Professional Documents

Culture Documents

1.4313 BS 3100 425C11

Uploaded by

g1ann1sOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.4313 BS 3100 425C11

Uploaded by

g1ann1sCopyright:

Available Formats

Outokumpu 4313 Martensitic Stainless Steel Σελίδα 1 από 1

Outokumpu 4313 Martensitic Stainless Steel

Categories: Metal; Ferrous Metal; Stainless Steel; Alloy Steel; Martensitic

Material Applications: Wet corrosion resistance and general service.

Notes:

Available in hot rolled plate (Quarto) form.

Key Words: EN 1.4313; ASTM S41500; JIS SUS Ti6NM

Vendors: Click here to view all available suppliers for this material.

Please click here if you are a supplier and would like information on how to add your

listing to this material.

Mechanical Properties Metric English Comments

Tensile Strength, Ultimate 850 MPa 123000 psi Outokumpu Typical, Quenched &

Tempered Hot Rolled Plate (Quarto); EN

10002-1

Tensile Strength, Yield 530 MPa 76900 psi EN min., 0.2% Strain; EN 10002-5

@Temperature 400 °C @Temperature 752 °F

560 MPa 81200 psi EN min., 0.2% Strain; EN 10002-5

@Temperature 200 °C @Temperature 392 °F

590 MPa 85600 psi EN min., 0.2% Strain; EN 10002-5

@Temperature 100 °C @Temperature 212 °F

650 MPa 94300 psi EN min., 0.2% Strain, RT; EN 10002-1

700 MPa 102000 psi Outokumpu Typical, 0.2% Strain,

Quenched & Tempered Hot Rolled Plate

(Quarto); EN 10002-1

770 MPa 112000 psi Outokumpu Typical, 1.0% Strain,

Quenched & Tempered Hot Rolled Plate

(Quarto); EN 10002-1

Elongation at Yield 20.0 % 20.0 % Outokumpu Typical, Quenched &

Tempered Hot Rolled Plate (Quarto); EN

10002-1

Material Components Metric English Comments

Properties

Carbon, C 0.0500 % 0.0500 %

Chromium, Cr 13.0 % 13.0 %

Iron, Fe 82.45 % 82.45 %

Molybdenum, Mo 0.500 % 0.500 %

Nickel, Ni 4.00 % 4.00 %

Some of the values displayed above may have been converted from their original units and/or rounded in order to display the information in a

consistant format. Users requiring more precise data for scientific or engineering calculations can click on the property value to see the

original value as well as raw conversions to equivalent units. We advise that you only use the original value or one of its raw conversions in

your calculations to minimize rounding error. We also ask that you refer to MatWeb's disclaimer and terms of use regarding this information.

Click here to view all the property values for this datasheet as they were originally entered into MatWeb.

NOUTOK03

http://www.matweb.com/search/datasheet_print.aspx?matguid=7edeaf6d0b57478b956... 27/7/2008

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- LDX 2101 OutokumpuDocument2 pagesLDX 2101 OutokumpuLahire Solér JuniorNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data Sheetducchinh080No ratings yet

- ASM Material Data Sheet 316Document2 pagesASM Material Data Sheet 316.xNo ratings yet

- 316 Stainless Steel, Anneal...Document3 pages316 Stainless Steel, Anneal...Moisés Vázquez ToledoNo ratings yet

- 316-SS-annealed Bar and Cold DrawnDocument2 pages316-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- T - Thermanit MTS 4 - Se - en - 5Document1 pageT - Thermanit MTS 4 - Se - en - 5bhanu.kiranNo ratings yet

- A40t En-UsDocument1 pageA40t En-UstobiaswatzingerNo ratings yet

- A40t En-UsDocument1 pageA40t En-UstobiaswatzingerNo ratings yet

- 316 Stainless Steel, Annealed SheetDocument2 pages316 Stainless Steel, Annealed SheetZASSNo ratings yet

- Aluminum 2014-T6; 2014-T651: High Strength Al-Cu-Mg AlloyDocument3 pagesAluminum 2014-T6; 2014-T651: High Strength Al-Cu-Mg Alloyvishwanadh kNo ratings yet

- 13CrMo45 P12 T12 Engl PDFDocument3 pages13CrMo45 P12 T12 Engl PDFYankMulya MusaNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10225Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10225farshid KarpasandNo ratings yet

