Professional Documents

Culture Documents

Steel Column Design

Uploaded by

vsnsfbOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Column Design

Uploaded by

vsnsfbCopyright:

Available Formats

Project Job Ref.

Section Sheet no./rev.

1

Calc. by Date Chk'd by Date App'd by Date

A 1/11/2011

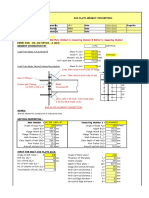

STEEL COLUMN DESIGN (EN 1993-1-1)

In accordance with recommended values

TEDDS calculation version 1.0.04

200

y y

z

200

Column and loading details

Column details

Column section; SHS 200x200x6.0

System length for buckling about y axis; Ly = ;3200; mm

System length for buckling about z axis; Lz = ;3200; mm;

Column loading

Axial load; NEd = 14 kN; (Compression)

Moment about y axis at end 1; My,Ed1 = -40.5 kNm

Moment about y axis at end 2; My,Ed2 = 0.0 kNm

Single curvature bending about y axis

Moment about z axis at end 1; Mz,Ed1 = 1.0 kNm

Moment about z axis at end 2; Mz,Ed2 = 0.0 kNm

Single curvature bending about z axis

Shear force parallel to z axis; Vz,Ed = 1 kN

Shear force parallel to y axis; Vy,Ed = 0 kN

Material details

Steel grade; S275

Yield strength; fy = 275 N/mm2

Ultimate strength; fu = 410 N/mm2

Modulus of elasticity; E = 210 kN/mm2

Poisson’s ratio; ν = 0.3

Shear modulus; G = E / [2 × (1 + ν)] = 80.8 kN/mm2

Buckling length for flexural buckling about y axis

End restraint factor; Ky = 1.000

Buckling length; Lcr_y = Ly × Ky = 3200 mm

Buckling length for flexural buckling about z axis

End restraint factor; Kz = 1.000

Buckling length; Lcr_z = Lz × Kz = 3200 mm

Project Job Ref.

Section Sheet no./rev.

2

Calc. by Date Chk'd by Date App'd by Date

A 1/11/2011

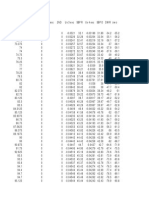

Section classification

Web section classification (Table 5.2)

Coefficient depending on fy; ε = √(235 N/mm2 / fy) = 0.924

Depth between fillets; cw = h - 3 × t = 182.0 mm

Ratio of c/t; ratiow = cw / t = 30.33

Length of web taken by axial load; lw = min(NEd / (2 × fy × t), cw) =4.1 mm

For class 1 & 2 proportion in compression; α = (cw/2 + lw/2) / cw = 0.511

Limit for class 1 web; Limit1w = (396 × ε) / (13 × α - 1) = ;64.84

The web is class 1

Flange section classification (Table 5.2)

Depth between fillets; cf = b - 3 × t = 182.0 mm

Ratio of c/t; ratiof = cf / t = 30.33

Conservatively assume uniform compression in flange

Limit for class 1 flange; Limit1f = 33 × ε = 30.51

Limit for class 2 flange; Limit2f = 38 × ε = 35.13

Limit for class 3 flange; Limit3f = 42 × ε = 38.83

The flange is class 1

Overall section classification

The section is class 1

Resistance of cross section (cl. 6.2)

Shear parallel to z axis (cl. 6.2.6)

Design shear force; Vz,Ed = 1.0 kN

Shear area; Avz = A × h / (b + h) = ;2309; mm2

Plastic shear resistance; Vpl,z,Rd = Avz × (fy / √(3)) / γM0 = 366.6 kN

PASS - Shear resistance parallel to z axis exceeds the design shear force

Vz,Ed <= 0.5×Vpl,z,Rd - No reduction in fy required for bending/axial force

Compression (cl. 6.2.4)

Design force; NEd = 14 kN

Design resistance; Nc,Rd = Npl,Rd = A × fy / γM0 = 1270 kN

PASS - The compression design resistance exceeds the design force

Bending about y axis (cl. 6.2.5)

Design bending moment; My,Ed = max(abs(My,Ed1), abs(My,Ed2)) = 40.5 kNm

Section modulus about y axis; W y = W pl.y = ;334.9; cm3

Design resistance; Mc,y,Rd = W y × fy / γM0 = 92.1 kNm

PASS - The bending design resistance about the y axis exceeds the design moment

Bending about z axis (cl. 6.2.5)

Design bending moment; Mz,Ed = max(abs(Mz,Ed1), abs(Mz,Ed2)) = 1.0 kNm

Section modulus about z axis; W z = W pl.z = ;334.9; cm3

Design resistance; Mc,z,Rd = W z × fy / γM0 = 92.1 kNm

PASS - The bending design resistance about the z axis exceeds the design moment

Combined bending and axial force (cl. 6.2.9)

Ratio design axial to design plastic resistance; n = abs(NEd) / Npl,Rd = 0.011

Ratio web area to gross area; aw = min(0.5, (A - 2 × b × t) / A) = 0.480

Project Job Ref.

