Professional Documents

Culture Documents

Silicon Etching

Uploaded by

Winai Wanburee0 ratings0% found this document useful (0 votes)

232 views2 pagesAnisotropic silicon etching is highly anisotropic: While the 100and 110-crystal planes are being etched, the stable 111 planes act as an etch stop: (111)-orientated wafers are almost not at[100] tacked by the etch. The degree of anisotropy (= etch rate selectivity [110] between different crystal planes), the etch rates, and the etching homogen

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAnisotropic silicon etching is highly anisotropic: While the 100and 110-crystal planes are being etched, the stable 111 planes act as an etch stop: (111)-orientated wafers are almost not at[100] tacked by the etch. The degree of anisotropy (= etch rate selectivity [110] between different crystal planes), the etch rates, and the etching homogen

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

232 views2 pagesSilicon Etching

Uploaded by

Winai WanbureeAnisotropic silicon etching is highly anisotropic: While the 100and 110-crystal planes are being etched, the stable 111 planes act as an etch stop: (111)-orientated wafers are almost not at[100] tacked by the etch. The degree of anisotropy (= etch rate selectivity [110] between different crystal planes), the etch rates, and the etching homogen

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Wet Chemical Etching

of Silicon

Revised: 2007-03-07

Source: www.microchemicals.eu/technical-information

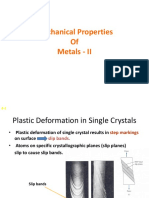

Anisotropic Silicon Etching

Strong alkaline substances (pH > 12) such as aqueous KOH- or TMAH-solutions etch Si via

Si + 4 OH- à Si(OH)4 + 4e-.

Since the bonding energy of Si atoms is different for each crystal plane, and KOH/TMAH Si

etching is not diffusion- but etch rate limited, Si etching is highly anisotropic: While the {100}-

and {110}-crystal planes are being etched, the stable {111} planes act as an etch stop:

(111)-orientated Si-

wafers are almost not at-

[100]

tacked by the etch.

(100)-orientated wafers

form square-based pyra-

[111]

mids with {111} sur-

faces. These pyramids

{111} are realised on c-Si solar

cells for the purpose of

reflection minimization.

(110)-orientated wafers

f or m perpen di cu l ar

trenches wi th {11 1}

side-walls, used as e. g.

microchannels in micro-

me ch an i cs an d mi -

[100] crofluidics.

[010]

The degree of anisotropy

[110] (= etch rate selectivity

between different crystal

planes), the etch rates,

and the etching homoge-

neity depend on the

etchin g tem perature,

atomic defects in the sili-

Anisotropic

con crystal, intrinsic im-

etching

purities of the Si crystal,

{100} {110} impurities (metal ions)

by the etchant, and the

[100] [110] concentration of Si-at-

oms already etched.

The doping concentration

of the Si to be etched

also strongly impacts on

the etching: During etch-

i n g, B or on d oped S i

forms borosilicate glass

on the surface which acts

{111} as etch stop if the boron

doping concentration ex-

ceeds 1019 cm-3.

Photoresists, developers, remover, adhesion promoters, etchants, and solvents ...

Phone: +49 731 36080-409 Fax: +49 731 36080-908 e-Mail: sales@microchemicals.eu

MicroChemicals GmbH

The following table lists etch rates of Si and the hard masks SixNy and SiO2, and etch selectivity

between different crystal planes as a function of the etchant.

Etch rate ratio Etch rate (absolute) Advantages (+)

Etchant

(100)/(111) (110)/(111) (100) Si3N4 SiO2 Disadvantages (-)

KOH (-) Metal ion containing

300 600 1.4 µm/min <1 Å/min 14 Å/min

(44%, 85°C) (+) Strongly anisotropic

TMAH 0.3-1 (-) Weak anisotropy

37 68 <1 Å/min 2 Å/min

(25%, 80°C) µm/min (+) Metal ion free

(-) Weak anisotropy , toxic

EDP

20 10 1.25 µm/min 1 Å/min 2 Å/min (+) Metal ion free, metallic

(115°C)

hard masks possible

Isotropic Etching of Silicon and SiO2

The following chemical reactions summarize the basic etch mechanism for isotropic silicon

etching (steps 1-4), and SiO2 (only step 4) using a HF/HNO3 etching mixture:

(1) NO2 formation (HNO2 always in traces in HNO3): HNO2 + HNO3 à 2 NO2 + H2O

(2) Oxidation of silicon by NO2: 2 NO2 + Si à Si 2+ + 2 NO2-

(3) Formation of SiO2: Si + 2 (OH)

2+ -

à SiO2 + H2

(4) Etching of SiO2: SiO2 + 6 HF à H2SiF6 + 2H2O

In conclusion, HNO3 oxidises Si, and HF etches the SiO2 hereby formed.

