Professional Documents

Culture Documents

Oilandgas 2010 Eng Final

Uploaded by

RafaelRoqueSequeiraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oilandgas 2010 Eng Final

Uploaded by

RafaelRoqueSequeiraCopyright:

Available Formats

w h i t e p a p e r

Efficient Design for the Oil and Gas Industry

S U M MARY

SolidWorks® CAD software provides a complete 3D product develop-

ment solution for meeting the demands of today’s rapidly evolving oil

and gas industry. With SolidWorks, engineers can more efficiently use

3D design data at every stage of the development process, realizing

productivity gains and reduced costs across the board. From conceptual

design and component selection through design validation and produc-

tion, SolidWorks software provides the integrated tools that oil and gas

engineers need to accelerate time-to-market, control development costs,

improve product quality and innovation, and compete successfully.

Introduction

Meeting the product development, equipment design, and systems engineer-

ing needs of manufacturers serving the oil and gas industry presents distinct

challenges in today’s ever-evolving and increasingly multifaceted global energy

marketplace. A range of factors—including the higher cost of energy, the

greater focus on safety and environmental concerns, and the increasing viability

of new energy sources—have combined to create a new set of competitive

pressures on designers and engineers who develop oil and gas equipment

and systems.

Whether a company manufactures products or systems that support exploration

In addition to accelerating product and drilling, distribution and transportation, refining and manufacturing process-

time-to-market, some oil and gas es, or alternative and biofuels technology development, competing successfully

engineers must shorten the time in the oil and gas industry carries new product development, engineering, and

it takes to develop proposals,

design demands. As a result, oil and gas engineers must develop more complex

while simultaneously expanding

the completeness of proposed products and systems faster, more cost-effectively, and with greater levels of

design concepts. collaboration. Engineers not only have to complete more complex projects on

time and on budget, but also must deliver enhancements in quality and innova-

tion. In addition to accelerating product time-to-market, some oil and gas engi-

neers must shorten the time it takes to develop proposals, while simultaneously

expanding the completeness of proposed design concepts.

In today’s increasingly competitive and continually changing oil and gas

environment, 2D design tools no longer represent a viable option, given their

limitations in efficiently utilizing design data to address multiple functional

requirements. By using SolidWorks CAD software, however, engineers can

meet emerging challenges at every stage of the development process: from

conceptual and proposal development through validation, production, and

implementation. With 3D design techniques, you can use the same model

for concept development, design automation, simulation, and communication,

as well as for prototype development and product manufacturing.

E f f icie n t D esi g n f o r t h e Oi l a n d Gas I n d u s t r y 1

By providing more capable design data management, automated drawing gen-

eration, and documentation tools, SolidWorks software enhances efficiencies

and improves productivity. Unlike 2D design tools, which are slow, laborious,

and inefficient, 3D design tools provide a wealth of capabilities. So you can eas-

ily compress development cycles, reduce development costs, create more inno-

vative products, and improve product quality—all at the same time.

SolidWorks software enables you to speed development by using modular

design, systems prefabrication, as well as design reuse, automation, and

configuration concepts. Because 3D design tools facilitate greater use of

standard components, you can download and import accurate SolidWorks

models of components and subassemblies from 3DContentCentral.com and

SolidWorks CAD software provides

the product data management (PDM), other sources.

2D editing, sketching, modeling, and

Specialized capabilities—such as weldment design, piping system design, and

design configuration capabilities

large-assembly development—provide added design efficiencies, while inte-

that you need to access, recon-

figure, model, and produce quality grated SolidWorks Simulation and SolidWorks Motion analysis capabilities sup-

designs within a dramatically com- port design validation and simulation. So you can refine your design, identify

pressed time frame. potential errors, and resolve design issues before building a single prototype.

With integrated SolidWorks Workgroup PDM software, you can simply and effi-

ciently manage design data and satisfy documentation requirements. Moreover,

SolidWorks communications tools, such as eDrawings® software, ensure effec-

tive, streamlined collaboration with your customers, clients, and prospects.

