Professional Documents

Culture Documents

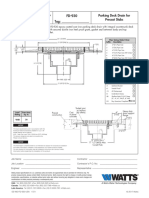

Mustang Series Series M110-10 or M6110-10 (Globe), M1110-10 or M61110-10 (Angle) Specification Sheet

Uploaded by

WattsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mustang Series Series M110-10 or M6110-10 (Globe), M1110-10 or M61110-10 (Angle) Specification Sheet

Uploaded by

WattsCopyright:

Available Formats

R

MODULATING FLOAT VALVE

01/05

Mustang Series

Specications

M110-10 or M6110-10 (Globe) M1110-10 or M61110-10 (Angle)

The Modulating Float Control Valve shall be a pilot operated diaphragm valve designed to maintain a constant liquid level in a tank or reservoir. It shall throttle open on a lowering liquid level and throttle closed upon a rising liquid level. The main valve shall be a hydraulically operated, single diaphragm actuated, globe or angle pattern valve. Y-pattern valves shall not be permitted. The valve shall contain a disc and diaphragm assembly that forms a sealed chamber below the valve cover, separating operating pressure from line pressure. The diaphragm shall be constructed of nylon reinforced Buna-N, and shall not seal directly against the valve seat and shall be fully supported by the valve body and cover. Rolling diaphragm construction will not be allowed and there shall be no pistons operating the main valve or any pilot controls. The main valve body and cover shall be Ductile Iron ASTM A536, and all internal cast components shall be Ductile Iron or CF8M (316) Stainless Steel. All Ductile Iron components, including the body and cover, shall be lined and coated with an NSF 61 Certied Epoxy Coating applied by the electrostatic heat fusion process. All main valve trim and throttling components (cover bearing, valve seat and disc guide) shall be Stainless Steel. The valve body and cover must be machined with a 360-degree locating lip to assure proper alignment. The disc and diaphragm assembly shall contain a Buna-N synthetic rubber disc with a rectangular crosssection that is securely retained on 3-1/2 sides by a disc retainer and disc guide. Diaphragm assemblies utilizing bolts or cap screws for component retention will not be permitted. The exposed portion of the seat disc shall contact the valve seat and seal drip-tight. The disc and diaphragm assembly must be guided by two separate bearings, one installed in the valve cover and one concentrically located within the valve seat, to avoid deection and assure positive disc-to-seat contact. Center guided valves will not be permitted. All necessary repairs shall be made from the top of the valve while the body remains in line. Pilot control systems for valves 3 and smaller shall contain a Flow Clean Strainer, Adjustable Closing Speed Control, and Modulating Float Pilot. Pilot control systems for valves 4 and larger shall contain an external Y-Strainer, Adjustable Closing Speed Control, Modulating Float Pilot and Isolation Ball Valves on all body connections. All pilot control systems shall utilize copper tubing and brass ttings regardless of valve size. The valve shall be Watts ACV Model M110-10 / M6110-10 (Globe) or M1110-10 / M61110-10 (Angle) pattern Modulating Float Control Valve.

8550 Hansen Road Houston, Texas 77075 (Ph) 713.943.0688 (Fx) 713.944.9445 www.wattsacv.com

You might also like

- Classic Series F110-10 (Globe), F1110-10 (Angle) Specification SheetDocument1 pageClassic Series F110-10 (Globe), F1110-10 (Angle) Specification SheetWattsNo ratings yet

- Classic Series F110-13 (Globe), F1110-13 (Angle) Specification SheetDocument1 pageClassic Series F110-13 (Globe), F1110-13 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S110-13 or S6110-13 (Globe), S1110-13 or S61110-13 (Angle) Specification SheetDocument1 pageStainless Series S110-13 or S6110-13 (Globe), S1110-13 or S61110-13 (Angle) Specification SheetWattsNo ratings yet