Fig. right-hand: High HF : HNO3 ratios promote rate-lim-

ited etching (strong temperature dependency of the etch [HF] Increasing etch

rate) of Si via the oxidation (1) - (3), while low HF : HNO3 rate tempera-

ratios promote diffusion-limited etching (lower tempera- ture depend-

ture dependency of the etch rate) via step (4). HNO3- ency

free HF etches do not attack Si.

The SiO2 etch rate is determined by the HF-concen- Increas-

tration, since the oxidation (1) - (3) does not ac- ing selec-

count. Compared to thermal oxide, deposited (e. g. tivity Si/

CVD) SiO2 has a higher etch rate due to its poros- SiO2

ity; wet oxide a slightly higher etch rate than dry

oxide for the same reason.

An accurate control of the etch rate requires a

temperature control within ± 0.5°C. Dilution

with acidic acid improves wetting of the hy-

drophobic Si-surface and thus increases and [H2O]+[CH 3COOH] [HNO3]

homogenizes the etch rate.

Doped (n- and p-type) silicon as well as phosphorus-doped SiO2 etches faster than undoped Si

or SiO2.

Our Silicon-Etch

Our Silicon-Etch „AFN 549“ for isotropic silicon etching has the composition

HF : HNO3 : CH3COOH : H2O = 10.2 % : 39.5 % : 23.2 %: 27.1 %

We supply this mixture in 2.5 L sales volumes in MR quality. Other grades/sales volumes

available on request.

Photoresists, developers, remover, adhesion promoters, etchants, and solvents ...

Phone: +49 731 36080-409 Fax: +49 731 36080-908 e-Mail: sales@microchemicals.eu

-2-

You might also like

- Astm A588Document2 pagesAstm A588jefersonjajNo ratings yet

- Copper ProcessingDocument26 pagesCopper ProcessingDiego GaliciaNo ratings yet

- Chapter 3 Crystal Growth, Wafer Fabrication and Basic Properties of Silicon WafersDocument40 pagesChapter 3 Crystal Growth, Wafer Fabrication and Basic Properties of Silicon WafersdifxNo ratings yet

- ACTIVITY NO. 11: The Atomic Number and The Synthesis of New Elements Name: Date: Year & Section: Score: Concept NotesDocument3 pagesACTIVITY NO. 11: The Atomic Number and The Synthesis of New Elements Name: Date: Year & Section: Score: Concept NotesDexter DizonNo ratings yet

- Slide Kuliah Umum Pak BoumanDocument69 pagesSlide Kuliah Umum Pak BoumanSusi JhrNo ratings yet

- Raft Foundations: - A Raft Foundation Is A Continuous Slab of Concrete UsuallyDocument13 pagesRaft Foundations: - A Raft Foundation Is A Continuous Slab of Concrete UsuallyRoberto LatorreNo ratings yet

- 0803134592Document278 pages0803134592Yap Wen KhongNo ratings yet

- 12 Seismic InversionDocument220 pages12 Seismic InversionGhassen LaouiniNo ratings yet

- A2 Test 11 Notes - Transition ElementsDocument11 pagesA2 Test 11 Notes - Transition Elementswill bellNo ratings yet

- Jan Scholten Remedy ThemeDocument4 pagesJan Scholten Remedy ThemeNasrullah100% (17)

- Plastic Deformation of Single crystal-AA PDFDocument42 pagesPlastic Deformation of Single crystal-AA PDFdecent mrdNo ratings yet

- Chapter 6 Hexavalent ChromiumDocument56 pagesChapter 6 Hexavalent Chromiumgabriel100% (1)

- Chemistry Form 4 Chapter 2Document6 pagesChemistry Form 4 Chapter 2Mur_nie91% (22)

