamNo ratings yet

- Understanding Coating Weight Designations For Zinc-Based Coatings On Steel SheetDocument11 pagesUnderstanding Coating Weight Designations For Zinc-Based Coatings On Steel SheetkhurshedlakhoNo ratings yet

- Understanding Coating Weight Designations For Zinc-Based Coatings On Steel SheetDocument11 pagesUnderstanding Coating Weight Designations For Zinc-Based Coatings On Steel SheetOlgalycosNo ratings yet

- C955 09Document4 pagesC955 09jacr27No ratings yet

- C 955 Â " 00 QZK1NS0WMEEDocument4 pagesC 955 Â " 00 QZK1NS0WMEESebastián RodríguezNo ratings yet

- 1) GalvInfoNote - 1 - 1Document2 pages1) GalvInfoNote - 1 - 1bernardNo ratings yet

- Publication - Painting, Coating & Corrosion Protection - Perry Metal Protection - Specifying Hot Dip GalvanizingDocument8 pagesPublication - Painting, Coating & Corrosion Protection - Perry Metal Protection - Specifying Hot Dip Galvanizingzinha_alNo ratings yet

- Investment CastingDocument8 pagesInvestment Castingbandit96No ratings yet

- Load-Bearing (Transverse and Axial) Steel Studs, Runners (Tracks), and Bracing or Bridging For Screw Application of Gypsum Panel Products and Metal Plaster BasesDocument4 pagesLoad-Bearing (Transverse and Axial) Steel Studs, Runners (Tracks), and Bracing or Bridging For Screw Application of Gypsum Panel Products and Metal Plaster BasesJesús Luis Arce GuillermoNo ratings yet

- CMP0034028 Dc1 Roof Wall &deckingDocument8 pagesCMP0034028 Dc1 Roof Wall &deckingyoga arkanNo ratings yet

- Bms HB 3000-b Brinell-HardheidstesterDocument20 pagesBms HB 3000-b Brinell-HardheidstesterKumara SubramanianNo ratings yet

- B 101 - 01 Qjewms1sruqDocument7 pagesB 101 - 01 Qjewms1sruqFadjar ZulkarnainNo ratings yet

- Wear Resistant Steel: Material Data Sheet, Edition April 2016Document6 pagesWear Resistant Steel: Material Data Sheet, Edition April 2016Zoltán PálfyNo ratings yet

- Ansi Sdi NC 2017 StandardDocument15 pagesAnsi Sdi NC 2017 StandardSiavash KNo ratings yet

- TR60+ Data SheetDocument2 pagesTR60+ Data SheetEmanuel PopaNo ratings yet

- Steel, Structural Tubing, Cold Formed, Welded, Carbon, Zinc-Coated (Galvanized) by The Hot-Dip ProcessDocument3 pagesSteel, Structural Tubing, Cold Formed, Welded, Carbon, Zinc-Coated (Galvanized) by The Hot-Dip ProcessAli Saleh Saad AL-isawiNo ratings yet

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- Asme2b sb-171 DDFDocument8 pagesAsme2b sb-171 DDFzingalehe25464No ratings yet

- Ajiya 2018 CATALOGUE-B2 Rev10-1Document4 pagesAjiya 2018 CATALOGUE-B2 Rev10-1manova enterpriseNo ratings yet

- Sheet MetalDocument46 pagesSheet Metalpreetham shekarNo ratings yet

- NEBB Talk I Basics PDFDocument40 pagesNEBB Talk I Basics PDFMohamedNo ratings yet

- Catalogue Sprinkler enDocument54 pagesCatalogue Sprinkler enHarendra kumarNo ratings yet

- A People's Manual On Rainwater Harvesting: Janhit FoundationDocument8 pagesA People's Manual On Rainwater Harvesting: Janhit FoundationHarendra kumarNo ratings yet

- Gs Site Char Guidance Draft Final 031611Document170 pagesGs Site Char Guidance Draft Final 031611Harendra kumarNo ratings yet

- How To Size and Design DuctsDocument91 pagesHow To Size and Design DuctsPrabir Bhowmik100% (1)

- Galvanized Steel Grade Data SheetsDocument3 pagesGalvanized Steel Grade Data Sheetsأيمن أبو عيدNo ratings yet

- HVAC Interview Test PDFDocument5 pagesHVAC Interview Test PDFHarendra kumarNo ratings yet

- Coil DesignDocument1 pageCoil DesignHarendra kumarNo ratings yet

- ASHRAE52Document8 pagesASHRAE52ziko23No ratings yet

- PMP Exam Prep Training BrochureDocument10 pagesPMP Exam Prep Training BrochureHarendra kumarNo ratings yet

- Cold Storage of Fruits and VegetablesDocument3 pagesCold Storage of Fruits and Vegetablesunforgiven66100% (1)

- StoryDocument2 pagesStoryHarendra kumarNo ratings yet

- NR 5 Chilled Beam ApplicationDocument75 pagesNR 5 Chilled Beam ApplicationLaurentiuNo ratings yet

