Professional Documents

Culture Documents

13 Dpconv

Uploaded by

Reena ThakurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

13 Dpconv

Uploaded by

Reena ThakurCopyright:

Available Formats

TIM 013 07.

97

Pressure Dew Point Conversion

Determining Comparable Readings Among Multiple Platforms

When installing a moisture analyzer, sometimes the reading is 1. Since the moisture table is in °C, convert the 53.6°F to

different than what you expected. This difference is often due to 12°C.

a change in the pressure at the measurement point where the

new probe has been installed. For example, a probe is installed 2. Look up the vapor pressure for 12°C dew point — 10.518

at line pressure in a process where the previous method of mmHg.

measurement was at atmospheric pressure. The problem then 3. Convert the original psig value into atmospheres by adding

becomes one of predicting the pressure effect on the probe and 14.7 psia to the 180 psig to get psia. This gives 194.7 psia,

achieving the desired result. which we divide by 14.7 to get 13.2449 atmospheres.

Dew point temperature is always directly related to the partial 4. Since the total pressure change is a factor of 13.2449 to 1,

pressure of water vapor in the gas. In other words, if you know the resulting vapor pressure goes through the same

the dew point, the partial pressure of water for that dew point change. Dividing the 10.518 mmHg by 13.2449

temperature can be found in published tables. S e e G e n e r a l atmospheres gives 0.794 mmHg vapor pressure at the

Eastern’s Humidity Handbook. reduced pressure.

The ability to predict the dew point change from the total 5. Referring to a vapor pressure table, the 0.794 mmHg vapor

pressure change is based on physical laws which govern the pressure converts into -19.76°C dew point. This converts

behavior of gases. The Ideal Gas Law and Dalton's Law are into -3.57°F dew point at atmospheric pressure.

both in operation here. The Ideal Gas Law gives the relationship

of pressure, temperature, and volume in PV = nRT. Dalton's Law

states that total pressure is equal to the sum of all the partial

pressures of the component gases.

PT = P1 + P2 + P3 + ... + Pn A similar calculation can be performed to predict the dew point

temperature for an increase in total pressure. An example of this

Simplified for the moisture problem, Dalton's Law would be where the measurement could not be made at

becomes: pressure. There might still be a need for avoiding a high dew

point temperature to prevent condensation or freeze-ups in the

PT = PD R Y G A S E S + PH 2 O ( W A T E R V A P O R )

piping.

If the total pressure changes, a l l the partial pressures will

change in the same proportion. This includes the partial Sample problem: If the dew point measured after dropping the

pressure of water in the sample. Since the total pressure change pressure to atmospheric is -40°C, what would the pressure dew

is easy to measure, the resulting change in dew point point be if the line pressure were 80 psig? (See Figure 1.)

temperature becomes predictable using the following 1. Even though the moisture table is in °C, -40°F equals -

calculation procedure: 40°C.

Sample problem: If the dew point measured at a total line 2. Look up the vapor pressure for the 40°C dew point, which

pressure of 180 psig is 53.6°F, what would the dew point be if is 0.0966 mmHg.

the same sample were measured at atmospheric pressure?

3. Convert the line psig value into atmospheres by adding

14.7 psia to the 80 psig to get psia. This gives 94.7 psia,

which we divide by 14.7 to get 6.442 atmospheres. Figure 2

4. Since the total pressure change is a factor of 6.442 to 1,

the resulting vapor pressure goes through the same

change. Multiplying the 0.0966 mmHg by 6.442 The calculations in this Application Note are based on the

atmospheres gives 0.622 mmHg vapor pressures at the Ideal Gas Law. At elevated pressures water vapor deviates

increased pressure. from the ideal gas law, however enhancement factors can be

employed to compensate.

5. Referring to the vapor pressure table, the 0.622 mmHg

vapor pressure converts into 022.3°C dew point. This

converts into -8.14°F dew point at line pressure.

In the above example, if the temperature of any section of the

piping drops to -8.14°F, there will be a danger of condensing

inside the pipe, freezing, and then bursting the lines.

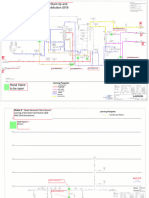

An easier method for measuring and comparing another

measurement at a different pressure is to simply operate at the

same pressures. The gold/aluminum oxide sensor General

Eastern uses for measuring the moisture is sensitive to change in

vapor pressure. A basic sample system which reduces or

equalizes the pressure will allow the two to agree within the

tolerances of the respective instruments. The flow cell diagram

on the next page, Figure 2, illustrates how simple this system

could be.

