Professional Documents

Culture Documents

Asco

Uploaded by

yanjiayuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asco

Uploaded by

yanjiayuCopyright:

Available Formats

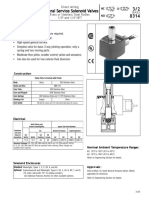

FILTER/REGULATOR Air service equipment

Series

Full 316L Stainless Steel

1/4 - 1/2

342

FEATURES

• Stainless steel filter/regulator intended for use in potentially explosive

atmospheres caused by gases, vapours, mists and/or dust according to:

(ATEX directive 94/9/EC).

SAFETY CODE: ` II 2G/D c IIC X T85°C (T6) (ZONE 1-21) Explosion group IIC

• Compliance with the essential health and safety requirements has been assured

with European Standards EN 13463-1 and EN 13463-5

• Filter/Regulator with reinforced diaphragm with PTFE lining and all metal parts in

316L stainless steel for a standard pressure of max. 20 bar

• Built-in overpressure relieving function

• Filtering effect by centrifugation of the air and 50 microns filtering element

• Large operating temperature -40°C to +80°C

• Body, bonnet and internal parts in 316L stainless steel according to

ASTM A 182/NACE MR 01.75

• Large bowl capacity

GENERAL

Fluids Compressed air and neutral gas

Ports 1/4 NPT and 1/2 NPT

Maximum inlet pressure 20 bar

Adjustable pressure 0,8 to 8 bar [1bar = 100 kPa]

Hysteresis < 0,2 bar

Filtering size 50 µm

Ambient temperature -40° to +80°C

Maximum flow (Qv at 6.3 bar) See specifications and charts

CONSTRUCTION

Body AISI 316L SS

Bowl AISI 316L SS

Filtering element AISI 316L SS

Diaphragm PTFE lined NBR (Nitrile) IN OUT

Condensate drain Manual drain

Pressure adjusting screw Allen head screw with locking nut

SPECIFICATIONS

catalogue number

maximum flow

port bowl filtering adjustable FILTER / REGULATOR

at 6,3 bar pressure setpoint

size type capacity capacity pressure gauge

and DP of 1 bar/setpoint without with 316L SS

connection

NPT (cl) (µm) (bar) l/min. (ANR) dm3/s (ANR) pressure gauge pressure gauge

NPT

50 µm filtration 0,8 - 8 bar adjustment - 316L Stainless Steel

1/4 314 ST 130 50 0,8 - 8 800(1) 14 1/4 34208001 34208002

1/2 312 ST 180 50 0,8 - 8 1500(2) 25 1/4 34208003 34208004

5 µm filtration 0,8 - 8 bar adjustment - 316L Stainless Steel

1/4 314 ST 130 5 0,8 - 8 680(3) 14 1/4 34208005 34208006

1/2 312 ST 180 5 0,8 - 8 1275(4) 25 1/4 34208007 34208008

50 µm filtration 0,8 - 8 bar adjustment - 316L Stainless Steel - Automatic Drain

1/4 314 ST 130 50 0,8 - 8 800(1) 14 1/4 34208011 34208012

1/2 312 ST 180 50 0,8 - 8 1500(2) 25 1/4 34208013 34208014

5 µm filtration 0,8 - 8 bar adjustment - 316L Stainless Steel - Automatic Drain

1/4 314 ST 130 5 0,8 - 8 680(3) 14 1/4 34208015 34208016

1/2 312 ST 180 5 0,8 - 8 1275(4) 25 1/4 34208017 34208018

2010/R01

(1)

KV = 0,67 [m3/h] and 11,1 [l/min] (3)

KV = 0,56 [m3/h] and 9,3 [l/min]

(2)

KV = 1,25 [m3/h] and 20,8 [l/min] (4)

KV = 1,06 [m3/h] and 17,6 [l/min]

All leaflets are available on: www.asco-process-scope.com

PIC-14-15-GB

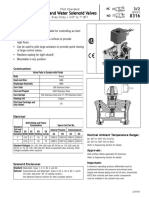

SERIES 342

MOUNTING BRACKET PRESSURE DROP vs. AIR FLOW CURVE

at 20 barg inlet pressure

2 8,5 38,5

FR - Type 314 ST

6,5

7

8

outlet pressure (barg)

7

6

5

53

4

3

2

21

1

7

0

0 50 100 150 200 250 300

6,5

22 flow [Nm3/h]

32

66 FR - Type 312 ST

8

outlet pressure (barg)

Bracket kit number : C117813 7

6

5

4

DIMENSIONS (mm), WEIGHT (kg) 3

2

1

0

M5 threaded 0 50 100 150 200 250 300

pressure relief

flow [Nm3/h]

M6 connection

~B (automatic drain) - ~C (manual drain)

OPTIONS & ACCESSORIES

spare parts kits

7,5

catalogue number type filtration kit number

34208001/002/011/012 314 ST 50 µm C117873

1/4" NPT

pressure 34208003/004/013/014 312 ST 50 µm C117874

gauge

34208005/006/015/016 314 ST 5 µm C117875

connection

34208007/008/017/018 312 ST 5 µm C117876

ØD

32 A

PIC-0014-15-GB -- Availability, design and specifications are subject to change without notice. All rights reserved.