- HvacDocument236 pagesHvacvinothNo ratings yet

- One Day The Pirate Modi Was Out Running Errands With His MomDocument1 pageOne Day The Pirate Modi Was Out Running Errands With His MomHarendra kumarNo ratings yet

- DM HvacDocument356 pagesDM HvacTuấn Quách100% (2)

- ASHRAE SWFL Chapter - Library Archive: HistoryDocument1 pageASHRAE SWFL Chapter - Library Archive: HistoryHarendra kumarNo ratings yet

- Advance Welding RME-081Document69 pagesAdvance Welding RME-081enjoy your dayNo ratings yet

- Medidor Caudal Kobold Flotador UrkDocument4 pagesMedidor Caudal Kobold Flotador UrkBase SistemasNo ratings yet

- Aropol in 1005 PDocument2 pagesAropol in 1005 PPathik PatelNo ratings yet

- WSP Post-Installed RebarDocument52 pagesWSP Post-Installed RebarSantosoNo ratings yet

- Aluminium Window and Door Hardware FittingsDocument76 pagesAluminium Window and Door Hardware FittingsLaborioso GeneralNo ratings yet

- Effect of Lightweight Concrete On Structural DesignDocument92 pagesEffect of Lightweight Concrete On Structural DesignRamez Bou-RizkNo ratings yet

- Mechanical Behavior and Microstructural Development in Phosphate Modified High Alumina CementDocument9 pagesMechanical Behavior and Microstructural Development in Phosphate Modified High Alumina CementAndhy Arya EkaputraNo ratings yet

- Advanced Building Construction Technology - NDQS - 201Document2 pagesAdvanced Building Construction Technology - NDQS - 201Mohamed ThabithNo ratings yet

- Packaging Fruit PracticesDocument18 pagesPackaging Fruit PracticesVikrant JaryanNo ratings yet

- Polystone G BrochureDocument8 pagesPolystone G BrochurewickednessNo ratings yet

- ECE 3223 Separation Processes I: B. Eng (Hons.) Chemical EngineeringDocument19 pagesECE 3223 Separation Processes I: B. Eng (Hons.) Chemical EngineeringJosh VatomNo ratings yet

- Aluminum AnodizingDocument7 pagesAluminum Anodizingkarthik venkatachalamNo ratings yet

- IsopanDocument27 pagesIsopanAndrei TeacăNo ratings yet

- Pressure Sensitive AdhesivesDocument22 pagesPressure Sensitive Adhesivesyemresimsek100% (2)

- Astm A351-18Document7 pagesAstm A351-18psytembeNo ratings yet

- Cement Consistency and Setting Time PDFDocument5 pagesCement Consistency and Setting Time PDFvelmurug_balaNo ratings yet

- Final GPC PosterDocument1 pageFinal GPC Posternaga bhushanNo ratings yet

- Lutrol F 127: Technical InformationDocument8 pagesLutrol F 127: Technical InformationJEAN CASTRONo ratings yet

- MarineLine784 Protective CoatingsDocument8 pagesMarineLine784 Protective CoatingsTimuçin ÇolakelNo ratings yet

- NF EN 573 3 Aluminium and Aluminium Alloys PDFDocument37 pagesNF EN 573 3 Aluminium and Aluminium Alloys PDFStefan Stan50% (2)

- Jurnal PengelasanDocument10 pagesJurnal Pengelasanyudha mamotsNo ratings yet

- Essar Petrol Pump ListDocument21 pagesEssar Petrol Pump ListRajesh PramanikNo ratings yet

- Rubber Standards in Today's World Economy: Special ReportDocument5 pagesRubber Standards in Today's World Economy: Special ReportMina RemonNo ratings yet

- AlloyDocument100 pagesAlloywahyuNo ratings yet

- C470 C470M-Standard Specification For Molds For Forming Concrete Test Cylinders VerticallyDocument5 pagesC470 C470M-Standard Specification For Molds For Forming Concrete Test Cylinders VerticallySainey 班才傑No ratings yet

- Effect of Concrete Mixture Components, Proportioning, and Compressive Strength On Fracture ParametersDocument14 pagesEffect of Concrete Mixture Components, Proportioning, and Compressive Strength On Fracture ParametersLương Chiến ThắngNo ratings yet

- Bayla (Las 4)Document6 pagesBayla (Las 4)Zeian Jacob BaylaNo ratings yet

- Camarines Sur Polytechnic Colleges: Republic of The Philippines Nabua, Camarines Sur A.Y. 2020-2021 2 SemesterDocument5 pagesCamarines Sur Polytechnic Colleges: Republic of The Philippines Nabua, Camarines Sur A.Y. 2020-2021 2 SemesterMarvin CarcidoNo ratings yet

- Carbon Family Mind MapDocument1 pageCarbon Family Mind Maparyangavli19No ratings yet

- 12 Seismic Design Requirements For Building StructuresDocument3 pages12 Seismic Design Requirements For Building StructuresLuis HidalgoNo ratings yet