Professional Documents

Culture Documents

16fc0160 Plans San Antonio, Cap

Uploaded by

Rhobbie NolloraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

16fc0160 Plans San Antonio, Cap

Uploaded by

Rhobbie NolloraCopyright:

Available Formats

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

F. PIMENTEL AVE. PASIG, DAET, CAMARINES NORTE REGION V

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE DISTRICT ENGINEER

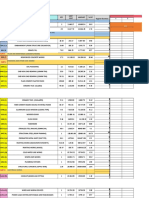

B.5 PROJECT BILLBOARD each 1.00

B.7 OCCUPATIONAL SAFETY & HEALTH PROGRAM L.S. 2.50

801(1) REMOVAL OF STRUCTURES & OBSTRUCTION L.S. 1.00

900(1)b4 STRUCT'L CONC. FOR COLUMNS cu.m. 2.97

902(1)a1 REINFORCING STEEL FOR COLUMNS kgs 850.43

900(1)b6 STRUCT'L CONC. FOR ROOF BEAM cu.m. 3.62

902(1)a1 REINFORCING STEEL FOR ROOF BEAM kgs 1,076.37

903(1) FORMS AND FALSEWORKS L.S. 1.00

1046(1)a CHB LOAD BEARING (Including Reinforcing Steel) sq.m. 88.50

1046(2)a CHB NON LOAD BEARING (Including Reinforcing Steel) sq.m. 28.77

1005(5) GRILLE WINDOW sq.m. 63.50

1007(1)b ALUMINUM SWING GLASS DOOR sq.m. 3.36

1010(2)b WOODEN PANEL DOOR sq.m. 1.68

1010(2)a WOODEN FLUSH DOOR sq.m. 1.47

1008(1)a ALUMINUM SLIDING GLASS WINDOW sq.m. 55.40

1053(2) STAINLESS STEEL RAILINGS mts. 4.00

1018(1) GLAZED WALL TILES sq.m. 8.16

N

1018(2) UNGLAZED FLOOR TILES sq.m. 2.04

1 2 3

1018(1) GLAZED FLOOR TILES sq.m. 165.60

1027(1) CEMENT PLASTER FINISH sq.m. 307.66

1.20 4.50

9.00

4.50 1.20

W E

1003(1)a1 CEILING ON METAL FRAME sq.m. 125.60

1.20

1003(5)a1 FASCIA BOARD sq.m. 48.40

D

1047(2)b STRUCTURAL STEEL FOR TRUSSES kgs. 537.38

S

4.00

1047(5)b METAL STRUCTURE ACCESSORIES STEEL PLATES kgs. 229.61

1047(2)c METAL STRUCTURE ACCESSORIES PURLINS kgs. 958.43

1047(3)b METAL STRUCTURE ACCESSORIES SAGROD pcs. 78.00

C

10.40

1014(1)b1 PRE-PAINTED METAL ROOFING SHEETS sq.m. 121.26

4.00

1032(1)a1 MASONRY/ CONCRETE SURFACE PAINTING sq.m. 239.94

1032(1)a2 WOODEN SURFACE PAINTING sq.m. 69.98

1032(1)a3 STEEL PAINTING sq.m. 63.50 B

2.40

1100(19) CONDUITS, BOXES & FITTINGS L.S. 1.00

1101(18) WIRES & WIRING DEVICES L.S. 1.00 A

1.20

1103(1) LIGHTING FIXTURES L.S. 1.00

1102(1)a1 PANEL BOARD CABINETS L.S. 1.00

1001(8) SEWER LINE WORKS L.S. 1.00

1002(6) COLD WATERLINE WORKS L.S. 1.00

1002(5) PLUMBING FIXTURES L.S. 1.00

1001(9) STORM DRAINAGE & DOWNSPOUT L.S. 1.00

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE DISTRICT ENGINEER

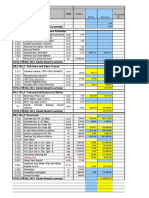

1 2 3 1 2 3

1.20 4.50

9.00

4.50 1.20 1.20 4.50

9.00

4.50 1.20

1 2 3 1 2 3

9.00 9.00

4.50 4.50 4.50 4.50

1.20

1.20

D D D D

4.00

4.00

4.00

4.00

C C C C

10.40

10.40

10.40

10.40

4.00

4.00

4.00

4.00

B B B B

2.40

2.40

2.40

2.40

A A A A

1.20

1.20

ROOF FRAMING PLAN ROOF PLAN ROOF FRAMING PLAN REFLECTED CEILING PLAN (SECOND FLOOR)

SCALE 1:100mts SCALE 1:100mts SCALE 1:100mts SCALE 1:100mts

A A

1 1' 2 2' 3 1 2 3

9.00 9.00

4.50 4.50 4.50 4.50

W 1 W3 W2 W3 W 1

D D D C B A 1 1' 2 2' 3

D3

4.00

4.00

1.80

W2 W 1 W 1

1.80

D 1

C C

3.00

3.00

10.40

10.40

4.00

4.00

W2 W2 W 1 W 1

B B

W 1 W2 W 1 W2

B D2

B D2

2.40

2.40

A A FRONT ELEVATION

GROUND FLOOR PLAN SECOND FLOOR PLAN LEFT SIDE ELEVATION SCALE 1:100mts

SCALE 1:100mts

SCALE 1:100mts SCALE 1:100mts

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE DISTRICT ENGINEER

3.00 1.80

1.60

0.60 0.60 0.60 0.60 0.60 0.60 0.60 0.60

0.80 0.80 0.80 0.70

0.50

0.30

0.30

0.50

1.20

1.20

2.40

2.40

2.10

2.10

2.10

2.10

1.60

0.90

0.90

SCHEDULE OF DOORS AND WINDOWS

D C B A SCALE 1:30 mts

ROD SUSPENSION HANGER WITH

ADJUSTMENT SPRING

1.80

3.00

1.175

0.30

REQUIRED DIMENSION

DEPTH OF CEILING TO

PREFORMED

WIRE CLIP

SECTION THRU "A" 0.40mm WALL

SCALE 1:100mts

ANGLE

3 2 1

25mm X 25mm WOOD SLAT

0.012 0.012 PROVIDE INSECT SCREEN

0.325 4.50mm THK. FIBER CEMENT

1.80

CEILING BOARD (PAINTED)

ON METAL FURRING

CHANNEL @ 400mm O.C.

FR. 25 x 75mm VENT FRAME

3.00

(PAINT FINISH) PRIMARY

0.025 0.30 0.025 CHANNEL

CEILING FURRING

FIBER CEMENT SECTION

CEILING BOARD

SECTION THRU "B"

SCALE 1:100mts

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE DISTRICT ENGINEER

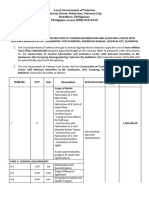

1. IN THE INTERPRETATION OF THE DRAWING, INDICATED DIMENSIONS SHALL GOVERN

1. UNLESS OTHERWISE NOTED IN PLANS, THE STRENGTH OF REINFORCING BARS SHALL BE: 1. PROVIDE EXTRA SETS OF TIES AT 100mm OC FOR TIED COLUMN REINFORCEMENT ABOVE AND

AND DISTANCES AND SIZES SHALL NOT BE SCALED FOR CONSTRUCTION PURPOSES.

