Professional Documents

Culture Documents

Manual Spot Checker

Uploaded by

carlosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Spot Checker

Uploaded by

carlosCopyright:

Available Formats

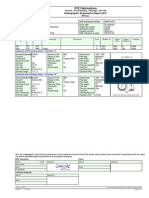

SpotChecker

Technical Reference and Operating Manual

Ident No. 49 131

Rev. 2.0

This Issue 02, 03/2009 applies to the version 1.0

Subject to change without notice.

Contents

1 Introduction 7 Echo display comparison method 13

1.1 Safety information 8 Limitations of software 14

Power supply 8 1.3 The SpotChecker 16

Software 8 Special features 16

Defects/errors and exceptional stresses 9 1.4 Standard package 18

Further information 9 1.5 Required accessories 19

1.2 Important information on ultrasonic 1.6 Spare parts requirements 20

testing 10

Preconditions for testing with ultrasonic

test equipment 10 2 Initial start-up and basics 25

Operator training 10 2.1 Overview of instrument 26

Technical test requirements 11 Front panel 26

Limitations of testing 11 Back panel 27

Ultrasonic wall thickness measurement 11

2.2 Installing the instrument 28

Effect of the test object’s material 12

2.3 Connecting a probe 29

Effect of temperature variations 12

Measurement of remaining wall thickness 12 2.4 Power supply 30

Ultrasonic evaluation of flaws 13 Operation using external power supply 30

Flaw boundary method 13 Operation using batteries 31

SpotChecker Issue 02, 03/2009 3

Contents

Inserting batteries 31 2.9 Software installation 39

Checking the battery charge level 31 Re-installation SpotChecker 39

Exchanging batteries 32 Updates 39

Charging batteries 32 Installation procedure 39

2.5 Power on/Power off 33 License after re-installation 40

Starting the operation 33 2.10 Basic settings 41

Closing the operation and shutting down 33 Selecting language 41

2.6 Interfaces 34 Restricting program access 41

USB 34 Activating the password protection 42

Network 34 Deactivating the password protection 42

WLAN 34 2.11 Data backup 43

Bluetooth 35 Saving data to external data media 44

2.7 Trackballs and touchscreen 36 Uploading data from external data media 44

Trackballs 36 2.12 Online Help 45

Touchscreen 36 Context-sensitive Help 45

2.8 Remote control 37 Starting the Online Help 45

Assigning the remote control to a receiver 38 Buttons: 46

Key assignment 38 Starting the Online Help without

the software 46

4 Issue 02, 03/2009 SpotChecker

Contents

Printing 47 Evaluation Assistance III 61

Printing a complete chapter 47 Evaluation Assistance IV 62

A-scan and Racer view 63

3 Individual inspection reports 49 Automatic A-scan freeze 65

Graphical marking of relevant echoes 66

3.1 Ultrasonic inspection of spot welds

within automotive industry 50 Interface echo gate 66

Basic principle 50 Reference A-scan 67

Comparison of ultrasonic inspection Other inspection methods 68

with other inspection methods 51

3.3 Dialog probes 69

3.2 The software SpotChecker 54

Overview 54

4 Care, maintenance, errors 71

Application ranges 55

4.1 Cleaning the instrument 72

Structured inspection plan: 56

Evaluation with UltraCAR 57 4.2 Maintenance 72

General procedure – 4.3 Care of batteries 72

linear inspection plans 58

Charging batteries 73

The evaluation assistance tools 59

Storage of batteries 73

Evaluation Assistance I 59

4.4 Errors 73

Evaluation Assistance II 60

SpotChecker Issue 02, 03/2009 5

Contents

5 Technical specifications 75 6 Annex 83

5.1 Specification of the interfaces 76 6.1 EC declaration of conformity 84

4-pin LEMO 0S connection +15V 76 6.2 Manufacturer/Service addresses 86

5.2 Specifications SpotChecker 77 6.3 Disposal 87

Enclosure 77 General view of the device 88

Connections 78 Recycling data of SpotChecker 90

Power supply 78

Ultrasound 79

7 Index 93

Settings and evaluation 79

6 Issue 02, 03/2009 SpotChecker

Introduction 1

SpotChecker Issue 02, 03/2009 7

Introduction Safety information

1.1 Safety information Power supply

The power supply for the SpotChecker is carried out

The SpotChecker has been designed and tested ac- via one or two batteries or via a connected power sup-

cording to DIN EN 61 010 Part 1, Safety requirements ply unit. The power supply unit may only be used in-

for electrical measuring, control and lab equipment, side buildings and may not be exposed to moisture or

and was technically in perfectly safe and faultless con- liquids. Follow all safety instructions that are applica-

dition when leaving the manufacturing works. ble for the power supply unit used.

In order to maintain this condition and to ensure a

safe operation, you should urgently read the following A Attention:

safety information before putting the instrument into Never open the housing of the power supply unit. The

operation. When connecting other equipment to the power supply unit does not contain any user-service-

SpotChecker, such as the power supply unit, follow able parts.

particularly all safety instructions that apply to these

devices.

Software

A Attention: According to the current state of the art, software is

never completely free from errors. Before using any

The SpotChecker is an instrument for materials software-controlled test equipment, please make sure

testing. Any use for medical applications or other that the required functions operate perfectly in the in-

purposes is not allowed! tended combination.

The SpotChecker may only be used in industrial

environments!

8 Issue 02, 03/2009 SpotChecker

Safety information Introduction

Defects/errors and exceptional stresses Further information

If you have reason to believe that a safe operation of

your SpotChecker is no longer possible, you have to A Attention:

disconnect the instrument and secure it against unin- Observe the documentation for the other equipment

tentional reconnection. connected to the SpotChecker, such as computer or

power supply unit. The documentation contains impor-

A safe operation is e.g. no longer possible

tant safety instructions and information about permit-

❚ if the instrument shows visible damages, ted uses.

❚ if the instrument no longer operates perfectly, The SpotChecker software provides extensive online

❚ after prolonged storage under adverse conditions help which is always available to you when working

(e.g. exceptional temperatures and/or especially with the system. In this operating manual you will find

high air humidity, or corrosive environmental condi- any additional information that you might require.

tions),

If you have any questions about the use of your test

❚ after being subjected to heavy stresses during equipment, please contact your nearest representative

transportation. of GE Sensing & Inspection Technologies.

If you install additional software on the computer, GE

Sensing & Inspection Technologies will not bear any

responsibility regarding the influence this may have on

SpotChecker operation. The existing software drivers

may be overwritten in such a case.

SpotChecker Issue 02, 03/2009 9

Introduction Important information on ultrasonic testing

1.2 Important information on ultra- Operator training

sonic testing The operation of an ultrasonic test device requires a

proper training in ultrasonic test methods.

Please read the following information before using

A proper training comprises for example adequate

your SpotChecker. It is important that you understand

knowledge of:

and observe this information to avoid any operator er-

rors that might lead to false test results. This could re- ❚ the theory of sound propagation,

sult in personal injuries or damages to property. ❚ the effects of sound velocity in the test material,

Preconditions for testing with ultrasonic test ❚ what happens to the sound wave at the interface

equipment between two different materials,

❚ the propagation of the sound beam,

In this operating manual you will find essential infor-

mation on how to operate your test equipment. In ad- ❚ the influence of sound attenuation in the test ob-

dition, there are a number of factors that affect the ject, and the influence of surface quality of the test

test results. A description of these factors would go object.

beyond the scope of an operating manual. Let us

Lack of such knowledge could lead to false test results

therefore only mention the three most important re-

with unforeseeable consequences. You can contact

quirements for a safe ultrasonic inspection in this con-

for example NDT societies or organizations in your

nection:

country (DGZfP in Germany; ASNT in the USA), or

❚ the operator training, GE Sensing & Inspection Technologies, for informa-

❚ the knowledge of special technical test require- tion concerning existing possibilities for the training of

ments and limits, ultrasonic inspectors as well as on the qualifications

and certificates that can finally be obtained.