- Stainless Steel S110-10 or S6110-10 (Globe), S1110-10 or S61110-10 (Angle) Specification SheetDocument1 pageStainless Steel S110-10 or S6110-10 (Globe), S1110-10 or S61110-10 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M116 or M6116 (Globe), M1116 or M61116 (Angle) Specification SheetDocument1 pageMustang Series M116 or M6116 (Globe), M1116 or M61116 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S116-31 or S6116-31 (Globe), S1116-31 or S61116-31 (Angle) Specification SheetDocument1 pageStainless Series S116-31 or S6116-31 (Globe), S1116-31 or S61116-31 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M116-31 or M6116-31 (Globe), M1116-31 or M61116-31 (Angle) Specification SheetDocument1 pageMustang Series M116-31 or M6116-31 (Globe), M1116-31 or M61116-31 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M127-1 or M6127-1 (Globe), M1127-1 or M61127-1 (Angle) Specification SheetDocument1 pageMustang Series M127-1 or M6127-1 (Globe), M1127-1 or M61127-1 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S110-14 or S6110-14 (Globe), S1110-14 or S61110-14 (Angle) Specification SheetDocument1 pageStainless Series S110-14 or S6110-14 (Globe), S1110-14 or S61110-14 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M115-11 or M6115-11 (Globe), M1115-11 or M61115-11 (Angle) Specification SheetDocument1 pageMustang Series M115-11 or M6115-11 (Globe), M1115-11 or M61115-11 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S110-18 or S6110-18 (Globe), S1110-18 or S61110-18 (Angle) Specification SheetDocument1 pageStainless Series S110-18 or S6110-18 (Globe), S1110-18 or S61110-18 (Angle) Specification SheetWattsNo ratings yet

- Classic Series F115-58 (Globe), F1115-58 (Angle) Specification SheetDocument1 pageClassic Series F115-58 (Globe), F1115-58 (Angle) Specification SheetWattsNo ratings yet

- Classic Series F118-3 (Globe), F1118-3 (Angle) Specification SheetDocument1 pageClassic Series F118-3 (Globe), F1118-3 (Angle) Specification SheetWattsNo ratings yet

- Classic Series F110-18 (Globe), F1110-18 (Angle) Specification SheetDocument1 pageClassic Series F110-18 (Globe), F1110-18 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S115-74 or S6115-74 (Globe), S1115-74 or S61115-74 (Angle) Specification SheetDocument1 pageStainless Series S115-74 or S6115-74 (Globe), S1115-74 or S61115-74 (Angle) Specification SheetWattsNo ratings yet

- Classic Series F113-12 (Globe), F1113-12 (Angle) Specification SheetDocument1 pageClassic Series F113-12 (Globe), F1113-12 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S113-19 or S6113-19 (Globe), S1113-19 or S61113-19 (Angle) Specification SheetDocument1 pageStainless Series S113-19 or S6113-19 (Globe), S1113-19 or S61113-19 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M116-52 or M6116-52 (Globe), M1116-52 or M61116-52 (Angle) Specification SheetDocument1 pageMustang Series M116-52 or M6116-52 (Globe), M1116-52 or M61116-52 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S110-14 or S6110-14 (Globe), S1110-14 or S61110-14 (Angle) Specification SheetDocument1 pageStainless Series S110-14 or S6110-14 (Globe), S1110-14 or S61110-14 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M113-21 or M6113-21 (Globe), M1113-21 or M61113-21 (Angle) Specification SheetDocument1 pageMustang Series M113-21 or M6113-21 (Globe), M1113-21 or M61113-21 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M113-19 or M6113-19 (Globe), M1113-19 or M61113-19 (Angle) Specification SheetDocument1 pageMustang Series M113-19 or M6113-19 (Globe), M1113-19 or M61113-19 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M513-14 or M6513-14 (Globe), M1513-14 or M61513-14 (Angle) Specification SheetDocument1 pageMustang Series M513-14 or M6513-14 (Globe), M1513-14 or M61513-14 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M113-29 or M6113-29 (Globe) M1113-29 or M61113-29 (Angle) Specification SheetDocument1 pageMustang Series M113-29 or M6113-29 (Globe) M1113-29 or M61113-29 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S113-21 or S6113-21 (Globe), S1113-21 or S61113-21 (Angle) Specification SheetDocument1 pageStainless Series S113-21 or S6113-21 (Globe), S1113-21 or S61113-21 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M113-32 or M6113-32 (Globe), M1113-32 or M61113-32 (Angle) Specification SheetDocument1 pageMustang Series M113-32 or M6113-32 (Globe), M1113-32 or M61113-32 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S115-43 or S6115-43 (Globe), S1115-43 or S61115-43 (Angle) Specification SheetDocument1 pageStainless Series S115-43 or S6115-43 (Globe), S1115-43 or S61115-43 (Angle) Specification SheetWattsNo ratings yet