A. FOOTINGS, FOOTING BEAMS AND GIRDERS -------------- fy = 275 mpa ( 40,000 psi ) BELOW BEAM - COLUMN CONNECTIONS FOR A DISTANCE FROM FACE OF CONNECTION

EQUAL TO THE GREATER OF THE OVERALL THICKNESS OF COLUMN, 1 / 6 THE CLEAR HEIGHT NOTE:

2. IN REFERENCE TO THE DRAWING, SEE ARCHITECTURAL DRAWINGS FOR DEPRESSIONS B. COLUMNS AND SHEAR WALLS ------------------------------- fy = 275 mpa ( 40,000 psi ) PURSUANT TO SECTION 4 OF ANNEX "A" OF THE REVISED

OF COLUMN OR 450mm.

IN FLOOR SLABS, OPENINGS IN THE WALLS AND SLABS, INTERIOR PARTITIONS, LOCATION C. BEAMS AND GIRDER -------------------------------------------- fy = 275 mpa ( 40,000 psi ) IMPLEMENTING RULES AND REGULATION OF R.A. 9184, APPROVAL

2. COLUMN TIES SHALL BE PROTECTED EVERYWHERE BY A COVERING OF CONCRETE CAST

OF DRAWING ETC. BY AUTHORIZED DPWH OFFICIALS OF DETAILED ENGINEERING

D. NON-LOAD BEARING WALL PARTITION, BEDDED SLABS, FLOOR & ROOF SLABS, MONOLITHICALLY WITH THE CORE WITH THE MINIMUM THICKNESS OF 40mm AND NOT LESS

THAN 40 TIMES THE MAXIMUM SIZE OF COARSE AGGREGATE IN MILLIMETERS. SURVEYS AND DESIGN UNDERTAKEN BY CONSULTANTS NEITHER

3. IN CASE OF DISCREPANCIES AS TO THE LAYOUT, DIMENSIONS, AND ELEVATION BETWEEN PARAPET, CATCH BASIN, SIDE WALK ------------------------- fy = 227.5 mpa ( 33,000 psi )

3. WHERE COLUMNS CHANGE SIZE, VERTICAL REINFORCEMENTS SHALL BE OFFSET AT A SLOPE DIMINISHES THE RESPONSIBILITY OF THE LATTER FOR THE

THE STRUCTURAL PLANS AND ARCHITECTURAL DRAWINGS, THE CONTRACTOR SHALL NOTIFY 2. ALL REINFORCING BARS SIZE 10mm OR LARGER SHALL BE DEFORMED IN ACCORDANCE WITH TECHNICAL INTEGRITY OF THE SURVEYS AND DESIGN NOR

OF NOT MORE THAN 1 IN 6 AND EXTRA 10mm TIES AT 100mm SHALL BE PROVIDED THRU OUT

BOTH THE STRUCTURAL ENGINEER AND THE ARCHITECT. ASTM A 706. BARS SMALLER THAN 10mm MAY PLAIN. TRANSFER ANY PART OF THAT RESPONSIBILITY TO THE APPROVING

THE OFFSET REGION

3. SPLICES SHALL BE SECURELY WIRED TOGETHER & SHALL LAP OR EXTEND IN ACCORDANCE 4. UNLESS OTHERWISE INDICATED IN THE PLANS , LAP SPLICES FOR VERTICAL COLUMN OFFICIALS.

4. ALL CONCRETE WORK SHALL BE DONE IN ACCORDANCE WITH THE ACI. 318 95 BUILDING WITH TABLE A. & TABLE B ( TABLE OF LAP SPLICE & ANCHORAGE LENGTH ) UNLESS OTHERWISE REINFORCEMENT SHALL BE MADE WITHIN THE CENTER HALF OF COLUMN HEIGHT, AND THE

CODE REQUIREMENTS FOR REINFORCED CONCRETE AND ALL STRUCTURAL STEEL WORK SHOWN ON DRAWINGS, SPLICES SHALL BE STAGGERED WHENEVER POSSIBLE. THE DESIGN CONSULTANT SHALL BE HELD FULLY

SPLICE LENGTH SHALL NOT BE LESS THAN 40 BAR . WELDING OR APPROVED MECHANICAL

ACCORDING WITH AISC SPECIFICATION ( 9th EDITION ) IN SO FAR AS THEY DO NOT CONFLICT DEVICES MAY BE USED PROVIDED THAT NOT MORE THAN ALTERNATE BARS ARE WELDED OR RESPONSIBLE FOR THE FAILURE OF THE FACILITY / IES /

WITH THE LOCAL BUILDING CODE REQUIREMENT. MECHANICALLY SPLICED AT ANY LEVEL AND THE VERTICAL DISTANCES BETWEEN THESE STRUCTURES DUE TO FAULTY DESIGN EXCEPT FOR THE CHANGES

WELDS OR SPLICES OF ADJACENT BAR IS NOT LESS THAN 600mm MADE WITHOUT THE CONFORMITY OF THE CONSULTANTS.

5. ACI REFERS TO AMERICAN CONCRETE INSTITUTE, AISC TO AMERICAN INSTITUTE OF STEEL

CONSTRUCTION AND ASTM TO AMERICAN SOCIETY FOR TESTING MATERIALS.

1. ALL SLAB REINFORCEMENTS SHALL BE 20mm CLEAR MINIMUM FROM BOTTOM AND FROM

6. CONSTRUCTION NOTES AND TYPICAL DETAILS APPLY TO ALL DRAWINGS UNLESS OTHERWISE H

TOP OF SLAB.

SHOWN OR NOTED. MODIFY TYPICAL DETAILS AS DIRECTED TO MEET SPECIAL CONDITION. CROSS-TIE

350mm MAX.

2. UNLESS OTHERWISE SHOWN, REINFORCEMENT IN CONTINUOUS SLAB SHALL BE CUT AS 1. UNLESS , OTHERWISE NOTED IN PLANS, CAMBER ALL BEAMS AND GIRDER AT

FOLLOWS. LEAST 6mm FOR EVERY 4.50m OF SPAN, EXCEPT CANTILEVERS FOR WHICH THE

7. SHOP DRAWINGS WITH ERECTION AND PLACING DIAGRAMS OF ALL STRUCTURAL STEEL,

MISCELLANEOUS IRON, PRE-CAST CONCRETE, ETC. SHALL BE SUBMITTED FOR ENGINEERS CAMBER SHALL BE AS NOTED IN PLANS OR AS ORDERED BY THE ENGINEER BUT

10

APPROVAL BEFORE FABRICATION. IN NO CASE LESS THAN 20mm FOR EVERY 3.0m OF FREE SPAN.

H

mi

L1 L2

n.