- Lecture02-Semiconductor BasicsDocument14 pagesLecture02-Semiconductor Basicskareem hamedNo ratings yet

- Micro MachiningDocument26 pagesMicro MachiningJishnu UnniNo ratings yet

- 04 packingIIDocument14 pages04 packingIIapi-3764139No ratings yet

- Silicon Ingot Production: Czochralski-And Float-Zone TechniqueDocument2 pagesSilicon Ingot Production: Czochralski-And Float-Zone TechniqueKarajá PtahNo ratings yet

- 9.bearings Selection and Hydrodynamic Lubrication March 17Document35 pages9.bearings Selection and Hydrodynamic Lubrication March 1724ijagraviNo ratings yet

- Key Questions For This Chapter: Slide 1-1Document31 pagesKey Questions For This Chapter: Slide 1-1Windarto Properti SoloNo ratings yet

- Erosion Wear of Axial Flow Impellers in A Solid-Liquid SuspensionDocument6 pagesErosion Wear of Axial Flow Impellers in A Solid-Liquid Suspensionfaiz ismaNo ratings yet

- Dynamic Wet Etching of Silicon Through Isopropanol Alcohol EvaporationDocument12 pagesDynamic Wet Etching of Silicon Through Isopropanol Alcohol EvaporationAlexander Quebra Madeira NemchinovNo ratings yet

- 제14주차 - Chapter09 - 몸체미세가공, 고종횡비 MEMS 가공Document11 pages제14주차 - Chapter09 - 몸체미세가공, 고종횡비 MEMS 가공K SiriusNo ratings yet

- Al-P-Si Schottky Diode PaperDocument3 pagesAl-P-Si Schottky Diode PaperHassaNo ratings yet

- Dislocation Strengthening CreepDocument22 pagesDislocation Strengthening CreepXyz AbcNo ratings yet

- Mems MaterilasDocument48 pagesMems MaterilasSanjay LahareNo ratings yet

- Etch Rates and Morphology of Silicon (H K L) Surfaces Etched in KOH and KOH Saturated With Isopropanol SolutionsDocument8 pagesEtch Rates and Morphology of Silicon (H K L) Surfaces Etched in KOH and KOH Saturated With Isopropanol SolutionsLeVanTamNo ratings yet

- Failure Mechanism of MatterDocument66 pagesFailure Mechanism of MatterSiva Kumar SalumuriNo ratings yet

- Lapping of Single Crystal Diamond ToolsDocument4 pagesLapping of Single Crystal Diamond ToolsCristian castroNo ratings yet

- SilconDocument63 pagesSilconMafnitha KKNo ratings yet

- Fabrication of (111) - Faced Single-Crystal Diamond Plates by Laser Nucleated CleavingDocument11 pagesFabrication of (111) - Faced Single-Crystal Diamond Plates by Laser Nucleated CleavingnapisahNo ratings yet

- F-Till:. 111111 WE MT! Am: Effect of Dynamic Bit Forces On Bit Bearing LifeDocument5 pagesF-Till:. 111111 WE MT! Am: Effect of Dynamic Bit Forces On Bit Bearing LifependexxNo ratings yet

- Foundation For Roller Press in A Cement Plant - A Case Study PDFDocument3 pagesFoundation For Roller Press in A Cement Plant - A Case Study PDFRajKumarNo ratings yet

- 18-Electrical and Structural Characteristics of Sputtered C-Oriented AlN Thin Films On Si (100) and Si (110) SubstratesDocument7 pages18-Electrical and Structural Characteristics of Sputtered C-Oriented AlN Thin Films On Si (100) and Si (110) Substratesshaoyun ZHOUNo ratings yet

- 4-1 - Horizontal Well Design - Wellbore StabilityDocument34 pages4-1 - Horizontal Well Design - Wellbore StabilitynappyNo ratings yet

- PB-1 Lab Analysis Proposal: - Tujuan - Data Input - Tata Waktu - Deliverable - Estimasi BiayaDocument9 pagesPB-1 Lab Analysis Proposal: - Tujuan - Data Input - Tata Waktu - Deliverable - Estimasi BiayaTogi Yonathan SitinjakNo ratings yet

- Buckling of Imperfect Elliptical Cylindrical Shells UnderDocument6 pagesBuckling of Imperfect Elliptical Cylindrical Shells UnderAdel MuslehNo ratings yet

