Professional Documents

Culture Documents

Large-Scale Uniform α-Co (OH) 2 Long Nanowire Arrays Grown on Graphite as Pseudocapacitor Electrodes

Uploaded by

kiankeatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Large-Scale Uniform α-Co (OH) 2 Long Nanowire Arrays Grown on Graphite as Pseudocapacitor Electrodes

Uploaded by

kiankeatCopyright:

Available Formats

Large-Scale Uniform R-Co(OH)2 Long

Nanowire Arrays Grown on Graphite as

ARTICLE

Pseudocapacitor Electrodes

Jian Jiang,† Jinping Liu,† Ruimin Ding,† Jianhui Zhu,† Yuanyuan Li,‡ Anzheng Hu,† Xin Li,†

and Xintang Huang*,†

Institute of Nanoscience and Nanotechnology, Department of Physics, Huazhong Normal University,

Wuhan 430079, P. R. China, and Department of Electronic Science and Technology, Huazhong University of

Science and Technology, Wuhan 430074, P.R. China

ABSTRACT Large-scale uniform R-Co(OH)2 nanowire arrays (NWAs) with an average length of ∼20 µm grown on pyrolytic graphite

(PG) were successfully synthesized by a hydrothermal method at 120 °C. Ultrasonication test was carried out toward the as-made

nanoarray products and the result demonstrated their robust adhesion to graphitic substrate. After 300 s of sonication testing, R-Co(OH)2

NWAs could still possess both integrated one-dimensional (1D) nanoarray architecture and good electronic connections with current

collector. When investigated as electrochemical pseudocapacitor electrodes, R-Co(OH)2 NWAs exhibited good energy-storage

performance in terms of high specific capacitance of 642.5 F/g, good rate capability, and excellent capacity retention. Our work not

only presents a cost-effective and scale-up synthetic method for R-Co(OH)2 NWAs but also holds promise in general synthesis of long

arrays of other metal hydroxides/oxide (TiO2, Fe2O3, SnO2, etc.) nanostructures on PG substrate by using R-Co(OH)2 NWAs as sacrificial

templates.

KEYWORDS: R-Co(OH)2 • long nanowire arrays • robust adhesion • graphite substrate • supercapacitor • sacrificial template

INTRODUCTION

A s a most promising energy conversion/storage and

power output technology for digital communications

and hybrid electronic vehicles, electrochemical ca-

pacitors have attracted much interest because of their

advantages of high power delivery and excellent cycling

lifespan in comparison to batteries (1-4). The capacitance

of traditional electrical double-layer capacitors (EDLCs) origi-

nates from the sole charge separation process occurring at

the electrode/electrolyte interface (5). However, such a

limited specific capacitance of EDLCs is far from perfect in

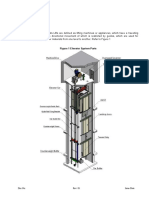

FIGURE 1. Schematic diagram of application advantages of building

accordance with the ever-growing need for peak-power

1D nanostructured arrays on graphite substrate.

assistance in electric vehicles. In contrast, electrochemical

pseudocapacitors (using hydroxides, oxides and conductive Recently, one-dimensional (1D) nanostructured arrays

polymers, etc.) exhibit much higher specific capacitance and (14-16) built on conductive substrates have been studied

energy density due to their reversible multielectron redox and demonstrated to be an optimized architecture for boost-

Faradaic reactions (6-8). The performance of electrochemi- ing the electrochemical behaviors of working electrodes

cal materials is influenced by numerous factors, such as (17, 18). As reported single nanowire/nanorod directly

specific surface area, particle size, morphology, Faradaic contacting with current collector can serve as a superhigh-

processes, etc. (9, 10). Particularly noteworthy is the electron way for the fast electron transportation (19, 20). Graphite is

transfer between active materials and electrode; establish- a kind of fundamental lightweight material and commonly

ment of a good electron transport channel to current collec- used as an important component of commercial electrodes

tor is considered as the fundamental prerequisite for the due to its low cost, good thermal/electronic conductivity (21)

development of advanced electrochemical devices (11-13). and excellent chemical stability in various electrolytes. Also,

single-crystal graphite consisting of numerous graphene

* To whom correspondence should be addressed: Fax +86-027-67861185. sheets stacked together is remarkably useful to synthesize

E-mail: xthuang@phy.ccnu.edu.cn. graphene (22-24). Thus, growing inorganic nanowire/rod

Received for review October 13, 2010 and accepted December 3, 2010

† arrays on economic pyrolytic graphite (PG) substrate (Figure

Huazhong Normal University.