- Classic Series F113-19 (Globe), F1113-19 (Angle) Specification SheetDocument1 pageClassic Series F113-19 (Globe), F1113-19 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S116-52 or S6116-52 (Globe), S1116-52 or S61116-52 (Angle) Specification SheetDocument1 pageStainless Series S116-52 or S6116-52 (Globe), S1116-52 or S61116-52 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S113-12 or S6113-12 (Globe), S1113-12 or S61113-12 (Angle) Specification SheetDocument1 pageStainless Series S113-12 or S6113-12 (Globe), S1113-12 or S61113-12 (Angle) Specification SheetWattsNo ratings yet

- Classic Series F113-41 (Globe), F1113-41 (Angle) Specification SheetDocument1 pageClassic Series F113-41 (Globe), F1113-41 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M113-41 or M6113-41 (Globe), M1113-41 or M61113-41 (Angle) Specification SheetDocument1 pageMustang Series M113-41 or M6113-41 (Globe), M1113-41 or M61113-41 (Angle) Specification SheetWattsNo ratings yet

- Classic Series F116-52 (Globe), F1116-52 (Angle) Specification SheetDocument1 pageClassic Series F116-52 (Globe), F1116-52 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S113-25 or S6113-25 (Globe), S1113-25 or S61113-25 (Angle) Specification SheetDocument1 pageStainless Series S113-25 or S6113-25 (Globe), S1113-25 or S61113-25 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S113-41 or S6113-41 (Globe), S1113-41 or S61113-41 (Angle) Specification SheetDocument1 pageStainless Series S113-41 or S6113-41 (Globe), S1113-41 or S61113-41 (Angle) Specification SheetWattsNo ratings yet

- Mustang Series M113-40 or M6113-40 (Globe), M1113-40 or M61113-40 (Angle) Specification SheetDocument1 pageMustang Series M113-40 or M6113-40 (Globe), M1113-40 or M61113-40 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S118-4 or S6118-4 (Globe), S1118-4 or S61118-4 (Angle) Specification SheetDocument1 pageStainless Series S118-4 or S6118-4 (Globe), S1118-4 or S61118-4 (Angle) Specification SheetWattsNo ratings yet

- Stainless Series S113-40 or S6113-40 (Globe), S1113-40 or S61113-40 (Angle) Specification SheetDocument1 pageStainless Series S113-40 or S6113-40 (Globe), S1113-40 or S61113-40 (Angle) Specification SheetWattsNo ratings yet

- Vane de Protectie La Soc HidraulicDocument2 pagesVane de Protectie La Soc Hidraulicsergethomas2010No ratings yet

- ON-OFF FLOAT VALVE Sizes R11/4" - DN 600Document2 pagesON-OFF FLOAT VALVE Sizes R11/4" - DN 600sergethomas2010No ratings yet

- Inlet ValveDocument5 pagesInlet Valveujwol_phaijuNo ratings yet

- Vane de Control DebitDocument2 pagesVane de Control Debitsergethomas2010No ratings yet

- Es Acv M115F M1115FDocument4 pagesEs Acv M115F M1115FWattsNo ratings yet

- Forged Steel Valves Manual-AllDocument7 pagesForged Steel Valves Manual-Allshganesh81gmailcomNo ratings yet

- Weflo Nrs Gate Op and MaintDocument5 pagesWeflo Nrs Gate Op and MaintyusufNo ratings yet

- T1002-PSV-1453 Type - 2600Document2 pagesT1002-PSV-1453 Type - 2600Jonson CaoNo ratings yet

- Series V100 Ball ValveDocument20 pagesSeries V100 Ball ValvejenniferNo ratings yet

- Isolation Valve - Watts E3243Document4 pagesIsolation Valve - Watts E3243AHMAD ISLAHINo ratings yet

- Technical Specification For ValvesDocument11 pagesTechnical Specification For ValvesSANDESHNo ratings yet

- Wa-4 Alivio Ul-Fm 1116fmDocument4 pagesWa-4 Alivio Ul-Fm 1116fmeselcosac100% (1)

- Valves Guide: Types, Parts, Standards & ClassificationDocument141 pagesValves Guide: Types, Parts, Standards & ClassificationSabith Mohammed100% (1)