- Chiral Topological Semimetal With Multifold Band Crossings and Long Fermi ArcsDocument8 pagesChiral Topological Semimetal With Multifold Band Crossings and Long Fermi Arcstapnath_45272029No ratings yet

- Chapter 1 Electrons and Holes in Semiconductors: 1.1 Silicon Crystal StructureDocument16 pagesChapter 1 Electrons and Holes in Semiconductors: 1.1 Silicon Crystal StructurepurseyNo ratings yet

- Precast Reinforced Concrete Manhole SectionsDocument8 pagesPrecast Reinforced Concrete Manhole SectionsРуслан АстраханцевNo ratings yet

- Thin-Film Crystalline Silicon Solar CellsDocument8 pagesThin-Film Crystalline Silicon Solar Cellsprimetrack20No ratings yet

- Crystal StructureDocument30 pagesCrystal StructureAyesha SamarakoonNo ratings yet

- CorbelDocument12 pagesCorbelSri Datta Kiran Kuchibhatla67% (3)

- Crystal Growth, Wafer Fabrication and Properties of Silicon WaferDocument30 pagesCrystal Growth, Wafer Fabrication and Properties of Silicon WaferSHAIK MUSTHAFANo ratings yet

- CVD DiamondDocument4 pagesCVD DiamondivandaNo ratings yet

- Slip-System Cal PDFDocument13 pagesSlip-System Cal PDFVanaja JadapalliNo ratings yet

- ME3251E-Topic IV Organic and Inorganic Materials (2020)Document73 pagesME3251E-Topic IV Organic and Inorganic Materials (2020)Teo Xuan MinNo ratings yet

- Lubricants: Misalignment-Induced Micro-Elastohydrodynamic Lubrication in Rotary Lip SealsDocument19 pagesLubricants: Misalignment-Induced Micro-Elastohydrodynamic Lubrication in Rotary Lip SealsKaarthicNatarajanNo ratings yet

- 4 - V - ShaleDocument10 pages4 - V - ShaleZain-Alabdeen Haithem LaftaNo ratings yet

- Silicate Ceramics: - Soils, Rocks, Clays, and Sand Come Under The Silicate ClassificationDocument32 pagesSilicate Ceramics: - Soils, Rocks, Clays, and Sand Come Under The Silicate ClassificationsairamNo ratings yet

- Chapter Eight Semiconductor Crystals: ElementsDocument50 pagesChapter Eight Semiconductor Crystals: ElementsKhanh Nguyen HuuNo ratings yet

- KilianDocument5 pagesKilianvenalum90No ratings yet

- MEC 300-Materials Science Chapter 9Document19 pagesMEC 300-Materials Science Chapter 9akashNo ratings yet

- Solid State 1 B TechDocument54 pagesSolid State 1 B TechIshan MahtoNo ratings yet

- Tech Tips: Can Hot Dip Galvanized Steel Be Friction Grip Bolted?Document2 pagesTech Tips: Can Hot Dip Galvanized Steel Be Friction Grip Bolted?Viorel UngureanuNo ratings yet

- Cavity-Through DrieDocument5 pagesCavity-Through DrieAyon DattaNo ratings yet

- Annealing Diamond-GaDocument5 pagesAnnealing Diamond-GaJackeline Valendolf NunesNo ratings yet

- 110 Slip With 112 Slip Traces in BCC Tungsten 2013Document7 pages110 Slip With 112 Slip Traces in BCC Tungsten 2013MartinAlfonsNo ratings yet

- Composite Beam: Dr. Mohd Irwan Bin Juki JKSB, F I (, Is UthmDocument28 pagesComposite Beam: Dr. Mohd Irwan Bin Juki JKSB, F I (, Is UthmFong Pei TyngNo ratings yet

- Research ArticleDocument7 pagesResearch ArticlePritha DasNo ratings yet

- 1 s2.0 0022024879900204 MainDocument3 pages1 s2.0 0022024879900204 MainVítězslav HegerNo ratings yet

- A Method For Studying Weld Fusion Boundary Microstructure Evolution in Aluminum AlloysDocument8 pagesA Method For Studying Weld Fusion Boundary Microstructure Evolution in Aluminum AlloystazzorroNo ratings yet

