Professional Documents

Culture Documents

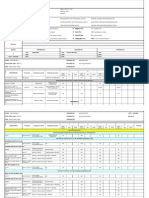

Cement Machinery Gearbox Inspection Checklist

Uploaded by

Praveenad047Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cement Machinery Gearbox Inspection Checklist

Uploaded by

Praveenad047Copyright:

Available Formats

Client: ShanDong Binani Supplier: CITIC Location: LuoYang, PRC Sheet 1 of 1

The below given inspection check list proposed to take in to account with utmost priority by the supplier so that cement

manufacturing machineries (CMM) could met their intended purpose to set up new coming project:

ITEM: LARGE SIZE GEAR BOX

Sr. No. Characteristics Type of Check Reference STD Acceptance Criteria TPIA

1 Raw materials including housing Visual Applicable standard Applicable standard R

2 Forged gear blank and shaft Visual Applicable standard Applicable standard R

Heat treatment of gear blank and To achieve the required

3 Visual R

shaft mechanical properties

4 NDT of gear blank and shaft UT ASTM A 388 Refer note 1 below R

5 Mechanical & Chemical test Measurement Applicable standard Applicable standard R

Establishment of WPS + PQR +

6 Visual ASME Section IX ASME Section IX R

WPQ for fabricated housing

7 Welding Visual Approved drawing Approved drawing R

Article 6 from ASME Appendix 8 from ASME

8 NDT of housing after welding 100% PT R

Sec V Sec VIII Div 1

Approved drawing Approved drawing and

9 PWHT of housing Visual R

refer note 2 below

10 Machining Visual Approved drawing Approved drawing R

Teeth cutting of gear blank (by Machining drawing Machining drawing

11 Visual

generation)

Dynamic balancing of gear after Approved drawing Approved drawing with

12 Measurement R

teeth cutting ISO 1940

Heat treatment of gear after To achieve the required

13 Visual R

teeth cutting hardness

NDT of gear after heat No linear indications No linear indications

14 treatment and shrink fitting with MT R

shaft

15 Assembly Visual Approved drawing Approved drawing W

Measurement of

dimensions, vibration,

noise level, gear ratio,

Inspection and performance

16 orientation, direction of Approved drawing Approved drawing W

test

rotation, leakage of

lube oil and bearing

temperature

17 Identification / rating detail Visual As per Contract W

Cross hatch adhesion Approved Painting

18 Final painting W

test & DFT procedure

19 Preparation of dossier Verification R

Note:

1. No defect shall be permitted in D/6 zone. Here D is the diameter of the forging. In isolated case back wall echo

shall be always more than 50% and defect echo less than 50% of FSH. In non isolated case the back wall

echo shall be minimum 40% and defect echo shall be maximum 50% of FSH. The maximum length of

continues indication shall be 50 mm and minimum distance between two successive indications shall be 250

mm.

2. In no case PWHT shall be replaced with vibratory stress relieving.

3. ITP of kiln support roller shall be applicable for cast steel housing in place of fabricated housing.

4. During performance test bearing temperature must stabilized and shall be within 400 Deg C above ambient

temperature.

Proposer: R. K. Pandey Company: Tata Projects Limited New Delhi, Republic of India

You might also like

- Inspection and Test Plan For Storage TankDocument8 pagesInspection and Test Plan For Storage TankAndreas AlexanderNo ratings yet

- Quality Control Form - 3Document1 pageQuality Control Form - 3ravi ajithNo ratings yet

- ITP Heat ExchangerDocument1 pageITP Heat Exchangersarmad009No ratings yet

- Process Piping Inspection and Test PlanDocument6 pagesProcess Piping Inspection and Test Planmanoj thakkarNo ratings yet

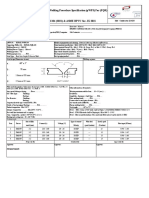

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- Hydraulic crash barriers ITPDocument4 pagesHydraulic crash barriers ITPmoytabura96No ratings yet

- WPS-PQR ListDocument1 pageWPS-PQR ListSandra SandersNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Inspection Plan NDTDocument7 pagesInspection Plan NDTEdison WalitNo ratings yet

- DVS 2207-3Document12 pagesDVS 2207-3gura9054No ratings yet

- Itp For Casing, Ducting, StackaaaaaaaaaaaDocument4 pagesItp For Casing, Ducting, Stackaaaaaaaaaaaaymanmalah100% (1)

- 1.13 Inspection & Test PlansDocument1 page1.13 Inspection & Test Plansabimanyubawono100% (2)

- Desmet Ballestra India PVT LTD: Inspection Test PlanDocument2 pagesDesmet Ballestra India PVT LTD: Inspection Test Plansameer patilNo ratings yet