Section Sheet no./rev.

3

Calc. by Date Chk'd by Date App'd by Date

A 1/11/2011

Ratio flange area to gross area; af = min(0.5, (A - 2 × h × t) / A) = 0.480

Bending about y axis (cl. 6.2.9.1)

Design bending moment; My,Ed = max(abs(My,Ed1), abs(My,Ed2)) = 40.5 kNm

Plastic design resistance; Mpl,y,Rd = W pl.y × fy / γM0 = 92.1 kNm

Modified design resistance about y axis; MN,y,Rd = Mpl,y,Rd × min(1, (1 - n) / (1 - 0.5 × aw)) = 92.1 kNm

PASS - Bending resistance about y axis in presence of axial load exceeds design moment

Bending about z axis (cl. 6.2.9.1)

Design bending moment; Mz,Ed = max(abs(Mz,Ed1), abs(Mz,Ed2)) = 1.0 kNm

Plastic design resistance; Mpl,z,Rd = W pl.z × fy / γM0 = 92.1 kNm

Modified design resistance about z axis; MN,z,Rd = Mpl,z,Rd × min(1, (1 - n) / (1 - 0.5 × af)) = 92.1 kNm

PASS - Bending resistance about z axis in presence of axial load exceeds design moment

Biaxial bending

Exponent α; α = min(6, 1.66 / (1 - 1.13 × n2)) = ;1.66

Exponent β; β = min(6, 1.66 / (1 - 1.13 × n2)) = ;1.66

Section utilisation at end 1; URCS_1 = [abs(My,Ed1) / MN,y,Rd] α + [abs(Mz,Ed1) / MN,z,Rd] β = 0.257

Section utilisation at end 2; URCS_2 = [abs(My,Ed2) / MN,y,Rd] α + [abs(Mz,Ed2) / MN,z,Rd] β = 0.000

PASS - The cross-section resistance is adequate

Buckling resistance (cl. 6.3)

Yield strength for buckling resistance; fy = 275 N/mm2

Flexural buckling about y axis

Elastic critical buckling force; Ncr,y = π2 × E × Iy / Lcr_y2 = 5836 kN

Non-dimensional slenderness; ⎯λy = √(A × fy / Ncr,y) = 0.466

Buckling curve (Table 6.2); a

Imperfection factor (Table 6.1); αy = 0.21

Parameter Φ; Φy = 0.5 × [1 + αy × (⎯λy - 0.2) +⎯λy2] = 0.637

Reduction factor; χy = min(1.0, 1 / [Φy + √(Φy2 -⎯λy2)]) = 0.934

Design buckling resistance; Nb,y,Rd = χy × A × fy / γM1 = 1186.4 kN

PASS - The flexural buckling resistance about the y axis exceeds the design axial load

Flexural buckling about z axis

Elastic critical buckling force; Ncr,z = π2 × E × Iz / Lcr_z2 = 5836 kN

Non-dimensional slenderness; ⎯λz = √(A × fy / Ncr,z) = 0.466

Buckling curve (Table 6.2); a

Imperfection factor (Table 6.1); αz = 0.21

Parameter Φ; Φz = 0.5 × [1 + αz × (⎯λz - 0.2) +⎯λz2] = 0.637

Reduction factor; χz = min(1.0, 1 / [Φz + √(Φz2 -⎯λz2)]) = 0.934

Design buckling resistance; Nb,z,Rd = χz × A × fy / γM1 = 1186.4 kN

PASS - The flexural buckling resistance about the z axis exceeds the design axial load

Minimum buckling resistance

Minimum buckling resistance; Nb,Rd = min(Nb,y,Rd, Nb,z,Rd) = 1186.4 kN

PASS - The axial load buckling resistance exceeds the design axial load

Buckling resistance moment (cl.6.3.2.1)

Square hollow section not subject to lateral torsional buckling therefore:-

Reduction factor; χLT = 1.0

Design buckling resistance moment; Mb,Rd = χLT × W y × fy / γM1 = 92.1 kNm

Project Job Ref.