Accelerating conceptual design, proposal development

To compete successfully in today’s global oil and gas industry, companies must

incorporate agility, flexibility, and automation into conceptual design. Whether

your company is putting together a proposal for a particular opportunity, such as

an offshore drilling platform, a refinery refit, or an ethanol-processing plant—or

is developing more generalized products, such as down-hole drill tools, valves,

compressors, pumps, or skid systems—the ability to accelerate conceptual

design and proposal development is vital to your success.

To overcome competitive time pressures, engineers must be able to automate

concept development by finding, reusing, and reconfiguring existing designs,

as well as by working, collaborating, and communicating more effectively with

strategic partners. SolidWorks CAD software provides product data manage-

ment (PDM), 2D editing, sketching, modeling, and design configuration capabili-

ties that you need to access, reconfigure, model, and produce quality designs

within a dramatically compressed time frame.

Using SolidWorks Workgroup PDM and SolidWorks design configuration tools,

you can quickly find and often modify previous designs to meet your changing

needs. For example, you can easily vary capacities, lengths, or threaded connec-

tions to produce new design concepts automatically from existing designs.

E f f icie n t D esi g n f o r t h e Oi l a n d Gas I n d u s t r y 2

SolidWorks 3D software also includes a powerful new feature that can help

companies develop more detailed design concepts faster. Sketch Blocks enable

engineers to produce initial layouts and test dynamic relationships

of the design. SolidWorks Intelligent Feature Technology (SWIFT™) allows

beginners to achieve expert-level 3D designs early in the process. You

can download models of commonly used components and assemblies from

3DContentCentral.com and insert them directly into your design. You can

then automatically generate production-quality drawings.

Kvaerner Oilfield Products develops subsurface products for the

offshore industry. By moving to SolidWorks software, the company

increased productivity as well as options for its existing designs.

Designing weldments, piping, and large assemblies

Engineers designing products and systems for oil and gas exploration, distribu-

tion, transportation, refining, and production rely heavily on certain specialized

design capabilities. While oil and gas equipment designers employ a wide range

of 3D CAD capabilities, they especially benefit from robust tools to develop

large assemblies, welded structures, and piping systems. The process of locat-

ing, extracting, transporting, refining, and distributing oil and gas typically

requires the development of components and systems that can benefit from

utilizing specialized weldment, piping, and large-assembly design tools.

SolidWorks CAD software enables you to model, visualize, and evaluate the

design of large assemblies, which often contain thousands of individual com-

ponents and subassemblies. In addition to viewing components as a single part

or in the context of an assembly, you can adjust component transparency and

use sectioning tools to reveal the inner workings of designs that you previously

could not visualize. With SolidWorks large-assembly collision detection tools,

you can check for interference during the early stages of design development

when problems are easier to fix, rather than discovering errors late in

the design cycle when they are more costly and time-consuming to resolve.

Using SolidWorks CAD software to create weldments saves time and elimi-

nates much of the guesswork involved in designing structural frames and plate

assemblies. Having the ability to sweep a weldment profile along a sketch line

E f f icie n t D esi g n f o r t h e Oi l a n d Gas I n d u s t r y 3

and then generate cut lists of the necessary segments enables you to improve

the quality of your designs, the completeness of bills of materials (BOMs), and

the accuracy of cost estimates.

In many areas of the oil and gas industry, companies typically have piping sys-

tem design needs. SolidWorks Routing software simplifies the design of piping

and tubing systems, along with electrical conduit, cable, and harness segments.

With this tool, you can save a substantial amount of time when designing piping

for oil and gas processing and distribution or when developing general machin-

ery and equipment that utilize pneumatic, hydraulic, or electrical subsystems.

Developing reliable oil and gas

equipment has become increasingly

important not only because of higher

energy costs, but also due to the

increased investment required to

find and tap new fields. Often this

entails more complex methods and

greater risks.

Halliburton Energy Services uses SolidWorks software to stan-

dardize its product design worldwide and to achieve consistency

in product engineering and manufacturing.

