Professional Documents

Culture Documents

Installation Instructions For Part #50002 WATER/METHANOL Injection System '99 - '03 Ford Powerstroke® 7.3L Diesel

Uploaded by

Josh HermanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Instructions For Part #50002 WATER/METHANOL Injection System '99 - '03 Ford Powerstroke® 7.3L Diesel

Uploaded by

Josh HermanCopyright:

Available Formats

Contents:

Parts List: ..................................................................................... 3

Introduction.................................................................................. 4

Installation Mechanical ............................................................... 4

Testing Pump and Mechanical System ..................................... 8

INSTALLATION Variable Controller Installation .................................................. 9

Testing the Controller ............................................................... 10

INSTRUCTIONS FOR PART Variable Controller Tuning ....................................................... 10

#50002 WATER/METHANOL Controller Operation Example.................................................. 11

Tuning Quick Reference ........................................................... 12

INJECTION SYSTEM Maintenance ............................................................................... 13

’99 – ’03 Ford Powerstroke® Fluid Level Switch (optional).................................................... 14

Solenoid Upgrade (optional) .................................................... 15

7.3L Diesel Install Notes: .............................................................................. 16

Disclaimer................................................................................... 17

Where to Contact:...................................................................... 19

CAUTION

You must completely read though these instructions before installing and

operating this product. Failure to due so can result in damage to this

product and the vehicle.

© 2005, Snow Performance, Incorporated

© 2005, Snow Performance, Incorporated

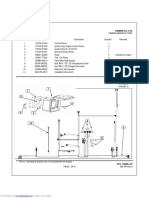

Parts List: Introduction

Pump-High pressure/high volume w/ (2) 3/8 elbows - Please refer to the System Diagram below during install. The

Reservoir optional fluid level switch, part #40030, is shown.

8ft. of Red Tubing

Black Wire Loom Arm Switch Injection Status LED

Red

Installation Instructions

White

Red

Electrical Packet Green

In small bag: Black

1 Green LED

Red

4 Blue Butt Connectors

Black Engine

3 Small Eyehook Pump Air Intake

1 Male Connectors

3 Female Connector

Air Flow

10 Tie Wraps from Turbo

Boost Pressure Line

armed” switch

VC-100 Controller w/ wiring harness

Vacuum “t”

Red

Mechanical Packet +12 Volt Key On Low Fluid LED

In small bag: White

Engine Ground White

1 nozzle holder

7 #8x1&1/2in. Screws White

Wire Connection

7-#8 washers

4 #6x1/2in. Screws

2 Stickers in Small Plastic Bag

dual nozzle upgrade ( nozzle holder,”t”, 2’ tubing*red

1/8” NPT Tap

extra bulkhead Installation Mechanical

18” 1/8”tygon tubing

1-375ml/min nozzle Step 1 Tank Install

2 625ml/min nozzles

Required tools Mount tank as high in engine

- Electric drill w/ drill bits compartment as possible using

- Teflon sealant (pipe sealant) #8x1½” sheet metal screws and

- Adjustable wrench washers provided.

- Utility knife

- Screw driver – Phillips Optional: If windshield washer reservoir is utilized, mount quick-

- 5/16” open end wrench (for nozzle) connect bulkhead in the bottom using “Goop” sealant or similar

methanol resistant adhesive/sealant.

The following procedure will allow the use of a nut on both sides of

bulkhead fitting for windshield washer reservoir:

© 2005, Snow Performance, Incorporated © 2005, Snow Performance, Incorporated

1. Drill ½” size hole in bottom of reservoir.

2. Attach tubing to threaded end of fitting. Nozzle sizing is a function of flywheel horsepower (FWHP), which

3. Pull tubing through the reservoir fill opening. approximates the engines airflow, and boost, which approximates

4. Slide the nut on the tubing. intake charge heat.

5. While pulling on the tube, thread the nut on the fitting after

applying sealant. Recommended starting points for 7.3L Powerstroke®:

You can mount the tank in the rear of the 625ml/min nozzle w/ Pump 2

175 – 250 RWHP

vehicle. The pump is a push pump by design Turns out on set screw.

so it needs to be mounted as close to the reservoir as possible. 250 - 300 RWHP: 625ml/min nozzle.

