Professional Documents

Culture Documents

Hall

Uploaded by

Muhammad FaheemOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hall

Uploaded by

Muhammad FaheemCopyright:

Available Formats

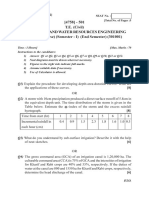

Department of Civil Engineering, N-W.F.

P UET, Peshawar Hall Design (Option 1)

Example 1(a): Design slab and beams of a 90′ × 60′ Hall. The height of Hall is 20′.

Concrete compressive strength (fc′) = 3 ksi.

Steel yield strength (fy) = 40 ksi.

60'

BRICK

MASONRY

WALL

90'

Figure 1: 90′ × 60′ Hall.

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 1 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Solution: Assume structural configuration. Take time to reach to a reasonable

arrangement of beams, girders and columns. It depends on experience. Several

alternatives are possible.

First option for structural arrangement of the given Hall, figure 2:

• Beams spaced at 10′ c/c running along 60′ side of Hall.

• As height of Hall is 20′, assume 18″ thick brick masonry walls.

BEAM

60'

18" BRICK

10' 10' MASONRY

WALL

90'

Figure 2: Structural Arrangement (90′ × 60′ Hall).

Discussion: Various structural configurations…

Discussion: Beam as thickened slab portions…

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 2 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

(1) SLAB DESIGN:

Step No 1: Sizes.

• Minimum thickness of continuous one way slab as given under ACI 9.5.2,

table 9.5 (a) is:

Table 2.1: ACI formulae for continuous one way slab thickness, ACI 9.5.2

Case Slab thickness (in)

End span (one end continuous) l/24

Interior span (both ends continuous) l/28

(i) l = Span length in inches.

(ii)For fy other than 60,000 psi, the values from above formulae shall be multiplied by

(0.4 + fy/100000).

Span length “l” of slab is defined in ACI 8.7

Span length (l):

• According to ACI 8.7.1: Span length of members not built integrally with

support shall be considered as the clear span plus depth of the member, but

need not exceed distance between center of supports.

• According to ACI 8.7.4: Span lengths for slabs built integrally with supports

can be taken equal to clear span, if clear span of slab is not more than 10′.

• ACI 8.7.1 applies to end span.

• ACI 8.7.4 applies to other spans.

Assuming the thickness of slab equal to 6″. Span length for end span of slab will

be equal to clear span plus depth of member (slab), but need not exceed center to

center distance between supports.

Slab

bw = 18" (assumed)

ln = 10 - bw /2= 9.25' ln = 10 - 2*(bw /2) = 8.5'

Beam

10.75' 10'

Figure 3: c/c & clear spans of slab.

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 3 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Table 2.2: Span length of slab (figure 3)

ln + depth of slab Span

Case c/c distance Clear span (ln)

(ACI 8.7.1) length(l)

End span (one end continuous) 10.75′ 9.25' 9.25 + 0.5 = 9.75' 9.75′

Interior spans (both ends

10′ 8.5' n/a 8.5′

continuous)

Table 2.3: Slab thickness calculation according to ACI 9.5.2.

Span Formula for thickness Thickness of slab (in)

End span (one end continuous) l/24 × (0.4+fy/100000) (9.75/24)×(0.4 +40000/100000) ×12=3.9″

Interior span (both ends continuous) l/28 × (0.4+fy/100000) (8.5/28)×(0.4 + 40000/100000)×12=2.9″

l = Span length in inches.

Therefore,

Slab thickness (hf) = 3.9″ (Minimum requirement by ACI 9.5.2.1).

Though any depth of slab greater than 3.9″ can be taken as per ACI minimum

requirement, we will use the same depth as assumed i.e. 6″

Effective depth (d) = hf – 0.75 – (3/8)/2 = 5″ (for #3 main bars)

Slab

Shrinkage reinforcement

6" 5"

Main

steel

reinforcement

10' Beam

Figure 4: Effective depth of slab.

Step No 2: Loading.

Table 2.4: Dead Loads.

Load = γ x thickness

Material Thickness (in) γ (kcf)

(ksf)

Slab 6 0.15 (6/12) × 0.15 = 0.075

Mud 3 0.12 (3/12) × 0.12 = 0.03

Tile 2 0.12 (2/12) × 0.12= 0.02

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 4 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Service Dead Load (D.L) = 0.075 + 0.03 + 0.02 = 0.125 ksf

Service Live Load (L.L) = 40 psf or 0.04 ksf (for Hall)

Class Activity: Calculate live load per square foot on the class room floor

when it is fully occupied.

Service Load (ws) = D.L + L.L = 0.125 + 0.04 = 0.165 ksf

Factored Load (wu) = 1.2D.L + 1.6L.L

= 1.2 × 0.125 + 1.6 × 0.04 = 0.214 ksf

Step No 3: Analysis.

Our Slab system is:

• One-way,

• Clear spans less than 10′, and

• Exterior ends of slab are discontinuous and unrestrained.