Integrated design analysis, simulation, and validation

Developing reliable oil and gas equipment has become increasingly important

not only because of higher energy costs, but also due to the increased invest-

ment required to find and tap new fields. Often this entails more complex

methods and greater risks. With SolidWorks, you can ensure that designs

meet reliability and environmental requirements.

Companies in the oil and gas industry simply do not have the time to conduct

extensive, costly, and time-consuming prototyping and testing regimens to

validate design performance. Since SolidWorks Simulation and SolidWorks

Motion design analysis applications are embedded in SolidWorks, engineers

can accurately model and validate the loading and kinematics performance

of equipment and components, minimizing prototyping and build-and-break

testing.

Using SolidWorks Simulation software, oil and gas engineers can validate the

performance of structures ranging from simple components to large offshore

platforms. You can easily apply a wide range of loads, dramatically reducing

the potential for field failures and minimizing—or even eliminating—the costs

and delays associated with prototyping and testing.

E f f icie n t D esi g n f o r t h e Oi l a n d Gas I n d u s t r y 4

The SolidWorks Motion feature enables you to realize similar benefits by con-

ducting kinematics and dynamic response analyses on moving assemblies and

mechanisms. This capability is especially useful for assemblies such as cranes

and drill pipe handling equipment, which must operate in confined spaces off-

shore. SolidWorks Motion can help engineers with tasks that range from sizing

motors and actuators to determining power consumption, developing cams, and

improving gear-drive performance.

Equipped with these powerful design analysis, simulation, and validation tools, oil

and gas equipment companies can ensure the quality and reliability of their prod-

ucts early in the design process. Instead of discovering necessary and expen-

sive design modifications in the field, companies can save time and money by

SolidWorks Motion can help engi-

neers with tasks that range from spotting and resolving design problems before they even build a prototype.

sizing motors and actuators to deter-

mining power consumption,

developing cams, and improving

gear-drive performance.

Bucyrus, Inc., a leader in equipment for extracting oil from tar sands,

designs its products using SolidWorks along with integrated

SolidWorks Simulation, SolidWorks Routing, and SolidWorks product

data management software.

Managing, documenting, and communicating design data

In an evolving energy market, a company’s ability to respond to demands

quickly and effectively is highly dependent on how well it can organize,

manage, and communicate its internal design data and expertise. Oil and gas

companies face competitive time pressures and require more collaborative

development relationships, data reuse, modular design, and systems prefabri-

cation. To complete their jobs effectively, engineers must have efficient data

management, documentation creation, and design communication tools.

E f f icie n t D esi g n f o r t h e Oi l a n d Gas I n d u s t r y 5

Completely integrated with SolidWorks CAD software, the SolidWorks

Workgroup PDM system enables you to safeguard, control, and manage

valuable project data. Powerful search tools help you find applicable design

data quickly and easily, so you can apply previous experience and lessons

learned to future projects.

Engineers can also use SolidWorks software to streamline the production of

design and assembly documentation for their products. Automatic drawing gen-

eration and the creation of exploded views, along with image and animation pro-

duction, enable you to quickly produce design documentation with minimal effort.

The ability to communicate design concepts and documentation to customers,

Oil and gas companies face com- clients, and prospects quickly and easily, and then obtain their feedback, has

petitive time pressures and require become increasingly important for improving an organization’s responsiveness.

more collaborative development With eDrawings software, included with SolidWorks, you can quickly create

relationships, data reuse, modular

compact, information-rich, lightweight model and drawing files. Collaborating,

design, and systems prefabrication.

To complete their jobs effectively, communicating, and interacting with contractors, partners, and customers is

engineers must have efficient as simple as sending an email.

data management, documentation

By moving to SolidWorks CAD software, you can realize dramatic improvements

creation, and design communica-

tion tools. in the ability to manage, document, and communicate internal design data.

After enabling its departments to share data using SolidWorks

Workgroup PDM software, TotalGaz, S.A., reduced its design time

by 50 percent and improved the quality of its gas control systems.