Because the pump is oversized, injection pressure will not be 325 - 400 RWHP: 375 & 625ml/min nozzle.

affected. 450 - 650 RWHP: 2 - 625ml/min nozzle

When mounting the nozzles, until you are

Step 2 Pump Install tuned, do not thread lock the nozzle(s) to the

th

nozzle holder. This will allow changing of the nozzles if

To avoid pump housing damage, it is not necessary to turn the 3/8 necessary without damage to the nozzle or holder. Once you

adaptor fittings all the way in. NPT threads are tapered and with are tuned, we recommend thread locking the nozzles to the

sealant (“Goop” household sealant/adhesive recommended), will holder.

usually seal with approx. ½ turn past hand tight. CAUTION: to over

torque the fittings will result in a cracked housing. - Assemble desired nozzles into nozzles holder using pipe sealant.

The end of the nozzle with the 100micron screen is to be inserted

Mount pump so it is positioned at into the nozzle holder. Torque at least 1/2 turn past hand tight.

the same level or lower than tank.

Pump can be mounted horizontally - Note: If nozzles are mounted lower then the reservoir, a solenoid

or vertically using (4) supplied must be used.

#8x1½” screws and washers.

- Once tuning is done it is imperative to use permanent thread

In cramped engine bays, inside locker such as loctite 262 to prevent a loose nozzle. Torque the

the fender is often a good nozzle approx ½ turn clockwise past hand tight using a 5/16”

alternative. wrench. CAUTION: to over torque the nozzle will result in

reduced nozzle flow.

-Measure from reservoir-to- pump inlet (the pump has an arrow

indicating flow direction between inlet and outlet ports) and cut - The amount injected can be adjusted by pump pressure which can

¼”OD red nylon tube to length allowing 1” extra for fittings. Insure be changed by turning the allen head in the pump regulator. The

no kinks are in the nylon tube. Push tubing into quick-connect pump is set at the factory at 150psi.(2-turns counter clockwise from

fittings 1/4-1/2”. the 220psi hard stop).

Mount the check valve between the reservoir and pump inlet. The

check valve is marked with an arrow to show flow direction. Counterclockwise = Less Pressure.

2-turns Counterclockwise = approx 100psi.

4-turns Counterclockwise = approx 60psi.

Step 3 Nozzle(s) Selection

© 2005, Snow Performance, Incorporated © 2005, Snow Performance, Incorporated

Step 4 Nozzle Mounting

The nozzle holder has threads on the outside

The nozzle assembly should be of it, but we do not recommend mounting the

installed at 90 degrees to the nozzle holder (1/4”npt thread). To eliminate the possibility of

direction of airflow. This will the nozzle coming loose and causing possible engine damage,

ensure maximum cooling as the we recommend mounting the 1/8”npt nozzle using the supplied

nozzle sprays in a 180 degree tap.

cone pattern. Choose and mark

location on air intake for nozzle

install. Use tie wraps to help route tubing and to ensure it doesn't contact

moving or hot parts in the engine compartment.

Drill and tap (11/32" pre-drill, 1/8

-27 NPT tap), metal air inlet tube as close as possible to intake.

Remove the cast inlet piece just before the intake and drill and tap Testing Pump and Mechanical System

for two nozzles.

- Using a 12v source, apply 12v to the pump red wire (disconnect

wire at pump). Pump should activate and fluid level in tank should

Step 5 Nozzle Connection go down. Also check for leaks.

Measure from pump outlet to - If pump goes on but fluid level

nozzle and cut red ¼”OD nylon doesn't go down, there is an

tubing to desired length and obstruction in the tube or nozzle.

install by pushing tube

completely (approx. 1/4-1/2") - If the pump doesn't go on,

into quick connect of pump there is a ground problem or a

outlet. Connect other end to faulty pump.

the “T” fitting. From one outlet

of “T” fitting, measure and cut - All pumps are tested before

tubing to one nozzle. Repeat shipment.

for other nozzle. Connect to

each nozzle assembly - Activation of pump for short

compression fitting by plugging periods (2 - 5 sec.) will not cause engine damage.

tube into compression fitting

(approx. ¼”) and tightening

compression nut approx ½ turn

past hand tight. Check for leaks

after initial testing.