❚ the choice of appropriate test equipment.

10 Issue 02, 03/2009 SpotChecker

Important information on ultrasonic testing Introduction

Technical test requirements Limitations of testing

Every ultrasonic test is subject to specific technical The information obtained from ultrasonic tests only re-

test requirements. The most important ones are: fers to those parts of the test object which are covered

by the sound beam of the probe used.

❚ the definition of the scope of inspection,

❚ the choice of the appropriate test method, Any conclusions from the tested parts to be applied to

the untested parts of the test object should be made

❚ the consideration of material properties, with extreme caution.

❚ the determination of the limits for recording and

Such conclusions are generally only possible in cases

evaluation.

where extensive experience and proven methods of

It is the task of those with overall responsibility for statistical data acquisition are available.

testing to ensure that the inspector is fully informed

The sound beam can be completely reflected from

about these requirements. The best basis for such in-

boundary surfaces within the test object so that flaws

formation is experience with identical test objects. It is

and reflection points lying deeper remain undetected.

also essential that the relevant test specifications are

It is therefore important to make sure that all areas to

clearly and completely understood by the inspector.

be tested in the test object are covered by the sound

GE Sensing & Inspection Technologies organizes spe- beam.

cialized training courses in the field of ultrasonic test-

ing at regular time intervals. The scheduled dates for Ultrasonic wall thickness measurement

these courses will be given to you on request.

All ultrasonic wall thickness measurements are based

on a time-of-flight measurement. Accurate measure-

ment results require a constant sound velocity in the

test object. In test objects made of steel, even with

SpotChecker Issue 02, 03/2009 11

Introduction Important information on ultrasonic testing

varying alloying constituents, this condition is mostly Effect of temperature variations

fulfilled: the variation in sound velocity is so slight that

it is only of importance for high-precision measure- The sound velocity within the test object also var-

ments. In other materials, e.g. nonferrous metals or ies as a function of the material’s temperature. This

plastics, the sound velocity variations may be even can cause appreciable errors in measurements if the

larger and thus affect the measuring accuracy. instrument has been calibrated on a cold reference

block and is then used on a warm or hot test object.

Such measurement errors can be avoided either by

Effect of the test object’s material

warming the reference block to the same temperature

If the test object’s material is not homogeneous, the before calibrating, or by using a correction factor ob-

sound may propagate at different sound velocities in tained from tables.

different parts of the test objects. In this case, an av-

erage sound velocity should be taken into account for Measurement of remaining wall thickness

the range calibration. This is achieved by means of a

reference block whose sound velocity corresponds to The measurement of the remaining wall thickness on

the average sound velocity of the test object. plant components, e.g. pipes, tanks and reaction ves-

sels of all types which are corroded or eroded from

If substantial sound velocity variations are to be ex- the inside, requires a perfectly suitable gauge and

pected, then the instrument calibration should be re- special care in handling the probe.

adjusted to the actual sound velocity values at shorter

time intervals. Failure to do so may lead to false thick- The inspectors should always be informed about the

ness readings. corresponding nominal wall thicknesses and the likely

amount of wall thickness losses.

12 Issue 02, 03/2009 SpotChecker

Important information on ultrasonic testing Introduction

Ultrasonic evaluation of flaws Echo display comparison method

In present-day test practice, there are basically two The echo from a small, natural flaw is usually smaller

different methods of flaw evaluation: than the echo from an artificial comparison flaw, e.g.

circular disc flaw of the same size. This is due, for in-

If the diameter of the sound beam is smaller than the stance, to the roughness of the surface of a natural

extent of the flaw, then the beam can be used to ex- flaw, or to the fact that the beam does not impinge on

plore the boundaries of the flaw and thus determine its it at right angles.

area.

If this fact is not taken into account when evaluating

If, however, the diameter of the sound beam is larger natural flaws, there is a danger of underestimating

than the size of the flaw, the maximum echo response their magnitude.

from the flaw must be compared with the maximum

echo response from an artificial flaw provided for com- In the case of very jagged or fissured flaws, e.g. shrink

parison purposes. holes in castings, it may be that the sound scatter-

ing occurring at the boundary surface of the flaw is so

Flaw boundary method strong that no echo at all is produced. In such cases,

a different evaluation method should be chosen, e.g.

The smaller the diameter of the probe’s sound beam, by using the backwall echo attenuation in the evalua-

the more accurately the boundaries (and therefore tion.

the flaw area) can be determined by the flaw bound-

ary method. If, however, the sound beam is relatively The distance sensitivity of the flaw echo plays an im-

broad, the flaw area determined can substantially dif- portant part when testing large components. Attention

fer from the actual flaw area. Care should therefore should be paid here to choosing artificial comparison

be taken to select a probe which will give a sufficiently flaws which are as far as possible governed by the

narrow beam at the position of the flaw. same “distance laws” as the natural flaws to be evalu-

ated.

SpotChecker Issue 02, 03/2009 13

Introduction Important information on ultrasonic testing

The ultrasonic wave is attenuated in any material. This Limitations of software

sound attenuation is very low, e.g. in parts made of

fine-grained steel, likewise in many small parts made Based on the present state of the art, software cannot

of other materials. However, if the sound wave travels be completely free of faults. Any software-controlled

larger distances through the material, a high cumula- equipment should therefore be checked before and af-

tive sound attenuation can result even with small at- ter use in order to ensure that the necessary functions

tenuation coefficients. There is then a danger that operate perfectly.

echoes from natural flaws appear too small. For this Always carry out a check by means of a calibration

reason, an estimate must always be made of the ef- standard both before and after the test.

fects of attenuation on the evaluation result and taken

into account if applicable.

If the test object has a rough surface, part of the inci-

dent sound energy will be scattered at its surface and

is not available for the test. The larger this initial scat-

tering, the smaller the flaw echoes appear, and the

more errors occur in the evaluation result.

It is therefore important to take the effect of the test

object’s surfaces on the height of the echo into ac-

count (transfer correction).

14 Issue 02, 03/2009 SpotChecker

Important information on ultrasonic testing Introduction

SpotChecker Issue 02, 03/2009 15

Introduction The SpotChecker

1.3 The SpotChecker Special features

❚ No additional computer hardware required, USB

The SpotChecker is a compact ultrasonic instrument interfaces for printer, external mouse/keyboard and

for manual testing. The consistent use of large-scale data communication with a computer

integrated components enables to carry out essential ❚ Easy to operate via touchscreen and two trackballs

functions of the system in a purely digital and conse- for both left- and right-handed operation

quently reproducible mode.

❚ 8.4" TFT color display (SVGA, 800 × 600 pixels)

The gates can be set either to echo flank or peak val-

ue of the positive or negative half-wave to make the

❚ Operating time approx. four hours by means of

two lithium-ion batteries with internal and external

measurement settings easier with wall thickness mea-

charging possibilities

surements.

❚ Program-specific assignment of functions to func-

The provided application software runs under the tion keys and remote control

powerful operating system Windows XP. An operator

interface optimized for use with detailed Online Help ❚ Optional integrated radio receiver for remote

enables you to master the function range of the sys- control

tem in no time at all. ❚ Optional integrated WLAN interface

The software for the user interface is supplied addi- ❚ Optional Bluetooth interface

tionally on a CD-ROM for the case of a possible com-

❚ Flexible use with handle and prop-up stand

puter failure or a necessary new installation.