8. CONTRACTOR SHALL NOTE AND PROVIDE ALL MISCELLANEOUS CURBS, SILLS, STOOLS, 2. TYPICAL BARS BENDING AND CUTTING DETAILS SHALL BE AS SHOWN IN FIG. B - 1

L1/3 L1/3 L2/3

EQUIPMENT'S AND MECHANICAL BASES THAT ARE REQUIRED BY THE ARCHITECTURAL, TOP BAR TOP BAR

ELECTRICAL AND MECHANICAL DRAWINGS.

LAP SPLICES ARE ALLOWED

9. ALL RESULTS OF MATERIAL TESTING FOR CONCRETE, REINFORCING BARS & STRUCTURAL ONLY IN THIS PORTION

JOINT REINF.CONF. REINF . PER SCHEDULE CONF. REINF. JOINT REINF.CONF. REINF.

STEEL MUST BE NOTED & APPROVED BY THE STRUCTURAL DESIGNER.

L1/6 BOTTOM BAR L1/5 L2/5 BOTTOM BAR JOINT HOOP SPACE @ "2Sh" WHEN THERE ARE

BEAMS HAVING WIDTH OF AT LEAST ONE-HALF THE L1 L2 L3

D

COLUMN WIDTH & DEPTHS NOT LESS THAN THREE L2/3 L2/3 L3/3 L3/3

QUARTERS OF THE DEEPEST BEAM THAT FRAME 2D 2D 2D 2D 2D

INTO FOUR SIDES OF THE COLUMN. ALL OTHER

CONDITIONS USE HOOP @ "Sh" CENTER

1. ALL CONCRETE SHALL DEVELOP A MINIMUM COMPRESSIVE STRENGTH AT THE END OF

TWENTY EIGHT ( 28) DAYS W/ CORRESPONDING MAXIMUM SIZE AGGREGATE & SLUMPS AS L2/5 L2/5 L3/5 L3/6

0.96

FOLLOW. 3. IF SLABS ARE REINFORCED BOTHWAYS BARS ALONG THE SHORTER SPAN SHALL BE PLACED

Sh

D

BELOW THOSE ALONG THE LONG SPAN AT THE CENTER AND OVER THE LONGER SPAN WEB BARS

2-12mm SIDE BARS BOTTOM BARS

FOR REINFORCING BARS NEAR THE SUPPORTS. THE SPACING OF THE BARS AT THE COLUMN TOP BARS

FOR COL. BAR SPLICES SEE TABLE OF MIN. LAP

COLUMN TIES AS

ALL OTHERS, INCLUDING STRIPS SHALL NOT BE MORE THAN ONE AND A HALF ( 1 21 ) SLAB THICKNESS

SUSPENDED SLABS 4000 psi ( 27.6 mpa ) 20mm 100mm SPLICE LENGTH OF COLUMN REINFORCEMENT

4. TEMPERATURE BARS FOR SLAB SHALL BE GENERALLY PLACED NEAR THE FACE IN TENSION (SPACING OF TIES ALONG THIS REGION SHALL NOT

COLUMNS 4000 psi ( 27.6 MPA ) 20mm 100mm AND SHALL NOT BE LESS THAN 0.0025 x GROSS CROSS-SECTIONAL AREA ( Ag ) OF THE SLAB BE LESS THAN 100mm)

BEAMS, SLABS 4000 psi ( 27.6 MPA ) 20mm 100mm ( SEE SCHEDULE BELOW )

TABLE "A" TABLE "B"

TENSION BARS COMPRESSION BARS

SLAB ON FILL 3000 psi ( 27.6 MPA ) 20mm 100mm EMBEDMENT LENGTHS AND LAPPED EMBEDMENT LENGTHS AND LAPPED

Sh

SPLICES IN MILLIMETERS SPLICES IN MILLIMETERS

D

BAR SIZE fc' = 20.7MPa (3000psi) fc' = 20.7MPa (4000psi) BAR SIZE fc' = 20.7MPa (3000psi) fc' = 20.7MPa (4000psi)

2. MAINTAIN MINIMUM CONCRETE COVER FOR REINFORCING STEEL AS FOLLOWS SCHEDULE OF MINIMUM SLAB REINFORCEMENT (DEFORMED) EMBEDMENT (DEFORMED) EMBEDMENT

LAPPED EMBEDMENT LAPPED LAPPED EMBEDMENT LAPPED

SUSPENDED SLABS ------------------------------------------------------------------ 20mm

THICKNESS MINIMUM TEMPERATURE BARS

NOTE:

10mm 300 300 300 300 10mm 225 300 200 300

SLAB ON GRADE ----------------------------------------------------------------------- 40mm ALL CONCRETE REINF. DETAIL SHOULD BE

WALLS ABOVE GRADE --------------------------------------------------------------- 25mm 100mm 10mm @ 250mm EACH WAY DONE IN ACCORDANCE WITH THE LATEST 12mm 300 300 300 300 12mm 275 300 250 300

BEAM STIRRUPS AND COLUMN TIES ----------------------------------------------- 40mm

CONF. REINF.

125mm 10mm @ 225mm EACH WAY EDITION OF ACI DETAILING MANUAL. 16mm 300 400 300 400 16mm 350 400 325 400

WHERE CONCRETE IS EXPOSED TO 20mm 20mm

400 550 350 500 450 500 475 500

D

EARTH BUT POURED AGAINST FORMS -------------------------------------------- 50mm 150mm 10mm @ 185mm EACH WAY

25mm 25mm

WHERE CONCRETE IS DEPOSITED 600 800 550 750 550 625 550 625

175mm 10mm @ 150mm EACH WAY 28mm 28mm

750 1000 650 850 625 675 625 675

DIRECTLY AGAINST THE EARTH ----------------------------------------------------- 75mm

3. CONCRETE SHALL BE DEPOSITED IN ITS FINAL POSITION WITHOUT SEGREGATION. 200mm 10mm @ 140mm EACH WAY 32mm 950 1300 850 1100 32mm 700 775 700 775

RE-HANDLING OR PLACING SHALL BE DONE PREFERABLY WITH BUGGIES, BUCKETS OR

WHEELBARROWS, NO CHUTES WILL BE ALLOWED EXCEPT TO TRANSFER CONCRETE FROM

HOPPER TO BUGGIES, WHEELBARROWS OR BUCKETS IN WHICH CASE THEY SHALL NOT EXCEED 3. IF THE BEAM REINFORCING BARS END IN A WALL THE CLEAR DISTANCE FROM THE BAR TO THE

SIX ( 6 ) METERS IN AGGREGATE LENGTH. FARTHER FACE OF THE WALL NOT BE LESS THAN 25mm. EMBEDMENT LENGTH SHALL BE AS

4. NO DEPOSITING OF CONCRETE SHALL BE ALLOWED WITHOUT THE USE OF VIBRATORS SHOWN IN A TABLE "A" FOR TENSION BARS AND TABLE "B" FOR COMPRESSION BARS UNLESS

LAP SPACE LENGTH: SPECIFIED IN PLAN. TOP BAR SHALL NOT BE SPLICED WITHIN THE COLUMN. AT LEAST TWO

UNLESS AUTHORIZED IN WRITING BY THE DESIGNERS AND ONLY FOR UNUSUAL CONDITIONS

5. UNLESS OTHERWISE NOTED IN THE PLANS ALL BEDDED SLABS SHALL BE REINFORCED WITH AT ANY LEVEL NO MORE THAN ALTERNATE BARS SHOULD BE SPLICED MIN. STIRRUPS SHALL BE PROVIDED AT ALL SPLICES.