‡

Huazhong University of Science and Technology. 1) possesses following electrochemical application advan-

DOI: 10.1021/am1009887 tages: (I) the establishment of integrated 1D nanoarray

XXXX American Chemical Society structure renders numerous fast electron-transport accesses

www.acsami.org VOL. xxx • NO. xx • 000 • XXXX A

to current collector; (II) well-ordered arrayed architecture is

able to reduce the ionic diffusion to the inner part of

electrodes, improving utilization of active materials and (III)

ARTICLE

outstanding thermal conductivity of graphite can facilitate

the release of jouleheat yielded from equipment when

electrodes are suffering from large discharge currents. To

date, some groups have reported the synthesis of simple

particle films on bulky PG by chemical vapor deposition

(CVD) or layer-by-layer growth method, etc. (25-27). How-

ever, to the best of our knowledge, no attention has been

yet focused on the direct synthesis of inorganic nanoarrays

on PG using a facile solution-based method.

Among transition-metal hydroxides, R-Co(OH)2 has long

been investigated as a significant category of electrochemical

material and widely used as supercapacitor material because

of its high theoretical specific capacitance up to 3460 F/g

(28). In this work, we report for the first time a facile and

direct synthesis of large-scale R-Co(OH)2 nanowire arrays

(NWAs) on PG with a mean length of ∼20 µm via a hydro-

thermal method. In addition, a sonication test lasting for FIGURE 2. (a) XRD pattern of as-made sample grown on graphite.

300 s toward the nanoarrayed products demostrates their Optical images of R-Co(OH)2 NWAs (b) before and (c) after ultra-

sonication lasting 300 s.

good mechanical adhesion to PG substrate. After sonication

test, R-Co(OH)2 NWAs on PG used as electrochemical The mass calculation was made according to weight change

pseudocapacitors have shown great potential in energy- caused by the removal of R-Co(OH)2 NWAs via a hydrochloric

storage devices and exhibited a high capacitance up to 642.5 acid treatment. Each electrode had a geometric surface area of

F/g, good rate capability and excellent capacity retention. ∼2 cm2 and contained ∼2 mg of electroactive materials.

Capacitances were measured by chronopotentionmetry in a

Meanwhile, we also find that scalable growth of R-Co(OH)2 potential range of -0.1-0.45 V and calculated by I∆t/(∆Vm),

NWAs can be realized regardless of the size or shape of where I is the constant discharge current, ∆t is the discharging

introduced PG substrate. time, m is the total mass of the electrode, and V is the voltage

drop upon discharging (excluding the IR drop). Examination of

mechanical adhesion between nanoarrays and substrate was

EXPERIMENTAL SECTION carried out by using a commercial sonication equipment (power,

Synthesis of R-Co(OH)2 NWAs Arrays on PG. PG substrates 250 W; frequencies, 40 K Hz; medium, 50 mL of distilled water)

were obtained from disused batteries (Toshiba Co., Ltd.; AA). for 300 s.

In a typical synthesis, 0.582 g (2 mmol) Co(NO3)2 · 6H2O, 0.37 g

(10 mmol) NH4F and 0.6 g (10 mmol) CO(NH2)2 were dissolved

in 50 mL of water under magnetic stirring. After 10 min, the

RESULTS AND DISCUSSION

as-obtained homogeneous solution was transferred into Teflon- Figure 2a shows XRD pattern of R-Co(OH)2 NWAs on PG.

lined stainless steel autoclave and hereafter a piece of clean PG Obviously, except for a representative peak from PG all the

substrate (50 × 7 × 3 mm3, pretreated by hydrochloric acid other diffraction peaks can be indexed to cobalt carbonate