© 2005, Snow Performance, Incorporated © 2005, Snow Performance, Incorporated

Variable Controller Installation Select a location for the LED (green-

on when pump activated) in

dashboard of vehicle. Run red wire

from the connection of the Green

1 2 3 4 controller wire and the Red pump wire

to the Red wire of the LED and make

connection (refer to wiring diagram).

Connect White wire of LED to good

The figure above shows the back view of the variable controller. ground source under dash.

Mount the variable controller to driver side engine bay using 4

#6x1/2 sheet metal screws. Mount “armed switch” in dash and

The VC series controllers are designed to withstand engine bay wire in the 12Vkey-on-to controller

conditions, but should not be mounted directly to the engine block. circuit. Do not route wires near hot or moving parts. Use

Attach 1/8” hose (supplied) to post on back of controller. The other corrugated wire loom and tie wraps (supplied) to protect and route

end attaches to manifold boost source using supplied vacuum “T”. wires.

Plug wire harness into back of controller. Note the terminal

positions are numbered on the bottom side of wire harness Testing the Controller

connector. Your controller has an internal self resetting fuse such

that an external automotive type fuse is not required. In the case of • Begin the testing process with both dials on the variable

a fault the internal fuse will attempt to reset after about 1 minute. controller at their lowest settings (counter-clockwise).

• Turn ignition key on so that the system has 12volt power. If the

pump runs, inspect ground wires for secure connection.

CAUTION: Disconnect Battery Negative (- ) terminal

while connecting wires to prevent electrical fire or damage to • Pump should be off at this point, apply light air pressure or blow

controller. into vacuum tube connection on back of controller. Pump

should active while low pressure is applied but not enough to

• Connect Green wire at position 4 to Pump Red power wire. spray fluid.

• Connect Red wire at position 3 to +12V key on source. When

selecting a 12V key-on source, try to find a dedicated circuit Start Psi Full Psi

with at least a 15 AMP fuse (25 AMP with 220psi pump). Variable Controller 15 22

Tuning VC-100 6 25 15 50

• Connect Black wire at position 1 to a good Ground location. 30 70

• Use a tie wrap to keep rubber vacuum/boost line on hose barb

in high boost applications.

Always insure to have a good electrical ground • With 7.3L Powerstroke®: with 23psi max boost, Start at 15psi /

connection. Poor ground will result in erratic Full at 23psi works well.

operation of controller.

• With 30psi max boost, Start at 20psi/ Full at 30psi is a good

starting point.

• It is not recommended that “Full” injection take place before

20psig or combustion quench may occur

© 2005, Snow Performance, Incorporated © 2005, Snow Performance, Incorporated

• Note - over lapping the settings, where the Full dial is lower then Tuning Quick Reference

Start, will result in max injection at the onset point.

If combustion quench occurs as evidenced by engine “bucking”,

• Adjust Full dial until a smooth power curve is felt with no

reduce the injection quantity or raise the onset boost level. This can

misfiring.

be done by:

Controller Operation Example 1. Lowering the pump pressure by turning the pump regulator

adjusting screw counterclockwise.

2. Using a smaller nozzle(s).

100 3. Introducing injection later at a higher boost setting.

90

Also, fresh methanol – less than 1 month old when exposed to

80

Pump Output %

atmosphere – and using a greater methanol concentration – up to

70

50% - will reduce combustion quench.

60

50 100% water will cool combustion and egt’s and will increase power

40 approx 20-30 HP.

30

75/25% water/methanol will cool egt’s and power will increase

20

approx 40HP.

10

Start Full

0 50/50% water/methanol will cool egt’s and increase power approx

8 12 16 20 24 28 32 36 70HP.