This flow cell installation has inlet and outlet valves that can

be used to operate the probe at line or

atmospheric pressure. If the inlet valve is opened completely

and the outlet valve is used to throttle the sample, the probe

will operate at line pressure. If the outlet valve is opened and

the inlet valve is used for throttling, the probe will operate at

atmospheric pressure. This installation provides the flexibility

for reading at a pressure that fits the application.

Sometimes the ability to change the pressure is not an option,

as in a system where the exhaust is routed back into a pressure

very close to the original inlet pressure.

You might also like

- Pressure Dew Point CalculationDocument2 pagesPressure Dew Point CalculationSelvaraji MuthuNo ratings yet

- Lab Marcet BoilerDocument12 pagesLab Marcet Boilerforestsecret100% (1)

- Thermodynamic and Flow Calculations For The Design of A Cold Air BlowerDocument12 pagesThermodynamic and Flow Calculations For The Design of A Cold Air Blowermm mmNo ratings yet

- Practical 2-Clement and DesormesDocument10 pagesPractical 2-Clement and Desormeswickedsinner767% (6)

- Marcet BoilerDocument7 pagesMarcet BoilerSt Oong100% (1)

- Applying Psychrometric RelationshipsDocument6 pagesApplying Psychrometric Relationshipssaifuddin722No ratings yet

- Marcet BoilerDocument9 pagesMarcet BoilerKayfe sayfadeenNo ratings yet

- L33 - Psychrometric Properties of Moist AirDocument22 pagesL33 - Psychrometric Properties of Moist AirHasif D. Müller100% (1)

- GF AN SFM-25 Reference and Flow Conversions D1Document6 pagesGF AN SFM-25 Reference and Flow Conversions D1Han LinNo ratings yet

- This Experiment Marcet Boiler Engineering EssayDocument11 pagesThis Experiment Marcet Boiler Engineering EssayBerry101No ratings yet

- Lab. Vapor PressureDocument4 pagesLab. Vapor PressureYiğit IlgazNo ratings yet

- Gases, Vapors, Liquids and Solids: Basic Principle II Second Class Dr. Arkan Jasim HadiDocument13 pagesGases, Vapors, Liquids and Solids: Basic Principle II Second Class Dr. Arkan Jasim Hadiالزهور لخدمات الانترنيتNo ratings yet

- SOP CalculationDocument8 pagesSOP Calculationmatteo2009No ratings yet

- Lesson 2 - Unit 1 - MTF1 - Basic Concepts Ot Thermodynamcis - 2021Document10 pagesLesson 2 - Unit 1 - MTF1 - Basic Concepts Ot Thermodynamcis - 2021Thabo MokgosiNo ratings yet

- Chapter 5 KimiaDocument3 pagesChapter 5 KimiaelmishaenandaeNo ratings yet

- 8 SolDocument4 pages8 SolRuan PretoriusNo ratings yet

- EntalpiDocument5 pagesEntalpiOnur KaplanNo ratings yet

- Using P-T Analysis As A Service ToolDocument8 pagesUsing P-T Analysis As A Service ToolMARCONo ratings yet

- Gas Measurements and Measuring DevicesDocument21 pagesGas Measurements and Measuring DevicesmohamedNo ratings yet

- Marcet Boiler Lab ReportDocument12 pagesMarcet Boiler Lab ReportShameerSamsuriNo ratings yet

- Accumulator Selection: 3.1 Method of Selection 3.2 Gas Precharge PressureDocument12 pagesAccumulator Selection: 3.1 Method of Selection 3.2 Gas Precharge Pressurereincidentesk8No ratings yet

- Fundamentals of Pressure and Temperature Measurement: Example - Calculation at .25 PsigDocument4 pagesFundamentals of Pressure and Temperature Measurement: Example - Calculation at .25 PsigPriscila Perez HerreraNo ratings yet

- Practical Use of EntropyDocument10 pagesPractical Use of EntropySantiago SeveinNo ratings yet

- Coolpack ManualDocument14 pagesCoolpack ManualAKHIL100% (3)

- Lab Report 5Document7 pagesLab Report 5Siti Syuhadah100% (1)

- Engineering Letter: FundamentalsofsteamDocument2 pagesEngineering Letter: FundamentalsofsteamJuan Pablo ApazaNo ratings yet