Refer to ACI 8.3.3 or page 396, Nilson 13th Ed, following ACI moment

coefficients apply:

1/11 1/16

0 1/12 1/12 1/12

ln = 9.25' ln = 8.5'

19.92 in-k/ft

11.64 in-k/ft

18.36 in-k/ft 15.48 in-k/ft 15.48 in-k/ft

Figure 5: Bending Moment Diagram for slab.

(i) AT INTERIOR SUPPORT (left side of support):

Negative moment (-MLint) = Coefficient × (wuln2)

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 5 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

= (1/12) × {0.214 × (9.25)2}

=1.53 ft-k/ft = 18.36 in-k/ft

(ii) AT INTERIOR SUPPORT (right side of support):

Negative moment (-MRint) = Coefficient × (wuln2)

= (1/12) × {0.214 × (8.5)2}

= 1.29 ft-k/ft = 15.48 in-k/ft

(iii)AT EXTERIOR MID SPAN:

Positive moment (+MMext) =Coefficient × (wuln2)

= (1/11) × {0.214 × (9.25)2}

= 1.66 ft-k/ft = 19.92 in-k/ft

(iv) AT INTERIOR MID SPAN:

Positive moment (+MMint) =Coefficient × (wuln2)

= (1/16) × {0.214 × (8.5)2}

= 0.97 ft-k/ft = 11.64 in-k/ft

Discussion: ACI analysis vs actual conditions for beam support, concepts of hinge,

roller supports etc.

Step No 4: Design.

Slab

Shrinkage reinforcement

6" 5"

Main

steel

reinforcement

10' Beam

Figure 6: Reinforcement Placement in slab.

Asmin = 0.002bhf (for fy 40 ksi, ACI 10.5.4)

= 0.002 × 12 × 6 = 0.144 in2/ft

a = Asminfy/ (0.85fc′b) = 0.144 × 40/ (0.85 × 3 × 12) = 0.188″

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 6 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

ΦMn = ΦAsminfy (d-a/2)

= 0.9 × 0.144 × 40 × (5-0.188/2) = 25.4 in-k/ft

Φ Mn calculated from Asmin is greater than all moments as calculated in Step No 3.

Therefore As = Asmin = 0.144 in2/ft

Using ½″ Φ (#4) {#13, 13 mm}, with bar area Ab = 0.20 in2

Spacing =Area of one bar (Ab)/As

= (0.20 in2/0.144 in2/ft) × 12 = 16.67 in

Discussion: Bar numbers commonly used in slabs…?

Using 3/8″ Φ (#3) {#10, 10 mm}, with bar area Ab = 0.11 in2

Spacing = Area of one bar (Ab)/As

= (0.11 in2/0.144 in2/ft) × 12 = 9.16″ ≈ 9″

Finally use #3 @ 9″ c/c (#10 @ 225 mm c/c). This will work for both Positive and

Negative steel as Asmin governs.

Shrinkage steel or temperature steel (Ast):

Ast = 0.002bhf

Ast = 0.002 × 12 × 6 =0.144 in2/ft

Shrinkage reinforcement is same as main reinforcement, because:

Ast = Asmin = 0.144 in2

• Maximum spacing for main steel reinforcement in one way slab according to

ACI 7.6.5 is minimum of:

(i) 3hf = 3 × 6 =18″

(ii) 18″

Therefore 9″ spacing is O.K.

• Maximum spacing for temperature steel reinforcement in one way slab

according to ACI 7.12.2.2 is minimum of:

(i) 5hf =5 × 6 =30″

(ii) 18″

Therefore 9″ spacing is O.K.

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 7 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

(2) BEAM DESIGN (single span, simply supported):

Data Given:

Exterior supports of beam = 18″ brick masonry wall.

fc′= 3 ksi; fy = 40 ksi

Beams c/c spacing =10′

Step No 1: Sizes.

According to ACI 9.5.2.1, table 9.5 (a):

Minimum thickness of beam (simply supported) = hmin = l/16

l = clear span (ln) + depth of member (beam) ≤ c/c distance between supports

[ACI 8.7]

l n = 60'-0"

Figure 7: Clear span of Beam.

hf

h

hw

bw

Figure 8: Beam cross-section.

Let depth of beam = 5′

ln + depth of beam = 60′ + 5′ = 65′

c/c distance between beam supports = 60 + 2 × (9/12) = 61.5′

Therefore l = 61.5′

Depth (h) = (61.5/16) × (0.4+fy/100000) × 12

= 36.9″ (Minimum requirement by ACI 9.5.2.1).

Though any depth of beam greater than 36.9″ can be taken as per ACI minimum

requirement, we will use the same depth as assumed i.e. 60″

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 8 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Take h = 5′ = 60″

d = h – 3 = 57″

Step No 2: Loads.