E f f icie n t D esi g n f o r t h e Oi l a n d Gas I n d u s t r y 6

Automating manufacturing and production

After using 3D design tools to develop and validate designs, oil and gas com-

panies can leverage 3D CAD data to automate manufacturing and production.

Because 3D design data is highly visual, engineers can communicate and col-

laborate more effectively with assembly and production personnel to balance

cost, quality, and delivery. With SolidWorks software, companies can generate

BOMs automatically as they develop their assemblies, thereby accelerating the

ordering and purchasing of standardized parts.

Through the use of integrated CAM (computer-aided machining) software,

SolidWorks CAD data can also help engineers automate machining and manu-

With SolidWorks CAD software, facturing. With SolidWorks Gold Solution Partner CAMWorks™ and SolidCAM

companies can generate BOMs software, you can automate the generation of NC programming for producing

automatically as they develop their custom parts, shaving additional time from the development process. Since this

assemblies, thereby accelerating

is all done without leaving SolidWorks, you can quickly make any changes to

the ordering and purchasing of

standardized parts. the parts that are needed to support machining inside SolidWorks.

In addition to cutting time from the production process, SolidWorks software

can help oil and gas companies to reduce the volume of scrap produced and

rework required. Because the design has been validated and manufacturing

relates directly to 3D CAD data, fewer questions and surprises will arise in

manufacturing than when using 2D development methods.

The ability to integrate design and manufacturing processes with

SolidWorks enables TOTALGAZ, S.A., to design complex gas regulator

geometry easily, resolve design problems early, and bring new prod-

ucts to market quickly.

Conclusion

As the oil and gas industry continues to confront new challenges, companies

are feeling the impact of higher energy costs, a greater focus on safety and

environmental concerns, and the increasing viability of new sources of energy.

Whether they manufacture products that support exploration and drilling, distri-

bution and transportation, refining and manufacturing processes, or alternative

and biofuels technology development, all companies face competitive pres-

sures. They must continually develop more complex products, equipment, and

systems—faster, better, and more cost-effectively.

By implementing SolidWorks CAD software as your product development

platform, your company can enhance its competitiveness—improving time-to-

market, controlling development costs, and designing better products. With

SolidWorks, you can realize improved efficiencies and productivity gains at

every stage of the development process: from conceptual and proposal devel-

opment through design validation, production, and implementation. Moreover,

the same model can be used for concept development, design automation,

simulation, and communication, as well as for prototype development and

product manufacturing.

Many oil and gas companies have quickly realized a return on their investment

in SolidWorks by decreasing development time, cutting material costs, reducing

design errors, and shortening time-to-market by as much as 50 percent in the

first year. With SolidWorks CAD software, you have the powerful tools needed

to improve product quality and innovation and to compete successfully in a

rapidly changing industry—now and in the future.

Dassault Systèmes SolidWorks Corp.

300 Baker Avenue

Concord, MA 01742 USA

Phone: 1 800 693 9000

Outside the US: +1 978 371 5011

Email: info@solidworks.com www.solidworks.com

SolidWorks and eDrawings are registered trademarks, and SWIFT is a trademark, of Dassault Systèmes SolidWorks Corp. All other

company and product names are trademarks or registered trademarks of their respective owners. ©2008 Dassault Systèmes. All rights

reserved SWMKOILWPENG0608

Image on cover courtesy of TotalGaz, S.A.