- Essential Variables for Welder QualificationDocument12 pagesEssential Variables for Welder QualificationMahmoud Alwasif100% (2)

- Welder Wise Repair PercentageDocument135 pagesWelder Wise Repair PercentageaakashNo ratings yet

- Al Wakrah Stadium Tank Inspection and Test PlanDocument19 pagesAl Wakrah Stadium Tank Inspection and Test PlanErin JohnsonNo ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- Insulating Flange Kits DatasheetDocument4 pagesInsulating Flange Kits DatasheetKykyRizkyNo ratings yet

- WPS-Shell To Tubesheet (CS-SS)Document1 pageWPS-Shell To Tubesheet (CS-SS)suria qaqcNo ratings yet

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- Daily piping fit-up reportDocument2 pagesDaily piping fit-up reportnguyenquanghiepNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocument2 pagesEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaNo ratings yet

- Inspection Report - ValvesDocument2 pagesInspection Report - ValvesJaspal KaurNo ratings yet

- Flare Stack ITP Inspection PlanDocument3 pagesFlare Stack ITP Inspection Planlailatul kodriNo ratings yet

- ITP For PipingDocument5 pagesITP For PipingAldeline SungahidNo ratings yet

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- Epilux 610 HBLD Primer Coating: Resistance Guide Product DataDocument2 pagesEpilux 610 HBLD Primer Coating: Resistance Guide Product DataBijaya RaulaNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- WPS - 2Document3 pagesWPS - 2aleventNo ratings yet

- NDT Report - Dovetail WheelsDocument4 pagesNDT Report - Dovetail WheelsOm Ar TanNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Quality control inspection reportDocument1 pageQuality control inspection reportKo Lin Tun0% (1)

- Piping System Hydraulic Test Procedure R0Document6 pagesPiping System Hydraulic Test Procedure R0cmc261185No ratings yet

- Piping Fabrication ITPDocument5 pagesPiping Fabrication ITPNatraji100% (1)

- Sample Heat Treatment ProcedureDocument13 pagesSample Heat Treatment ProcedureAnonymous uXdS9Y7100% (1)

- Structural Steel and Pipe Work ProcedureDocument5 pagesStructural Steel and Pipe Work ProcedureMohamed100% (2)

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- Dimensional Inspektion ReportDocument6 pagesDimensional Inspektion Reportdidi sudiNo ratings yet

- WFP 2-01 ASME B31 Piping Welding ProcedureDocument8 pagesWFP 2-01 ASME B31 Piping Welding Procedureleodavid87No ratings yet

- July weld repair rate reportDocument2 pagesJuly weld repair rate reportSalahuddin FarooquiNo ratings yet

- F07-Visual Inspection Report NEWDocument1 pageF07-Visual Inspection Report NEWmohd as shahiddin jafriNo ratings yet

- Inspection and Test Plan For Silos and HoppersDocument15 pagesInspection and Test Plan For Silos and HoppersHOMAYOUN KHADIVINo ratings yet

- Cold Tap Coating Report 2Document1 pageCold Tap Coating Report 2Jamal BakhtNo ratings yet

- Circularity Inspection Report: Shell Course (LW) CW CWDocument14 pagesCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNo ratings yet

- Nisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)Document3 pagesNisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)pejman.imaniNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding & Site Assembly of Spherical Vessel SATIP-W-010-02 31-Dec-14 MechanicalpravinNo ratings yet

- CV UpdateDocument8 pagesCV UpdateAlya Chyank San-sanNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198No ratings yet

- Walk Down Punch ListDocument7 pagesWalk Down Punch ListGomathyselviNo ratings yet

- Asme Sections ListDocument1 pageAsme Sections ListShreekanthKannathNo ratings yet

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- Refractory Inspection: Prepared by Integrity EngineeringDocument17 pagesRefractory Inspection: Prepared by Integrity EngineeringAhmedNo ratings yet

- Client: Supplier: Location: Sheet: Item: Large Size Gear BoxDocument1 pageClient: Supplier: Location: Sheet: Item: Large Size Gear BoxirwanNo ratings yet

- Qap Reciever TanksDocument6 pagesQap Reciever Tanksyamunaengg2011No ratings yet

- Oxygen MSDS Safety GuideDocument4 pagesOxygen MSDS Safety Guidelutfi_thalib3175No ratings yet

- Quantitative Mueller Matrix Polarimetry With Diverse ApplicationsDocument63 pagesQuantitative Mueller Matrix Polarimetry With Diverse ApplicationsHarsh Purwar100% (1)

- TDS Energrease MP-MG 2 InfoDocument9 pagesTDS Energrease MP-MG 2 InfoLucian IftemieNo ratings yet