WHERE VIBRATIONS IS EXTREMELY DIFFICULT TO ACCOMPLISH.

10mm AT 250mm O.C EACH WAY TO CENTER OF SLAB AND CONSTRUCTION JOINTS FOR SAME DISTANCE BETWEEN TWO ADJACENT BARS SPLICES SHALL BE 600mm.

5. ALL ANCHOR BOLTS, DOWELS, AND OTHER INSERTS, SHALL BE PROPERLY POSITIONED & SHALL NOT BE LESS THAN 3.65 METER APART

SECURED IN PLACE PRIOR TO PLACING OF CONCRETE. 4. IF THERE ARE TWO OR MORE LAYERS OF REINFORCING BARS, USE 25mm BAR SEPARATORS

SPACED AT 1.0m ON CENTER IN NO CASE SHALL THERE BE LESS THAN TWO

6. ALL CONCRETE SHALL BE KEPT MOIST FOR A MINIMUM OF SEVEN ( 7 ) CONSECUTIVE DAYS 6. PROVIDE EXTRA REINFORCEMENTS FOR CORNER SLAB ( TWO ADJACENT DISCONTINUOUS

( 2 ) SEPARATORS BETWEEN TWO LAYERS OF BARS.

IMMEDIATELY AFTER POURING BY THE USE OF WET BURLAP, FOG SPRAYING, CURING EDGES ) AS SHOWN BELOW.

COMPOUNDS OR OTHER APPROVED METHODS. 5. MINIMUM CONCRETE PROTECTION FOR REINFORCING BARS OR STEEL SHAPES BE AS

7. CONCRETE SLAB REINFORCEMENTS SHALL BE PROPERLY SUPPORTED WITH 10mm STEEL

7. STRIPPING OF FORMS AND SHORES : CHAIR OR APPROVED EQUIVALENT SPACED AT 1.0 METER ON CENTER BOTHWAYS SHOWN IN FIG. B - 2 UNLESS SPECIFIED ELSEWHERE.

FOUNDATION -------------------------------------------------------------------------- 24 hrs.

SUSPENDED SLAB EXCEPT WHEN ----------------------------------------------- 8 days A

ADDITIONAL LOADS ARE IMPOSED

WALLS --------------------------------------------------------------------------------- 24 days 12 x 1000 LONG @

MID-DEPTH OF SLAB b

BEAMS --------------------------------------------------------------------------------- 24 days DOWN INTO EDGE BEAM. EXTENDED

4- 12@ 1800 LONG TOP BARS BEND @ EACH CORNER LAP SPLICE LENGTH:

COLUMNS ----------------------------------------------------------------------------- 24 days

BARS MINIMUM OF 1200 ( 4'-0" ) INTO BARS. 1- 12 TOP & AT ANY LEVEL NO MORE THAN

t

8. THE CONTRACTOR SHALL SUBMIT THE SCHEDULE OF POURING AND THE LOCATION OF THE

BOTTOM BARS ALTERNATE BARS SHOULD BE MAIN REINFORCEMENT

CONSTRUCTION JOINTS TO THE STRUCTURAL ENGINEER AT LEAST ( 4 ) DAYS PRIOR TO THE SPLICED. MIN. DISTANCE BET. see note

4- 12 BOTTOM BARS WEB BARS

t or 1/4D

WITHIN CENTER

POURING FOR APPROVAL.

400

ht

1- 12 EA. TWO ADJACENT BARS SPLICES see note

HALF OF "H"

t

9. THE CONTRACTOR SHALL FURNISH AND MAINTAIN ADEQUATE FORMS AND SHORING UNTIL TOP & BOTTOM SHALL BE 600mm. SLEEVES FOR UTILITY

THE CONCRETE MEMBERS HAVE ATTAINED THEIR WORKING CONDITION AND STRENGTH

D

PIPES MAX 1/5D

0 L/4

0 SLAB

6 38mm TOP BARS @ SUPPORT (CONT.) 0.025m SEPARATOR

OPENING see note PROVIDE 3-10 EXTRA STIRR.

CLEAR

REQ'D. BOTT. BARS @ SUPPORT EACH SIDE OF SLEEVES

JT. REINF.

400

1. FOOTINGS ARE DESIGNED FOR AN ALLOWABLE SOIL BEARING PRESSURE OF 96 kpa

0

1- 12 EA.

0

( 2000 psf ). CONTRACTOR SHALL REPORT TO THE ENGINEER, IN WRITING, THE ACTUAL TOP & BOTTOM

D

6

SOIL CONDITION UNCOVERED AND CONFIRM ACTUAL BEARING CAPACITY OF SOIL BEFORE

DEPOSITING CONCRETE. INTO TWO WAY SLAB EXTEND 6. WHEN A BEAM CROSSES A GIRDER, REST BEAM ON TOP OF GIRDER BARS, BEAM

BARS UP TO BEAM SUPPORT REINFORCING BAR SHALL BE SYMMETRICAL ABOUT CENTER LINE WHENEVER POSSIBLE.

2. FOOTINGS SHALL REST AT LEAST 15800mm BELOW NATURAL GRADE LINE UNLESS OMIT TRIMMER BARS WHERE

6

OTHERWISE INDICATED IN PLANS. NO FOOTING SHALL REST ON FILL. OPENING IS FRAMED BY BEAM BOTTOM BARS AT 7. GENERALLY NO SPLICES SHALL BE PERMITTED AT POINTS WHERE CRITICAL BENDING

0

SPLICE

0

MID SPAN STRESSES OCCUR, SPLICES WHERE NO PERMITTED SHALL BE INDICATED IN THE TABLE "A"

3. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENTS SHALL BE 75mm CLEAR AND "B" WELDED SPLICES SHALL BE DEVELOP IN TENSION AT LEAST 125% OF THE

FOR CONCRETE DEPOSITED THE GROUND AND 50mm FOR CONCRETE SPECIFIED YIELD STRENGTH OF THE BAR. NOT MORE THAN 50% OF THE BARS AT ANY ONE

DEPOSITED AGAINST A FORMWORK. SECTION IS ALLOWED TO BE SPLICED THEREIN.

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE DISTRICT ENGINEER

2. DESIGN STRESS

1. ALL WALLS SHALL BE REINFORCED ACCORDING TO THE FOLLOWING SCHEDULE OF WALL A. CONCRETE

REINFORCEMENT UNLESS OTHERWISE INDICATED IN THE PLANS.