- Control Valves BasicsDocument203 pagesControl Valves Basicszeeshansuboor100% (1)

- Maintenance and RepairDocument4 pagesMaintenance and RepairNyoman RakaNo ratings yet

- N-583 Foot ValveDocument1 pageN-583 Foot ValveSầu ĐờiNo ratings yet

- 09 Pressure Sustaining Valve CPSVDocument2 pages09 Pressure Sustaining Valve CPSVCamilo AyalaNo ratings yet

- Valves Gate DamperDocument54 pagesValves Gate DamperLalit MeenaNo ratings yet

- Claval PRV TM-90-01Document30 pagesClaval PRV TM-90-01DuxToyNo ratings yet

- Manual Mantenimiento Cuadradas Rev.1Document10 pagesManual Mantenimiento Cuadradas Rev.1pelaeztemplarioNo ratings yet

- Wafer Check Valves - O&MDocument4 pagesWafer Check Valves - O&MjayakumarNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Es WD TD 300 UsaDocument1 pageEs WD TD 300 UsaWattsNo ratings yet

- Es WD Li 12 LT UsaDocument1 pageEs WD Li 12 LT UsaWattsNo ratings yet

- Es OfpsysDocument2 pagesEs OfpsysWattsNo ratings yet

- Es WQ PwsrtaDocument2 pagesEs WQ PwsrtaWattsNo ratings yet

- Is WD DLSZ InstallationDocument1 pageIs WD DLSZ InstallationWattsNo ratings yet

- Es Oftwh CDocument2 pagesEs Oftwh CWattsNo ratings yet

- Series 97FB-FSFE Specification SheetDocument2 pagesSeries 97FB-FSFE Specification SheetWattsNo ratings yet

- Es WQ PWFMZDocument2 pagesEs WQ PWFMZWattsNo ratings yet

- Es WQ PwfgacDocument2 pagesEs WQ PwfgacWattsNo ratings yet

- Es WQ PWSRDocument2 pagesEs WQ PWSRWattsNo ratings yet

- Es WQ PwfcalDocument2 pagesEs WQ PwfcalWattsNo ratings yet

- Es FHBDocument1 pageEs FHBWattsNo ratings yet

- Es BD1156FDocument2 pagesEs BD1156FWattsNo ratings yet

- Is WD DLSZ InstallationDocument1 pageIs WD DLSZ InstallationWattsNo ratings yet

- Series LFFHB Specification SheetDocument2 pagesSeries LFFHB Specification SheetWattsNo ratings yet

- Es WD FD 930 UsaDocument1 pageEs WD FD 930 UsaWattsNo ratings yet

- ES PW SmartStream ADocument4 pagesES PW SmartStream AWattsNo ratings yet

- Es Lfemvii 6400SSDocument4 pagesEs Lfemvii 6400SSWattsNo ratings yet

- Es Lf474aDocument2 pagesEs Lf474aWattsNo ratings yet

- Es 957isrDocument2 pagesEs 957isrWattsNo ratings yet

- Es WD Hy 800 CanDocument1 pageEs WD Hy 800 CanWattsNo ratings yet

- Es 757isrDocument2 pagesEs 757isrWattsNo ratings yet

- Es BD911Document2 pagesEs BD911WattsNo ratings yet

- ES WD DeadLevel S USADocument1 pageES WD DeadLevel S USAWattsNo ratings yet

- Es Lf474aDocument2 pagesEs Lf474aWattsNo ratings yet

- Es-Of1465tm 1665TMDocument3 pagesEs-Of1465tm 1665TMWattsNo ratings yet

- ES WD DeadLevel Z USADocument1 pageES WD DeadLevel Z USAWattsNo ratings yet

- Es LFRC105Document2 pagesEs LFRC105WattsNo ratings yet

- Basic Construction Operation Troubleshooting: WarningDocument2 pagesBasic Construction Operation Troubleshooting: WarningWattsNo ratings yet

- Es LFMMV HTKDocument2 pagesEs LFMMV HTKWattsNo ratings yet

- Kitchen DetailsDocument12 pagesKitchen DetailsAJ PAJENo ratings yet

- Ship Stability 5Document31 pagesShip Stability 5jeaneva guiaoNo ratings yet

- Hotel Service Quality ChecklistDocument3 pagesHotel Service Quality ChecklistKarthik BhandaryNo ratings yet