- Compression and Condensation of Carbon DioxideDocument11 pagesCompression and Condensation of Carbon DioxideNguyen Dang Hanh100% (3)

- Basic-Thermodynamics 4Document20 pagesBasic-Thermodynamics 4Bonsay 23No ratings yet

- Relief PDFDocument0 pagesRelief PDFscribpenumakaNo ratings yet

- Air Density CalculatorDocument3 pagesAir Density CalculatorcaturskNo ratings yet

- 18 Ee 88 Marcet Boiler PDFDocument15 pages18 Ee 88 Marcet Boiler PDFSHADES 4 ALLNo ratings yet

- TH5Document18 pagesTH5Sia How TanNo ratings yet

- 2 Psychrometry PDFDocument24 pages2 Psychrometry PDFFaiz FauziNo ratings yet

- Dewpoint in Compressed Air FAQDocument4 pagesDewpoint in Compressed Air FAQamirthalingam_b671No ratings yet

- Antoine'sDocument3 pagesAntoine'sGarcia RaphNo ratings yet

- Marcet Boiler AppartusDocument13 pagesMarcet Boiler AppartusNIKHIL DHIMANNo ratings yet

- The Basis of API Corrolation For Fire Relief of Unwetted VesselsDocument5 pagesThe Basis of API Corrolation For Fire Relief of Unwetted VesselscedwNo ratings yet

- Exp.2-Principles of Saturation Pressure MeasurementDocument65 pagesExp.2-Principles of Saturation Pressure MeasurementAmir Hamzah25% (4)

- Lab 3 - Marcet BoilerDocument9 pagesLab 3 - Marcet Boilercog0812No ratings yet

- Determination of Vapor PressuresDocument2 pagesDetermination of Vapor PressuresMyvizhi SomasundaramNo ratings yet

- How To Properly Size A Steam TrapDocument4 pagesHow To Properly Size A Steam TrapJessicalba Lou100% (1)

- Gas Law DemonstrationsDocument6 pagesGas Law Demonstrationsmayur mulikNo ratings yet

- Joule-Thomson EffectDocument4 pagesJoule-Thomson EffectRandomNo ratings yet

- Ideal Gas-Worked ExamplesDocument4 pagesIdeal Gas-Worked ExamplesMuhammad MosaNo ratings yet

- Control Valve Sizing For SteamDocument26 pagesControl Valve Sizing For SteamproxywarNo ratings yet

- Lab 11: Lab Report Cooling TowerDocument7 pagesLab 11: Lab Report Cooling TowerKhairulAzwanizam100% (2)

- Dewpoint Compressed Air Application NoteDocument4 pagesDewpoint Compressed Air Application NoteKarthick Velayutham100% (1)

- IT Module - N2 Equipment & CalculationsDocument7 pagesIT Module - N2 Equipment & CalculationsMohamedNo ratings yet

- 3 Process Variables Part 2Document22 pages3 Process Variables Part 2Snow DropNo ratings yet

- CondenserDocument26 pagesCondenserFRANCISCO JOSE GARCIA IBAÑEZNo ratings yet

- Lab Report of Mearcot Boiler.Document6 pagesLab Report of Mearcot Boiler.Salam AlbaradieNo ratings yet

- Heat of Vaporization The Clausius-Clapeyron: Importance & CalculationDocument9 pagesHeat of Vaporization The Clausius-Clapeyron: Importance & CalculationSàtz ÑÖÑïtNo ratings yet

- TIN 818699 00 INFO C1 2 Utilization of The Sensible Heat of Condensate enDocument6 pagesTIN 818699 00 INFO C1 2 Utilization of The Sensible Heat of Condensate enhappale2002No ratings yet

- The Operation of Direct-Contact Condenser at Thermodynamic EquilibriumDocument5 pagesThe Operation of Direct-Contact Condenser at Thermodynamic EquilibriumLeonardo da Silva AlvesNo ratings yet

- CHE144 - Lab Report Marcet Boiler 2015 PDFDocument23 pagesCHE144 - Lab Report Marcet Boiler 2015 PDFyash1997No ratings yet

- RM 135Document8 pagesRM 135pvirgosharmaNo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- Progress of PV Cell TechnologyDocument17 pagesProgress of PV Cell TechnologysriNo ratings yet

- Moduł Igbt Mg25j2ys40 25a 600v Toshiba DatasheetDocument4 pagesModuł Igbt Mg25j2ys40 25a 600v Toshiba Datasheetmouelhi karimNo ratings yet

