Professional Documents

Culture Documents

Knauf E816696 1

Uploaded by

Ahmet_Cullu_681Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Knauf E816696 1

Uploaded by

Ahmet_Cullu_681Copyright:

Available Formats

Pipe & Tank Insulation

Submittal Date _________________

Description Technical Data Application

Knauf Pipe and Tank Insulation is a semi-rigid fiber Temperature Range (ASTM C 411) For easy installation of Knauf Pipe and Tank Insulation

glass board in roll form faced with a factory-applied • Operating temperature to 850°F (454°C). simply follow these guidelines.

FSK or ASJ vapor retarder or a glass mat facing. The • Refer to the Stretch-out Chart (back page) to find

Compressive Strength (ASTM C 165)

glass fibers are adhered perpendicular to the jacketing the appropriate length to cut for the specific pipe

• Not less than 150 PSF (7.18 kPa) at 10% deforma-

for flexibility and easy installation. size. Be sure to add an additional 2" (51 mm) to 4"

tion for 2" (51 mm) thickness.

(102 mm) for your staple flap.

Application • Not less than 275 PSF (13.2 kPa) at 10% deforma-

tion for 3" (76 mm). • Cut your stretch-out length and wrap the material

Knauf Pipe and Tank Insulation is typically used on around the iron pipe to ensure the proper fit.

tanks, vessels and large-diameter pipes. It can be used Water Vapor Transmission

for any curved or irregular surfaces that require finished • Staple the lap on 3" (76 mm) centers with outward

(ASTM E 96, Procedure A) clinching staples.

characteristics of rigid fiber glass insulation. • Both FSK and ASJ vapor retarders have a

maximum water vapor transmission rate of .02 • Butt edges shall be firmly secured, and butt strips

Features and Benefits perms. matching the jacket shall be applied at each joint.

Excellent Thermal Properties Note

Puncture Resistance (TAPPI Test T803)

• Low thermal conductivity ratings to 850°F (454°C). When using Knauf Pipe and Tank Insulation on below

(Beach Units)

Low-Cost Installation • FSK facing: 25 ambient piping, appropriate UL approved vapor retar-

• Flexible. dant adhesives should be applied on all longitudinal

• ASJ facing: 50 and circumferential joints before taping.

• Easy to handle and fabricate.

Surface Burning Characteristics Caution

Inventory Savings • Does not exceed 25 Flame Spread, 50 Smoke

• No need to stock multiple sizes. Fiber glass may cause temporary skin irritation. Wear

Developed when tested in accordance with ASTM E long-sleeved, loose-fitting clothing, head covering,

• Various thicknesses available to meet all your pipe 84, NFPA 225 and UL 723. gloves and eye protection when handling and applying

and tank insulation needs. Linear Shrinkage (ASTM C 356) material. Wash with soap and warm water after han-

Resists Damage • Negligible. dling. Wash work clothes separately and rinse washer.

• Tough and durable. A disposable mask designed for nuisance type dusts

• Resists damage in shipment, during and after Application and Specification Guidelines should be used where sensitivity to dust and airborne

installation. Precautions particles may cause irritation to the nose or throat.

• ASJ and FSK jackets should not be used if outer-

Resists Microbial Growth Fiber Glass and Mold

surface temperature exceeds 150°F (66°C).

• Does not promote the growth of fungi or bacteria. Fiber glass insulation will not sustain mold growth.

• During initial heat-up to operating temperatures However, mold can grow on almost any material

• Will not rot.

above 350°F (177°C), a slight odor and some when it becomes wet and contaminated with organic

• Will not sustain vermin. smoke may be given off as a portion of the bonding materials. Carefully inspect any insulation that has

Non-Corrosive material used in the insulation begins to undergo a been exposed to water. If it shows any sign of mold

• Will not accelerate the corrosion of aluminum, steel controlled decomposition. it must be discarded. If the material is wet but shows

or copper. • If natural convection is not adequate in confined no evidence of mold, it should be dried rapidly and

areas, forced ventilation should be provided in order thoroughly. If it shows signs of facing degradation from

Specification Compliance to protect against any harmful fumes and vapors wetting, it should be replaced.