Boost Pressure psi

Over 50% methanol has been demonstrated to increase egt’s and

can cause diesel “knock” in applications with significantly advanced

The above chart plots three different settings for the VC-100 injection timing.

water/methanol injection controller

Caution: To avoid “pooling” in the intake and possible engine

For setting 1, green, the chart shows the Start dial at 8psi and the damage upon start-up, it is recommended that: 1. the engine be run

Full dial at 24psi. At 8psi of boost pressure the pump will operate at without water/methanol for at least 5 min. after injection before

10%. At 24psi of boost pressure, the pump will deliver 100% of turning the engine off. 2. The “armed switch” is turned to the off

injection pressure. position when the engine is off.

For boost pressure readings between the Start and Full settings, the Caution: The use of methanol with propane is not recommended

controller will linearly adjust the pump pressure as shown on the due to their similar combustion characteristics. Using both could

graph. induce diesel “knock” and cause head gasket problems. For this

reason, 100% water is recommended when using this system in

conjunction with propane.

© 2005, Snow Performance, Incorporated © 2005, Snow Performance, Incorporated

Maintenance Fluid Level Switch #40030 (optional)

Remove nozzle(s) and clean screen filters at least once per

year using carb cleaner.

Red

The Boost Cooler® has been designed to operate with high

concentrations of methanol. Oil or other additives are not Low Fluid LED

required for system lubrication. White

For best performance, cooling and system life it is recommend

that Snow Performance Boost Juice™, part #40008, be the

exclusive fluid used in the system. White

Instructions

- After mounting reservoir, mount red LED in dash next to the green

“injection” LED is usually easiest.

- Wire LED per diagram with Red wire to a 12v key-on source, and

the White wire to one of the White wires of the level switch.

- Connect other White wire of the level switch to vehicle ground.

- With key-on source enabled, the red LED should be “on” with no

fluid in the reservoir. Upon filling the reservoir, the red LED should

be “off”.

- The system is designed to indicate when there is less than 1” of

fluid in the reservoir.

© 2005, Snow Performance, Incorporated © 2005, Snow Performance, Incorporated

Solenoid Upgrade (optional) Install Notes:

Pump Setting ____________(psi)

The optional solenoid upgrade from Snow Performance, part

#40060, is required if the fluid reservoir is mounted higher then the Nozzle Size ____________(ml/min)

nozzle.

Controller setting Start:________

Engine

Full: ________

Black Air Intake

Injection Status LED

Red

Black

Misc:

Green from 3

Variable Controller White

2 1

Red

Black

Pump

Air Flow

- Hand thread the two 1/8” NPT quick connect fittings into ports

labeled 1 and 2 on the solenoid. Tighten an additional half turn.

- Cut high pressure line at location solenoid is to be installed. Insert

ends of cut line into quick connect fittings of solenoid. The port

labeled #2 is the inlet side, port #1 is the outlet. Firmly pull on line

to check secure connection. If line pulls out, re-insert farther into

fitting to engage locking clips. If high pressure line removal is

required, firmly press in plastic fitting ring to disengage locking clips

while pulling hose from fitting.

- Connect one of the Black wires from solenoid to the Red positive

pump wire. Note that connecting the wire to any other power

source other then the pump wire will result in improper operation of

solenoid. Connect the second Black wire to a secure chassis

ground location.

© 2005, Snow Performance, Incorporated © 2005, Snow Performance, Incorporated

Disclaimer LIFETIME WARRANTY

Do not use this product until you have carefully read the following Snow Performance’s commitment to providing the best

agreement. water/methanol system is reflected in the Lifetime Warranty that

This sets forth the terms and conditions for the use of this product. is standard on all Snow Performance Boost Coolers™. We are

The installation of this product indicates that the BUYER has read able to offer this warranty due to our control of manufacturing

and understands this agreement and accepts its terms and quality and the historically high reliability of our products in the

conditions. field.

Performance products by their nature are designed to increase

horsepower and performance not engineered in the original vehicle Warranty Policy

and the increased stress could result in damage to related systems.