Section Sheet no./rev.

4

Calc. by Date Chk'd by Date App'd by Date

A 1/11/2011

Design bending moment; My,Ed = max(abs(My,Ed1), abs(My,Ed2)) = 40.5 kNm

PASS - The design buckling resistance moment exceeds the maximum design moment

Combined bending and axial compression (cl. 6.3.3)

Characteristic resistance to normal force; NRk = A × fy = 1270 kN

Characteristic moment resistance about y axis; My,Rk = W y × fy = 92.1 kNm

Characteristic moment resistance about z axis; Mz,Rk = W z × fy = 92.1 kNm

Moment distribution factor about y axis; ψy = My,Ed2 / My,Ed1 = ;0.000

Moment factor about y axis; Cmy = max(0.4, 0.6 + 0.4 × ψy) = 0.600

Moment distribution factor about z axis; ψz = Mz,Ed2 / Mz,Ed1 = ;0.000

Moment factor about z axis; Cmz = max(0.4, 0.6 + 0.4 × ψz) = 0.600

Moment distribution factor for LTB; ψLT = My,Ed2 / My,Ed1 = ;0.000

Moment factor for LTB; CmLT = max(0.4, 0.6 + 0.4 × ψLT) = 0.600

Interaction factor kyy; kyy = Cmy × [1 + min(0.8,⎯λy - 0.2) × NEd / (χy × NRk / γM1)] = 0.602

Interaction factor kzy; kzy = 0.6 × kyy = 0.361

Interaction factor kzz; kzz = Cmz × [1 + min(0.8,⎯λz - 0.2) × NEd / (χz × NRk / γM1)] = ;0.602

Interaction factor kyz; kyz = 0.6 × kzz = 0.361

Section utilisation; URB_1 = NEd / (χy × NRk / γM1) + kyy × My,Ed / (χLT × My,Rk / γM1) + kyz × Mz,Ed / (Mz,Rk / γM1)

URB_1 = 0.280

URB_2 = NEd / (χz × NRk / γM1) + kzy × My,Ed / (χLT × My,Rk / γM1) + kzz × Mz,Ed / (Mz,Rk / γM1)

URB_2 = 0.177

PASS - The buckling resistance is adequate

You might also like

- Splices & ConnectionsDocument37 pagesSplices & Connectionsprabhu81No ratings yet

- Crane Beam DesignDocument7 pagesCrane Beam DesignTharanga Pradeep100% (2)

- Steel Beam Design As Per AISC ASDDocument2 pagesSteel Beam Design As Per AISC ASDKov Chanthy100% (1)

- Design of I-Shape Column Base PlateDocument6 pagesDesign of I-Shape Column Base PlatebuildconNo ratings yet

- Column Base Plate DesignDocument5 pagesColumn Base Plate Design_jessecaNo ratings yet

- Steel Column DesignDocument4 pagesSteel Column Designanshutomar7915100% (2)

- Base PlateDocument12 pagesBase PlateD SRINIVAS100% (1)

- Crane Beam Web Splice DesignDocument7 pagesCrane Beam Web Splice DesignCrystal JaneNo ratings yet

- Crane Gantry Girder (BS5950 - Part1 - 2000)Document6 pagesCrane Gantry Girder (BS5950 - Part1 - 2000)sayed100% (1)

- Design of square footing for 600 KN column loadDocument2 pagesDesign of square footing for 600 KN column loadVishwajith KadriNo ratings yet

- Steel ColumnDocument2 pagesSteel ColumnNikki Roberts100% (2)

- End Plate Beam To Column Moment ConnectionDocument84 pagesEnd Plate Beam To Column Moment ConnectionNguyen Duc CuongNo ratings yet

- Baseplate Design Input DataDocument166 pagesBaseplate Design Input DataAnonymous ciKyr0t86% (7)

- Eurocode2 - RC Design SheetDocument2 pagesEurocode2 - RC Design Sheetumutakin100% (1)

- Pinned and fixed base plate design calculations for I-section and tube columnsDocument7 pagesPinned and fixed base plate design calculations for I-section and tube columnsabdul karee100% (6)

- Scaffold Brackets BoltDocument2 pagesScaffold Brackets BoltHafiz KamarudinNo ratings yet

- Crane Load-Chemical Storage ShelterDocument44 pagesCrane Load-Chemical Storage ShelterAndreas HendiNo ratings yet