(37%) and distilled water successively and dried in air at room hydroxide hydrate (CCHH), which is consistent with the

temperature) was immersed into the reaction solution, placed value in the standard card (JCPDS Card No.38-0547).

against the liner wall, and fixed in the autoclave. Then, the liner

was sealed and maintained still at 120 °C for 6 h in an electric Images b and c in Figure 2 respectively display the optical

oven. After the equipment cooled to room temperature natu- images of the as-made sample before and after ultrasonica-

rally, the PG substrate with pink samples grown on was fetched tion testing. As is known, making a good contact between

out and cleaned by an ultrasonication treatment for 20-30 s inorganic nanoarrays and substrate is of quite important on

in order to remove the residual nanoparticle debris. electrochemical applications in terms of high-rate electron-

Characterization Techniques and Electrochemical Testing.

For further characterizations and measurements, products on transfer devices (18, 19). It is observed that the film of

PG substrate were preserved at 300 K in drying oven and then R-Co(OH)2 NWAs can still survive on PG substrate even

thoroughly characterized with X-ray powder diffraction (XRD, suffering from a powerful sonication treatment lasting 300 s,

Cu KR radiation; λ ) 1.5418 Å), scanning electron microscopy from which we can conclude that instead of a precipitation

(SEM, JSM-6700F; 5 kV) and transmission electron microscopy film formed by simple chemical deposition, as-prepared

(TEM and HRTEM, JEM-2010FEF; 200 kV). Electrochemical

measurements were conducted in 2 M aqueous KOH (by a half- R-Co(OH)2 NWAs with good adhesion property are really

cell setup configuration) at room temperature on a CHI660C grown on graphite substrate. In addition, it is noteworthy

electrochemical working station. A platinum gauze electrode that the growth of R-Co(OH)2 NWAs on PG can be achieved

and a standard calomel electrode (SCE) served as counter regardless of tailored size or shape of graphite substrates.

electrode and reference electrode, respectively. Different from This feature magnifies their potential capability for mass

the traditional method (29), after cleanness and encapsulation

(in detail, nail enamel was used to insulate the edge of PG.) the production on large area. To understand the good mechan-

products can be directly used as working electrodes; no other ical adhesion, we believe that defects existing on carbon-

ancillary materials such as carbon black or binder were needed. aceous surface, as recently reported by Dai et al. (29) could

B VOL. xxx • NO. xx • 000 • XXXX Jiang et al. www.acsami.org

ARTICLE

FIGURE 3. (a, b) Cross-sectional and (c) top-view SEM images of R-Co(OH)2 NWAs grown on graphite substrate. (d) TEM image and FFT pattern

(inset), and (d) HRTEM image of a single CCHH nanowire.

be very helpful for the growth of hydroxide and formation of R-Co(OH)2 but also good electronic connects and nanoar-

of strong chemical interactions. Besides, the surface of bulky rayed structural features. Thanks to the unique 1D architec-

PG could be oxidized in air atmosphere so that a couple of ture firmly built on current collector, R-Co(OH)2 NWAs can

oxygen functional groups, such as hydroxyl and carbonyl directly serve as working electrodes in the absence of any

groups, may exist on PG’s outer surface (30). These dangling extra conducting materials or polymer/binder. Figure 4a

functional groups can act as anchor sites through hydrogen shows the cyclic voltammetry (CV) curves of R-Co(OH)2

bonding in reaction solution and make the as-formed crystal NWAs (on PG) and PG substrate alone in 2 M KOH solution

seeds stick to PG substrate (31). at a scanning rate of 50 mV/s, respectively. According to the

After sonication testing, R-Co(OH)2 NWAs were in depth literature (28), there are two plausible reactions (quasi-

characterized by SEM and TEM/HRTEM, respectively. Figure reversible redox processes) occurring at the electrode/

3a displays the cross-sectional SEM image of uniform electrolyte interface as listed below

R-Co(OH)2 NWAs on PG substrate, from which it is con-

firmed that the average thickness of R-Co(OH)2 film is of ∼20 Co(OH)2 + OH- a CoOOH + H2O + e- E1/2 ) 0.1 V