Service Dead Load (D.L) = 0.075 + 0.03 + 0.02 = 0.125 ksf (Table 2.3)

Service Live Load (L.L) = 40 psf or 0.04 ksf (for Hall)

Beam is supporting 10′ slab. Therefore load per running foot will be as follows:

Service Dead Load from slab= 0.125 × 10 = 1.25 k/ft

Service Dead Load from beam’s self weight = hwbwγc

= (54 × 18/144) × 0.15 =1.0125 k/ft

Total Service Dead Load = 1.25 + 1.0125 =2.2625 k/ft

Service Live Load = 0.04 × 10 = 0.4 k/ft

ws = D.L +L.L = 1.0125 + 0.4 = 1.4125 k/ft

wu =1.2D.L + 1.6L.L =1.2 × 2.2625 + 1.6 × 0.4 =3.355 k/ft

Step No 3: Analysis.

3.355 k/ft

61.5'

Vu =84.71 k

103.16 k

2

wl /8 =19034 in-k

Figure 9: Shear Force & Bending Moment Diagrams.

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 9 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Mu = wul2/8 (l = span length of beam)

Mu = 3.355 × 61.52/8 = 1586.18 ft-k =1586.18 × 12 = 19034 in-k

d = 57″ = 4.75′

Vmax = 103.16 k

Vu = 84.70 k

Step No 4: Design of beam.

(A) Flexural Design:

Step (a): According to ACI 8.10, beff for T-beam is minimum of:

(i) 16hf + bw = 16 × 6 + 18 =114″

(ii) (c/c span of beam)/4 =(61.5′/4) × 12 =184.5″

(iii)c/c spacing between beams =10′ × 12 =120″

So beff = 114″

Step (b): Check if beam is to be designed as rectangular beam or T-beam.

Trial #1:

(i) Assume a = hf = 6″

As =Mu/ {Φfy (d–a/2)}

As =19034/ {0.9 × 40 × (57–6/2)} = 9.79 in2

(ii) Re-calculate “a”:

a =Asfy/ (0.85fc′beff)

a =9.79 × 40/ (0.85 × 3 × 114) = 1.34″ < hf

Therefore design beam as rectangular beam.

Trial #2:

As =19034/ {0.9 × 40 × (57–1.34/2)} = 9.38 in2

a = 9.38 × 40/ (0.85 × 3 × 114) = 1.29″

This value is close enough to the previously calculated value of “a”,

therefore, As = 9.38 in2, O.K.

Step (c): Check for maximum and minimum reinforcement.

Asmax = ρmaxbwd

ρmax = 0.85β1(fc′/fy) {εu/(εu + εy)}

ρmax = 0.85 × 0.85 × (3/40) × {0.003/(0.003 + 0.005)} = 0.0203

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 10 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

Asmax = 0.0203 × 18 × 57 = 20.83 in2

Asmin = ρminbwd = (200/40000) × 18 × 57 = 5.13 in2

Asmin<As<Asmax, O.K.

Note that ρmin & ρmax can also be found using table A.4, Nelson 13th Ed.

Beam (main reinforcement):

As = 9.38 in2

Using #8, 1″ Φ {#25, 25 mm}, with bar area Ab = 0.79 in2

No. of bars = As/Ab = 9.38/0.79 = 11.87 ≈ 12 bars

Use 12 #8 bars (12 #25 bars, 25 mm).

e Check the capacity of designed beam:

Area of 12 #8 Bars = 12 × 0.79 = 9.48 in2

a = Asfy/ (0.85fc′beff) = 9.48 × 40/ (0.85 × 3 × 114) = 1.30″

d′ = 1.5 + (3/8) + 1 + (1/2) = 3.375″

d = h – d′ = 60 – 3.375 = 56.625″

6"

d

h = 60"

d'

1.5" clear cover b = 18"

Figure 10: Beam section dimensions.

Md = ΦAsfy (d – a/2) = 0.9 × 9.48 × 40 × (56.625 – 1.30/2) = 19103.2 in-k

Md > (Mu = 19034 in-k), O.K.

e Skin Reinforcement:

According to ACI 10.6.7 “If the effective depth d of a beam or joist

exceeds 36 in., longitudinal skin reinforcement shall be uniformly

distributed along both side faces of the member for a distance d /2 nearest

the flexural tension reinforcement. The spacing ssk between longitudinal

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 11 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

bars or wires of the skin reinforcement shall not exceed the least of d/6, 12

in., and 1000Ab/(d – 30). It shall be permitted to include such

reinforcement in strength computations if a strain compatibility analysis is

made to determine stress in the individual bars or wires. The total area of

longitudinal skin reinforcement in both faces need not exceed one-half of

the required flexural tensile reinforcement”.

Figure 11: Skin reinforcement for beams and joists with d > 36 inches.