You might also like

- CAD Engineering Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #3From EverandCAD Engineering Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #3Rating: 4.5 out of 5 stars4.5/5 (4)

- Efficient Design For The Oil and Gas Industry: InspirationDocument9 pagesEfficient Design For The Oil and Gas Industry: InspirationHassan KhalidNo ratings yet

- 3DS SWK DtoM Brochure A4 071017 PDFDocument6 pages3DS SWK DtoM Brochure A4 071017 PDFsankarNo ratings yet

- Design To Manufacturing SolutionDocument6 pagesDesign To Manufacturing SolutionsfghjkNo ratings yet

- Exploring Autodesk Revit 2018 for MEP, 5th EditionFrom EverandExploring Autodesk Revit 2018 for MEP, 5th EditionRating: 1 out of 5 stars1/5 (1)

- Solidworks Solutions: The Power You Need To Drive InnovationDocument6 pagesSolidworks Solutions: The Power You Need To Drive Innovationsamar2011No ratings yet

- Autodesk Generative Design Capabilities For Machinery IndustriesDocument22 pagesAutodesk Generative Design Capabilities For Machinery IndustriesPuneethNo ratings yet

- SOLIDWORKS Simulation 2016: A Tutorial ApproachFrom EverandSOLIDWORKS Simulation 2016: A Tutorial ApproachRating: 5 out of 5 stars5/5 (1)

- 5826 Multicad BP WP En4Document7 pages5826 Multicad BP WP En4khantoNo ratings yet

- Consumer Product Design WP ENGDocument8 pagesConsumer Product Design WP ENGPrithviraj DagaNo ratings yet

- UnigraphicsDocument24 pagesUnigraphicsKarthik SubramanianNo ratings yet

- Gyro Asset1 WhitepaperDocument9 pagesGyro Asset1 WhitepaperMarco BernardesNo ratings yet

- GEOPLM Siemens PLM Tecnomatix Process DesignerDocument2 pagesGEOPLM Siemens PLM Tecnomatix Process DesignerbehnyaNo ratings yet

- Unit I Fundamentals of Computer GraphicsDocument25 pagesUnit I Fundamentals of Computer GraphicsChockalingamNo ratings yet

- SIMULIA ROI White Paper PreviewDocument3 pagesSIMULIA ROI White Paper PreviewReginatoNo ratings yet

- NX Tooling Brochure W 1 - tcm642-4494 PDFDocument16 pagesNX Tooling Brochure W 1 - tcm642-4494 PDFvijayNo ratings yet

- FEA For All EngineersDocument14 pagesFEA For All EngineersMarta TanaskovicNo ratings yet

- Digital Model DefinitionDocument3 pagesDigital Model DefinitionMilin JainNo ratings yet

- Delphi Horiz ModelingDocument7 pagesDelphi Horiz Modelingsh33No ratings yet

- SolidWorks BrochureDocument2 pagesSolidWorks BrochureNatarajan RamamoorthyNo ratings yet

- SW Process PlantDocument12 pagesSW Process PlantarcelitasNo ratings yet

- February 5, 1999 R/L 2/2000: Standard SoftwareDocument3 pagesFebruary 5, 1999 R/L 2/2000: Standard SoftwareMEGAN ASBROCKNo ratings yet

- Lattice-Leveraging Design Review White PaperDocument9 pagesLattice-Leveraging Design Review White PaperkarthegreNo ratings yet

- Smarter Decisions, Better ProductsDocument16 pagesSmarter Decisions, Better ProductsOctavio RojoNo ratings yet

- 3DS 2016 SWK Oil Gas Whitepaper USLetterDocument11 pages3DS 2016 SWK Oil Gas Whitepaper USLetterAnand BhiseNo ratings yet

- DELMIA Digital Manufacturing Portfolio: IBM Product Lifecycle ManagementDocument20 pagesDELMIA Digital Manufacturing Portfolio: IBM Product Lifecycle ManagementsrinivaschakriNo ratings yet

- Gyro Asset1 Whitepaper PDFDocument9 pagesGyro Asset1 Whitepaper PDFpaco_7979No ratings yet

- NX For Mechanical Design: BenefitsDocument4 pagesNX For Mechanical Design: BenefitsName UnknownNo ratings yet

- A Practical Guide To Design For Manufacturability: Get StartedDocument18 pagesA Practical Guide To Design For Manufacturability: Get StartedrihabNo ratings yet

- Autodesk Revit Architecture 2013Document4 pagesAutodesk Revit Architecture 2013pastor2009No ratings yet