µm (the dash line represents the interface between arrayed

nanowires and PG substrate). Herein, we need to emphasize

that among the previous reports (32-34), the length of CoOOH + OH- a CoO2 + H2O + e- E1/2 ) 0.4 V

R-Co(OH)2 nanowire is only around several micrometers

(<10 µm). In contrast, the length of R-Co(OH)2 nanowire

presented in our work is the longest. Figure 3b shows an The CV curve of R-Co(OH)2 NWAs is plotted (red), and we

enlarged SEM image of Figure 3a. It is interesting to find that can observe that two reversible electron-transfer processes

several nanowires of R-Co(OH)2 grown nearly vertically to are visible in Figure 4a. This result is consistent with the

substrate have formed a bundlelike structure on top. Typical reaction processes mentioned above during the potential

top-view SEM image over large area has been made and sweep of R-Co(OH)2 NWA electrode, indicating that the

shown in Figure 3c, which signifies the large-scale growth measured capacitance is on the basis of the redox mecha-

of R-Co(OH)2 nanostructured arrays on PG substrate. From nism. The CV curve made from PG alone (black) under the

TEM observation and the fast Fourier transform (FFT) pat- same conditions demonstrates that PG electrode itself has

tern manifested in Figure 3d, we can learn that a single an excellent electrochemical stability in alkaline solution

R-Co(OH)2 nanowire with a mean diameter of ∼200 nm within the potential range of -0.3 to 0.6 V (vs SCE) and

reveals a high crystallinity property. To make a further meanwhile suggests that PG’s contribution (double-layer

investigation on crystallinity, HRTEM observation of a single capacitance) to the total electrochemical capacitance can be

nanowire has been made. As shown in Figure 3e, the negligible in contrast with that of R-Co(OH)2 NWAs. Accord-

R-Co(OH)2 nanowire exhibits a single-crystalline structure; ingly, we can make a conclusion that R-Co(OH)2 NWAs are

the spacing of the lattice fringes observed from the magni- totally responsible for the measured capacitance. Figure 4b

fication region is calculated to be 2.94 Å, which can be shows the galvanostatic charge/discharge curve of R-Co(OH)2

indexed as (300) of orthorhombic CCHH. NWAs at a current denstity of 1 A/g. The specific capacitance

R-Co(OH)2 NWAs with robust adhesion to conductive is calculated as high as 642.5 F/g, multiple times higher than

graphite electrode were investigated as pseudocapacitors. that of carbon materials. This is primarily determined by the

The interest in studying their electrochemical performances energy-storage mechanism (36). Although carbon nanotube

stems from not only the outstanding theoretical capacitance (CNT) array with high density and long length (∼cm) feature

www.acsami.org VOL. xxx • NO. xx • 000 • XXXX C

ARTICLE

FIGURE 4. (a) CV curves of R-Co(OH)2 NWAs (red) and graphite (black) in potential range of -0.3 to 0.6 V, respectively. (b) Galvanostatic

charge-discharge curve, (c) specific capacity (as a function of current density), and (d) cycling performance of as-made sample.

grown on carbon materials (like carbon paper) using CVD cycles. Besides, the capacitance of R-Co(OH)2 NWAs can be

method is a kind of promising material for supercapacitors, totally recovered after variable power delivery tests. To

its specific capacitance value (usually less than 250 F/g) is account for the reasons corresponding to their good elec-

still limited by the charge storage mechanism of EDLCs, trochemical behaviors, we consider that good capacity

whose capacitances merely depend on the accessible surface retention could be potentially associated with both the robust

area of materials (36, 37), rather than the battery-like adhesion between nano materials and PG substrate and the

reversible faradic reactions; In addition, geometrical and architectural advantages of R-Co(OH)2 NWAs. 1D architec-

structural advantages of CNT array can only optimize elec- ture design provides numerous fast electron-transport ac-

trochemical performances (rate capability, etc.). Electro- cesses to current collector, allowing for quick electron

chemical capacitances of as-made sample at various dis- transfer from active redox sites to electrode. On the other

charge current densities have been evaluated and displayed hand, large surface to volume ratio of 1D nanostructure is

in Figure 4c. With the increasing of discharge current densi- also able to provide more active sites than bulk counterparts

ties, the specific capacitance of R-Co(OH)2 NWAs is calcu- and obviously shorten the pathway of anion transport.