Maximum area of skin reinforcement allowed by ACI:

Askin, max = Main flexural reinforcement/2 = 9.38/2 = 4.69 in2

Range up to which skin reinforcement is provided:

d/2 = 56.625/2 = 28.3125″

For #6 bar used in skin reinforcement,

ssk is least of:

• d/6 = 56.625/6 = 9.44″

• 12″

• 1000Ab/(d – 30) = 1000×0.44/(56.625 – 30) = 16.53″

Therefore ssk = 9.44″ ≈ 9″

With this spacing, 3 bars on each face are required. And for #6 bar, the

total area of skin reinforcement is:

Askin = 6 × 0.44 = 2.64 in2 < Askin, max = 4.69 in2, O.K

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 12 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

(B) Shear Design:

Vu = 84.71 k

ΦVc = Φ2√ (fc′)bwd = (0.75 × 2 × √ (3000) × 18 × 57)/1000 = 84.29 k

ΦVc < Vu {Shear reinforcement is required}

sd = ΦAvfyd/(Vu – ΦVc)

Using #3, 2 legged stirrups with Av = 0.11 × 2 =0.22 in2}

sd = 0.75 × 0.22 × 40 × 57/(84.71 – 84.29) = 895″

Maximum spacing and minimum reinforcement requirement as permitted by

ACI 11.5.4 and 11.5.5.3 shall be minimum of:

(i) Avfy/(50bw) =0.22 × 40000/(50 × 18) ≈ 9.5″

(ii) d/2 =57/2 =28.5″

(iii) 24″

(iv) Avfy/ 0.75√(fc′)bw = 0.22 × 40000/ {(0.75 × √(3000) × 18} = 11.90″

Other checks:

(a) Check for depth of beam:

ΦVs ≤ Φ8√ (fc′)bwd (ACI 11.5.6.9)

Φ8√ (fc′)bwd = 0.75 × 8 × √ (3000) × 18 × 57/1000 = 337.18 k

ΦVs = (ΦAvfyd)/sd

= (0.75 × 0.22 × 40 × 57)/9.5 = 39.6 k < 337.18 k, O.K.

So depth is O.K. If not, increase depth of beam.

(b) Check if “ΦVs ≤ Φ4√ (fc′)bwd” {ACI 11.5.4.3}:

If “ΦVs ≤ Φ4√ (fc′)bwd”, the maximum spacing (smax) is O.K.

Otherwise reduce spacing by one half.

Φ4√ (fc´)bwd = 0.75 × 4 × √ (3000) × 18 × 57/1000= 168.58 k

ΦVs = (ΦAvfyd)/sd

= (0.75 × 0.22 × 40 × 57)/9.5 = 39.6 k < 168.58 k, O.K.

Arrangement of stirrups in the beam: With #3, 2 legged vertical

stirrups @ 9.5″ c/c (maximum spacing and minimum reinforcement

requirement as permitted by ACI), the shear capacity (ΦVn ) of the

beam will be equal to:

ΦVn = ΦVc + ΦVs

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 13 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

ΦVs = (ΦAvfyd)/smax

ΦVs = (0.75 × 0.22 × 40 × 57/9.5) = 39.6 k

Therefore ΦVn = 84.29 + 39.6 = 123.89 k > (Vu = 87.22 k)

It means that theoretically, from a section at a distance equal to s/2 up

to a section where shear is equal to ΦVc/2, #3, 2 legged vertical

stirrups @ 9.5″ c/c shall be provided. Beyond the value of ΦVc/2, no

shear reinforcement is theoretically required. However # 3, 2 legged

vertical stirrups @ 12″ c/c are recommended to hold the flexural

reinforcement bars.

Vu = 87.22 k

φVc = 84.29 k

φVc /2 = 42.145 k 42.145 k

d = 4.75' 12.56'

s/2 = 4.75"

Theoretically no

#3 @ 9.5" c/c

stirrups needed

#3, 2 legged stirrups @ 12" c/c

Figure 12: Stirrups arrangement.

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 14 of 30

Department of Civil Engineering, N-W.F.P UET, Peshawar Hall Design (Option 1)

(3) DRAFTING:

(I) Slab (S1 and S2):

A A

MT1 MT1

60'-0"

B1

B1

B1

B1

B1

B1

B1

B1

M1 M1

M1 M1

MT1 MT1

S1 S2 S2 S2 S2 S2 S2 S2 S1

90'-0"

Bottom

Panel Depth (in) Mark Mark Top reinforcement

Reinforcement

S1 6" M1 3/8" φ @ 9" c/c MT1 3/8" φ @ 9" c/c Non continuous End

S2 6" M1 3/8" φ @ 9" c/c MT1 3/8" φ @ 9" c/c Continuous End

#3 @ 18" c/c (supporting bars or chairs)

MT1

M1 (Shrinkage Reinforcement)

MT1

L1 /4 = 2.5' L1 /3 = 3.25' L2 /3 = 3' L2 /3 = 3' L2 /3 = 3'

#3 @ 18" c/c (supporting bars or chairs) hf =6"

M1 (Main steel Reinforcement)

L = 9.25' L2= 8.5'

1

Section A-A. Refer to figure 5.15, chapter 5, Nelson 13th Ed for bar cutoff.