= =

catalogue number A B C ØD E weight

A

34208001/002/005/006 60 264 257 1/4 1,5 1,35 kg

34208003/004/007/008 70 270 265 1/2 5 1,90 kg

34208011/012/015/016 60 264 257 1/4 1,5 1,55 kg

34208013/014/017/018 70 270 265 1/2 5 2,10 kg

ADDITIONAL OPTIONS

● Other pipe threads are available on request

● Threaded connections BSP or with flanges

● EPDM/FPM gaskets

● With a 5 µm filtering element the max. flow is reduced by approx. 15%

● Stainless steel pressure gauge (0-10 bar scale division), kit number: C117814. Other scale divisions on request

INSTALLATION

● Installation/maintenance instructions are included with each filter/regulator

● Filter/Regulator must be installed with the bowl in vertical position

● Air flow direction indicated by an arrow

● Pipe connection has standard thread according to NPT (ANSI 1.20.3)

2010/R01

All leaflets are available on: www.asco-process-scope.com

14-15-2

You might also like

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Advances in Medical Linear Accelerator TechnologyDocument22 pagesAdvances in Medical Linear Accelerator TechnologyNawel MorjanNo ratings yet

- PN50SD0L01 2015Document4 pagesPN50SD0L01 2015romerobernaNo ratings yet

- Heater Catalog 0618Document576 pagesHeater Catalog 0618abasakNo ratings yet

- Biology WS AnswersDocument17 pagesBiology WS AnswersKazeNo ratings yet

- Hendricks, David W-Fundamentals of Water Treatment Unit Processes - Physical, Chemical, and biological-CRC Press (2011) PDFDocument930 pagesHendricks, David W-Fundamentals of Water Treatment Unit Processes - Physical, Chemical, and biological-CRC Press (2011) PDFÂn HồngNo ratings yet

- Thermatrac Air-To-Water Heat Pump Water HeaterDocument15 pagesThermatrac Air-To-Water Heat Pump Water Heatercodefinder100% (1)

- Dental Ceramics Properties Uses AdvantagesDocument31 pagesDental Ceramics Properties Uses AdvantagespatotiwotieNo ratings yet

- 01SD0J01Document5 pages01SD0J01raobabar21No ratings yet

- Longair - Light and ColorDocument38 pagesLongair - Light and Colormordsith90No ratings yet

- Ampere Weber Electrodynamics HistoryDocument59 pagesAmpere Weber Electrodynamics Historyhanon90% (1)

- SS-2 Pressure Switch OptionsDocument4 pagesSS-2 Pressure Switch OptionsNavas100% (1)

- Blast Furnace Heat and Material Balance Using MS-Excel-Solver WBDocument42 pagesBlast Furnace Heat and Material Balance Using MS-Excel-Solver WBbabuxavier10No ratings yet

- Tecnicomar-General CatalogueDocument232 pagesTecnicomar-General CatalogueecrNo ratings yet

- Asco New SS FRDocument3 pagesAsco New SS FRNyoman RakaNo ratings yet

- SB37Document2 pagesSB37deepak kumarNo ratings yet

- Rotameter Overview PDFDocument8 pagesRotameter Overview PDFSteve Goke AyeniNo ratings yet

- Numatics Series 342Document6 pagesNumatics Series 342Jebran FarazNo ratings yet

- High Flow Direct Acting Valves: FeaturesDocument2 pagesHigh Flow Direct Acting Valves: FeaturesBurhan AyubNo ratings yet

- Midland STANDARDDocument63 pagesMidland STANDARDmhaioocNo ratings yet

- Asco Series 290 Angle Body CatalogDocument10 pagesAsco Series 290 Angle Body CatalogcillongNo ratings yet

- Mid LandDocument6 pagesMid LandGopinath GunasekaranNo ratings yet

- Technical Information Sheet SLS1 I - SLS2 I - SLS3 I: CharacteristicsDocument2 pagesTechnical Information Sheet SLS1 I - SLS2 I - SLS3 I: Characteristicsyopi permanaNo ratings yet

- ADCA TSS22 Thermostatic Steam TrapDocument1 pageADCA TSS22 Thermostatic Steam TrapedlistiantoNo ratings yet