lated to be 480.45 F/g (1.5 A/g), 422.36 F/g (3 A/g), 350.54 Furthermore, as a fundamental requirement for free-stand-

F/g (10 A/g), 330.75 F/g (20 A/g), respectively. To the best ing films, good mechanical adhesion plays a key role in

of our knowledge, the rate performance of R-Co(OH)2 NWAs ensuring the excellent electrical contact and capacity reten-

is far better than that of NiO NWAs (35). From the perspec- tion during energy storage/conversion processes occurred

tive of engineering/technology and practical working de- in alkaline solution.

mands, the study in terms of variable power delivery is Building long functional metal hydroxide/oxide NWAs on

highly desired and worthy. As can be seen, Figure 4d conductive substrate is exceptionally important for many

illustrates the cycling performance of R-Co(OH)2 NWAs on applications on energy conversion/storage (e.g., dye-sensi-

PG with various current densities. The cycling response with tized solar cells and batteries) because long nanowires can

a steplike shape at progressive rates can be evidently elevate the load of active materials, increase the internal

recorded. Together with the increasing of discharging cur- surface area, and create more reactive sites (38, 39). How-

rent rates, the average capacitance of R-Co(OH)2 NWAs can ever, it remains challenging to synthesize long metal hy-

be measured around 430 F/g (3A/g), 345 F/g (10 A/g), and droxide/oxide NWAs directly on substrate via simple solution-

300 F/g (20 A/g), respectively. Herein, it is noteworthy that based method without any seeded process. In our work,

the electrode reveals good electrochemical stability even there is a highlight that the length of R-Co(OH)2 NWAs is up

when suffering from sudden change of current delivery. to ∼20 µm, nearly multiple times that of other metal

After 3000 cycles, the average capacitance is successively hydroxides/oxides NWAs (e.g., four times that of ZnO NWAs

recorded as 340 F/g, 436 F/g by decreasing the current rate (∼4 µm)) (40). Recently, Liu et al. reported a novel “sacrificial

from 20 A/g to 3 A/g. Compared with initial cycles, there is template-accelerated hydrolysis” (STAH) method for the

no obvious capacitance decrease appearing over 3000 preparation of FeOx nanotublar arrays on alloy substrate

D VOL. xxx • NO. xx • 000 • XXXX Jiang et al. www.acsami.org

using ZnO NWAs as sacrificial templates (17). As a category (9) Zhou, H. S.; Li, D.; Hibino, M.; Honma, I. Angew. Chem., Int. Ed.

of hydroxide carbonate, R-Co(OH)2 itself can be gradually 2005, 5, 807–812.

(10) Hosono, E.; Fujihara, S.; Honma, I.; Ichihara, M. J. Power Sources

dissolved by acid. Accordingly, we suppose that R-Co(OH)2

ARTICLE

2006, 158, 779 –783.

long NWAs on PG substrate might be capable of being in situ (11) Yu, T.; Zhu, Y. W.; Xu, X. J.; Shen, Z. X.; Chen, P.; Lim, C. T.;

dissolved and serving as sacrificial templates that would in Thong, J. T. L.; Sow, C. H. Adv. Mater. 2005, 17, 1595–1599.

(12) Yu, T.; Zhu, Y. W.; Xu, X. J.; Yeong, K. S.; Shen, Z. X.; Chen, P.;

turn initiate nanoarrays formation. This feature shows great Lim, C. T.; Thong, J. T. L.; Sow, C. H. Small 2006, 2, 80 –84.

potential in the preparation of a wild spectrum of long (13) Liu, J. P.; Li, Y. Y.; Huang, X. T.; Li, G. Y.; Li, Z. K. Adv. Funct.

inorganic oxide NWAs (e.g., NiO, MnO2, SnO2, Fe2O3, etc.) Mater. 2008, 18, 1448 –1458.