(DOWEL)

1. UNLESS OTHERWISE SHOWN IN PLANS ALL CONCRETE HOLLOW BLOCKS AND CERAMIC BLOCKS COMPRESSIVE STRENGTH AT 28 DAYS fc' = 20.70 MPa ( 3,000 psi)

VERIFY ARCHITECTURAL

400

SHALL BE REINFORCED AS SHOWN IN THE SCHEDULE OF CONCRETE HOLLOW BLOCKS AND B REINFORCING BARS

CERAMIC BLOCK REINFORCEMENT a) FOR BARS 16mm AND GREATER fy = 275 MPa (40,000 psi)

2. PROVIDE 150mm X 300mm STIFFENER COLUMN REINFORCED WITH 4 -12mm WITH 6mm TIES AT b) FOR BARS LESS THAN 16mm fy = 230 MPa (33,000 psi)

150mm ON CENTER WHERE CONCRETE HOLLOW BLOCK TERMINATES AND AT EVERY 3.00m C STRUCTURAL STEEL, ASTM - A36

LENGTH OF CONCRETE HOLLOW BLOCK WALLS UNLESS NOTED IN STRUCTURAL PLANS. FOR TRUSSES, BRACINGS, AND STRUTS fy = 248MPa (36,000 psi)

D PURLINS

COLD FORMED LIGHT CAGE SHAPES fy = 248MPa (36,000 psi)

REINFORCING BARS SHALL HAVE 25mm CLEAR CONCRETE COVER FROM FACE OF WALL EXCEPT E MASONRY UNIT (CHB)

(DOWEL)

SCHEDULE OF CONCRETE HOLLOW BLOCK AND CERAMIC BLOCK REINFORCEMENT FOR WALLS IN CONTACT WITH THE GROUND WHERE A MINIMUM OF 60mm SHALL BE PROVIDED, NON - LOADING BEARING CHB WALLS fm' = 3.45 MPa (500psi)

400

AND FOR EXPOSED FACES FORMED WALLS WHERE THE MINIMUM SHALL BE 50mm CLEAR. F WELDS - USED E - 60xx ELECTRODE

2. CARRY VERTICAL BARS AT LEAST 60mm ABOVE FLOOR LEVEL TO PROVIDE FOR SPLICES WHEN G STRUCTURAL BOLTS, ASTM - A307

NECESSARY STOP AT 50mm BELOW TOP SLAB OR SOLID BAND WHERE THE WALL ENDS a) Ft = 96.60 MPa (14,000 psi) b) Fv = 69MPa(10,000 psi)

VERTICAL AND HORIZONTAL BARS SHALL BE SPLICED BY LAPPING A DISTANCE EQUAL TO 30

AND WIRED SECURELY WITH 16 G.I. WIRE PROVIDED THAT SPLICES IN ADJACENT BARS ARE

STAGGERED AT LEAST 1.50M OC

3. UNLESS OTHERWISE NOTED IN THE PLANS, ALL OPENINGS IN WALLS 250mm OR THICKER SHALL 1 WHERE A CONSTRUCTION JOINT IS TO BE MADE, THE SURFACE OF CONCRETE SHALL BE

BE REINFORCED AROUND WITH 2 - 20mm BARS FOR 225mm, 200mm, 175mm, 150mm, USE 2 - 16mm CLEANED AND ALL LAITANCE AND STANDING WATER REMOVED. SHEAR KEY SHALL BE

. FOR 125mm AND 100mm WALLS, USE 2 - 12mm BARS. ALL WALLS SPANNING SHALL HAVE PROVIDED AT THE JOINT.

VERTICAL REINFORCEMENT BENT TO A U - FORM LIKE STIRRUPS AND SPACED ACCORDING TO THE

SCHEDULE UNLESS OTHERWISE NOTED ( SEE FIG. 1 )

550

30 BAR DIA. 30 BAR DIA.

t/3

LINTELS IN BLOCK WALLS 40

500

(min.) (min.)

CLEAR TOTAL MIN. HEIGHT

50

VARIES

t/3

SPAN LENGTH fc' OF

t

("L") (L + 0.40m) (MPa) LINTEL

D/3 D/3

BOTTOM TOP STIRRUPS

(mm)

D/3

D

600 (MIN.)

t/3

1.20m 1.60m 200 1- 10 1- 10 6mm @ 200mm

1.50m 1.90m 14.0 200 1- 10 1- 10 6mm @ 200mm 500 550

1.80m 2.20m 200 1- 12 1- 10 6mm @ 200mm

250

2.10m 2.50m 250 1- 12 1- 10 6mm @ 200mm

2.40m 2.90m 17.0 250 1- 12 1- 10 6mm @ 200mm

2.70m 3.10m 250 1- 16 1- 12 10mm @ 200mm

3.00m 3.40m

20.0

300 1 - 16 1- 12 10mm @ 200mm 400

3.30m 3.70m 300 1 - 16 1- 12 10mm @ 200mm

3.60m 4.00m 300 1 - 20 1- 12 10mm @ 200mm

1. USE E70xx ELECTRODES FOR ALL MEMBERS WELDED.

2. WELDS SHALL DEVELOP THE FULL STRENGTH OF MEMBERS JOINED UNLESS OTHERWISE SHOWN

OR DETAILED IN THE DRAWINGS.

300

(TYP.)

1. STRUCTURAL STEEL TO BE USED FOR FABRICATION AND ERECTION OF THIS STRUCTURE SHALL

DOWEL

COMPLY WITH ALL THE PERTINENT PROVISION OF AISC SPECIFICATION OR DESIGN, FABRICATION

400

DOWEL

AND ERECTION OF STRUCTURAL STEEL FOR BUILDING LATEST EDITION.

400

2. ALL STRUCTURAL STEEL SHAPES SHALL CONFORM TO ASTM A36 STRUCTURAL STEEL UNLESS 38mm CLEAR

OTHERWISE INDICATED.

250

3. ALL WELDED CONNECTIONS SHALL DEVELOP THE FULL STRENGTH OF THE MEMBERS CONNECTED.

4. UNLESS OTHERWISE SPECIFIED ALL WELDING RODS SHALL CONFORM AWS E60 ELECTRODES.

5. ALL BOLTS USED UNLESS OTHERWISE SPECIFIED SHALL BE ASTM A 307 BOLTS.

400

A. ALL EMBEDDED PIPES FOR UTILITIES, ETC. THAT PASS THRU BEAMS SHALL NOT EXCEED 100mm IN

OR 1 / 3 BEAM DEPTH WHICHEVER IS LESS, UNLESS OTHERWISE APPROVED IN WRITING BY THE

STRUCTURAL ENGINEER

B. NO PIPES SHALL BE ALLOWED TO PASS THRU BEAMS VERTICALLY. NOTES OF STIRRUPS:

C. NO PIPES SHALL BE EMBEDDED IN COLUMNS.

1 ALL REINFORCEMENT SHALL BE BENT COLD UNLESS

300 OTHERWISE PERMITTED BY THE STRUCTURAL

DOWEL

(TYP) ENGINEER.