- ASHCROFT Diaphragm Seal Model 400-401Document2 pagesASHCROFT Diaphragm Seal Model 400-401HanzoNo ratings yet

- 312 RegulatorDocument3 pages312 RegulatorMozzy GuNo ratings yet

- General Service Solenoid Valves: NC NO UDocument4 pagesGeneral Service Solenoid Valves: NC NO UDevinNo ratings yet

- Filters-Deaerators VafDocument8 pagesFilters-Deaerators VafAntony BonillaNo ratings yet

- General Service Solenoid Valves: NC NO UDocument4 pagesGeneral Service Solenoid Valves: NC NO UgiopetrizzoNo ratings yet

- Asco Series Nt320 Nuclear CatalogDocument4 pagesAsco Series Nt320 Nuclear CatalogJota JotaNo ratings yet

- Fig - 3616 TI P160 04 ENDocument4 pagesFig - 3616 TI P160 04 ENAditomo PutrantoNo ratings yet

- GA Drawing - Nitrogen Manifold As Built Drawing-Layout2Document1 pageGA Drawing - Nitrogen Manifold As Built Drawing-Layout2Aditya Rinaldi Yusuf Abbas100% (1)

- 3-Way General Service Solenoid ValvesDocument31 pages3-Way General Service Solenoid ValvesJuan Carlos Pardo RimachiNo ratings yet

- Optimize Pneumatic Transmitter SpecsDocument4 pagesOptimize Pneumatic Transmitter SpecsMohammad HosseinNo ratings yet

- Asco Series 040 NC CatalogDocument4 pagesAsco Series 040 NC CatalogrtgeorgeNo ratings yet

- Pilot Operated Air and Water Solenoid ValvesDocument4 pagesPilot Operated Air and Water Solenoid ValvesDevinNo ratings yet

- P PT Industrial Stainless Steel Filter HousingsDocument4 pagesP PT Industrial Stainless Steel Filter Housingsliceth.emilio30mpNo ratings yet

- Swagelok HoseDocument28 pagesSwagelok HoseRashi Akmal0% (1)

- All Stainless Steel Process Gauge Open or Solid Front Model T5500 and T6500Document2 pagesAll Stainless Steel Process Gauge Open or Solid Front Model T5500 and T6500Ferdinand LizadaNo ratings yet

- PDS LSFDocument2 pagesPDS LSFjeriko22No ratings yet

- AMF900 V1.2.1.A4.enDocument4 pagesAMF900 V1.2.1.A4.engilangNo ratings yet

- 115NZ NZCDocument4 pages115NZ NZCOdicoNo ratings yet

- Muc 5 52003821.58084010 59902230Document16 pagesMuc 5 52003821.58084010 59902230zhou NickyNo ratings yet

- Valvula ASCO Falcon SB2500Document2 pagesValvula ASCO Falcon SB2500Elmer HuashuayoNo ratings yet

- Shavo Norega Af RegulatorDocument2 pagesShavo Norega Af Regulatorshanmugam17No ratings yet

- ALIA AMF900 Electromagnetic FlowmeterDocument4 pagesALIA AMF900 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- Astm A312 Stainless Steel Pipe: NavigationDocument6 pagesAstm A312 Stainless Steel Pipe: NavigationnitinNo ratings yet

- pt100 PDFDocument0 pagespt100 PDFCarlos Labarca GallardoNo ratings yet

- technical_datasheet_2_pieces_forged_stainless_steel_ball_valve_800lbsDocument7 pagestechnical_datasheet_2_pieces_forged_stainless_steel_ball_valve_800lbsBenny 37No ratings yet

- Gas Shutoff Valves: FeaturesDocument136 pagesGas Shutoff Valves: FeaturesJuan BejaranoNo ratings yet

- Push Button Manual Reset Valves: FeaturesDocument2 pagesPush Button Manual Reset Valves: FeaturesrockieballNo ratings yet

- Hansen strainer_T479eDocument2 pagesHansen strainer_T479eRikiNo ratings yet

- Series 99 Data SheetDocument10 pagesSeries 99 Data SheetSireesh AdimadhyamNo ratings yet

- Stainless steel IFR filter regulatorDocument1 pageStainless steel IFR filter regulatorGuillermo de la Fuente SantiagoNo ratings yet

- TSS22HDocument1 pageTSS22HAntonio VelardeNo ratings yet

- Asco Series 316 Air Water CatalogDocument4 pagesAsco Series 316 Air Water CatalogekoNo ratings yet

- Asco Valve 8298a002 ReplacementDocument4 pagesAsco Valve 8298a002 ReplacementAugusto Leudo AngelNo ratings yet