(14) Li, L.; Yang, Y. W.; Li, G. H.; Zhang, L. D. Small 2006, 2, 548 –

on PG substrate via “STAH” method. Our future work would

553.

focus on this strategy. (15) Ding, R. M.; Liu, J. P.; Jiang, J.; Li, Y. Y.; Hu, Y. Y.; Ji, X. X.; Chi,

Q. B.; Wu, F.; Huang, X. T. Chem. Commun. 2009, 4548 –4550.

CONCLUSIONS (16) Zeng, H. B.; Xu, X. J.; Bando, Y.; Gautam, U. K.; Zhai, T. Y.; Fang,

In summary, large-scale R-Co(OH)2 NWAs with a length of X. S.; Liu, B. D.; Golberg, D. Adv. Funct. Mater. 2009, 19, 3165–

∼20 µm has been synthesized on graphite substrate via a 3172.

(17) Liu, J. P.; Li, Y. Y.; Fan, H. J.; Zhu, Z. H.; Jiang, J.; Ding, R. M.; Hu,

hydrothermal method and furthermore applied as electrodes Y. Y.; Huang, X. T. Chem. Mater. 2010, 22, 212–217.

of electrochemical pseudocapacitors. Robust mechanical adhe- (18) Liu, J. P.; Li, Y. Y.; Huang, X. T.; Ding, R. M.; Hu, Y. Y.; Jiang, J.;

sion of as-made arrayed products is confirmed by a long time Liao, L. J. Mater. Chem. 2009, 19, 1859 –1864.

(19) Jiang, J.; Li, Y. Y.; Liu, J. P.; Huang, X. T. Nanoscale 2011, DOI:

sonication test. R-Co(OH)2 NWAs firmly grown on PG save the

10.1039/c0nr00472c.

tedious process of mixing active material with ancillary materi- (20) Jiang, J.; Liu, J. P.; Ding, R. M.; Ji, X. X.; Hu, Y. Y.; Li, X.; Hu, A. Z.;

als and show a high specific capacitance of ∼642.5 F/g, Wu, F.; Zhu, Z. H.; Huang, X. T. J. Phys. Chem.C 2010, 114, 929 –

remarkable rate capability, and good capacity retention due to 932.

(21) Taylor, R.; Gilchrist, K. E.; Poston, L. J. Carbon 1968, 6, 537–544.

1D architectural advantages and good electronic contacts. Our (22) Tung, V. C.; Allen, M. J.; Yang, Y.; Kaner, R. B. Nat. Nanotechnol.

result not only presents a cost-effective and scale-up synthetic 2009, 4, 25–29.

method for R-Co(OH)2 NWAs but also holds promise in the (23) Novoselov, K. S.; Geim, A. K.; Morozov, S. V.; Jiang, D.; Zhang,

Y.; Dubonos, S. V.; Grigorieva, I. V.; Firsov, A. A. Science 2004,

development of general synthesis of another metal hydroxide/ 306, 666 –669.

oxide long nanoarrays on PG substrate using R-Co(OH)2 NWAs (24) Lin, Y. M.; Jenkins, K. A.; Garcia, A. V.; Small, J. P.; Farmer, D. B.;

as sacrificial templates. Avouris, P. Nano Lett. 2009, 9, 422–426.

(25) Yang, H.; Coombs, N.; Sokolova, I.; Ozin, G. A. J. Mater. Chem.

Acknowledgment. We gratefully acknowledge financial 1997, 7, 1285–1290.

(26) Ma, H. Y.; Hu, N. F.; Rusling, J. F. Langmuir 2000, 16, 4969 –4975.

support from the National Natural Science Foundation of (27) Li, W. Z.; Wang, D. Z.; Yang, S. X.; Wen, J. G.; Ren, Z. F. Chem.

China (50872039 and 50802032), China Postdoctoral Sci- Phys. Lett. 2001, 335, 141–149.

ence Foundation (20090460996), the Open Project Program (28) Cao, L.; Xu, F.; Liang, Y. Y.; Li, H. L. Adv. Mater. 2004, 16, 1853–

of Key Laboratory of Quak & Lepton Physics (Huazhong 1857.

Normal University) Ministry of Education, China (QL- (29) Wang, H. L.; Casalongue, H. S.; Liang, Y. Y.; Dai, H. J. J. Am. Chem.