400

DOWEL

2 REINFORCEMENT PARTIALLY EMBEDDED IN CONCRETE

400

SHALL NOT BE FILLED BENT, EXCEPT AS SHOWN IN

1. LOADINGS THE DESIGN DRAWINGS OR PERMITTED BY THE

250

A. DEAD LOAD STRUCTURAL ENGINEER.

400 CONCRETE - 23.56 KN / m3 3 TIES AND CLOSE STIRRUPS MUST BE

DOWEL STEEL - 76.93 KN / M3 db

150mm THK. CHB WALL - 2.73 kPA

db

1.25 L

100mm THK. CHB WALL - 2.11 kPA

D + 2db

L

D

B. LIVE LOAD

ROOF - 1.00 kPA 4db or 65mm

C. WIND LOAD ( NSCP 2010 )

D

db

BASIC WIND VELOCITY, V = 250 KPH

200(mm) 200(mm) P = qh [(GCpf) - (GCpi)] (DESIGN WIND PRESSURE)

WHERE: qh = VELOCITY PRESSURE, kPA

db

GCpf = EXTERNAL PRESSURE COEFFICIENT

VERIFY DEPRESSION

30 BAR DIA. 30 BAR DIA GCpi = INTERNAL PRESSURE COEFFICIENT

12db

L

NOTE:

(min.) (min.) PURSUANT TO SECTION 4 OF ANNEX "A" OF THE D. SEISMIC LOAD ( NSCP 2010 )

D = FOR BEAM

t = FOR SLAB

REVISED IMPLEMENTING RULES AND REGULATION V = [( Cvl / RT ) W] ( DESIGN BASE SHEAR ) D

OF R.A. 9184, APPROVAL BY AUTHORIZED DPWH L

OFFICIALS OF DETAILED ENGINEERING SURVEYS Vmax = ( 2.50CAL / R ) W Vmin = 0.11 CalW

Vmin = ( 0.80 ZNvl / R ) W (ZONE 4) L1

AND DESIGN UNDERTAKEN BY CONSULTANTS

200 (DOWEL)

NEITHER DIMINISHES THE RESPONSIBILITY OF THE

LATTER FOR THE TECHNICAL INTEGRITY OF THE WHERE : W = TOTAL DEAD LOAD

400

SURVEYS AND DESIGN NOR TRANSFER ANY PART

OF THAT RESPONSIBILITY TO THE APPROVING T = NATURAL PERIOD = Ct (hn) ;

OFFICIALS. WHERE : C = NUMERICAL COEFFICIENT

h = BUILDING HEIGHT

D = FOR BEAM THE DESIGN CONSULTANT SHALL BE HELD I = IMPORTANCE FACTOR = 1.50

2t = FOR SLAB FULLY RESPONSIBLE FOR THE FAILURE OF THE

R = NUMERICAL FACTOR = 8.50

FACILITY / IES / STRUCTURES DUE TO FAULTY

30 BAR DIA. DESIGN EXCEPT FOR THE CHANGES MADE WITHOUT SEISMIC COEFFICIENT Cv = 0.44Nv

THE CONFORMITY OF THE CONSULTANTS. Ca = 0.64N

(min.)

NEAR SOURCE FACTOR ( 10km ) Nv = 1.20

Na = 1.00

Z = SEISMIC ZONE = 0.40 ( ZONE 4 )

S = SOIL TYPE = D

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE DISTRICT ENGINEER

3

5.4

1.80

10mm RSB VERTBARS @

0.60m O.C, AND 10mm RSB

HORBARS @ 0.60m O.C

FIN. FLOOR LINE

0.40

10mm RSB

@0.60mm OC

3 - 10mm

BASEBARS

DETAIL OF STEEL TRUSS 0.15m THK. WALL

SCALE 1:25mts 10mm RSB VERT. FOOTING

BARS @ 0.60m OC

DETAIL OF WALL FOOTING

TEKSCREW 50mm. w/ 5.43 SCALE 1:20mts

NEOPRENE

2 - 4.0mm. THK. x 50mm. x 50mm.

ANGLE BAR WEB MEMBER

1.80

O.C. w/ 50mm. x 50mm. ANGULAR CLEATS

HORIZONTALY WELD (SEE DETAIL)

12mm. THREADED SAGROD w/

STD. NUTS & WASHER

0.05 0.25

0.05 0.25

0.20 0.20 0.20

DETAIL OF STEEL TRUSS

SCALE 1:25mts

9.20 SPOT DETAILS "A"

L SCALE 1:20mts

L/4 L/2 L/4

7.40 RCB-1

1.80

6

2.3 4.90

0.58

1.08

0.05 0.25

0.05 0.25

L/4

1.24

TRUSS 2 TRUSS 5 TRUSS 4

0.20 0.20 0.20

5.80 3.39

10mm BENTBARS @

0.20m OC, BOTHWAYS

STEEL TRUSS DIAGRAM

L/2

SCALE 1:50mts

L

RCB-1

RCB-1

10mm BASE BAR

SPACED @ 0.20mm O.C.

L 0.50 1.50 0.50

L/4 L/4 7 - 16mm DOWEL, 10mm TEMP.BARS @

0.20 0.20 1.00m EXTENDED 0.20m OC, BOTHWAYS

1-16mm SPOT DETAILS "B"

4-16mm 4-16mm SCALE 1:20mts

12mm CUTBARS @

2-16mm 2-16mm 0.10m OC, BOTHWAYS

L/4

1-16mm

@ SUPPORT @ MIDSPAN

L/5 L/5

RCB-1

TYPICAL DETAIL OF RCB TYPICAL DETAIL OF SLAB

SCALE 1:30mts SCALE 1:20mts

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE DISTRICT ENGINEER

GENERAL ELECTRICAL NOTES:

ELECTRICAL LEGEND:

FLOURESCENT LIGTHING OUTLET

DISTRIBUTION BOARD / PANEL

CIRCUIT HOMERUN

LIGHT OUTLET

AIRCONDITION CONV.OUTLET

WALL LAMP

WEATHERPROOF CONV. OUTLET

KILOWATTHOUR METER

WEATHERPROOF CONV. OUTLET

CIRCUIT BREAKER

8" PINLIGTH

6" PINLIGTH x 2400mm LENGTH

RISER DIAGRAM

SCALE NTS

1 2 3

9.00

1 2 3

4.50 4.50 9.00

4.50 4.50

D

D

TYPICAL SCHEDULE OF LOAD

4.00

AMPERE PER

4.00

OUTLET VOLTS VA PROTECTION WIRE SIZE CONDUIT

CIRCUIT

C

C

10.40

10.40

4.00

4.00

USE:

B AMP. MOLDED CIRCUIT BREAKER, 2-WIRE 250 VOLTS

B WITH 4 BRANCH CIRCUIT.