- SOLIDWORKS 3DCAD - BrochureDocument2 pagesSOLIDWORKS 3DCAD - BrochureAmitNo ratings yet

- Ten Strategies Cad Leader White Paper PDFDocument12 pagesTen Strategies Cad Leader White Paper PDFez1010No ratings yet

- PLM Application Acceleration: Optimize Performance in Distributed R&D EnvironmentsDocument6 pagesPLM Application Acceleration: Optimize Performance in Distributed R&D EnvironmentsMTNo ratings yet

- Packaging Design and Manufacturing SoftwareDocument16 pagesPackaging Design and Manufacturing Software- ΠερίλαμπροNo ratings yet

- Based Manufacturing: Kiowledge Distributed Product Design and IDocument6 pagesBased Manufacturing: Kiowledge Distributed Product Design and ITrinh VtnNo ratings yet

- CATIA for Mold & Die: Boosting Efficiency and Saving TimeDocument4 pagesCATIA for Mold & Die: Boosting Efficiency and Saving TimeGeorge NicoloiuNo ratings yet

- FEED Screen Whitepaper PlantDocument10 pagesFEED Screen Whitepaper PlantazamshafiqNo ratings yet

- NX Design Brochure W 3 - tcm73-4285Document16 pagesNX Design Brochure W 3 - tcm73-4285r0n41dNo ratings yet

- BR TC EngineeringDocument12 pagesBR TC Engineeringgaurav12345@No ratings yet

- DELMIA Config - Portfolio - R19Document14 pagesDELMIA Config - Portfolio - R19smartroy2No ratings yet

- SWPrem DesigningBetterProducts by DedicatedComSaDocument14 pagesSWPrem DesigningBetterProducts by DedicatedComSaMX100No ratings yet

- Building Lifecycle ManagementDocument6 pagesBuilding Lifecycle ManagementDani VNo ratings yet

- Streamlining Product Documentation Across The Manufacturing Enterprise With 3dvia ComposerDocument9 pagesStreamlining Product Documentation Across The Manufacturing Enterprise With 3dvia Composerpaulf1_85No ratings yet

- Autodesk Inventor: Open - Connected - Professional GradeDocument4 pagesAutodesk Inventor: Open - Connected - Professional GradeAhmedBrahamNo ratings yet

- Unigraphics Total Product EngineeringDocument12 pagesUnigraphics Total Product EngineeringNguyễn Thế Quang DũngNo ratings yet

- Process Planning 2Document10 pagesProcess Planning 2Janhavi PatilNo ratings yet

- Fundamentals of CadDocument16 pagesFundamentals of CadKrishna veniNo ratings yet

- Siemens PLM NX For Automotive BR Tcm1023 233712Document16 pagesSiemens PLM NX For Automotive BR Tcm1023 233712Yathreb BettoumiNo ratings yet

- AngalisDocument5 pagesAngalisMounir KrkNo ratings yet

- How Do I Coordinate DesignDocument8 pagesHow Do I Coordinate DesignjvwzyxktuvnjohdkbjNo ratings yet

- 3237 tcm1023-79835Document3 pages3237 tcm1023-79835Karthik RavichandranNo ratings yet

- Analysis Guide Machine Design WP ENGDocument10 pagesAnalysis Guide Machine Design WP ENGPrithviraj Daga100% (3)

- Autodesk Design Review Getting Started GuideDocument56 pagesAutodesk Design Review Getting Started GuideKamal SekarNo ratings yet

- Putting Concurrent Engineering Into Practice - 2Document5 pagesPutting Concurrent Engineering Into Practice - 2Reddy LokeshNo ratings yet

- Autodesk Architecture Brochure Letter En1Document4 pagesAutodesk Architecture Brochure Letter En1nguyenmythien_91No ratings yet

- NX Overview: Siemens PLM SoftwareDocument12 pagesNX Overview: Siemens PLM SoftwareRajeshNo ratings yet