- End-To: Metrolurzy-# Distr-StrengtheningDocument233 pagesEnd-To: Metrolurzy-# Distr-StrengtheningERRNo ratings yet

- Gear Lubricants EffectDocument37 pagesGear Lubricants EffectTatumi Sobue100% (1)

- Wide-Lite Effex Series Area Light Brochure 1996Document16 pagesWide-Lite Effex Series Area Light Brochure 1996Alan Masters100% (1)

- (Subj Ectcode: Kmbn106) Subj Ectname:Desi GNT Hi Nki NGDocument2 pages(Subj Ectcode: Kmbn106) Subj Ectname:Desi GNT Hi Nki NGThis Time TechnicalNo ratings yet

- Wire RodDocument71 pagesWire RodTeka KamNo ratings yet

- Chemistry F321: 1.1.1 AtomsDocument15 pagesChemistry F321: 1.1.1 AtomsMohammad KhanNo ratings yet

- 1st Final Examination of OcDocument2 pages1st Final Examination of OcRahmanida SusianaNo ratings yet

- 56-1-3 (Chemistry)Document16 pages56-1-3 (Chemistry)avineshkushwaha47No ratings yet

- CH 4 MC AnswersDocument6 pagesCH 4 MC Answerskirki pNo ratings yet

- Thermochemistry Review Questions (Chemistry 30) : 2C H (l) + 15O (g) 12CO (g) + 6H O (l) ΔH = -6.535x10 kJDocument4 pagesThermochemistry Review Questions (Chemistry 30) : 2C H (l) + 15O (g) 12CO (g) + 6H O (l) ΔH = -6.535x10 kJQuindo, Alexis FayeNo ratings yet

- CHEMISTRY-11-03 - (12th & 13) (POI) Paper-1Document12 pagesCHEMISTRY-11-03 - (12th & 13) (POI) Paper-1Raju SinghNo ratings yet

- BOD and COD Removal Using Hydrogen Peroxide H2O2 - USP TechnologiesDocument3 pagesBOD and COD Removal Using Hydrogen Peroxide H2O2 - USP TechnologiesAshish PhadnisNo ratings yet

- Class 12 Diwali Assignment Inorganic ChemistryDocument12 pagesClass 12 Diwali Assignment Inorganic ChemistryPrashantNo ratings yet

- Chapter 20: Oxidation-Reduction ReactionsDocument5 pagesChapter 20: Oxidation-Reduction ReactionsKM10 khalidNo ratings yet

- Organohalides: Based On Mcmurry'S, 7 EditionDocument32 pagesOrganohalides: Based On Mcmurry'S, 7 EditionmaherNo ratings yet

- Corrosion: Non-Metals. ... Oxygen and Water Are RequiredDocument4 pagesCorrosion: Non-Metals. ... Oxygen and Water Are Requiredreal nameNo ratings yet

- Experiment 2.2Document8 pagesExperiment 2.2BenjaminLauNo ratings yet

- SubstanceDocument10 pagesSubstanceAndriyani YaniNo ratings yet

- Soluble Insoluble 6. Ca (NO 3. K Soluble Soluble: Follow This Format For Question B, C and DDocument4 pagesSoluble Insoluble 6. Ca (NO 3. K Soluble Soluble: Follow This Format For Question B, C and DBEST OF ONE PIECENo ratings yet

- LanthanideDocument120 pagesLanthanideAnonymous gUjimJK100% (1)

- Selected Phase Transition Temperatures: Periodic Table of ElementsDocument1 pageSelected Phase Transition Temperatures: Periodic Table of ElementsmuthuphysicsNo ratings yet

- Basha-Asme (Ferrous and Non Ferrous)Document846 pagesBasha-Asme (Ferrous and Non Ferrous)AhmedHussainQureshiNo ratings yet

- Perdiodic Table FinalDocument64 pagesPerdiodic Table FinalAbelyn DangpilenNo ratings yet

- Coupling Effect of Iron Class 12 ProjectDocument12 pagesCoupling Effect of Iron Class 12 ProjectTamil SelvanNo ratings yet

- Evs PPT Final 1Document18 pagesEvs PPT Final 1KaranNo ratings yet

- NCERT Solutions For Class 7 Science Chapter 6Document4 pagesNCERT Solutions For Class 7 Science Chapter 6raju bhowalNo ratings yet