- Philips Flat TV 15PF9936 - LeafletDocument2 pagesPhilips Flat TV 15PF9936 - LeafletVlad FlorescuNo ratings yet

- Comp Notes 122 PDFDocument57 pagesComp Notes 122 PDFmuhammad wisalNo ratings yet

- PHD Thesis BentzDocument320 pagesPHD Thesis Bentzcrusanu50% (2)

- D Screenplay DialoguesDocument75 pagesD Screenplay DialoguesReza GhalibNo ratings yet

- Vibratory Motion and Single Degree of Freedom SystemsDocument29 pagesVibratory Motion and Single Degree of Freedom Systemsmm0493440No ratings yet

- Solid Mechanics: Amit Sir (M-Tech (STRUCTURE), BE, Diploma in Civil), 7020059691/7385990691Document9 pagesSolid Mechanics: Amit Sir (M-Tech (STRUCTURE), BE, Diploma in Civil), 7020059691/7385990691Nikita GonnadeNo ratings yet

- Arc Flash and Electrical Safety HazardsDocument24 pagesArc Flash and Electrical Safety HazardsJulios Charl Panuncialman TagupaNo ratings yet

- Bill of Quantities: Fifteen-Classrooms ADocument1 pageBill of Quantities: Fifteen-Classrooms AFritz NatividadNo ratings yet

- Assignment No1 Current and ElectricityDocument1 pageAssignment No1 Current and ElectricityshreyaNo ratings yet

- ABH-2 Pile - RamDocument5 pagesABH-2 Pile - RamGaneshalingam Ramprasanna2No ratings yet

- Planning of Electrical NetworksDocument32 pagesPlanning of Electrical NetworksSerge RINAUDONo ratings yet

- UML For Java ProgrammersDocument47 pagesUML For Java ProgrammersRajesh KumarNo ratings yet

- HUM 2220 Rome Engineering An Empire Notetaking GuideDocument4 pagesHUM 2220 Rome Engineering An Empire Notetaking GuideDelmarie RodríguezNo ratings yet

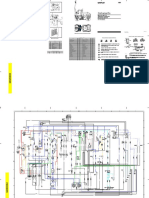

- Electric Schematic CB113 114 QENR2003 PDFDocument2 pagesElectric Schematic CB113 114 QENR2003 PDFHipac TapicuNo ratings yet

- COILDATADocument1 pageCOILDATABarış TaşkınNo ratings yet

- Biometric ATMDocument17 pagesBiometric ATMSushma100% (1)

- Seller DashboardDocument8 pagesSeller DashboardAditya KumarNo ratings yet

- Ms Acess 2Document80 pagesMs Acess 2Mebrie1No ratings yet

- Railway Signaling Concepts and DefinitionsDocument92 pagesRailway Signaling Concepts and DefinitionsGopipavanNo ratings yet

- Intelligent Traffic Manager - White PaperDocument12 pagesIntelligent Traffic Manager - White Paperharishv_scribdNo ratings yet

- If Steam Drum Under Vacuum Then What Will HappenDocument2 pagesIf Steam Drum Under Vacuum Then What Will HappenyogacruiseNo ratings yet

- Profile Summary:: Curriculum VitaeDocument3 pagesProfile Summary:: Curriculum Vitaepritam banerjeeNo ratings yet

- Acoustic Emission-Based Monitoring Approach For Friction Stir Welding of Aluminum Alloy AA6063-T6 With Different Tool Pin ProfilesDocument10 pagesAcoustic Emission-Based Monitoring Approach For Friction Stir Welding of Aluminum Alloy AA6063-T6 With Different Tool Pin ProfileslarryNo ratings yet

- IES 2012 Exam Civil Engineering Paper II Solved With Answer KeyDocument21 pagesIES 2012 Exam Civil Engineering Paper II Solved With Answer KeyPratik Nayak0% (2)

- Kinematics of Machinery ManualDocument29 pagesKinematics of Machinery ManualShubham NaikNo ratings yet

- Fuel Pressure Regulator - Remove and InstallDocument3 pagesFuel Pressure Regulator - Remove and InstallGerardo VelazquezNo ratings yet

- Marking Fixture PresentationDocument31 pagesMarking Fixture PresentationAvinash JejurkarNo ratings yet