❚ Compact housing dimensions

The system uses standard and dialog probes: the lat-

ter are automatically recognized. ❚ Weight: 3,2 kg with two batteries

16 Issue 02, 03/2009 SpotChecker

The SpotChecker Introduction

SpotChecker Issue 02, 03/2009 17

Introduction Standard package

1.4 Standard package

Product code Description Order No.

SpotChecker Portable ultrasonic flaw detector SpotChecker, 36 763

incl.

Carrying case 36 764

Lithium-ion battery 10.8 V, 4.8 Ah 109 412

Power supply unit 36 777

USB cable B-A, 1 m 109 397

Product CD SpotChecker 36 778

Driver CD 36 779

Windows multilanguage CD 35 602

Operating manual German/English, Manufacturer’s certificate 49 131

18 Issue 02, 03/2009 SpotChecker

Required accessories Introduction

1.5 Required accessories

Product code Description Order No.

Spot-BAT Lithium-ion batteries 10.8 V, 4.8 Ah 109 412

Spot-Chrg External battery charger 36 748

SpotChecker Issue 02, 03/2009 19

Introduction Spare parts requirements

1.6 Spare parts requirements

Product code Description Order No.

Housing, upper part

Housing, upper part Spotchecker 36 767

Keypad Spotchecker 36 738

Backlight inverter 109 413

Cable, backlight inverter 36 775

Trackball, left 6 p. 109 407

Cable, trackball left 6 p. 36 772

Trackball, right 10 p. 109 408

Cable, trackball right 10 p. 36 773

LCD module 800 × 600 109 411

Cable, LCD module 36 776

20 Issue 02, 03/2009 SpotChecker

Spare parts requirements Introduction

Product code Description Order No.

Housing, lower part

Housing, lower part 36 766

Battery cover 36 768

Gasket, battery cover 36 770

Knurled screw, battery cover 36 806

Shaft, battery cover 36 805

Cover interfaces 36 769

Gasket, cover interfaces 36 771

Knurled screw, cover interfaces 36 807

Handgrip, Spotchecker 36 741

Locking disk, USM 20 34 796

Holder, handgrip Phasor XL 36 585

Washer, red (Receiver) 35 651

Washer, black (Transmitter) 36 652

SpotChecker Issue 02, 03/2009 21

Introduction Spare parts requirements

Product code Description Order No.

PCB Touchview main

PCB, Touchview main 36 667

Harddisk MHW2040AC-20° 104 457

Cable, harddisk IDE 109 492

Embedded PC 109 352

DDR SDRAM module 109 373

Heat cunductive foil, thin 36 753

Heat cunductive foil, thick 36 754

Battery, backup, CR2032 14 452

Cable battery 36 774

Cable, main-USLT 36 797

Jack RJ45/2 × USB/LAN/2 × USB pulse 109 268

22 Issue 02, 03/2009 SpotChecker

Spare parts requirements Introduction

Product code Description Order No.

PCB USLT-Spotchecker:

PCB, USLT USB Spotchecker 36693

Spacer for LEMO 00 36695

Miscellaneous:

Power supply/Charger (Standard) 36777

Charger (external) 36748

Battery 109412

Adaptor, Bluetooth (external, USB) 109523

Module WLAN (internal) 36823

Remote control, transmitter 36818

Remote control, receiver (internal) 36819

Cable USB A/B, 1 m 109397

SpotChecker Issue 02, 03/2009 23

24 Issue 02, 03/2009 SpotChecker

Initial start-up and basics 2

SpotChecker Issue 02, 03/2009 25

Initial start-up and basics Overview of instrument

2.1 Overview of instrument Front panel

1 Trackball with two keys,

1 2 3

for operation of the software

2 Touch-sensitive screen (touchscreen),

for direct operation of the graphic interface

3 Trackball with two keys,

for direct operation of the graphic interface

4 Function keys F1 to F6,

function assignment programmable via software

5 Key for switching on and off

4 5

26 Issue 02, 03/2009 SpotChecker

Overview of instrument Initial start-up and basics

6 7 Back panel

6 LEMO 00 TRIAX sockets,

for connecting the transmitter probe and

the receiver probe

7 Interfaces USB, Ethernet and +15V,

for connecting further instruments, network con-

nection and for connecting the power supply unit

8 Prop-up stand and handle,

for transportation and inclined installation

9 Battery compartment at the bottom,

for holding one or two lithium-ion batteries

8 9

SpotChecker Issue 02, 03/2009 27

Initial start-up and basics Installing the instrument

2.2 Installing the instrument Avoid direct heat, heat accumulation and overheating

by direct sunlight or other heat sources. Ensure there

is adequate and unhindered circulation of air.

The SpotChecker has a prop-up stand and handle

at the rear that in different positions locks into place. Ensure that no dirt or only dry, nonconducting dirt ap-

Completely folded out it serves for the transport of the pears on the instrument, in particular at the connec-

instrument. You can install the SpotChecker with dif- tors. The following conditions must be met at installa-

ferent inclinations to have the best possible view of the tion:

screen.

❚ The instrument must not show any sign of moisture

condensation inside. Moisture and condensation

A Attention: water reduce the functional safety. Avoid quick or

Place the SpotChecker on a stable flat surface. intense changes in temperature. If the instrument

has been exposed to temperature change of more

The device is intended for indoor use. Select a suit- than 10 °C, you must wait two hours or three be-

able location for installation that guarantees to meet fore switching-on the SpotChecker.

the environmental conditions. The ambient tempera-

❚ No iron or steel dust must penetrate into the instru-

ture must be between 0 and +45 °C. The relative hu-

ment, in particular at the connectors. Apply protec-

midity must not exceed 95 %.

tive caps on the connectors that are not in use.

The SpotChecker generates heat during operation,

ensure that there is adequate ventilation and enough

clearance between the unit and heat-sensitive objects

or equipment.

28 Issue 02, 03/2009 SpotChecker

Connecting a probe Initial start-up and basics

2.3 Connecting a probe The connectors for transmitter and receiver are

marked with red ring (= receiver) and black ring

(= transmitter).

A wide range of probes manufactured by GE Sensing

& Inspection Technologies may be used in combination

with the SpotChecker, provided the suitable connecting A Attention:

cable is available. Wrong connections lead to a mismatching which may

In addition, the dialog probes of GE Sensing & Inspec- result in considerable power losses or distortions of

tion Technologies can also be connected, and they the echo waveform.

are automatically recognized by the USLT system. When connecting a dual-element (TR) probe (having

This requires the use of the probe connecting cables one transmitter element and one receiver element), or

MPKL2X or SEKL2X. two probes (of which one is transmitting and the other

The probe connecting cable must be equipped with a one receiving), attention should be paid to the follow-

LEMO 00 plug at the instrument end. Existing cables ing assignment:

can also be used by means of a probe adapter. – Connect the transmitter element to the socket

The connector sockets for one or more probes are lo- marked with the black ring.

cated on the top side of the SpotChecker. – Connect the receiver element to the socket marked

When connecting probes having only one transducer with the red ring.

element, both connector sockets are equally suitable

(connected in parallel) so that it does not matter which

one of the two sockets is used.

SpotChecker Issue 02, 03/2009 29

Initial start-up and basics Power supply

2.4 Power supply A Attention:

Be sure not to overexpand the cover when opening.

The SpotChecker can be powered using an external

power supply or by up to two lithium-ion batteries. – Loosen the knurled screw in the cover on the top

side of the instrument and open the cover com-

You can connect the SpotChecker to the mains supply

pletely.

system when the battery is in the instrument. A dis-

charged battery will be charged in this case, parallel to – Plug the Lemo connector of the external power

the instrument operation. supply unit into the socket connector +15V until it

snaps into place with a clearly audible click.