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 15 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

#3, 2 legged

#3, 2 legged vertical stirrups @ 9.5" c/c #3, 2 legged vertical stirrups @ 9.5" c/c

vertical stirrups @ 12" c/c

A B C Skin reinforcement

2 #8 bars

sd /2 = 4.75" #6 @ 9" c/c

(6 + 6) #8 Bars 6 #8 Bars

A B C

Greatest of d or 12d b= 3.75' #8 Spacer bars @ 3' c/c

0.14L - (greatest of d or 12d b)= 4.75'

0.14L = 8.375'

17'-6" 25'-0" 17'-6"

L = 60'-0"

Beam (B1) Details

(a) Use graph A2 to find location of points where bars can be bent up or cutoff for simply supported beams uniformly loaded.

(b) Approximate locations of points where bars can be bent up or cotoff for continuous beams uniformly loaded and built

integrally with their supports according to the coefficients in ACI code.

2 #8 Bars 2 #8 Bars 2 #8 Bars

6" 6" 6"

#3, 2 legged #3, 2 legged #3, 2 legged

60" stirrups @ 9.5" c/c 60" stirrups @ 9.5" c/c 60" stirrups @ 12" c/c

(6+6) #8 Bars (6+6) #9 Bars

6 #8 Bars

Skin Reinforcement

#6 @ 9" c/c

18" 18" 18"

SECTION A-A SECTION B-B SECTION C-C

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 15 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Appendix A

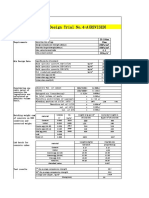

Comparison of ACI coefficients analysis with analysis of SAP2000 (finite element

method based software): Assumptions made in SAP model are,

a. Brick masonry walls are modeled as hinged support.

b. Slab is modeled as shell element.

c. Beams are modeled as frame elements.

Figure 13: Plan view of hall showing variation in slab moment (kip-in/in). Marked

points show the locations picked for comparison purpose.

Table 2.5: Slab moments

ACI 318-02 See figure SAP Results

Percentage Difference

(kip-in/in) 9 (k-in/in)

M (at wall) 0 MI 0.02 -

MF 4.59 64

M (at ext. mid span) 1.66 MG 3.40 51

MH 1.55 -7

MB 1.47 -4

M (at int. support) 1.53 MC 1.48 -4

ME 0.617 -60

MA 1.04 7

M (at int. mid span) 0.97

MD 1.2 19

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 16 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Table 2.6: Simply supported beam moment.

ACI 318-02 SAP Results Percentage Difference

M,mid span (k-in) 19034 18987.253 0.25

Conclusions:

• There is more variation between SAP and ACI in slab moments.

• Less variation in beam moment.

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 17 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Appendix B

Relevant Pictures

Figure 14: Supporting chairs for slab reinforcement.

Figure 15: Reinforcement in slab.

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 18 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Figure 16: Flexure and shear reinforcement in a beam.

Figure 16: Local arrangement for bar bending.

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 19 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Appendix C

Minimum uniformly distributed live load:

Representative values of minimum live loads to be used in a wide variety of buildings are found

in Minimum Design Loads for Buildings and Other Structures, SEI/ASCE 7-02, American Society

of Civil Engineers, a portion of which is reproduced in table C1. The table gives uniformly

distributed live loads for various types of occupancies; these include impact provisions where

necessary. These loads are expected maxima and considerably exceed average values.

Table C1: Minimum uniformly distributed live loads.

Live

Occupancy or Use Load, Live

psf Load, psf

Apartments (see residential) Dining rooms and restaurants 100

Access floor systems Dwellings (see residential)

Office use 50 Fire escapes 100

Computer use 100 On single-family dwellings only 40

Armories and drill rooms 150 Garages (passenger cars only) 40

Assembly areas and theaters Trucks and buses (see foot note)

Grandstands (see stadium and arena

Fixed seats (fastened to floors) 60

bleachers)

Gymnasiums, main floors, and

Lobbies 100 100

balconies

Movable seats 100 Hospitals

Platforms (assembly) 100 Operating rooms, laboratories 60

Stage floors 150 Private rooms 40

Balconies (exterior) 100 Wards 40

On one and two family residences

60 Corridors above first floor 80

only, and not exceeding 100ft2

Bowling alleys, poolrooms, and

75 Hotels (see residential)

similar recreational areas

Catwalks for maintenance access 40 Libraries

Corridors Reading rooms 60

First floor 100 Stack rooms 150

Other floors, same as occupancy

Corridors above first floor 80

served except as indicated

Dance halls and ballrooms 100 Manufacturing

Decks (patio and roof) Light 125

Same as area served, or for the

Heavy 250

type of occupancy accommodated

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 20 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Table C1: (Continued)

Live

Occupancy or Use Load, Occupancy or Use Live

psf Load, psf

Sidewaks, vehicular

Marquees and Canopies 75 driveways, and yards subject 250

to trucking

Office Buildings Stadium and arenas

File and computer rooms shall be

designed for heavier loads based on Pleachers 100

anticipated occupancy

Fixed seats (fastened to

Lobbies and first-floor corridors 100 60

floors)