2.40

2.40

A

A

LIGHTING LAYOUT POWER LAYOUT

SCALE 1:100mts SCALE 1:100mts

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE DISTRICT ENGINEER

GENERAL PLUMBING NOTES:

0.50

0.075

0.30 0.10

PLUMBING LEGEND : 0.50

0.10 0.30 0.10

0.10

0.50

0.675

0.30

0.50

0.10

0.10

PLAN SECTION

DETAIL OF CATCH BASIN

SCALE: 1:10m

1 1' 2 2' 3

1 2 3

9.00 9.00

4.50 4.50 4.50 4.50

D D

4.00

4.00

C C

10.40

10.40

4.00

4.00

B B

2.40

2.40

A A

ISOMETRIC DRAWING

N T S

PLUMBING LAY OUT (GROUND FLOOR)

PLUMBING LAY OUT (SECOND FLOOR)

SCALE 1:100mts

SCALE 1:100mts

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE DISTRICT ENGINEER

You might also like

- 24KC0079 - Construction of Multipurpose Building (Tribal Tulugan)Document57 pages24KC0079 - Construction of Multipurpose Building (Tribal Tulugan)Marco RoaNo ratings yet

- Facilities For The Engineer Qty. IUDocument64 pagesFacilities For The Engineer Qty. IUKent Aeron Jordan FobarNo ratings yet

- 20EG0069 Reconstruction of ITRDocument1 page20EG0069 Reconstruction of ITRjayson mariNo ratings yet

- Rudhil Construction & Enterprises, Inc.: Statement of Work AccomplishedDocument6 pagesRudhil Construction & Enterprises, Inc.: Statement of Work AccomplishedRegieBacharoNo ratings yet

- PDF TestDocument10 pagesPDF TestCed LucasNo ratings yet

- EstimateDocument2 pagesEstimateJohn vincent SalazarNo ratings yet

- 2sty 4CL Esperanza IsDocument70 pages2sty 4CL Esperanza IsKaren Balisacan Segundo RuizNo ratings yet

- 22gg0015 - MZ BuildersDocument1 page22gg0015 - MZ BuildersJan JanNo ratings yet

- Alimodian Bridge (Final Estimate) JigzzzDocument14 pagesAlimodian Bridge (Final Estimate) JigzzzJose JacintoNo ratings yet

- Estimate FormatDocument64 pagesEstimate FormatMark Kenneth SolbitaNo ratings yet

- Helakanda BODocument103 pagesHelakanda BOisurupushNo ratings yet

- Detailed Estimate PNP HeadquarterDocument33 pagesDetailed Estimate PNP HeadquarterLizza AnnaNo ratings yet

- Boq Print - 03-SepDocument2 pagesBoq Print - 03-SepRoshan KejariwalNo ratings yet

- Program of Works SampleDocument1 pageProgram of Works SamplemikiNo ratings yet

- Item GuidelinesDocument34 pagesItem GuidelinesLorena AñosàNo ratings yet

- Summary of Bid Prices DPWHDocument1 pageSummary of Bid Prices DPWHInsorPiNo ratings yet

- Bill of Quantities 16FI0009Document1 pageBill of Quantities 16FI0009AJothamChristianNo ratings yet

- Project: XXXXX Location: XXXXX Client: XXXXX Consultant: XXXXX Date: 16-12-2015 Revision: XXXXXDocument77 pagesProject: XXXXX Location: XXXXX Client: XXXXX Consultant: XXXXX Date: 16-12-2015 Revision: XXXXXSangram Biplab Manabendra Thakur100% (3)

- Estimate of Sluice & RCC Barrel (1) 16 NovDocument7 pagesEstimate of Sluice & RCC Barrel (1) 16 NovSubhriti MishraNo ratings yet

- Department of Public Works and Highways (DPWH)Document2 pagesDepartment of Public Works and Highways (DPWH)Fedilino P. FornollesNo ratings yet

- Contructor Superviser/Inspector Consultant: Description Unit Quantity Rate Amount (Birr) Item NoDocument2 pagesContructor Superviser/Inspector Consultant: Description Unit Quantity Rate Amount (Birr) Item Nobilisuma sebokaNo ratings yet

- Program of WorksDocument15 pagesProgram of WorksRA CruzNo ratings yet

- Balibathgoda BOQDocument33 pagesBalibathgoda BOQisurupushNo ratings yet

- AdditionalDocument9 pagesAdditionalflashbuiltacctgNo ratings yet

- Inspection Report: Negros Occidental 1st District Engineering Office Matab-Ang, Talisay City, Negros OccidentalDocument1 pageInspection Report: Negros Occidental 1st District Engineering Office Matab-Ang, Talisay City, Negros OccidentalMae Ann GonzalesNo ratings yet

- BOQ BridgeDocument3 pagesBOQ BridgeReffisa JiruNo ratings yet

- Summary of Quantities: Item Description of Work Unit Quantity RemarksDocument1 pageSummary of Quantities: Item Description of Work Unit Quantity RemarkssidNo ratings yet

- Estimates Finalized!Document102 pagesEstimates Finalized!RenNo ratings yet

- Element 111 - 1211-BOQDocument2 pagesElement 111 - 1211-BOQBusinge FrancisNo ratings yet

- Time Required For ROWDocument2 pagesTime Required For ROWContract DesktopNo ratings yet

- Project Cost Breakdown: DescriptionDocument2 pagesProject Cost Breakdown: Descriptionmia LynNo ratings yet

- 22gg0023 - MZ Builders - 90 CDDocument2 pages22gg0023 - MZ Builders - 90 CDJan JanNo ratings yet

- Dupa SummaryDocument2 pagesDupa SummaryNeil Dahab67% (3)

- SpecDocument10 pagesSpecSisay chaneNo ratings yet

- Plan Part 2 20hm0092Document23 pagesPlan Part 2 20hm0092jomari galiasNo ratings yet

- Meaurement Sheet - 12 MAY 2023Document2 pagesMeaurement Sheet - 12 MAY 2023tnd tbecNo ratings yet

- Quotation - T221-Plus Seven ContractingDocument2 pagesQuotation - T221-Plus Seven Contractingdubai eyeNo ratings yet

- 20EG0075 Widening of ITRDocument1 page20EG0075 Widening of ITRjayson mariNo ratings yet

- AjayDocument7 pagesAjaydreamdesignstudio017No ratings yet

- Structural Concrete, Class ADocument105 pagesStructural Concrete, Class AAnonymous so3w0QNo ratings yet

- Agency - Any Project Director - Any: Measurement BookDocument13 pagesAgency - Any Project Director - Any: Measurement BookDimas Cahyo SNo ratings yet

- Local Government of Valencia Catarata Street, Poblacion, Valencia City, Bukidnon, Philippines Philippine Access (088) 828-5430Document6 pagesLocal Government of Valencia Catarata Street, Poblacion, Valencia City, Bukidnon, Philippines Philippine Access (088) 828-5430Agno ZinNo ratings yet

- First BillingDocument1 pageFirst BillingEmmanuel CristobalNo ratings yet

- Detail Estimate of Cross Drainage 2.00MX2.00M Slab CulvertDocument3 pagesDetail Estimate of Cross Drainage 2.00MX2.00M Slab Culvertbharatram dehariyaNo ratings yet

- CP1 Quantity Calc Roadworks 20221027Document2 pagesCP1 Quantity Calc Roadworks 20221027captaincharizma07100% (1)

- Bill of Quantities18Document4 pagesBill of Quantities18Juma SaidNo ratings yet

- Abstract of Cost: Unit Price (NPR) Amount Remarks A M.S Structure Works DATE: 30th MARCH, 2021Document3 pagesAbstract of Cost: Unit Price (NPR) Amount Remarks A M.S Structure Works DATE: 30th MARCH, 2021Utsab ShakyaNo ratings yet