The power supply unit provided is only intended for in-

door operation. – When pulling off the Lemo plug, withdraw the met-

al bushing on the plug first in order to release the

Operation using external power supply lock.

The external power supply is delivered with two differ- – When transporting the SpotChecker always shut

ent power cables – for European and for US standard the cover and fasten the knurled screw.

specifications. The external power supply automatical-

ly adjusts to any AC voltage between 90 V and 240 V H Note:

(nominal voltage).

When powering from mains operation, it is recom-

Connect the SpotChecker to the mains socket-outlet mended to use a battery in the SpotChecker in order

using the external power supply with the appropriate to prevent a system crash and data loss in the case of

power cable. The socket connector is under the cover a power failure.

on the top side of the SpotChecker.

30 Issue 02, 03/2009 SpotChecker

Power supply Initial start-up and basics

Operation using batteries Checking the battery charge level

Use either one or preferably two lithium-ion batteries The lithium-ion battery is equipped with a battery

for the battery operation mode (option). These have a charge indicator. The battery charge indicator is lo-

high capacity each. Consequently two lithium-ion bat- cated at the front of the battery. Five LCD segments

teries ensure a long operating time of the instrument. indicate the battery charge level. The number of filled

LCD segments show the charging level as follows:

Inserting batteries ❚ 5 segments – battery charge level 100 ... 81 %

The battery compartment is located at the bottom of ❚ 4 segments – battery charge level 80 ... 61 %

the instrument and the cover is fixed with one knurled

screw.

❚ 3 segments – battery charge level 60 ... 41 %

❚ 2 segments – battery charge level 40 ... 21 %

– Loosen the knurled screw in the cover on the bot-

tom side of the instrument. ❚ 1 segments – battery charge level 20 ... 1 %

– Fold the cover down. You will see two battery com-

partments.

– Insert a battery into the left-hand or into the right-

hand battery compartment. Observe the accurate

position of the battery: the contacts have to point

back- and downwards.

– Close the cover and fasten the knurled screw.

SpotChecker Issue 02, 03/2009 31

Initial start-up and basics Power supply

Exchanging batteries The charging time is approx. 6 hours per battery. The

charging time is not reduced if the instrument is not

simultaneously used for ultrasonic tests. The charging

A Attention:

time applies to ambient temperatures from 25 °C to

If you remove both batteries during operation and the 30 °C. Please keep in mind that the batteries are not

instrument is not connected to mains supply, all un- charged to their full capacity at high temperatures.

saved data will get lost.

Charging lithium-ion batteries is also possible with the

external battery charger recommended and delivered

by GE Sensing & Inspection Technologies.

You can exchange one battery during operation.

– First insert a fully charged battery into an empty H Note:

compartment.

You will find information on how to handle the external

– Subsequently remove the other battery. charger in the documentation of your battery charger.

Charging batteries

You can charge the lithium-ion battery either directly

in the instrument or by means of an external battery

charger. Several batteries are charged in succession.

If there is a battery in the instrument, the charging pro-

cess starts automatically as soon as you connect the

external power supply. You can carry out ultrasonic

tests and charge a battery at the same time.

32 Issue 02, 03/2009 SpotChecker

Power on/Power off Initial start-up and basics

2.5 Power on/Power off – Click the button Start in the taskbar and select the

menu item Shut Down to shut down the Windows

operating system.

Starting the operation

– After Windows is closed down, the SpotChecker

To start the SpotChecker press the switch-on but- will switch off automatically.

ton at the down right of the display. The instrument is

switched on and the operating system Windows XP H Note:

boots up. The green LED illuminates during operation.

To switch off the SpotChecker without shutting down

After start of the software the SpotChecker is ready the software or the operating system, you have to

for testing operation. keep the button on the front panel depressed for at

least 4 seconds.

Closing the operation and shutting down

Switching off without shutting down the software may

be required as severe exception, e.g. if the instrument

A Attention: does no longer react. All unsaved data are lost in such

Always close the software first before shutting down a case.

the instrument. Not following this sequence may result

in a loss of data.

– Select the menu item Exit from the menu File.

All current settings are saved and the program is

closed.

SpotChecker Issue 02, 03/2009 33

Initial start-up and basics Interfaces

2.6 Interfaces Network

You can connect the SpotChecker with an Ether-

Five USB sockets and one network interface are locat- net network, e.g. for data transfer. The basic network

ed behind the cover on the top side of the SpotChecker. functions are already set up, but have to be adapted

and configurated to specific local-dependent condi-

USB tions.

The four USB Type A sockets offer multifunction-

al connection possibilities, e.g. a mouse, keyboard,

H Note:

printer or external data carriers. You will find information on the network functions un-

der Windows XP in the documentation for the operat-

The USB Type B socket you can use to connect the

ing system Windows.

SpotChecker with a computer.

WLAN

H Note:

The SpotChecker optionally features an internal

You will find information on the installation of the pe-

WLAN adapter. If it is installed, connections via WLAN

ripherals under Windows XP and the relevant software

are possible.

in the documentation of the respective manufacturer.

34 Issue 02, 03/2009 SpotChecker

Interfaces Initial start-up and basics

Bluetooth

The SpotChecker optionally features an external Blue-

tooth adapter. If included in the delivery, connections

via Bluetooth are possible.

Attaching and initializing of the Bluetooth adapter is

also possible during program run.

– Loosen the knurled screw in the cover on the top

side of the instrument and open the cover com-

pletely.

– Plug the Bluetooth adapter in a free USB connec-

tor. If the SpotChecker is switched on, the adapter

is initialized and immediately ready for operation.

– Shut the cover and fasten the knurled screw.

In order to communicate via Bluetooth the involved

instruments have to establish a connection with each

other (Pairing). The method depends on the instru-

ment used in each case and is not described here.

SpotChecker Issue 02, 03/2009 35

Initial start-up and basics Trackballs and touchscreen

2.7 Trackballs and touchscreen (selecting and clicking) is in this case replaced with di-

rect touch on the screen. A mouse pointer is therefore

not necessary.

Trackballs

To select or to mark an element of the user interface,

The SpotChecker features two trackballs to operate just touch the corresponding point of the screen briefly

the graphical software interface. Both trackballs work with your finger.

independently of each other and independently of a

connected mouse.

A Attention:

Each trackball has a big and a small button. The big Do not touch the touchscreen with any hard or sharp-

one of the respective trackball is equivalent to the left edged objects (e.g. ball-point pen or screw driver).

mouse button, the small button of each trackball to the The touch-sensitive surface may be severely dam-

right mouse button. aged by them. Do not apply any high pressure to the

You can operate both trackballs simultaneously, e.g. screen, the touchscreen needs only slight pressure to

move the mouse pointer with the right trackball and react.

trigger functions with the buttons of the left trackball.

Touchscreen

The SpotChecker is equipped with a touchscreen

enabling a direct operation of the menus appearing on

the screen.

The operation by means of a mouse

36 Issue 02, 03/2009 SpotChecker

Remote control Initial start-up and basics

2.8 Remote control H Notes:

Remote control operation can be influenced by exter-

The wireless remote control is not included with the nal interference (e.g. welding robot in the production

standard package of the SpotChecker. It is available line). Therefore, especially before storing, check to

as an accessory. The remote control consists of a see whether the transmitted commands (e.g. evalua-

transmitter with eight keys and the receiver integrated tion) have been correctly recognized by the program.

in the SpotChecker.