This is a high performance product – use at your own risk. Snow Performance, Inc. (hereafter "Snow") warrants that the Product

shall conform to and perform in accordance with published technical

Snow Performance Inc., Its agents, employees or owners shall not

specifications and shall be free of defects in materials and workmanship as

be under any liability whether in contract or otherwise whether or not long as :

resulting from our negligence or contents of information supplied for

any damage or loss resulting from such information. The exclusive fluid used in the kit has been Snow performance’s Boost

The BUYER is responsible to fully understand the capability and Juice™ water methanol product as evidenced by sales receipts confirming

limitations of his/her vehicle according to manufacturer purchases.

specifications and agrees to hold the SELLER harmless from any In the event that Boost Juice has not exclusively been used, A One Year

damage resulting from failure to adhere to such specifications. Warranty applies.

The SELLER disclaims any warranty and expressly disclaims any

In the event of failure, Snow will repair or replace the part at Snow's sole

liability for personal injury or damages. The BUYER acknowledges discretion. Failures resulting from misapplication or misuse of the Product,

and agrees that the disclaimer of any liability for personal injury is a failure to adhere to any specifications or instructions, or failure resulting

material term for this agreement and the BUYER agrees to from neglect, abuse, accidents, or acts of nature are not covered under

indemnify the SELLER and to hold the SELLER harmless from any this warranty.

claim related to the item of the equipment purchased. Under no

Warranty service may be obtained by delivering the part to Snow and

circumstances will the SELLER be liable for any damages or

providing proof of purchase. Customer agrees to insure the Product or

expenses by reason of use or sale of any such equipment. assume the risk of loss or damage in transit, to prepay shipping charges

The BUYER is responsible to obey all applicable federal, state, and to Snow, and to use the original shipping container or equivalent.

local laws, statutes, and ordinances when operating his/her Warranty is valid only for original purchaser and is not transferable. This

vehicle, and the BUYER agrees to hold SELLER harmless from any Warranty gives you specific legal rights, and you may also have other

violation thereof. rights which may vary from state to state.

The SELLER assumes no liability regarding the improper This warranty applies to Snow manufactured Boost Cooler™ kits.

installation or misapplication of its products.

It is the installer's responsibility to check for proper installation and if Non-Warranty Repair/Retest

Products returned due to damage or misuse and Products retested with no

in doubt, contact the manufacturer. problem found are subject to repair/retest charges. A purchase order or

credit card number and authorization must be provided in order to obtain

an RMA (Return Merchandise Authorization) number prior to returning

Product.

© 2005, Snow Performance, Incorporated © 2005, Snow Performance, Incorporated

Where to Contact:

http://www.snowperformance.net

Sales (719) 633-3811, Toll Free (866) 365-2762

Tech Support Line (540) 760-3384

FAQ and Technical Forum: http://www.snowperformance.net/forum/

Snow Performance, Inc.

2205 Valley View Dr.

Woodland Park, CO 80863

Notes

The contents of this document are subject to change without prior

notice. No part of or this entire document may be reproduced in any

form without prior written permission of Snow Performance, Inc

under the copyright except for private use.

The names, addresses and telephone numbers mentioned are

current as of December 1, 2005. Note that this information is

subject to change. Please refer to www.snowperformance.net for

current information.

© 2005, Snow Performance, Incorporated

You might also like

- Booster Pump Package Operating & Installation InstructionsDocument4 pagesBooster Pump Package Operating & Installation InstructionsGerry Dan ChanliongcoNo ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- SB 10096454 1020Document8 pagesSB 10096454 1020Sushil KumarNo ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- Manual de Usuario RTX ACTADocument15 pagesManual de Usuario RTX ACTARobertIsaiRuizAcostaNo ratings yet

- Electronic Unit Injector - Test: Shutdown SIS Previous ScreenDocument2 pagesElectronic Unit Injector - Test: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- WaterWorker Digital Pressure Control WWDPC Operation ManualDocument8 pagesWaterWorker Digital Pressure Control WWDPC Operation ManualSNo ratings yet

- MANUAL Bomba de VacioDocument40 pagesMANUAL Bomba de VacioAngelica MarulandaNo ratings yet

- Quick Start Guide GMXa EN ES IT PT WebDocument64 pagesQuick Start Guide GMXa EN ES IT PT WebDugPigeonNo ratings yet

- Cat 12 12v Electic TrainingDocument26 pagesCat 12 12v Electic TrainingAnonymous 7vG2OUBfKI100% (1)