• ASTM C 795 that might be generated.

• NRC 1.36 • Care must also be taken when using sealants, Notes

• MIL-I-24244C solvents or flammable adhesive during installation. The chemical and physical properties of Knauf Pipe

• ASTM C 1136 and Tank Insulation represent typical average values

Storage

– Type I, II, III, IV (ASJ) determined in accordance with accepted test methods.

• Protect stored insulation from water damage or

The data is subject to normal manufacturing variations.

– Type II, IV (FSK) other abuse.

The data is supplied as a technical service and is sub-

• HH-B-100B (jackets) • Protect from welding sparks and open flame. ject to change without notice. References to numerical

– Type I and II (ASJ) • Cartons are not designed for outside storage. flame spread ratings are not intended to reflect hazards

– Type II (FSK) Preparation presented by these or any other materials under actual

• HH-I-558C; Form A, Class 3 • Apply Knauf Pipe and Tank Insulation on clean, dry fire conditions.

surfaces. Check with your Knauf sales representative to assure

information is current.

www.KnaufInsulation.com Knauf Insulation GmbH One Knauf Drive, Shelbyville, IN 46176 Tel: (800) 825-4434 ext. 8283 FAX: (317) 398-3675

© 2006 Knauf Insulation GmbH.

PE-SS-7 05-06

Pipe & Tank Insulation

Submittal Date _________________

Stretch-Outs*

Thickness

Nominal Iron Iron Pipe

Pipe Size Outside Diameter 551" (25 mm) 551 /2"1

(38 mm) 552" (51 mm) 553" ( 76 mm)

10" (254 mm) 103/4" (273 mm) 5401/8" (1019 mm) 5431/4" (1099 mm) 5463/8" (1178 mm) 5525/8" (1337 mm)

12" (305 mm) 123/4" (324 mm) 5463/8" (1178 mm) 5491/2" (1257 mm) 5523/4" (1340 mm) 559" (1499 mm)

14" (356 mm) 14" (356 mm) 550 /8"

3

(1280 mm) 553 /2"1

(1359 mm) 5565/8" (1438 mm) 5627/8" (1597 mm)

16" (406 mm) 16" (406 mm) 556 /8"

5

(1438 mm) 559 /4"3

(1518 mm) 562 /8"

7

(1597 mm) 569 /8"

1

(1756 mm)

18" (457 mm) 18" (457 mm) 5627/8" (1597 mm) 566" (1676 mm) 5691/4" (1756 mm) 5751/2" (1918 mm)

20" (508 mm) 20" (508 mm) 569 /8"

1

(1756 mm) 572 /8"3

(1838 mm) 575 /2"

1

(1918 mm) 581 /4"

3

(2076 mm)

22" (559 mm) 22" (559 mm) 5751/2" (1918 mm) 5785/8" (1997 mm) 5813/4" (2076 mm) 588" (2235 mm)

24" (610 mm) 24" (610 mm) 581 /4"

3

(2076 mm) 584 /8"7

(2156 mm) 588" (2235 mm) 594 /8"

3

(2397 mm)

26" (660 mm) 26" (660 mm) 588" (2235 mm) 5911/8" (2315 mm) 5943/8" (2397 mm) 1005/8" (2556 mm)

28" (711 mm) 28" (711 mm) 5943/8" (2397 mm) 5971/2" (2477 mm) 1005/8" (2556 mm) 1067/8" (2715 mm)

30" (762 mm) 30" (762 mm) 100 /8"

5

(2556 mm) 103 /4"3

(2635 mm) 106 /8"

7

(2715 mm) 113 /8"

1

(2873 mm)

32" (813 mm) 32" (813 mm) 1067/8" (2715 mm) 110" (2794 mm) 1131/8" (2873 mm) 1191/2" (3035 mm)

34" (864 mm) 34" (864 mm) 113 /8"

1

(2873 mm) 116 /4"1

(2953 mm) 119 /2"