The assignment of the transmitter (coding) to the re-

The inspector can easily operate the inspection-rele- quired receiver is made after the system start-up by

vant functions via a wireless radio control if required. pressing the keys 1 and 8 of the transmitter unit simul-

The user has eight keys at his disposal to which he taneously.

can assign the functions most frequently required, e.g.

gain setting, A-scan freeze on/off, saving. It must be ensured at this moment that no other in-

struments are waiting for a receiver assignment in the

Thanks to the radio link, the remote control is non- neighborhood, otherwise several instruments are con-

directional; it has a radius of approx. 10 meters. trolled by one transmitter.

The remote control is automatically recognized. Sev-

eral remote control systems can also be simultane-

ously operated without any mutual interferences. This

independence of several remote control systems is

automatically ensured by a special code.

SpotChecker Issue 02, 03/2009 37

Initial start-up and basics Remote control

Assigning the remote control to a receiver

– In order to establish the first-time connection hold

the remote control as close as possible to the de-

sired SpotChecker.

– Press key 1 of the remote control, hold it down and

press key 8 simultaneously for approx. 2 seconds.

The transmitter will be assigned to the receiver.

After this, the remote control is ready for operation.

Key assignment

You can assign program-specific function to the eight

keys of the radio remote control.

– Select Options in the menu Configuration and

then click the tab Function keys.

– Select the program function you want in the re-

spective list box for the keys and activate the ap-

propriate tag.

– Confirm the changes you have made with OK.

38 Issue 02, 03/2009 SpotChecker

Software installation Initial start-up and basics

2.9 Software installation Updates

If you install an update, don’t delete the old version. In-

The SpotChecker is completely configurated and stall the new version in the directory suggested by the

ready for testing operation. installation program. The old program version is auto-

matically deleted; the old database is maintained and

The software SpotChecker is installed as well as all

automatically copied into the correct directory.

required drivers.

Installation procedure

H Note:

For a new installation or an update, please follow the

You will find basic information on how to use the Win-

procedure outlined below. In each case you have to

dows operating system in the documentation for Win-

connect the SpotChecker with an adequate external

dows and in the Windows Online Help (Start – Help).

USB CD drive.

Re-installation SpotChecker – Switch the SpotChecker on. Windows will start.

The software has to be re-installed e.g. in the case of – Insert the software CD into the CD drive. The in-

a system failure. For re-installing you need the sup- stallation program will start automatically.

plied software CD.

Follow the instructions of the installation program.

During the program run, please observe the following:

H Note:

❚ Enter your name and the name of your company in

Subsequent to the installation of the software you will

the window Registration.

need a valid license file to start the program.

SpotChecker Issue 02, 03/2009 39

Initial start-up and basics Software installation

❚ When installing the update you will be asked if you – Click the button Start in the Windows taskbar and

wish to convert the old database. Normally you choose Programs – Accessories – Command

would want to keep and process your data, there- Prompt. The window Command Prompt will be

fore select Yes. The database is then automatically opened.

converted and can be used in the updated version.

– Enter the command ipconfig/all and press the

If you select No, then a new empty database will

Enter key. Depending on the number of installed

be created.

network interface cards one or more MAC ad-

dresses will be shown, each in the parameter line

License after re-installation Physical Address (example: 00-14-22-48-57-BB).

With the first-time start of the software after a re-in- – Send the detected MAC addresses to GE Sensing

stallation you will be asked for a valid license. & Inspection Technologies. After this you will be

To obtain the license key you must send the MAC given a license file.

address (unique physical address) of one of the net- – Copy the license file license.txt into the installa-

work interface cards installed in the computer to GE tion directory SpotChecker.

Sensing & Inspection Technologies. After this you

will be given a license file valid for the corresponding

computer.

The MAC address normally consists of six groups of

two hexadecimal digits. You can detect it as follows:

– Switch on the computer. Windows will start.

40 Issue 02, 03/2009 SpotChecker

Basic settings Initial start-up and basics

2.10 Basic settings Restricting program access

You should restrict access to the software SpotCheck-

Selecting language er by assigning passwords. After a password has

been entered and the password protection has been

The SpotChecker is available in multiple languages. activated, a name together with a valid password must

All program texts are displayed in the selected lan- be entered every time the program is started. The

guage. entered password determines the allowed operating

possibilities. A master password allows access to all

– Select the menu item Dialog in the menu Setup. functions including the entry or deletion of passwords.

A menu containing the selectable language options After an inspector password has been entered, the

is displayed. The currently selected language is processing of inspection plans is possible but settings

marked with a tick. and views (A-scan and Racer) cannot be changed,

– Click the language of your choice. The selected and access to the database is denied.

language is marked with a tick. All texts are now

displayed in the selected language. A Attention:

Without a master password, access to the system set-

tings is no longer possible. If the master password is

lost, please contact your nearest GE Sensing & In-

spection Technologies representative.

SpotChecker Issue 02, 03/2009 41

Initial start-up and basics Basic settings

Activating the password protection Deactivating the password protection

Please pay attention to correct spelling using capital – Choose the menu item Options from the menu

and small letters as well as blanks with names and Settings.

passwords.

– Click the tab Program access.

– Choose the menu item Options from the menu

Settings. – Click the check box Activate in order to deactivate

the password protection. If the password protection

– Click the tab Program access. is deactivated, the box is not marked with a tick.

– Enter at least one name and one password in the The system allows free access when it’s started the

table on the left. next time.

– If necessary, enter one or several inspector names

and passwords in the table on the right.

– Click the check box Activate to activate the pass-

word protection. If the password protection is acti-

vated, the box is marked with a tick.

– A registered name must be entered, together with

a valid password, when the system is started the

next time.

42 Issue 02, 03/2009 SpotChecker

Data backup Initial start-up and basics

2.11 Data backup It is absolutely necessary that you also make a back-

up of your data prior to any software updates. Please

observe the special information on this.

With normal program exit, the last setup is saved; all

data are filed in the database of the system You should always make a backup of the following file:

(UltraLog.mdb). The adjustment parameters are re- UltraLog.mdb

stored when the system is restarted.

H Note:

H Note:

In order to reduce the volume of the database as far

With Always create database backup copy on the as possible and to make access as quick as possible,

General tab of the Options, you can additionally cre- it’s advisable to compress the database at regular in-

ate a backup copy of the database with the suffix .bak tervals. Unnecessary entries are deleted during this

on each program exit. If necessary, you can recopy process, and the data are reorganized.

this file.

Apart from this, you should save the data generated to

external data carriers (e.g. CD-ROM) at regular time

intervals. In addition to the quick restoring of the set-

ting in the case of a possible computer failure, this

method gives the opportunity to create a library for dif-

ferent inspections which can be loaded as required.

We recommend the Windows Backup tool for for the

data backup.

SpotChecker Issue 02, 03/2009 43

Initial start-up and basics Data backup

Saving data to external data media Uploading data from external data media

Loading data from CD or DVD requires a correspond-

A Attention: ing external USB drive connected to the SpotChecker.

Quit working with the SpotChecker before starting with

the data backup. A Attention:

The data backup on CD or DVD requires a corre- When uploading files to the computer, an overwrite will

sponding external USB drive with appropriate record- occur if any files of the same name already exist. Quit

ing software. working with the SpotChecker before uploading any

data.

– Close the program SpotChecker.

– Insert a CD containing backup files into the drive.

– Insert an CD into the drive.

– Click the Start button in the Windows taskbar.

– Click the Start button in the Windows taskbar.

– Select Backup in the folder System Tools –

– Choose Backup in the folder System Tools – Accessories and click the Restore tab.

Accessories.

– Follow the instructions of the Backup program.

– Follow the instructions of the Backup program.