Soc. 2010, 132, 7472–7477.

PL200902), and the self-determined research funds of CCNU

(30) Xu, J. J.; Wang, K.; Zu, S. Z.; Han, B. H.; Wei, Z. X. ACS Nano 2010,

from the colleges’ basic research and operation of MOE 4, 5019 –5026.

(CCNU09A01019). (31) Wang, Y.; Xia, H.; Lu, L.; Lin, J. Y. ACS Nano 2010, 4, 1425–1432.

(32) Xu, R.; Zeng, H. C. J. Phys. Chem. B 2003, 107, 12643–12649.

REFERENCES AND NOTES (33) Hosono, E.; Fujihar, S.; Honma, I.; Zhou, H. S. J. Mater. Chem.

(1) Service, R. F. Science 2006, 313, 902. 2005, 15, 1938 –1945.

(2) Bruce, R. F.; Scrosati, B.; Tarascon, J. M. Angew. Chem., Int. Ed. (34) Jiang, J.; Liu, J. P.; Huang, X. T.; Li, Y. Y.; Ding, R. M.; Ji, X. X.;

2008, 47, 2930 –2946. Hu, Y. Y.; Chi, Q. B.; Zhu, Z. H. Cryst. Growth Des. 2010, 10, 70 –

(3) Talapatra, S.; Kar, S.; Pal, S. K.; Vajtai, R.; Ci, L.; Victor, P.; 75.

Shaijumon, M. M.; Kaur, S.; Nalamasu, O.; Ajayan, P. M. Nat. (35) Pang, H.; Lu, Q. Y.; Zhang, Y. Z.; Li, Y. C.; Gao, F. Nanoscale 2010,

Nanotechnol. 2006, 1, 112–116. 2, 920 –922.

(4) Miller, J. R.; Simon, P. Science 2008, 321, 651–651. (36) Zhang, H.; Cao, G. P.; Yang, Y. S. Energy Environ. Sci. 2009, 2,

(5) Chen, P. C.; Shen, G. Z.; Sukcharoenchoke, S.; Zhou, C. W. Appl. 932–943.

Phys. Lett. 2009, 94, 043113. (37) Kim, B.; Chung, H.; Kim, W. J. Phys. Chem. C 2010, 114, 15223–

(6) Hu, C. C.; Chang, K. H.; Lin, M. C.; Wu, Y. T. Nano Lett. 2006, 6, 15227.

2690 –2695. (38) Chan, C. K.; Zhang, X. F.; Cui, Y. Nano Lett. 2008, 8, 307–309.

(7) Ke, Y. F.; Tsai, Y. S.; Huang, Y. S. J. Mater. Chem. 2005, 15, 2122– (39) Xu, C. K.; Shin, P.; Cao, L. L.; Gao, D. J. Phys. Chem.C 2010, 114,

2127. 125–129.

(8) Xiao, W.; Xia, H.; Fuh, J. Y. H.; Lu, L. J. Power Sources 2009, 193, (40) Liu, J. P.; Huang, X. T.; Li, Y. Y.; Ji, X. X.; Li, Z. K.; He, X.; Sun,

935–938. F. L. J. Phys. Chem. C 2007, 111, 4990 –4997.

www.acsami.org VOL. xxx • NO. xx • 000 • XXXX E

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Samsung Ue65ks9000t Chassis Uwq60 Suhd TVDocument92 pagesSamsung Ue65ks9000t Chassis Uwq60 Suhd TVkevinalleinNo ratings yet

- 3926-Article Text-15001-1-10-20180918 PDFDocument20 pages3926-Article Text-15001-1-10-20180918 PDFDored AkareNo ratings yet

- Basics of Measuring The Dielectric Properties of MaterialsDocument16 pagesBasics of Measuring The Dielectric Properties of MaterialsYouli TianNo ratings yet

- Bearing Insulation For VFD Driven MotorDocument2 pagesBearing Insulation For VFD Driven Motorมนตรี เดชธนาศักดิ์No ratings yet

- Lecture Impedance and Admittance On Smith ChartsDocument15 pagesLecture Impedance and Admittance On Smith ChartsBill WhiteNo ratings yet