1

(3035 mm) 125 /4"

3

(3194 mm)

36" (914 mm) 36" (914 mm) 1191/2" (3035 mm) 1225/8" (3115 mm) 1253/4" (3194 mm) 132" (3353 mm)

38" (965 mm) 38" (965 mm) 125 /4"

3

(3194 mm) 128 /8"7

(3273 mm) 132" (3353 mm) 138 /4"

1

(3512 mm)

40" (1016 mm) 40" (1016 mm) 132" (3353 mm) 1351/8" (3432 mm) 1381/4" (3512 mm) 1445/8" (3673 mm)

42" (1067 mm) 42" (1067 mm) 138 /4"

1

(3512 mm) 141 /2"1

(3594 mm) 144 /8"

5

(3673 mm) 150 /8"

7

(3832 mm)

*Additional 2" (51 mm) to 4" (102 mm) should be added for lap.

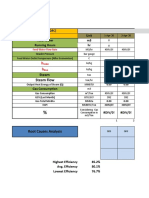

Thermal Efficiency (ASTM C 177) Forms Available

Thickness Width† Length

.70 .101 1" (25 mm) 48' (14.63 m)

Thermal Conductivity (Sl Units ) (W/m • oC)

11/2" (38 mm) 32' (9.75 m)

Thermal Conductivity (BTU-in./hr • ft • oF)

.60 .086

2

2" (51 mm) 24' (7.32 m)

.50 .072

2 1 /2 " (64 mm) 36" (914 mm) 19' (5.79 m)

.40 .057

3" (76 mm) 16' (4.88 m)

.30 .043 3 1 /2 " (89 mm) 14' (4.67 m)

.20 .029 4" (102 mm) 12' (3.66 m)

†

Cut-to-length sizes also available.

0 100 200 300 400 500 (oF)

38 93 149 204 260 (oC)

Mean T emperature

Mean Temperature k k (SI)

100°F (38°C) .26 .037

200°F (93°C) .35 .050

300°F (149°C) .45 .065

400°F (204°C) .57 .082

500°F (260°C) .75 .108

You might also like

- SmartPlant3D 000Document2 pagesSmartPlant3D 000Ahmet_Cullu_681No ratings yet

- Introduction To BS9999 - 2008 - Maurice JohnsonDocument54 pagesIntroduction To BS9999 - 2008 - Maurice JohnsonAhmet_Cullu_681100% (3)

- 06HMT047-ARCMASTER Sell SheetLoResDocument2 pages06HMT047-ARCMASTER Sell SheetLoResAhmet_Cullu_681No ratings yet

- CockpitsDocument20 pagesCockpitsBGSLCNo ratings yet

- JM-CI-177 Pipe and Equipment Insulation Product Selection GuideDocument4 pagesJM-CI-177 Pipe and Equipment Insulation Product Selection GuideAhmet_Cullu_681No ratings yet

- BTE Internal Floating Roof Input Data Sheet: ST ND RDDocument1 pageBTE Internal Floating Roof Input Data Sheet: ST ND RDAhmet_Cullu_681No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- DDFC Boiler Effeciency AnalysisDocument21 pagesDDFC Boiler Effeciency AnalysisPublic DemandNo ratings yet

- Watford 2001Document7 pagesWatford 2001CARDIO 2019No ratings yet

- Deaerator Post MCQ'sDocument50 pagesDeaerator Post MCQ'sEhtisham ul haqNo ratings yet

- ChapterEight1 - 20 of SpectrocopicDocument20 pagesChapterEight1 - 20 of SpectrocopicHung Le VanNo ratings yet

- Compressor AM2Document3 pagesCompressor AM2Hendra KurniawanNo ratings yet

- Gas Arc Welding - GMAW and GTAW Gas Arc Welding - GMAW and GTAWDocument3 pagesGas Arc Welding - GMAW and GTAW Gas Arc Welding - GMAW and GTAWJulioNo ratings yet

- T-Technology Pintér WorksDocument5 pagesT-Technology Pintér Worksmig232323No ratings yet