44 Issue 02, 03/2009 SpotChecker

Online Help Initial start-up and basics

2.12 Online Help Starting the Online Help

The Online Help for the SpotChecker consists of sev-

Context-sensitive Help eral chapters and individual sections just like a manu-

al. To view the required information, you have to start

The SpotChecker software contains a context-sensi- Help, choose a topic, and then have the page dis-

tive Help. This is the fastest way to get information on played in the Help window.

individual elements of the program interface. The con-

text-sensitive Help is always active and does not have Proceed as follows:

to be started separately. – Start the SpotChecker software. You will see the

Proceed as follows: program interface.

– Start the SpotChecker software. You will see the – Click the button with the question mark. The win-

program interface. In the title bar of each window dow for selecting the Help topics appears.

you will see the ? symbol at the right. – Choose a Help topic as in the General Help for

– Click ?. The mouse pointer now also receives a ?. Windows.

– Move the ? mouse pointer to an element of the op- H Note:

erator interface, e.g. a button.

In all windows or panels, please pay attention to the

– Briefly press the left mouse button. A window con- information on how to select and display Help topics.

taining information on the program element where

the mouse pointer is placed appears. After a topic has been selected, the Help window for

displaying the selected page appears. Every Help

window has a button bar. By clicking one of the but-

tons you can move within the Online Help, e.g. to the

SpotChecker Issue 02, 03/2009 45

Initial start-up and basics Online Help

list of Contents or to the next section of a sequence of Starting the Online Help without the software

topics.

The Online Help for the SpotChecker can be opened

without activating the program itself beforehand. To do

Buttons:

this, you have to call the Help file.

Contents Back to Contents

Proceed as follows:

Index Move to Index

– Click the icon of the Help file on the Windows

Back Back to the page that was opened last desktop,

Print Print currently active page or

<< Move to the previous section of a se- – start the Windows Explorer and click the icon of

quence of topics (not always active) the file ultralog_en.hlp in the folder C:\UltraLog.

>> Move to the next section of the sequence The Online Help will start and windows will appear for

of topics (not always active) selecting the Help topics.

Some elements of a Help page refer to related Help

topics. These cross-references are highlighted green

and underlined in the text. Other cross-references are

made via icons or buttons. When you move the mouse

pointer over to a cross-reference, the mouse pointer is

shown as a pointing hand.

In that case you can press the left mouse button and

call another Help topic.

46 Issue 02, 03/2009 SpotChecker

Online Help Initial start-up and basics

Printing H Note:

All information displayed in the Help window may be All topics that can be clicked in the list of Contents

printed via a connected printer. are printed out (individually or as a book). If there are

links (underlined words or phrases) to other topics on

Proceed as follows: the printed pages, they are not automatically included

in the printout. If you want to have a printout of them,

– Choose a Help topic. The Help window appears,

click the topics and print out the displayed pages one

and the required page is displayed.

by one.

– Click the Print button to print out the page.

Printing a complete chapter

You can print out individual chapters of the Online

Help completely if required.

Proceed as follows:

– Click the Contents button of the Help window. The

window Help Topics appears.

– Click a chapter (book symbol) or a topic (? symbol)

and then the Print button.

SpotChecker Issue 02, 03/2009 47

48 Issue 02, 03/2009 SpotChecker

Individual inspection reports 3

SpotChecker Issue 02, 03/2009 49

Individual inspection reports Ultrasonic inspection of spot welds within automotive industry

3.1 Ultrasonic inspection of spot quickly because the welding structure is coarse-

grained and therefore presents a high sound atten-

welds within automotive industry uation. The echo distances correspond to the total

thickness of the welded plates less the electrode

Basic principle mark.

Spot-welded joints of two and three sheets are nowa- 2. In the case of a too small spot weld, the inspec-

days inspected using the pulse-echo method. Due to tor observes small intermediate echoes originating

the non-uniform surface quality, the inspection is most from the interface between the plates in addition to

reliably carried out in manual mode. the normal echo sequence. This makes it possible

to determine whether a nugget diameter is smaller

Special probes are used for inspecting spot welds. than the diameter of the sound beam. This is the

They contain a water delay path with a flexible rubber reason why probes having corresponding element

membrane. This ensures that the sound wave can be diameters are chosen for different nominal diam-

perfectly introduced even with the typically curved sur- eters of weld nuggets.

faces of spot welds without any problem. The sound

frequency usually chosen is 20 MHz. The transducer 3. If there is a cold weld or a “stick weld”, an extended

element diameters vary between 3.6 and 10 mm. echo sequence is received from the double plate.

However, a fine-grained structure is given in the

The sound waves introduced into the plate produce a case of the cold weld, and this leads to a flatter

repetitive echo sequence from the inspection object. echo drop with a lower sound attenuation.

In this connection, the weld quality is derived from the

shape of this echo sequence. 4. Finally, a non-existing weld produces a long echo

sequence with small echo distances corresponding

1. In the case of a perfectly sound spot weld, the am- to the single plate thickness.

plitudes of the successive echoes drop relatively

50 Issue 02, 03/2009 SpotChecker

Ultrasonic inspection of spot welds within automotive industry Individual inspection reports

Good spot weld (OK) regard to the nugget diameter, provided the inspector

does not make any fundamental mistakes, e.g. use a

wrong gain setting or a wrong probe.

Too small nugget On the other hand, the comparison of the nugget di-

ameter with the sound beam diameter requires a high

quality of the probes. Probe certificates are issued to

Stick weld prove the sound beam properties.

Comparison of ultrasonic inspection with other

Loose joint inspection methods

The shop methods include the button test, the de-

structive chipping test and the nondestructive chip-

To determine a too small weld nugget diameter, the ping test using hammer and chisel. In the case of the

nugget diameter is compared with the diameter of the button test and the destructive chipping test, the spot

sound beam: if the nugget diameter is too small, in- welds are subjected to stress load until breakage oc-

termediate echoes are produced. This is on the one curs using simple test equipment, without recording

hand on the condition that the inspector positions the any reading. Used as evaluation criteria are the type

probe at the spot weld center. If the probe is not ex- of breakage and the size of the torn spot weld. The

actly at the center, intermediate echoes will likewise volume of test scrap causes considerable amount of

be produced. This means that an adequately large cost.

weld nugget may be evaluated as being “too small”.

Conversely, however, it is not possible that a too small The advantage of the chipping test using chisel is that

nugget be evaluated as being “OK”. The inspection it can also be applied to a finished component, e.g.

result is consequently always on the safe side with a body shell. In these cases it is nevertheless mainly

SpotChecker Issue 02, 03/2009 51

Individual inspection reports Ultrasonic inspection of spot welds within automotive industry

applied as a nondestructive inspection, i.e. the joint is The micrographic examination enables information to

not subjected to load until breakage occurs. The costs be obtained on the nugget geometry, on the internal

for this inspection are comparatively low, but so is also flaws, and assessments to be made about the struc-

the value of its inspection results. This especially ap- ture. The good correlation between the nugget geom-

plies to the nondestructive chipping test using chisel. etry and the results of destructive tests using stan-

It can only be used for detecting defective spot welds dardized inspection methods makes the results of the

whose strength already lies way below the permissible micrographic examination an important and reliable, if

minimum value, e.g. so-called “stick welds”. Added to only indirect, assessment scale for the strength of the

this is the fact that the inspection results vary within spot weld.

wide limits due to the relatively indefinite inspection

conditions that cannot be kept constant. Three disadvantages limit the application of this in-

spection method:

The inspection methods using testing machines in-

clude the shearing test, the peeling tensile test, the a) The spot has to be destroyed.

top tensile test and the torsional test as standard- b) The inspection cannot be carried out on the fin-

ized inspection methods. Their advantage is that the ished car body to be further used.

strength tested under defined conditions in each case,

e.g. shearing load at the breakage of the welded joint, c) The inspection costs are relatively high in compari-

is reliably determined. This statement should be quali- son with all other inspection methods.

fied by saying that only information on the strength

under the selected load can be obtained, e.g. the pure With the exception of the nondestructive inspection

top tension, and not the mixed loads generally occur- methods mentioned above, all other inspection meth-

ring. A disadvantage of these methods is the fact that ods are used in the production. A 100 % volume in-

an inspection on the finished component is not pos- spection is nevertheless not possible for economic

sible. reasons and, in the case of destructive inspection

methods, also for technical reasons. As a result of

52 Issue 02, 03/2009 SpotChecker

Ultrasonic inspection of spot welds within automotive industry Individual inspection reports

this, sampling tests are carried out. It goes without

saying that the frequency with the low-cost, nonde-

structive chipping tests producing unreliable inspec-

tion results is higher than with the micrographic exami-

nation giving reliable inspection results, yet requiring a

lot of cost and energy.