- Veterinary Radiography, A Workbook For Students (VetBooks - Ir) PDFDocument131 pagesVeterinary Radiography, A Workbook For Students (VetBooks - Ir) PDFDragos HodorNo ratings yet

- Namma Kalvi 9th Science Term 2 Guide emDocument50 pagesNamma Kalvi 9th Science Term 2 Guide emVadivel KmNo ratings yet

- 104 Servomotor Se BoschDocument76 pages104 Servomotor Se BoschelektronNo ratings yet

- Socomec AtysDocument2 pagesSocomec AtysmehdivinciNo ratings yet

- Elevator Test Method Rev. 1 (Dood)Document12 pagesElevator Test Method Rev. 1 (Dood)ThomasNo ratings yet

- Design of A Wireless Power Transfer System Using Inductive Coupling and MATLAB ProgrammingDocument9 pagesDesign of A Wireless Power Transfer System Using Inductive Coupling and MATLAB Programmingvijay patilNo ratings yet

- Theoretical Modeling of Tm-Doped Silica Fiber LasersDocument9 pagesTheoretical Modeling of Tm-Doped Silica Fiber Lasersteektak1No ratings yet

- Ds 1ln6 Uu U Utp Cat6 4p0.565 PVC CMDocument1 pageDs 1ln6 Uu U Utp Cat6 4p0.565 PVC CMFelisha FebryNo ratings yet

- Current A LevelDocument9 pagesCurrent A Levelnazran68No ratings yet

- Training Report On Embedded SystemDocument16 pagesTraining Report On Embedded SystemTarun kumarNo ratings yet

- ELYM 115 2nd Opp Examination MC-2022-09-21 TTDocument3 pagesELYM 115 2nd Opp Examination MC-2022-09-21 TTTrevor TolibadiNo ratings yet

- MMLB 01 - 02 Manual GB - FR-FR PDFDocument8 pagesMMLB 01 - 02 Manual GB - FR-FR PDFAnonymous xBi2FsBxNo ratings yet

- Akhwat Yar MirzaDocument1 pageAkhwat Yar MirzaAnonymous BZQOJwWIh6No ratings yet

- EC6011 QBDocument6 pagesEC6011 QBJulia JosephNo ratings yet

- DR AF T: Annex A Product Safety StandardsDocument4 pagesDR AF T: Annex A Product Safety StandardstatacpsNo ratings yet

- Circuit Simulation Using X CosDocument16 pagesCircuit Simulation Using X Cosmcardinot12No ratings yet

- Ee 6501 - Power System Analysis Unit-3 Fault Analysis-Balanced Faults Part ADocument4 pagesEe 6501 - Power System Analysis Unit-3 Fault Analysis-Balanced Faults Part AVbalaji VaithiyanathanNo ratings yet

- AUMAMATICba Sar1!07!16 Am1 Parallel enDocument68 pagesAUMAMATICba Sar1!07!16 Am1 Parallel enqasim_maqboolNo ratings yet

- FVC800 FLUXVERTER DRIVES - BrochureDocument11 pagesFVC800 FLUXVERTER DRIVES - BrochureVenu BallaNo ratings yet

- Course Title: Building Services (Electrical) : Prepared By: Olabode Oluwafemi. RDocument25 pagesCourse Title: Building Services (Electrical) : Prepared By: Olabode Oluwafemi. ROlawale AdebesinNo ratings yet

- Flomat EngDocument8 pagesFlomat Engalex.amaral9292No ratings yet

- Mccsemi:) HdwxuhvDocument2 pagesMccsemi:) HdwxuhvfreddyNo ratings yet

- Epas G9 M Q3 W3-W4Document4 pagesEpas G9 M Q3 W3-W4ALLYSSA MAE PELONIANo ratings yet

- CMOS Logic Circuit: CMOS Two Input NOR GateDocument3 pagesCMOS Logic Circuit: CMOS Two Input NOR GateSheikh Abdullah Al SalmanNo ratings yet

- BTA40 and BTA/BTB41 Series: 40A TriacDocument6 pagesBTA40 and BTA/BTB41 Series: 40A TriacnandobnuNo ratings yet