Offices 50 Stairs and exitways 100

One and two-family

Corridors above first floor 80 40

residences only

Penal institutions Storage areas above ceilings 20

Storage warehouses (shall be

designed for heavier loads if

Cell blocks 40

required for anticipated

storage)

Corridors 100 Light 125

Residential Heavy 250

Dwellings (one and two-family) Stores

Uninhabitable attics without storage 10 Retail

Uninhabitable attics with storage 20 First floor 100

Habitable attics and sleeping areas 30 Upper floors 73

All other areas except stairs and

40 Wholesale, all floors 125

balconies

Walkways and elevated

Hotels and multifamily houses platforms (other than 60

exitways)

Private rooms and corridors serving Yards and terraces,

40 100

them pedestrians

Public rooms and corridors serving

100

them

Reviewing stands, grandstands and

100

bleachers

Schools

Classrooms 40

Corridors above first floor 80

First-floor corridors 100

a

Garages accommodating trucks and buses shall be designed in accordance with an approved method that contains provisions for

truck and bus loadings.

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 21 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Appendix D

Various Structural Configurations

60'

90'

90' x 60' Hall

60'

90'

90' x 60' Hall

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 22 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

60'

90'

90' x 60' Hall

60'

90'

90' x 60' Hall

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 23 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

60'

90'

90' x 60' Hall

60'

90'

90' x 60' Hall

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 24 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

60'

90'

90' x 60' Hall

60'

90'

90' x 60' Hall

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 25 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

60'

90'

90' x 60' Hall

60'

90'

90' x 60' Hall

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 26 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

60'

90'

90' x 60' Hall

60'

90'

90' x 60' Hall

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 27 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

Appendix E

Cutoff or bend points for bars in approximately equal spans with uniformly

distributed loads:

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 28 of 30

Department of Civil Engineering, N-W.F.P UET Peshawar Hall Design (Option 1)

References

¾ Design of Concrete Structures by Nilson, Darwin and Dolan (13th ed.)

¾ ACI 318-02/05

Prof Dr. Qaisar Ali (http://www.eec.edu.pk) Page 29 of 30

You might also like

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Design of Concrete Structures - I Question PaperDocument3 pagesDesign of Concrete Structures - I Question PaperSourav Sil50% (2)

- Everything You Need to Know About Pile FoundationsDocument45 pagesEverything You Need to Know About Pile FoundationsGoutam NandiNo ratings yet

- CE4070 Structural Modelling Yield Line Analysis of Slab IETDocument18 pagesCE4070 Structural Modelling Yield Line Analysis of Slab IETkartheepan100% (1)

- C1-Analytical Methods Assignment 1Document2 pagesC1-Analytical Methods Assignment 1JP de AzevedoNo ratings yet

- T.E Question Papers (2012 Pattern) May 2015Document297 pagesT.E Question Papers (2012 Pattern) May 2015Prof. Avinash MahaleNo ratings yet

- Important RCC Questions-Short and LongDocument15 pagesImportant RCC Questions-Short and LongmailjoelsamuelNo ratings yet

- Cont Beam DesignDocument76 pagesCont Beam Designsiti HawaNo ratings yet

- Ce 208Document58 pagesCe 208julesNo ratings yet

- Surrey ENGM030 Unit 2a PresentationDocument38 pagesSurrey ENGM030 Unit 2a PresentationPhilip Yap100% (2)

- M. Tech. (Structural Engineering) SCHEME OF EXAMINATIONDocument26 pagesM. Tech. (Structural Engineering) SCHEME OF EXAMINATIONAjay AjaiNo ratings yet

- Reinforced Concrete - I-Notes and ProblemsDocument199 pagesReinforced Concrete - I-Notes and ProblemsAbrham Teklebrhan100% (1)

- Introduction To Shell TheoryDocument45 pagesIntroduction To Shell TheorySurendraBhatta100% (1)

- Progressive Collapse Analysis of Steel Braced FramesDocument9 pagesProgressive Collapse Analysis of Steel Braced FrameswalaywanNo ratings yet

- Memo STRUCTURAL ANALYSIS II - SAN2601 Assignments 2020Document28 pagesMemo STRUCTURAL ANALYSIS II - SAN2601 Assignments 2020Rachel Du PreezNo ratings yet

- Theory II, March 2015Document26 pagesTheory II, March 2015amangirmaNo ratings yet

- Reinforced Concrete - I DMU Lecture NotesDocument206 pagesReinforced Concrete - I DMU Lecture NotesAntenehNo ratings yet

- Reinforced Concrete Slab DesignDocument29 pagesReinforced Concrete Slab DesignMapanguriSitoeNo ratings yet

- Beams On Elastic FoundationDocument20 pagesBeams On Elastic FoundationShashi Bhushan KumarNo ratings yet

- Chapter 2 - Classification of Cross-SectionDocument20 pagesChapter 2 - Classification of Cross-SectionMuhd Zuhairi100% (2)