- Design of FoundationDocument66 pagesDesign of FoundationShaikh Muhammad Ateeq100% (2)

- Eurocode example ex3.1.4 connection designDocument4 pagesEurocode example ex3.1.4 connection designРостислав Василев100% (2)

- Slab Deflection Check CP-65Document1 pageSlab Deflection Check CP-65Hari Amudhan IlanchezhianNo ratings yet

- Design Calculation Main Column 11M LC I 06052011Document10 pagesDesign Calculation Main Column 11M LC I 06052011Goutam Chakraborty100% (1)

- Design of C and I Shape Weld GroupDocument4 pagesDesign of C and I Shape Weld GroupkarthicksipNo ratings yet

- Unit 10 Gantry Girders: StructureDocument54 pagesUnit 10 Gantry Girders: StructureMahendra DewasiNo ratings yet

- Axially Loaded Columns - SteelDocument1 pageAxially Loaded Columns - SteelHari Amudhan IlanchezhianNo ratings yet

- Design of Rectangular Water TankDocument242 pagesDesign of Rectangular Water Tankmumarbsc7244No ratings yet

- Moment ConnectionsDocument15 pagesMoment ConnectionsHector Aguana100% (1)

- Bolted Moment ConnectionDocument9 pagesBolted Moment ConnectionAmey Gudigar100% (1)

- Purlin DesignDocument3 pagesPurlin DesignHafiz Budean RahmanNo ratings yet

- Design SectionDocument19 pagesDesign SectionKrishna KumarNo ratings yet

- End Plate DesignDocument4 pagesEnd Plate DesignAgnon Fung100% (4)

- Hansen's Equation Bearing CapicityDocument4 pagesHansen's Equation Bearing CapicityEngDbt100% (1)

- Base Plate CalculationDocument6 pagesBase Plate CalculationbuildconNo ratings yet

- Crane Beam-Web Splice DesignDocument1 pageCrane Beam-Web Splice DesignkalpanaadhiNo ratings yet

- Staircase DesignDocument2 pagesStaircase Designbkwagle100% (1)

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignVivek AnandanNo ratings yet

- Bridge Load Calculation SheetDocument8 pagesBridge Load Calculation SheetNats DizonNo ratings yet

- P 5.0.1 Loading Condition For Columns: 5.0 Analysis of ColumnDocument6 pagesP 5.0.1 Loading Condition For Columns: 5.0 Analysis of Columnanimesh91No ratings yet

- Design of Steel BeamDocument18 pagesDesign of Steel BeamOuseppachan Ambooken100% (4)

- Eaves Connection Design and AnalysisDocument37 pagesEaves Connection Design and AnalysisHui LiuNo ratings yet

- Gantry CraneDocument31 pagesGantry CraneWaheed AhmadNo ratings yet

- Section Size: W200X36: Refer Appendix D For Support ReactionsDocument10 pagesSection Size: W200X36: Refer Appendix D For Support Reactionsramuce04No ratings yet

- Staircase DesignDocument1 pageStaircase DesignJennifer PearsonNo ratings yet

- Column Base PlateDocument3 pagesColumn Base PlatePurnima ArkalgudNo ratings yet

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- Base Plate Design for Bagging Tower SupportDocument9 pagesBase Plate Design for Bagging Tower SupportbuildconNo ratings yet

- Purlin Design LSMDocument10 pagesPurlin Design LSMFazilat Mohammad Zaidi0% (1)

- Shear Connection - Beam - Steel Column - Fin PlateDocument30 pagesShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- Steel ColumnDocument4 pagesSteel ColumnsansamNo ratings yet

- Applied Moment, Shear and Axial LoadsDocument8 pagesApplied Moment, Shear and Axial LoadsMallesh NenkatNo ratings yet

- Stub ColumnDocument4 pagesStub ColumnCHRISTOPHER EKIRAPANo ratings yet

- Project Job No.: CHS 139.7x4.0 (Tata Steel Celsius)Document4 pagesProject Job No.: CHS 139.7x4.0 (Tata Steel Celsius)Ruemu Godwin InikoriNo ratings yet

- STEEL COLUMN DESIGNDocument5 pagesSTEEL COLUMN DESIGNShingirai JoeNo ratings yet

- Proposed Mezzanine Floor Deck DesignDocument8 pagesProposed Mezzanine Floor Deck DesignBernard KiruiNo ratings yet

- Project Job Ref.: V B T, y T, R CDocument3 pagesProject Job Ref.: V B T, y T, R CM IQbalNo ratings yet