- Bridge Chitrakoot (Pre-Bid-07.02.2024)Document187 pagesBridge Chitrakoot (Pre-Bid-07.02.2024)Amit PhadatareNo ratings yet

- Brgy. Bonifacio Road, Unisan PDFDocument1 pageBrgy. Bonifacio Road, Unisan PDFfrancis pacaigueNo ratings yet

- Town Site Quantity VoDocument1 pageTown Site Quantity Vobanzonadriel025No ratings yet

- Expansion of Safaniyah Civil Boq - UpdatedDocument9 pagesExpansion of Safaniyah Civil Boq - UpdatedBhavanishankar ShettyNo ratings yet

- Boq - 162-Cca (Vi)Document11 pagesBoq - 162-Cca (Vi)Syed Adnan AqibNo ratings yet

- Construction Cost of 7 Storeyed Bldg. Sr. No. Description RS./SFTDocument29 pagesConstruction Cost of 7 Storeyed Bldg. Sr. No. Description RS./SFTOm Krish RamNo ratings yet

- Boq of Culvert @615+498Document12 pagesBoq of Culvert @615+498Sharat SahaNo ratings yet

- 5.0 Itemized Cost of RevisionDocument9 pages5.0 Itemized Cost of Revisiondexter guanzon serotNo ratings yet

- Anal Is Is FinalDocument11 pagesAnal Is Is FinalANA SOFIA HERRERA HERNADEZNo ratings yet

- House EstimateDocument141 pagesHouse EstimateGani AnosaNo ratings yet

- BOQ Abdulla Jamal-R1Document4 pagesBOQ Abdulla Jamal-R1dubai eyeNo ratings yet

- LuckyDocument2 pagesLuckyMahesh SuryawanshiNo ratings yet

- 02 Bridge Wizard 1.2Document19 pages02 Bridge Wizard 1.2Rhobbie NolloraNo ratings yet

- 01 Boundary Conditions - MTA 1.3Document23 pages01 Boundary Conditions - MTA 1.3Rhobbie Nollora100% (1)

- Mark-Upamount %weight: ComplishedDocument20 pagesMark-Upamount %weight: ComplishedRhobbie NolloraNo ratings yet

- Gantt ChartDocument19 pagesGantt ChartRhobbie NolloraNo ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument3 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryRhobbie NolloraNo ratings yet

- Trinidad, Ricardo RosalesDocument1 pageTrinidad, Ricardo RosalesRhobbie NolloraNo ratings yet

- Tiongson, Rolando JR SaportezaDocument1 pageTiongson, Rolando JR SaportezaRhobbie NolloraNo ratings yet

- Sison, Crisanto TorrecampoDocument1 pageSison, Crisanto TorrecampoRhobbie NolloraNo ratings yet

- Tabunan, Arnold Joy TorresDocument1 pageTabunan, Arnold Joy TorresRhobbie NolloraNo ratings yet

- Praba, Andres E.Document1 pagePraba, Andres E.Rhobbie NolloraNo ratings yet

- Assessment 1Document4 pagesAssessment 1Beman EasyNo ratings yet

- Cqi 12V2 PDFDocument47 pagesCqi 12V2 PDFProductionNo ratings yet

- ICS 29.260.20 ISBN 0-626-17140-7 Edition 1: Warning Should Be Read in Conjunction WithDocument33 pagesICS 29.260.20 ISBN 0-626-17140-7 Edition 1: Warning Should Be Read in Conjunction Withchris541125No ratings yet

- Module 1 Engineering Design ProcessDocument16 pagesModule 1 Engineering Design ProcessvivekNo ratings yet

- Department of Computer Science,: Bahauddin Zakariya University, Multan. Semester Result BS (IT) SemesterDocument3 pagesDepartment of Computer Science,: Bahauddin Zakariya University, Multan. Semester Result BS (IT) SemesterZaini MalikNo ratings yet

- Trans Tech: PublicationsDocument48 pagesTrans Tech: PublicationsSulochana KannanNo ratings yet

- Harga Barang PembinaanDocument212 pagesHarga Barang PembinaanMark Flowers91% (11)

- Employer Feedback Form Gcu OBEDocument3 pagesEmployer Feedback Form Gcu OBEArsi LoveNo ratings yet

- Plumbing - Specification 2011.Document8 pagesPlumbing - Specification 2011.Ponz MadianoNo ratings yet

- CELAWSQUIZ2Document48 pagesCELAWSQUIZ2Shyrene YgoñaNo ratings yet

- 00 Class OrientationDocument12 pages00 Class OrientationRenz Jasper Bumagat LizaNo ratings yet

- Project On MbaDocument41 pagesProject On MbaAvula Shravan Yadav50% (2)

- Commercial Block GIFT City - MEP-DBR-R0 PDFDocument142 pagesCommercial Block GIFT City - MEP-DBR-R0 PDFRamakrishnan SitaramanNo ratings yet

- Post HydrotestingDocument7 pagesPost HydrotestingVineet SinghNo ratings yet

- Especificaciones Tecnicas Scorbot ER-14Document2 pagesEspecificaciones Tecnicas Scorbot ER-14sebastian_alvarez_7No ratings yet

- Web Survey GeneratorDocument2 pagesWeb Survey GeneratorRatan BaghNo ratings yet

- Engineer: For Technical Pattern EngineersDocument5 pagesEngineer: For Technical Pattern EngineersMD NasimNo ratings yet

- Substation On Different LevelsDocument5 pagesSubstation On Different Levelsnarinder kumarNo ratings yet

- Building A Firm FoundationDocument1 pageBuilding A Firm FoundationHonolulu Star-Advertiser100% (3)

- AbstractDocument5 pagesAbstractSyed Azeem0% (1)

- BS ISO 05149-3-2014 Msuse62487Document26 pagesBS ISO 05149-3-2014 Msuse62487marksplat24100% (2)

- Copen 13 - BrochureDocument2 pagesCopen 13 - BrochureRamanvlrNo ratings yet

- Study in Taiwan Manual 20190918Document52 pagesStudy in Taiwan Manual 20190918lord fifaNo ratings yet

- Engineering Design QuizDocument2 pagesEngineering Design QuizChoy Hau Yan100% (1)

- 0 200 Ac MotorsDocument177 pages0 200 Ac MotorsBrion Bara Indonesia0% (1)

- Bits RCCDocument5 pagesBits RCCalekhya gollapudiNo ratings yet

- ETABS Presentation 1Document56 pagesETABS Presentation 1V.m. Rajan100% (9)

- Brochure ETP and CETP Operation and Maitenance - 1337551Document7 pagesBrochure ETP and CETP Operation and Maitenance - 1337551Global Certification RegistrarNo ratings yet

- Hydraulic Bearing PullerDocument28 pagesHydraulic Bearing PullerBoopathi KalaiNo ratings yet

- Outline CourseDocument2 pagesOutline CourseFaiz MechyNo ratings yet