If we look at the inspection methods usually applied to

in-process inspections at a higher inspection frequen-

cy and acceptable with regard to the costs involved,

only the chipping test using chisel and the ultrasonic

inspection are competitive in principle.

This rough overview of the current inspection possibili-

ties already reveals the reasons for the high motiva-

tion with which the well-known, unsolved problem of

nondestructive inspection of spot welds using ultra-

sonics has been extensively taken up again for some

years now.

SpotChecker Issue 02, 03/2009 53

Individual inspection reports The software SpotChecker

3.2 The software SpotChecker The basic version already offers various possibilities

for inspection, evaluation, documentation and (statis-

tical) further processing of inspection-relevant data.

Overview The basic version was developed in cooperation with

the automotive industry, and it is especially suitable

The software SpotChecker is used for recording in- for use within the production (e.g. body shell construc-

spection results from ultrasonically inspected spot tion) and for quality assurance purposes. The access

welds, e.g. within the automotive industry. In addition, to the various program functions is only possible using

results of destructive/nondestructive inspections can the specifically assigned passwords for inspectors and

also be documented. The software consists of sev- methods engineers/inspection planners.

eral modules and can therefore be adapted to special

application requirements. The modular design of the SpotChecker is a database program especially devel-

software enables to realize the most different inspec- oped for the automated implementation and evaluation

tion philosophies: as well as documentation of spot weld inspections.

SpotChecker stores and manages inspection results

❚ Mobile single-station system

and helps you with the evaluation of echo displays.

(one or several users)

For this purpose, you have a large choice of detailed

❚ Stationary single-station system flaw classifications directly at your disposal (for ex-

(one or several users) ample loose or burnt spot weld, bad through-welding,

❚ Mobile multi-station system (network) with or with- inadequate nugget diameter).

out host computer interface You can create inspection plans containing detailed

❚ Stationary multi-station system (network) with or descriptions of the spot weld location, material data,

without host computer interface test sketches and complete instrument settings of the

test system. All you have to do is to select predefined

inspection plans in the inspection mode, and you can

54 Issue 02, 03/2009 SpotChecker

The software SpotChecker Individual inspection reports

immediately start inspecting. With a corresponding ❚ adaptation possibility of Evaluation Assistance II, III

configuration, the inspection results are immediately and IV to varying requirements in daily inspection

displayed in color after coupling. situations (material/plate thickness)

During the inspection, you can adjust the most impor- ❚ support of “intelligent” dialog probes

tant ultrasonic parameters to your requirements at any

❚ special remote control with user-programmable

time, or use stored instrument settings if you like.

functions

SpotChecker provides ❚ export of inspection results to MS-Excel and

❚ the greatest ease of program operation according MS-Access, e.g. for statistical further processing

to Windows standards ❚ classification of ultrasonic inspection results ac-

❚ storage of inspection data and program information cording to six inspection criteria

in a standard database ❚ display and printout of stored data sets

❚ definition of inspection plans including any chosen

spot weld name for individual applications Application ranges

❚ true-to-location inspection according to the individ- SpotChecker can be used for mobile or stationary

ual inspection plan spot weld inspections. It likewise supports the joint

❚ entry of comments management of several inspection stations, for one or

several inspectors each.

❚ automatic evaluation assistance tools (Evaluation

Assistance I/II/III/IV) to support the inspection ac- SpotChecker can be immediately used for simple,

cording to a maximum of six different criteria non-standardized inspections, without any further

preparations. Corresponding inspection plans must

be created beforehand for structured inspection se-

SpotChecker Issue 02, 03/2009 55

Individual inspection reports The software SpotChecker

quences (standardized processes, repeated inspec- Example (please see figure on the left):

tions). An inspection plan is called by the inspector at

the location of the spot weld inspection. The inspec- Linear inspection plan:

tion plan contains all the necessary information for the Top door

inspection and guides the inspector through the in- 1 A049 – 3 plates – setting A

spection sequence. Inspection results are saved to the 2 A050 – 3 plates – setting A

SpotChecker database together with the inspection 3 A051 – 3 plates – setting A

plan they were based on. ...

Linear inspection plans describe the inspection of

a group of spot welds of the same type. These simple Structured inspection plan:

inspection plans can be directly created and managed

1 right side/top door/A051 – 3 pl. – setting A

using SpotChecker quickly and reliably.

2 right side/mid door/C024 – 2 pl. – setting B

3 right side/mid door/C023 – 2 pl. – setting B

4 right side/mid door/C022 – 2 pl. – setting C

5 right side/bottom door/B017 – 2 pl. – setting D

6 right side/bottom door/B016 – 2 pl. – setting D

...

Structured inspection plans are created on the ba-

sis of a structural description of the inspection ob-

ject (assemblies, subassemblies, plate joints). These

structured inspection plans enable a high degree of

specification of the inspection sequence and a split-

ting-up of complete vehicles according to hierarchical

levels. This means that SpotChecker meets the re-

56 Issue 02, 03/2009 SpotChecker

The software SpotChecker Individual inspection reports

quirements of complex organizational processes with- Evaluation with UltraCAR

in the automobile manufacture (please see figure).

UltraCAR is a program from GE Sensing & Inspec-

Structured inspection plans can only be created tion Technologies for the statistical evaluation and

by means of the Database Manager. But they can be documentation of ultrasonic inspection results from

loaded and used by the means of SpotChecker. spot-welded joints determined and saved using

SpotChecker.

The measurement and statistical tracking of param-

eters are integral parts of the continuous improvement

of processes and included as a proof of the improve-

ment of quality in the state-of-the-art quality manage-

ment concepts.

UltraCAR can integrate the results from the different

inspection stations into a centralized database system.

This enables to use the program for the collection and

the evaluation all inspection results obtained over a

certain period of time (e.g. day/week/year) or for the

corresponding inspection object (spot, component, car

body).

For more details, please contact your local represen-

tative of GE Sensing & Inspection Technologies or di-

rectly one of the addresses mentioned in chapter 6.

SpotChecker Issue 02, 03/2009 57

Individual inspection reports The software SpotChecker

General procedure – linear inspection plans An inspection plan contains all the data and settings

for a standardized inspection sequence. This provides

The inspection using SpotChecker generally includes a high degree of reliability, both for the inspection pro-

the following steps: cess and for the inspector.