- Mustang Coyote 10rib R11Document9 pagesMustang Coyote 10rib R11WayneNo ratings yet

- 4 TNV 84 TZDocument6 pages4 TNV 84 TZCarlos Rivera MontesNo ratings yet

- DMLEU Iom1Document12 pagesDMLEU Iom1duongbk24 luu quang duongNo ratings yet

- I630-E-01 Pneumatic Control BoxDocument18 pagesI630-E-01 Pneumatic Control BoxEdson Pires da SilvaNo ratings yet

- Installation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"Document2 pagesInstallation Instructions: Diesel/Alternator Tachometer 3-3/8" & 5"heartofdixieNo ratings yet

- Manual Medidores GPI Serie TMDocument40 pagesManual Medidores GPI Serie TMangel delgadoNo ratings yet

- XI-921 NEW Service Manual 22mar2011Document52 pagesXI-921 NEW Service Manual 22mar2011Novy adi syaputra 93No ratings yet

- LetRipp Fuel Tuner Tuning Guide V1.0!07!03 - 07Document10 pagesLetRipp Fuel Tuner Tuning Guide V1.0!07!03 - 07tastreNo ratings yet

- D-040 Rev 004 E150 Pump ELASTECDocument13 pagesD-040 Rev 004 E150 Pump ELASTECalvaro yepes oviedoNo ratings yet

- Water Treatment System Conductivity Controller: Installation & Operation ManualDocument82 pagesWater Treatment System Conductivity Controller: Installation & Operation ManualLuis Angel Guzman TomayllaNo ratings yet

- 12V24V Electrical SystemsDocument26 pages12V24V Electrical SystemsAllan Lariosa100% (17)

- Hydraulic Hand Pump and Jack Manual PM-5250Document11 pagesHydraulic Hand Pump and Jack Manual PM-5250Mobile HackNo ratings yet

- Minor CAN 3 Issue 4.0.1 (English)Document48 pagesMinor CAN 3 Issue 4.0.1 (English)Ana IancuNo ratings yet

- Minor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsDocument46 pagesMinor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsBogdan NgrNo ratings yet

- 259-16749 Elfläktstyrn CorvetteDocument2 pages259-16749 Elfläktstyrn CorvetteSjoling8211No ratings yet

- MN 726Document20 pagesMN 726Vytautas AbromaitisNo ratings yet

- SB 10054723 6187Document19 pagesSB 10054723 6187Vicente Salazar TorresNo ratings yet

- Installation Instructions 30-3000Document12 pagesInstallation Instructions 30-3000Toni RodriguezNo ratings yet

- Manual UK300 ENDocument16 pagesManual UK300 ENAlexComanNo ratings yet

- Yamaha P-200Document65 pagesYamaha P-200EduardoBeltraminoNo ratings yet

- Cat 12 12v Electic TrainingDocument26 pagesCat 12 12v Electic TrainingZenaki Kurniawan100% (1)

- Slim WS BNT65 Valve Operation ManualDocument18 pagesSlim WS BNT65 Valve Operation ManualSamanthaNo ratings yet

- Owner'S Manual: RIM-U Universal Ice Machine PumpDocument12 pagesOwner'S Manual: RIM-U Universal Ice Machine PumpDavid SanchezNo ratings yet

- Pieces DétachéesDocument86 pagesPieces DétachéespmcisissengueNo ratings yet

- GD Qf450sb FeDocument11 pagesGD Qf450sb FeCesar MoraNo ratings yet

- 60 Cycle Centrifugal Pump J Series JB Series Manual PDFDocument16 pages60 Cycle Centrifugal Pump J Series JB Series Manual PDFMartin Ernst RedeckerNo ratings yet

- Laser Sand Filter System: Owner's Manual and Installation GuideDocument20 pagesLaser Sand Filter System: Owner's Manual and Installation GuideDavid HidalgoNo ratings yet

- 30-3020 Water Methanol Failsafe DeviceDocument18 pages30-3020 Water Methanol Failsafe DeviceB-ertNo ratings yet