- SEO-Optimized Title for Steel Beam Design Project DocumentDocument3 pagesSEO-Optimized Title for Steel Beam Design Project DocumentRifki SaputraNo ratings yet

- Steel Member Design (EN1993)Document5 pagesSteel Member Design (EN1993)neekrissNo ratings yet

- 200 THK Grade Slab-50kn Variable Load-With FibreDocument7 pages200 THK Grade Slab-50kn Variable Load-With FibreFazilat Mohammad Zaidi0% (1)

- W Section (ASD) ExampleDocument5 pagesW Section (ASD) ExampleMallesh NenkatNo ratings yet

- MP1 Design (EN1993)Document6 pagesMP1 Design (EN1993)blerandNo ratings yet

- Design Check CofferdamDocument3 pagesDesign Check Cofferdamzms msswiNo ratings yet

- HouseDocument3 pagesHousevsnsfbNo ratings yet

- Estimation r0Document2 pagesEstimation r0vsnsfbNo ratings yet

- Daily Task List - 20150414Document10 pagesDaily Task List - 20150414vsnsfbNo ratings yet

- Tunnel Taper CalculationDocument1 pageTunnel Taper CalculationvsnsfbNo ratings yet

- Load CasesDocument1 pageLoad CasesvsnsfbNo ratings yet

- Bending Moment Diagram Pos 115 to Neg 2000 kNm/mDocument1 pageBending Moment Diagram Pos 115 to Neg 2000 kNm/mvsnsfbNo ratings yet

- Load Cases Circular ShaftsDocument1 pageLoad Cases Circular ShaftsvsnsfbNo ratings yet

- Estimation r0Document2 pagesEstimation r0vsnsfbNo ratings yet

- Ponniyin Selvan - SynopsisDocument5 pagesPonniyin Selvan - Synopsisvsnsfb100% (1)

- For Reference Only (Confidential) : Ryobi Geotechnique International Pte LTDDocument8 pagesFor Reference Only (Confidential) : Ryobi Geotechnique International Pte LTDvsnsfbNo ratings yet

- Report Check ListDocument1 pageReport Check ListvsnsfbNo ratings yet

- Fillet Welding Capacity in KNDocument2 pagesFillet Welding Capacity in KNvsnsfbNo ratings yet

- Deflection of WallDocument5 pagesDeflection of WallvsnsfbNo ratings yet

- Steel member design EN1993 (40Document8 pagesSteel member design EN1993 (40vsnsfbNo ratings yet

- Drop Shaft 1Document1 pageDrop Shaft 1vsnsfbNo ratings yet

- Bending Moment Shear ForceDocument3 pagesBending Moment Shear ForcevsnsfbNo ratings yet

- Drop Shaft 1Document1 pageDrop Shaft 1vsnsfbNo ratings yet

- Comparision Wall ForcesDocument3 pagesComparision Wall ForcesvsnsfbNo ratings yet

- Solid Plate Gates DesignDocument1 pageSolid Plate Gates DesignvsnsfbNo ratings yet

- Metro Deck Module GatesDocument3 pagesMetro Deck Module GatesvsnsfbNo ratings yet

- Window SizesDocument1 pageWindow SizesvsnsfbNo ratings yet

- Steel Plate Gate DesignDocument5 pagesSteel Plate Gate DesignvsnsfbNo ratings yet

- IPL - 2004-r1 Training Option2Document1 pageIPL - 2004-r1 Training Option2vsnsfbNo ratings yet

- DWG INU CS 004a BWDocument1 pageDWG INU CS 004a BWvsnsfbNo ratings yet

- Slab RF CalculationsDocument1 pageSlab RF CalculationsvsnsfbNo ratings yet

- Corroded Bar Treatment 2Document1 pageCorroded Bar Treatment 2vsnsfbNo ratings yet

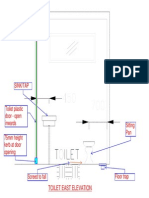

- Toilet East Elevation - SketchDocument1 pageToilet East Elevation - SketchvsnsfbNo ratings yet

- Corroded Bar TreatmentDocument1 pageCorroded Bar TreatmentvsnsfbNo ratings yet

- IPL - 2004-r1 Training Option1Document1 pageIPL - 2004-r1 Training Option1vsnsfbNo ratings yet

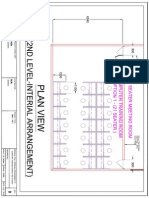

- IPL - 2004-r1 Meeting RoomDocument1 pageIPL - 2004-r1 Meeting RoomvsnsfbNo ratings yet