❚ creating an inspection plan,

When creating an inspection plan, the program pro-

❚ calling and starting an inspection plan, vides forms to guide through the required data step by

❚ if necessary, recalibration of the instrument settings, step so that nothing is missed or forgotten. The in-

spector can fully concentrate on carrying out the in-

❚ carrying out the inspection on the basis of the data spection after starting an inspection plan. Among oth-

in the inspection plan, er things, the inspection plan contains data

❚ manual or automatic saving of and commenting on ❚ on the inspection object,

the inspection results,

❚ on instrument settings,

❚ ending the inspection plan,

❚ on evaluation methods and tolerances,

❚ documentation of the inspection (printout of inspec-

tion reports, saving as ASCII file, or exporting to an ❚ on the use of automatic evaluation assistance

Excel file). tools,

❚ on the selection of automated sequences (e.g. au-

Inspection plans are used for defining standardized

tomatic A-scan freeze after successful coupling),

default data and settings as well as a uniform se-

quence for repetitive inspections on components of ❚ on the classification of inspection results and

the same type. The inspection of a large number of ❚ on the envisaged spot weld locations (if available,

components of the same type can in each case be together with a drawing).

carried out using one and the same inspection plan

which has once been created.

58 Issue 02, 03/2009 SpotChecker

The software SpotChecker Individual inspection reports

The access to program functions can be protected by Evaluation Assistance I

passwords. By this means it is possible to ensure for

example that inspections are only carried out accord- The following fixed inspection criteria are filed in the

ing to the required inspection plans if necessary. program for the Evaluation Assistance I:

❚ OK

The evaluation assistance tools

❚ Small nugget

SpotChecker makes three different evaluation assis- ❚ Stick weld

tance tools available to support the inspection accord-

ing to a maximum of six criteria. Using the algorithms ❚ Burnt

of the evaluation assistance tools, SpotChecker calcu- ❚ Bad through-welding

lates the inspection results after coupling and A-scan

❚ Loose

freeze. With Evaluation Assistance III, SpotChecker

compares the currently active A-scan with a collection The evaluation and allocation of the inspection crite-

of model scans which are characterized with the help ria are carried out on the basis of the currently active

of gates. Up to 20 reference scans can be filed for A-scan from the backwall echo sequence, and from

each evaluation criterion for this purpose. the flaw echoes if necessary. SpotChecker has an

empirically determined table containing typical echo

By using the evaluation assistance tools, SpotChecker

sequences for the range of 1 to 5 mm total plate thick-

is able to carry out an automatic evaluation and to se-

ness.

lectively save the required data (e.g. only certain flaw

types). Advantage: The Evaluation Assistance I provides a

simple method requiring no additional data entries by

A visual evaluation by the inspector is also always

the user. It is particularly well suited for steel alloys

possible by pressing a key.

(deep-drawing steel plates).

SpotChecker Issue 02, 03/2009 59

Individual inspection reports The software SpotChecker

Evaluation Assistance II

The Evaluation Assistance II is applicable to two-

and three-plate inspections (total wall thickness 1 to

12 mm). The sound path (round trip) is determined for

all echoes exceeding the evaluation threshold. The

corresponding inspection criterion is calculated for

the sound path intervals filed in the table “Sound path

ranges”. In this connection, the evaluation criteria take

the drop in the echo sequence due to the sound atten-

uation in the spot weld structure into account.

The default setting of the table can be changed by the

user in order to adapt the evaluation assistance tool H Note:

to individual material conditions. For this purpose, it is The allocation of sound paths to evaluation criteria

necessary to carry out a sufficient number of corre- must be based on a sufficient number of exact com-

sponding comparison measurements. The evaluation parison measurements in order to avoid any measure-

results depend on the occurrence of flaw echoes. ment errors in the automatic evaluation as far as pos-

Simultaneously with the definition of the evaluation sible.

ranges in tabular form, SpotChecker presents the Advantage: The Evaluation Assistance II is well suited

graphical display and setting of the ranges. The rang- for steel alloys. The evaluation criteria can be adapted

es shown by different colors can be easily edited and to specific local or material-dependent conditions by

moved by means of the mouse. The graphical repre- an ultrasonic specialist.

sentation makes the setting easier together with the

clear marking of the backwall and flaw echoes.

60 Issue 02, 03/2009 SpotChecker

The software SpotChecker Individual inspection reports

Example: overlap. We therefore recommend that the ranges be

set so that no overlapping occurs. Range gaps are un-

The Evaluation Assistance is based on the following acceptable.

calculation of sound paths:

2 × total plate thickness × number of bw echoes Evaluation Assistance III

If the total plate thickness is 3.46 mm, as is the case The Evaluation Assistance III is likewise applicable to

in the example shown, and the number of backwall two- and three-plate inspections (total thickness min.

echoes (above the set evaluation threshold 10 % 1 mm, max. 12 mm). Any chosen inspection criteria

screen height) is 6, the following calculation results: can be filed for this evaluation assistance tool.

2 × 3.46 × 6 = 41.52 The evaluation is based on a complex A-scan com-

parison. The user files a typical A-scan for each evalu-

The calculated sound path falls into the range from ation criterion in the database. It is possible to file a

35.7 to 60 mm in the table filed, i.e. the results “stick maximum of 20 typical A-scans per criterion which

weld” or “bad-through welding” would match the val- can have 20 (max.) two-dimensional gates each, re-

ues. However, as intermediate echoes (flaw echoes) cording as exactly as possible the characteristic curve

between the backwall echo sequence likewise exceed of the backwall or flaw echo sequence for the evalua-

the evaluation threshold, the left result column (“with tion.

FE”) applies in this case. The indicated result is con-

sequently “stick weld”. During the inspection process, SpotChecker com-

pares the currently active A-scan with all A-scan char-

acteristics stored in the database and carries out the

H Note:

evaluation after this, i.e. if the characteristics match,

Double evaluations or non-evaluation (symbol: evalu- the corresponding inspection criterion is displayed.

ation not possible) can occur if the evaluation ranges

SpotChecker Issue 02, 03/2009 61

Individual inspection reports The software SpotChecker

The gate logic can be set for each gate: coincidence Example:

(match) or anticoincidence (non-match).

Definition of a model scan for inspection criterion OK.

An overview shows the number of the sets of gates

already stored for each evaluation criterion during the

configuration. At the same time, the number of refer-

ence scans matching the currently frozen A-scan is in-

dicated. If an A-scan is frozen, all stored sets of gates

are immediately checked against this A-scan. The

numbers of the matching reference scans are marked.

This enables a fast, intuitive, and optimum configura-

tion of the Evaluation Assistance.

H Note:

The description of typical echo sequences by the two-

dimensional gates must be based on a sufficient num- H Note:

ber of exact comparison measurements using refer-

If, during evaluation, no result is obtained (symbol:

ence spot welds in order to avoid any measurement

evaluation not possible) then there is no comparable

errors in the automatic evaluation as far as possible.

model scan for the active A-scan, i.e. not all cases

Advantage: Model results can be filed for any chosen were acquired during recording of the model scans.

materials. The system can be trained and is open to

future applications. Evaluation Assistance IV

The Evaluation Assistance IV has been developed for

special process requirements in spot weld inspections.

62 Issue 02, 03/2009 SpotChecker

The software SpotChecker Individual inspection reports

It is based on the thickness measurement in correla- H Note:

tion with the evaluation of the echo sequence. The to-

The individual configuration of Evaluation Assis-

tal wall thickness is subdivided into zones whose limits

tance IV should in any case only be made in agree-

can be individually defined by you. An evaluation class

ment with the Service of GE Sensing & Inspection

has been assigned to each thickness zone in correla-

Technologies.

tion with the number of backwall echoes. The zones

may be overlapping in this connection in order to allow

several evaluation possibilities in limit zones.

The evaluation classes do not specify the flaw (e.g.

“burnt”) but indicate any production interventions re-

quired.

The following evaluation classes are permanently filed

in the memory:

❚ OK (No flaw)

❚ NOK (Flaw)

❚ TR + (Upper tolerance range)

A-scan and Racer view

❚ TR – (Lower tolerance range)

As an alternative to the view with the A-scan and the

You can individually define the evaluation ranges by most important ultrasonic settings, the operator can