- Theory of Structure II, NewDocument3 pagesTheory of Structure II, NewSujan Singh50% (2)

- Investigation of Omo River Bridge CollapseDocument5 pagesInvestigation of Omo River Bridge Collapseambachew abebeNo ratings yet

- CE-411 Structural Analysis and Design II (2010-2016) PDFDocument28 pagesCE-411 Structural Analysis and Design II (2010-2016) PDFAhmed RolinNo ratings yet

- Final Exam of Structural Behavior and Analysis IDocument3 pagesFinal Exam of Structural Behavior and Analysis INeven Ahmed HassanNo ratings yet

- Chapter One in Elastic Moment RedistributionDocument8 pagesChapter One in Elastic Moment RedistributionHaftom GebreegziabiherNo ratings yet

- Earthquake Analysis of Linear SystemsDocument67 pagesEarthquake Analysis of Linear SystemsPrantik Adhar Samanta67% (3)

- Slab Design DR - Zahid Ahmad SiddiqiDocument6 pagesSlab Design DR - Zahid Ahmad SiddiqiNoor MohdNo ratings yet

- Foundation Engineering CourseDocument193 pagesFoundation Engineering CourseamandeepsuperanNo ratings yet

- Week 5 - Practice Problem (Solution)Document6 pagesWeek 5 - Practice Problem (Solution)benzhuNo ratings yet

- Study Guide 001 (Both) For TST271ZDocument332 pagesStudy Guide 001 (Both) For TST271Zstevens50% (2)

- Design of Retaining Walls (B&W)Document29 pagesDesign of Retaining Walls (B&W)Abdul SalamNo ratings yet

- RC Practice Set 2 2016 SolutionsDocument5 pagesRC Practice Set 2 2016 SolutionsSayed YusufNo ratings yet

- Traffic Characterization MethodsDocument11 pagesTraffic Characterization MethodsAlejandro GonzalezNo ratings yet

- Two Way Slab DesignDocument16 pagesTwo Way Slab DesignMandar NadgaundiNo ratings yet

- Ce2404-Prestressed Concrete StructuresDocument1 pageCe2404-Prestressed Concrete StructuresDhivya RamachandranNo ratings yet

- Finite Element Modelling of Reinforced Concrete Frame PDFDocument109 pagesFinite Element Modelling of Reinforced Concrete Frame PDFArun Das PhNo ratings yet

- Two-Way Concrete Slab Analysis and DesignDocument81 pagesTwo-Way Concrete Slab Analysis and DesignBizimenyera Zenza TheonesteNo ratings yet

- Chapter 1 - Introduction To RCDocument34 pagesChapter 1 - Introduction To RCMARVINNo ratings yet

- DDM - Slab With Beams (Lecture)Document222 pagesDDM - Slab With Beams (Lecture)Farag Hussein AlhassiNo ratings yet

- SDMF Question Paper 1Document2 pagesSDMF Question Paper 1G. SASIDHARA KURUPNo ratings yet

- Plastic analysis of frame structuresDocument65 pagesPlastic analysis of frame structuresgirma kebedeNo ratings yet

- Structural Analysis II Notes Rev1Document106 pagesStructural Analysis II Notes Rev1Chris Jansen Van Rensburg100% (1)

- Chapter Five, Torsion of BeamsDocument7 pagesChapter Five, Torsion of BeamsTemesgenAbiyNo ratings yet

- Deflection of BeamsDocument28 pagesDeflection of BeamsishwaryaNo ratings yet

- TR 334 Tutorial-1Document5 pagesTR 334 Tutorial-1Adaminovic MrishoNo ratings yet

- 2017 Winter Model Answer Paper PDFDocument12 pages2017 Winter Model Answer Paper PDFabdul rehman syed parvezNo ratings yet

- Design in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)Document66 pagesDesign in Reinforced Concrete: Prepared By: M.N.M Azeem Iqrah B.SC - Eng (Hons), C&G (Gdip)rashmiNo ratings yet

- Assignment # 4Document2 pagesAssignment # 4Anonymous Vx9KTkM8nNo ratings yet

- AssignmentDocument2 pagesAssignmentWudu Mulat AhmedNo ratings yet

- CE 402 - Module 2Document62 pagesCE 402 - Module 2lakshmi dileep100% (1)

- Gravity LoadDocument24 pagesGravity Loadapi-19884175100% (2)

- Advanced Design of Concrete StructuresDocument24 pagesAdvanced Design of Concrete StructuresVarun. hrNo ratings yet

- Chapter 1 - IntroductionDocument26 pagesChapter 1 - IntroductionEvo LanzNo ratings yet

- Surrey ENGM030 Unit 2 NoteDocument29 pagesSurrey ENGM030 Unit 2 NotePhilip YapNo ratings yet