- Rigid Pavements For Airports: J. M. Barling and J. E. GrimsdaleDocument35 pagesRigid Pavements For Airports: J. M. Barling and J. E. GrimsdaleCarlo RabaiottiNo ratings yet

- Models For Metals Subjected To Cyclic Loading - ABAQUS PDFDocument13 pagesModels For Metals Subjected To Cyclic Loading - ABAQUS PDFMohamed AhmedNo ratings yet

- Waler Beam 28.09.2022Document18 pagesWaler Beam 28.09.2022spk ReviewNo ratings yet

- R. C. Batra - On The Coincidence of The Principal Axes of Stress and Strain in Isotropic Elastic BodiesDocument5 pagesR. C. Batra - On The Coincidence of The Principal Axes of Stress and Strain in Isotropic Elastic BodiesCola7890No ratings yet

- Adobe Wall Numerical ModellingDocument12 pagesAdobe Wall Numerical ModellingGonzalo TorrisiNo ratings yet

- 2019 Key Changes Section VIII 2 ModDocument81 pages2019 Key Changes Section VIII 2 Modhiman_chongiNo ratings yet

- Asphalt-Concrete-Stiffness-Prediction-Based-On-Composition-And-Binder-Propertie Full Thesis PDFDocument138 pagesAsphalt-Concrete-Stiffness-Prediction-Based-On-Composition-And-Binder-Propertie Full Thesis PDFDipendra AwasthiNo ratings yet

- Textile tensile properties guideDocument3 pagesTextile tensile properties guidesfsman1No ratings yet

- Introduction & Direct Integration MethodDocument21 pagesIntroduction & Direct Integration MethodMalingha SamuelNo ratings yet

- BMEN 301 F2021 Module 3-The Mechanics of Soft TissueDocument18 pagesBMEN 301 F2021 Module 3-The Mechanics of Soft TissueAyesha ANo ratings yet

- Design of BeamDocument14 pagesDesign of BeamUdhasu NayakNo ratings yet

- ATENA-Engineering Example Manual PDFDocument90 pagesATENA-Engineering Example Manual PDFHugo Kstelblanco RNo ratings yet

- Model Answer: Winter-2018Document22 pagesModel Answer: Winter-2018SurajNo ratings yet

- Practise Problem (Exercise - 1)Document2 pagesPractise Problem (Exercise - 1)Deepak Kumar SinghNo ratings yet

- J2 BahanDocument21 pagesJ2 Bahanmr mustofaNo ratings yet

- Precast concrete pipe rack structureDocument13 pagesPrecast concrete pipe rack structuredinu69inNo ratings yet

- Elastic Analysis - Limit Analysis (Plastic Analysis)Document42 pagesElastic Analysis - Limit Analysis (Plastic Analysis)Abhijeet Singh Jamwal100% (1)

- FYP - Niall - Morton - 0602279m - Sy 35Document80 pagesFYP - Niall - Morton - 0602279m - Sy 35KubilayNo ratings yet

- Finite Element Analysis of Automotive Wheel Rim AssemblyDocument6 pagesFinite Element Analysis of Automotive Wheel Rim AssemblyHakim SakibNo ratings yet

- FinalDocument20 pagesFinalRajesh GamblerNo ratings yet

- 3D Finite-Element Analysis of Shear Connectors With Partial InteractionDocument12 pages3D Finite-Element Analysis of Shear Connectors With Partial InteractionMohamedNo ratings yet

- UEME1263 - Solid Mechanics - P1GroupDDocument13 pagesUEME1263 - Solid Mechanics - P1GroupDKiritoNo ratings yet

- Soil Mechanics Vertical Stress FormulasDocument13 pagesSoil Mechanics Vertical Stress FormulasSaša MarinNo ratings yet

- Tabel Geotek 22 - 23Document26 pagesTabel Geotek 22 - 23Septian Yudha AgungNo ratings yet

- Usace - Response Spectra & Seismic Analysis For Concrete Hyd StructDocument248 pagesUsace - Response Spectra & Seismic Analysis For Concrete Hyd StructOmar ElioNo ratings yet

- Ufc+3 220 01 PDFDocument183 pagesUfc+3 220 01 PDFNicolas Fuentes Von KieslingNo ratings yet

- Zubov1997 PDFDocument12 pagesZubov1997 PDFwintersoulsNo ratings yet

- Lesson 2 Fillers FibersDocument35 pagesLesson 2 Fillers FibersEr Ravindra JagdhaneNo ratings yet