- Calcium-Magnesium by EDTA TitrationDocument5 pagesCalcium-Magnesium by EDTA TitrationnisscriNo ratings yet

- (Alan R. Katritzky, Otto Meth-Cohn, and Charles W.Document1,287 pages(Alan R. Katritzky, Otto Meth-Cohn, and Charles W.Ganesh KashinathNo ratings yet

- Method of Statement For FRP Lining TankDocument5 pagesMethod of Statement For FRP Lining Tankmoytabura96100% (3)

- Bamboo+Alumina CompositeDocument5 pagesBamboo+Alumina CompositeAmmineni Syam PrasadNo ratings yet

- Basf Master BatchDocument6 pagesBasf Master Batchapi-3842599100% (1)

- Marine Adhesives Product CatalogueDocument35 pagesMarine Adhesives Product CatalogueDaniela TomovaNo ratings yet

- Graphene Quantum Dot, S: Presented by Fiza Aziz Roll No 151226 Department of PhysicsDocument25 pagesGraphene Quantum Dot, S: Presented by Fiza Aziz Roll No 151226 Department of PhysicsFiza AzizNo ratings yet

- DOC316.53.01122 11ed PDFDocument6 pagesDOC316.53.01122 11ed PDFJean Carlos ArangoNo ratings yet

- HLBDocument6 pagesHLBDracu MemeNo ratings yet

- PS-08 Painting System MSDSDocument20 pagesPS-08 Painting System MSDSGiorgi KOGOSHVILINo ratings yet

- Gas Laws Worksheet #2 Boyles Charles and CombinedDocument3 pagesGas Laws Worksheet #2 Boyles Charles and CombinedJeromeNo ratings yet

- Chemistry Revision Guide For IGCSE Coordinated Science Chemistry Revision Guide For IGCSE Coordinated ScienceDocument20 pagesChemistry Revision Guide For IGCSE Coordinated Science Chemistry Revision Guide For IGCSE Coordinated SciencekarlabrooksNo ratings yet

- RESONANCE Haloalkanes & HaloarenesDocument36 pagesRESONANCE Haloalkanes & HaloarenesAlok pandey67% (6)

- Prospectus Syllabus: Post Graduate Diploma Course in Food Analysis and Quality AssuranceDocument19 pagesProspectus Syllabus: Post Graduate Diploma Course in Food Analysis and Quality Assurancepriyanka thapliyal100% (1)

- Effect of Temperature On Sliding Wear of AISI 316 L (N) Stainless Steel  " Analysis of Measured Wear and Surface Roughness of Wear TracksDocument7 pagesEffect of Temperature On Sliding Wear of AISI 316 L (N) Stainless Steel  " Analysis of Measured Wear and Surface Roughness of Wear TracksSamir BoseNo ratings yet

- Rser D 16 02436R1Document88 pagesRser D 16 02436R1Jitender KaushalNo ratings yet

- Bunting Powered Bronze Bushings PDFDocument56 pagesBunting Powered Bronze Bushings PDFFitunopNo ratings yet

- Nutritional GSO PDFDocument14 pagesNutritional GSO PDFjacky786No ratings yet

- Practical Physical Chemistry (II) Laboratory ManualDocument25 pagesPractical Physical Chemistry (II) Laboratory Manualabdu30esNo ratings yet

- DSM-0295.0 Al2O3 NiAl CermetDocument3 pagesDSM-0295.0 Al2O3 NiAl CermetApichitNo ratings yet

- Bpharm 5 Sem Industrial Pharmacy 1 bp502t 2020Document1 pageBpharm 5 Sem Industrial Pharmacy 1 bp502t 2020Amol TupeNo ratings yet

- AYJR 2022 July - Shift 2Document70 pagesAYJR 2022 July - Shift 2आस्तिक शर्माNo ratings yet

- Mahle Air Filter For KPC: Industrial FiltrationDocument2 pagesMahle Air Filter For KPC: Industrial Filtrationsuraj pandeyNo ratings yet