- Short Answer Questions For Theory of Structures-I (Structural Analysis-I) in B.E. (Civil) - UIT-RGPV BHOPALDocument4 pagesShort Answer Questions For Theory of Structures-I (Structural Analysis-I) in B.E. (Civil) - UIT-RGPV BHOPALSantosh Kumar100% (1)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- Basement: ME-P2-BS-1-FO099 Basement Floor Plan Fuel Oil Layout 1:100 A0Document5 pagesBasement: ME-P2-BS-1-FO099 Basement Floor Plan Fuel Oil Layout 1:100 A0rajatNo ratings yet

- Precast Concrete Staircases and Landings PDFDocument12 pagesPrecast Concrete Staircases and Landings PDFjurisco100% (1)

- 2792CP Stone SlabDocument11 pages2792CP Stone SlabKhan SakNo ratings yet

- 8 Stairs PDFDocument6 pages8 Stairs PDFMasoudRmdnNo ratings yet

- Dosage TableDocument5 pagesDosage TableAarish KhanNo ratings yet

- HDMF or Pag IBIG FINAL LIST OF ACQUIRED ASSETS As of August 31 2011 Unoccupied PDFDocument43 pagesHDMF or Pag IBIG FINAL LIST OF ACQUIRED ASSETS As of August 31 2011 Unoccupied PDFChristian D. Orbe67% (3)

- RFP Womens Homeless ShelterDocument4 pagesRFP Womens Homeless ShelteraialosangelesNo ratings yet

- Classic Lite Rh90: Texture and Grid IntersectionsDocument2 pagesClassic Lite Rh90: Texture and Grid Intersectionszikrillah1No ratings yet

- Ns2-Xb02-p0uyq-174247 - Vehicle Repair Shop - Structural Misc Detail - Rev.0Document1 pageNs2-Xb02-p0uyq-174247 - Vehicle Repair Shop - Structural Misc Detail - Rev.0Doan Ngoc DucNo ratings yet

- Essential (2019)Document2 pagesEssential (2019)namita nagarNo ratings yet

- Resume Adam WilliamsDocument1 pageResume Adam WilliamsAdam WilliamsNo ratings yet

- Ce36-Construction Techniques, EquipmentsDocument27 pagesCe36-Construction Techniques, EquipmentshelloitskalaiNo ratings yet

- Eave To Slab Detail Valley Gutter Detail Ridge Detail: Scale 1:10Document1 pageEave To Slab Detail Valley Gutter Detail Ridge Detail: Scale 1:10Jordan BrownNo ratings yet

- Data Sheet - APE SEALKOTE - Waterproof - Latex Bitumen EmulsionDocument2 pagesData Sheet - APE SEALKOTE - Waterproof - Latex Bitumen EmulsionMochamad BhadawiNo ratings yet

- Urban Planning Theory and Practice - M.pratap Rao ContentsDocument2 pagesUrban Planning Theory and Practice - M.pratap Rao ContentsNupur Bhadra0% (3)

- FLYT (Selected Projects 1999-2015)Document106 pagesFLYT (Selected Projects 1999-2015)Frven Lim Yew TiongNo ratings yet

- Architectural SymbolDocument11 pagesArchitectural SymbolJEH222No ratings yet

- Minor Works - Category - 15Document1 pageMinor Works - Category - 15Abraham ShumNo ratings yet

- Stair CaseDocument14 pagesStair CaseSubhajyoti DasNo ratings yet

- Sample Field ReportDocument6 pagesSample Field ReportIsabellaPeriginaNo ratings yet

- Deconstructivism - WikipediaDocument9 pagesDeconstructivism - WikipediaShrishank RudraNo ratings yet

- Landscape Design Styles-1Document13 pagesLandscape Design Styles-1Shubham ZarkarNo ratings yet

- OBJ Datastream PDFDocument104 pagesOBJ Datastream PDFБјелић ТеодораNo ratings yet

- Cold Rooms Amp Insulated Panels TSSCDocument32 pagesCold Rooms Amp Insulated Panels TSSCZar KhariNo ratings yet

- Desert Tower Level 35-45 GuideDocument16 pagesDesert Tower Level 35-45 GuideIqbal BaihaqiNo ratings yet

- Topic 4 - Precast Concrete Connections For Framed Buildings - 2Document90 pagesTopic 4 - Precast Concrete Connections For Framed Buildings - 2Abdullah RamziNo ratings yet

- Hydro Building Systems Middle East: Fax: Tel: (+973) 17203878 (+973) 17229299Document16 pagesHydro Building Systems Middle East: Fax: Tel: (+973) 17203878 (+973) 17229299atif_aman123No ratings yet

- DRG 02Document1 pageDRG 02Palak BhatiaNo ratings yet

- Lab Concrete Mix Design C15-C40Document19 pagesLab Concrete Mix Design C15-C40Soundar Pachiappan100% (1)

- Ethical Consideration For A Better Collaboration Between Architect and Engineer - Design of Hospital BuildingsDocument5 pagesEthical Consideration For A Better Collaboration Between Architect and Engineer - Design of Hospital BuildingsNURULNo ratings yet