- Centrifugal Pump TheoryDocument5 pagesCentrifugal Pump TheoryFungsam LimNo ratings yet

- ABRASIVE JET MACHINING ModellingDocument3 pagesABRASIVE JET MACHINING ModellingAnkit OlaNo ratings yet

- Specifyingstainlesssteelsurfacetreatments 10068 PDFDocument5 pagesSpecifyingstainlesssteelsurfacetreatments 10068 PDFshazia khanNo ratings yet

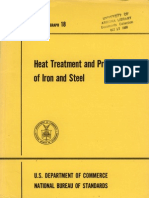

- NBS18 Heat TreatmentDocument46 pagesNBS18 Heat Treatmentshailesh_tiwari_mechNo ratings yet

- Airfoil Lift Procedures PDFDocument12 pagesAirfoil Lift Procedures PDFmatthias.s.sommer3656No ratings yet

- 9 InsulatorDocument39 pages9 InsulatorLeo KhkNo ratings yet

- TPAO-KTHDB PremiumThread TubingTechSpecSheet PH6Document1 pageTPAO-KTHDB PremiumThread TubingTechSpecSheet PH6ilkerkozturkNo ratings yet

- How To Process and Print Black-and-White FilmDocument6 pagesHow To Process and Print Black-and-White FilmPepParamosNo ratings yet

- Full download book Quantum Dots Fundamentals Synthesis And Applications Pdf pdfDocument41 pagesFull download book Quantum Dots Fundamentals Synthesis And Applications Pdf pdfhilda.pellowski343100% (19)

- Media File Sheehan Perf of HDG in Coastal Envs PDFDocument18 pagesMedia File Sheehan Perf of HDG in Coastal Envs PDFFrankie ChanNo ratings yet

- ISA-TR20.00.01 CD-ROM Table of Contents PDFDocument5 pagesISA-TR20.00.01 CD-ROM Table of Contents PDFmegojasNo ratings yet

- Experiment 4Document5 pagesExperiment 4chsullivan17No ratings yet

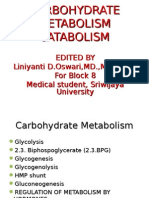

- Carbohydrate Metabolism Catabolism 2013Document108 pagesCarbohydrate Metabolism Catabolism 2013Anonymous nErkwtXnuS100% (1)

- Shimadzu System GC CatalogDocument48 pagesShimadzu System GC CatalogTerry Osenbach100% (1)

- P Block Short NotesDocument22 pagesP Block Short Notesthapliyaldivyanshu274No ratings yet

- What Is Calcium Oxalate PrecipitationDocument3 pagesWhat Is Calcium Oxalate PrecipitationluismiguelmmercadoNo ratings yet

- Fluoride, SPADNS Method 8029, 02-2009, 9th EdDocument7 pagesFluoride, SPADNS Method 8029, 02-2009, 9th EdAnonymous FRAdEnNo ratings yet

- SITI SOLEHAH BINTI OMAR (2015834112) /EH224 7A1 Heuristics of ReactorDocument2 pagesSITI SOLEHAH BINTI OMAR (2015834112) /EH224 7A1 Heuristics of ReactorSolehah OmarNo ratings yet

- Science Test - 1 QuarterDocument3 pagesScience Test - 1 QuarterCeeKay0% (1)

- Millenium Ro System Specifications: A Ge Osmonics Portable Reverse Osmosis SystemDocument7 pagesMillenium Ro System Specifications: A Ge Osmonics Portable Reverse Osmosis SystemgimenNo ratings yet

- Corrosol VE GP - TDS - Rev 4 - Feb 19Document2 pagesCorrosol VE GP - TDS - Rev 4 - Feb 19mkash028No ratings yet

- MSc Surveying and Water Resources TopicsDocument3 pagesMSc Surveying and Water Resources TopicsNirjhor KabirNo ratings yet

- RC Corbel Design (ACI318-05)Document2 pagesRC Corbel Design (ACI318-05)Mohammed Z. AlSaqqa100% (1)

- ARGUS ReportDocument22 pagesARGUS ReportNguyễn Tường MinhNo ratings yet

- Section 05-05 Fiber Optic NetworkDocument24 pagesSection 05-05 Fiber Optic NetworkYusuf AbdinasirNo ratings yet

- TRIBOLOGY & LUBRICATION TECHNOLOGY May 2016Document228 pagesTRIBOLOGY & LUBRICATION TECHNOLOGY May 2016Jorge Cuadros Blas100% (4)

- Distillation Column Tray Selection & Sizing - 1 - Separation TechnologiesDocument18 pagesDistillation Column Tray Selection & Sizing - 1 - Separation TechnologiesOmesh Borole100% (1)