- General Service Solenoid Valves for Fluid ControlDocument4 pagesGeneral Service Solenoid Valves for Fluid Controlpacho916No ratings yet

- CAT114 A-Rev.2Document2 pagesCAT114 A-Rev.2Jordi Enjuanes BalaguerNo ratings yet

- 3 4lps15m PDFDocument3 pages3 4lps15m PDFAseem Vivek MasihNo ratings yet

- Quick Exhaust Solenoid Valves: NC NODocument4 pagesQuick Exhaust Solenoid Valves: NC NOMuhammad AsadNo ratings yet

- 38lha 40lha h15 1pd Rev2Document28 pages38lha 40lha h15 1pd Rev2nhatNo ratings yet

- Low Pressure SW Series Compression FittingsDocument20 pagesLow Pressure SW Series Compression FittingsShankar RajNo ratings yet

- High Flow High Pressure Reducing RegulatorsDocument4 pagesHigh Flow High Pressure Reducing Regulatorsامیر علیNo ratings yet

- PDF N1301281618440Document2 pagesPDF N1301281618440wawanNo ratings yet

- PDF N1301281618440Document2 pagesPDF N1301281618440Agustin CesanNo ratings yet

- MEUR310 ENaDocument3 pagesMEUR310 ENaAbhijeet PandeyNo ratings yet

- Development of Ghat River in Jaunpur City: 1-Anil BhartiDocument9 pagesDevelopment of Ghat River in Jaunpur City: 1-Anil BhartiA8304008005No ratings yet

- Chromatography Guide: Key Terms and Definitions for Adsorption ChromatographyDocument35 pagesChromatography Guide: Key Terms and Definitions for Adsorption ChromatographyafdillenburgNo ratings yet

- How to read a pump curve and understand key parameters like best efficiency point, NPSH, friction losses and moreDocument2 pagesHow to read a pump curve and understand key parameters like best efficiency point, NPSH, friction losses and moreNo PersonNo ratings yet

- Current Events: Internet 1: An Optical Switch Based On A Single Nano-DiamondDocument3 pagesCurrent Events: Internet 1: An Optical Switch Based On A Single Nano-Diamondjennylee00182No ratings yet

- Silicone Materials Guide SnapDocument4 pagesSilicone Materials Guide SnapParagNo ratings yet

- Float ValveDocument1 pageFloat Valveabdulkidwai2009No ratings yet

- Bracing Requirements For Elastic Steel BeamsDocument87 pagesBracing Requirements For Elastic Steel BeamsbiomechanicsNo ratings yet

- Investigating Osmolarity in Plant TissuesDocument2 pagesInvestigating Osmolarity in Plant TissuessofiaNo ratings yet

- Unit 2 Welding III HazDocument9 pagesUnit 2 Welding III HazHada NanuNo ratings yet

- Article1379594984 - Sivakumar and GomathiDocument7 pagesArticle1379594984 - Sivakumar and GomathiEdda GeregetanNo ratings yet

- ProblemsDocument2 pagesProblemsJoisy Sarco CondoriNo ratings yet

- Barcelona ScriptDocument35 pagesBarcelona ScriptSerious ComedianNo ratings yet

- Different Forms of Corrosion - Intergranular Corrosion - Weld DecayDocument2 pagesDifferent Forms of Corrosion - Intergranular Corrosion - Weld DecayHarry NuryantoNo ratings yet

- Freeze-Drying of Acerola (Malpighia Glabra L.)Document7 pagesFreeze-Drying of Acerola (Malpighia Glabra L.)mNo ratings yet

- Everything StarsDocument166 pagesEverything StarsBilly The KidNo ratings yet

- P Block Short NotesDocument22 pagesP Block Short Notesthapliyaldivyanshu274No ratings yet

- Inorganic Chemistry Lab Synthesis and CharacterizationDocument6 pagesInorganic Chemistry Lab Synthesis and CharacterizationÖmer SaygılıNo ratings yet

- ATSDR 2017 SPL Support DocumentDocument12 pagesATSDR 2017 SPL Support DocumentGela EcalNo ratings yet

- Vibration Isolation PDFDocument9 pagesVibration Isolation PDFl8o8r8d8s8i8v8No ratings yet

- Determining Cation Exchange Capacity: A New Procedure For Calcareous and Gypsiferous SoilsDocument5 pagesDetermining Cation Exchange Capacity: A New Procedure For Calcareous and Gypsiferous SoilsM. Yusuf HermawanNo ratings yet

- Benzene Structure and Delocalised Model ExplainedDocument8 pagesBenzene Structure and Delocalised Model ExplainedHisham Jafar AliNo ratings yet

- Analysis of Steady Flow in Pipelines2Document12 pagesAnalysis of Steady Flow in Pipelines2Shafika AliaNo ratings yet