- Hurst Roll Control Installation Instructions # 5671518: 2010 and Up CAMARODocument8 pagesHurst Roll Control Installation Instructions # 5671518: 2010 and Up CAMAROpramodh kumarNo ratings yet

- Cdi Troubleshooting Guide Johnson EvinrudeDocument35 pagesCdi Troubleshooting Guide Johnson EvinrudeEvan CollinsNo ratings yet

- C32 MOTOR CAT Electronic Unit Injector - TestDocument2 pagesC32 MOTOR CAT Electronic Unit Injector - TestFreddy Villegas100% (1)

- Titan ManualDocument16 pagesTitan ManualpedropcNo ratings yet

- Parveen: Technical ManualDocument16 pagesParveen: Technical ManualDEATH ASSASSIN GAMERNo ratings yet

- Medidor Flujo Marca Gpi, Modelo TM300-N Inf TecnicaDocument40 pagesMedidor Flujo Marca Gpi, Modelo TM300-N Inf TecnicadeliaabreguNo ratings yet

- ASX-560 ASX-280 Quick Installation GuideDocument16 pagesASX-560 ASX-280 Quick Installation GuideCENTEC ARAUCONo ratings yet

- WEG Regulador Automatico de Tensao Grt7 Th4Document51 pagesWEG Regulador Automatico de Tensao Grt7 Th4rayxonga14No ratings yet

- Den-Jet Ce20-500 - Master Mariner Manual - Dec 2017Document40 pagesDen-Jet Ce20-500 - Master Mariner Manual - Dec 2017First LastNo ratings yet

- EN ManualDocument32 pagesEN Manualantonio vukeNo ratings yet

- Ap900 Manual - enDocument32 pagesAp900 Manual - enCarlos Javier MirandaNo ratings yet

- Installation Instructions Transmission - Remote Cooler Install Kit PART # 13023Document2 pagesInstallation Instructions Transmission - Remote Cooler Install Kit PART # 13023qusayNo ratings yet

- Installation Instructions Transmission - Remote Cooler Install Kit PART # 13023Document2 pagesInstallation Instructions Transmission - Remote Cooler Install Kit PART # 13023qusayNo ratings yet

- DP6013 Jeep 1992-96 Rev 08292022Document10 pagesDP6013 Jeep 1992-96 Rev 08292022Eduar AcvdoNo ratings yet

- Manual Quad BopDocument28 pagesManual Quad BopParag PadoleNo ratings yet

- 01 Manual Om Mechanical Seal PumpDocument16 pages01 Manual Om Mechanical Seal Pumpmauro.vergaraNo ratings yet

- Read Instructions Before Installing: Losed YstemDocument2 pagesRead Instructions Before Installing: Losed YstemPuji NugrohoNo ratings yet

- Motor C6.6 Caterpillar Prueba de AireDocument4 pagesMotor C6.6 Caterpillar Prueba de AiremanuelNo ratings yet

- Tachometer-Gauge Install IS0012 ADocument4 pagesTachometer-Gauge Install IS0012 Amyinves00No ratings yet

- Owners Manual: Frame Mounted Centrifugal PumpDocument32 pagesOwners Manual: Frame Mounted Centrifugal Pumprhusseinpos4765No ratings yet

- Aristotel RepublicaDocument357 pagesAristotel RepublicaAlexander LeftaracheNo ratings yet

- NL 200Document60 pagesNL 200Leo Benítez VillanuevaNo ratings yet

- GR# 189655Document10 pagesGR# 189655Simeon SuanNo ratings yet

- Footscan Footscan: Installation Guide and User Manual System With 9Document179 pagesFootscan Footscan: Installation Guide and User Manual System With 9ARTURO ALEJANDRO GONZÁLEZ OLGUÍNNo ratings yet

- Blazemaster CPVC Fire Sprinkler Pipe & Fittings Submittal SheetDocument6 pagesBlazemaster CPVC Fire Sprinkler Pipe & Fittings Submittal SheetIlyasaNo ratings yet

- OM WALTCO RGL RBGL-Series Owners Manual en-US 160225-w Original 85078Document38 pagesOM WALTCO RGL RBGL-Series Owners Manual en-US 160225-w Original 85078oscar gandaraNo ratings yet