- Design Engineering-A Need To Rethink The Solution Using Knowledge Based EngineeringDocument11 pagesDesign Engineering-A Need To Rethink The Solution Using Knowledge Based EngineeringsonirocksNo ratings yet

- CVDocument5 pagesCVNewaz KabirNo ratings yet

- Starting Duty Limitations for Large MotorsDocument2 pagesStarting Duty Limitations for Large Motorsmalika_00No ratings yet

- Vibration Monitoring 1Document4 pagesVibration Monitoring 1Anonymous DKv8vpNo ratings yet

- EE153 Notes No. 1 - The Electric Distribution SystemDocument129 pagesEE153 Notes No. 1 - The Electric Distribution SystemAnonymous EnggrUsm100% (3)

- Ideals Vs PsalmDocument2 pagesIdeals Vs PsalmJesse Nicole Santos100% (1)

- San Clemente VillagesDocument2 pagesSan Clemente VillagesHarichandan PNo ratings yet

- Hancock Series 5505Document8 pagesHancock Series 5505Ricardo CastroNo ratings yet

- Offshore Renewables BrochureDocument24 pagesOffshore Renewables BrochureAhmed TahaNo ratings yet

- 160202nora's Quotation For Ice Cream FreezerDocument1 page160202nora's Quotation For Ice Cream FreezerjosegomeroNo ratings yet

- List of Maharatna, Navratna and Miniratna CPSEsDocument3 pagesList of Maharatna, Navratna and Miniratna CPSEsraviNo ratings yet

- 90 250 Single Stage Horizon Domestic PDFDocument6 pages90 250 Single Stage Horizon Domestic PDFherrerafaridNo ratings yet

- PT. PANA OIL INSPECTION FORMDocument1 pagePT. PANA OIL INSPECTION FORMD Wahyu BawonoNo ratings yet

- Upper Kotmale Hydropower Project Field Visit ReportDocument6 pagesUpper Kotmale Hydropower Project Field Visit ReportMuhammadh ZiyanNo ratings yet

- Flyback SMPS Design GuideDocument16 pagesFlyback SMPS Design GuideRevathy100% (1)

- Cibes Catalogue PDFDocument31 pagesCibes Catalogue PDFNold AlburoNo ratings yet

- AHRIDocument3 pagesAHRISithuNo ratings yet

- MP Solar Power Policy PDFDocument23 pagesMP Solar Power Policy PDFarvindNo ratings yet

- Guía de Lubricación de Motos Honda PDFDocument3 pagesGuía de Lubricación de Motos Honda PDFMartin LabatNo ratings yet

- Himsen Cat h2533Document12 pagesHimsen Cat h2533Mohsen50% (2)

- Castillo ProfileDocument46 pagesCastillo ProfileprabhumanocNo ratings yet

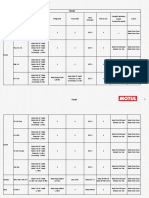

- Petroleum wholesaler sales recordsDocument9 pagesPetroleum wholesaler sales recordsabdulazizNo ratings yet

- Nick Williams PGE Bill 01.2023Document3 pagesNick Williams PGE Bill 01.2023César Dávila0% (1)

- LT bill details for mobile towerDocument2 pagesLT bill details for mobile towerAMolNo ratings yet

- Energy Utilization IndexDocument3 pagesEnergy Utilization IndexRobertNo ratings yet

- Project Report in JSWDocument44 pagesProject Report in JSWmohd arif khan71% (14)

- Inox Wind Receives Type Certification For 113 Meter Rotor Diameter Wind Turbine Generator (Company Update)Document3 pagesInox Wind Receives Type Certification For 113 Meter Rotor Diameter Wind Turbine Generator (Company Update)Shyam SunderNo ratings yet

- RRB Energy LTD: Strategic SWOT Analysis ReviewDocument18 pagesRRB Energy LTD: Strategic SWOT Analysis ReviewLiew Chi ChiengNo ratings yet

- Sample Resume-Mechanical EngineerDocument1 pageSample Resume-Mechanical Engineersanjay_lingotNo ratings yet