- Radial Turbine Design ProcessDocument15 pagesRadial Turbine Design ProcessKamaldeep GuptaNo ratings yet

- Temperature MeasuremenntDocument25 pagesTemperature MeasuremenntJan Edward L. SuarezNo ratings yet

- ElecDocument40 pagesElecakela_life100% (4)

- Management Analysis of MayfairDocument42 pagesManagement Analysis of MayfairIrfan KhalidNo ratings yet

- Sthil MS 201 TC User ManualDocument44 pagesSthil MS 201 TC User ManualCrazy IT GeekNo ratings yet

- Volvo: Electrical Wiring DiagramDocument7 pagesVolvo: Electrical Wiring Diagramrusadi100% (5)

- Venturimeter ProjectDocument43 pagesVenturimeter ProjectPangambam Suman100% (1)

- 1151-00 MANUAL - Redi Purge - Model - 007 R11 123 - TRANE REPLACEMENT - Etl LabeledDocument37 pages1151-00 MANUAL - Redi Purge - Model - 007 R11 123 - TRANE REPLACEMENT - Etl LabeledJames MurrayNo ratings yet

- 10 - CapacitorsDocument5 pages10 - Capacitorschie CNo ratings yet

- Pipe Flow Rate MeasurementDocument7 pagesPipe Flow Rate MeasurementSyed Osama MunibNo ratings yet

- Catalogue Power CableDocument28 pagesCatalogue Power CableAzli FitriNo ratings yet

- Washing Machine: Service ManualDocument41 pagesWashing Machine: Service Manualimagex5No ratings yet

- OIDA Improved CarbonizerDocument14 pagesOIDA Improved CarbonizerRicardo F. OrgeNo ratings yet

- Selected Bibliography On Brickmaking in Developing CountriesDocument4 pagesSelected Bibliography On Brickmaking in Developing CountriesRobert PetrutNo ratings yet

- Lesson 12a - Et332bDocument23 pagesLesson 12a - Et332bLawiii KkkNo ratings yet

- Electrical Disturbances in LV Networks Due To Energization of MV NetworksDocument5 pagesElectrical Disturbances in LV Networks Due To Energization of MV NetworksAlejandro Solis GomezNo ratings yet

- E4PA OmronDocument8 pagesE4PA OmronCong NguyenNo ratings yet

- Hi-Kalibre Actuator ManualDocument13 pagesHi-Kalibre Actuator Manual柴俊卿No ratings yet

- YAMAHA XV-250TC - XV-250T Virago (2005 Service Manual) - (@krzycho)Document95 pagesYAMAHA XV-250TC - XV-250T Virago (2005 Service Manual) - (@krzycho)api-19780903No ratings yet

- A Proactive 2-Stage Indoor CO2-based Demand-Controlled Ventilation Method Considering CoDocument18 pagesA Proactive 2-Stage Indoor CO2-based Demand-Controlled Ventilation Method Considering CoMariaNo ratings yet

- Smpling - Storage - Transportation - Installation ProcedureDocument75 pagesSmpling - Storage - Transportation - Installation ProcedurePaddyNo ratings yet

- SISTO-Diaphragm Valves: 1. Installation InstructionsDocument1 pageSISTO-Diaphragm Valves: 1. Installation InstructionsEric LarrondoNo ratings yet

- Som Intelligent Densities Vertical CommunitiesDocument50 pagesSom Intelligent Densities Vertical CommunitiesRizwan Yousaf CheemaNo ratings yet

- Ii 2G Ex D Iic T6 GB Cesi 03 Atex 323 X: Sonde A Transmetteur 4÷20ma Pour Gaz InflammablesDocument10 pagesIi 2G Ex D Iic T6 GB Cesi 03 Atex 323 X: Sonde A Transmetteur 4÷20ma Pour Gaz Inflammablesdewidewi76No ratings yet

- Mass BalanceDocument8 pagesMass BalanceShiraz NajatNo ratings yet

- Dh3 Generation Lototo Plan Phase 2 RGC 08sep2023Document8 pagesDh3 Generation Lototo Plan Phase 2 RGC 08sep2023Borislav VulicNo ratings yet

- Installation and Operation Manual: 2301A Speed Control With Ma Speed Setting InputDocument40 pagesInstallation and Operation Manual: 2301A Speed Control With Ma Speed Setting Inputsorangel_123No ratings yet

- 33-50-14 (Epu301)Document30 pages33-50-14 (Epu301)BehroozNo ratings yet