- CrafcoDocument59 pagesCrafcofersigalNo ratings yet

- Despiece Easycoder - Px6iDocument48 pagesDespiece Easycoder - Px6iAgustin Garcia VazquezNo ratings yet

- Screen Printing 101Document2 pagesScreen Printing 101sis & broNo ratings yet

- Unit - 2: Conditions & Warranties: Learning OutcomesDocument14 pagesUnit - 2: Conditions & Warranties: Learning OutcomesAarav TripathiNo ratings yet

- Module 06-Scope of Work-Stacey Hopkins v2Document30 pagesModule 06-Scope of Work-Stacey Hopkins v2api-621467446No ratings yet

- Daq 1200 ManualDocument93 pagesDaq 1200 ManualsilicomNo ratings yet

- Audit of LiabDocument9 pagesAudit of LiabCielo Mae Parungo0% (1)

- Tebg Emsd Novec 1230 Best Practice Guide 2020 Digital A4 FV Ref - Omi28965Document4 pagesTebg Emsd Novec 1230 Best Practice Guide 2020 Digital A4 FV Ref - Omi28965Ahmed MohamedNo ratings yet

- 2014 Field Commander Wiring Manual For Reinke Pivots: Second End Gun Relay WiringDocument25 pages2014 Field Commander Wiring Manual For Reinke Pivots: Second End Gun Relay WiringLuis RolaNo ratings yet

- KMD Owners Manual PDFDocument14 pagesKMD Owners Manual PDFAhmed Emad AhmedNo ratings yet

- Test Bank For 2010 Living in A Microbial World 1st Edition Study AidDocument19 pagesTest Bank For 2010 Living in A Microbial World 1st Edition Study Aidbeastlyfulberj6gkg100% (43)

- Vishay 115lDocument3 pagesVishay 115lrogerNo ratings yet

- AMX Autopatch 4ydm Instruction ManualDocument154 pagesAMX Autopatch 4ydm Instruction ManualNoah Weston100% (2)

- Gen3 WallConnector Installation ManualDocument35 pagesGen3 WallConnector Installation ManuallinseysabrinaNo ratings yet

- Motorola CP200d Service ManualDocument93 pagesMotorola CP200d Service ManualCalvin DeSarioNo ratings yet

- Test Bank For Seeleys Essentials of Anatomy and Physiology 10th Edition Cinnamon Vanputte and Jennifer Regan and Andrew RussoDocument13 pagesTest Bank For Seeleys Essentials of Anatomy and Physiology 10th Edition Cinnamon Vanputte and Jennifer Regan and Andrew Russounco.forcut.rlln100% (43)

- Storz Thermoflator 26 - Service ManualDocument110 pagesStorz Thermoflator 26 - Service Manualservice iyadMedicalNo ratings yet

- Test Bank For American Politics Today Essentials 6th Edition William T Bianco David T CanonDocument20 pagesTest Bank For American Politics Today Essentials 6th Edition William T Bianco David T Canonmingarannikj100% (11)

- Recipes With S7-1200Document47 pagesRecipes With S7-1200MyScribdNo ratings yet

- TrioTIO6203A Screen Manual (SN. 257)Document43 pagesTrioTIO6203A Screen Manual (SN. 257)Enso E Rosales FNo ratings yet

- Full Download Solution Manual For e Marketing 7 e Judy Strauss Raymond Frost PDF Full ChapterDocument19 pagesFull Download Solution Manual For e Marketing 7 e Judy Strauss Raymond Frost PDF Full Chapterbradleywardxg7pz0100% (21)

- Weed Eater FL20CDocument14 pagesWeed Eater FL20CKevin RothrockNo ratings yet

- PHILIPPINE STEEL COATING CORP., Vs EDUARD QUINONESDocument12 pagesPHILIPPINE STEEL COATING CORP., Vs EDUARD QUINONESGenesis ManaliliNo ratings yet

- Model 300Scw-1: Selectone CommandDocument23 pagesModel 300Scw-1: Selectone Commandalexander vicenteNo ratings yet