- 1 4501 Super Duplex TubesDocument3 pages1 4501 Super Duplex TubesAlma JakirovićNo ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- NiCrFe alloy welding electrodeDocument1 pageNiCrFe alloy welding electrodeRoberto_PrrNo ratings yet

- Brick A 35 SDocument1 pageBrick A 35 SMuhammad TayyabNo ratings yet

- X20Cr13 %C %si %MN %P %S %CR %cu %mo %NB %niDocument2 pagesX20Cr13 %C %si %MN %P %S %CR %cu %mo %NB %nibhanu.kiranNo ratings yet

- Metal Plate Resistors MPR 2W/5W/10WDocument3 pagesMetal Plate Resistors MPR 2W/5W/10Wxavier morenoNo ratings yet

- 316L-SS-annealed BarDocument2 pages316L-SS-annealed BarARUNKANNANNo ratings yet

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Martensitic Stainless Steel EN 1.4057, QT 800Document2 pagesMartensitic Stainless Steel EN 1.4057, QT 800LebasNo ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- 316L SS CrucibleDocument2 pages316L SS CrucibleARUNKANNANNo ratings yet

- Alloy 6082 - Rev2012Document2 pagesAlloy 6082 - Rev2012Ysraels Santisteban DurandNo ratings yet

- AISI Type 304L Stainless Steel Material Data - 12676Document1 pageAISI Type 304L Stainless Steel Material Data - 12676Ian Pillay100% (1)

- SS 420 PropertiesDocument2 pagesSS 420 PropertiesmrbookaniNo ratings yet

- Martensitic Stainless Steel EN 1.4021-QT 700Document2 pagesMartensitic Stainless Steel EN 1.4021-QT 700LebasNo ratings yet

- Martensitic Stainless Steel PropertiesDocument2 pagesMartensitic Stainless Steel PropertiesmrbookaniNo ratings yet

- Sandvik 3re60 Tube and Pipe, Seamless: DatasheetDocument10 pagesSandvik 3re60 Tube and Pipe, Seamless: DatasheetVinay TrivediNo ratings yet

- Thermanit GE-316L PDFDocument1 pageThermanit GE-316L PDFsmpoe017No ratings yet

- Aluminum 5052Document6 pagesAluminum 5052lalfredoperezNo ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- The Aluminium Evolution: Continuous Casting Aluminium AlloysDocument2 pagesThe Aluminium Evolution: Continuous Casting Aluminium AlloysHareth MRAIDINo ratings yet

- 30 CR Ni Mo 8Document2 pages30 CR Ni Mo 8Amy GriffinNo ratings yet

- Alloy Steel p22 PlatesDocument3 pagesAlloy Steel p22 PlatesMiguel PulidoNo ratings yet

- Autrod 1264Document2 pagesAutrod 1264Anonymous yL7oldKNo ratings yet

- Aluminum 6351-T6, Aluminium DatasheetDocument2 pagesAluminum 6351-T6, Aluminium DatasheetvikrantNo ratings yet

- SINOXX 4006 Steel: Designation by StandardsDocument3 pagesSINOXX 4006 Steel: Designation by StandardsKiranNo ratings yet

- 1 8550-34CrAlNi710Document2 pages1 8550-34CrAlNi710Michel PortalNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocument3 pagesAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloySaad SaudNo ratings yet

- Exhaust Rim E722 - Epoxy - PDSDocument5 pagesExhaust Rim E722 - Epoxy - PDSSpace MuskNo ratings yet

- 1.4305 Sae303 DatasheetDocument2 pages1.4305 Sae303 Datasheetehudingram6535No ratings yet

- 303-Stainless Steel-Annealed BarDocument2 pages303-Stainless Steel-Annealed BarARUNKANNANNo ratings yet

- 16 Ni CR 11Document2 pages16 Ni CR 11ceca nikolicNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- kme_STOL76_C19010_enDocument1 pagekme_STOL76_C19010_enMattia Terri TerrandoNo ratings yet

- L1_34428_en__B_Boehler-AWS-ER309L_ss_en_1Document1 pageL1_34428_en__B_Boehler-AWS-ER309L_ss_en_1Edgar HornusNo ratings yet

- Ti 5al 2.5feDocument2 pagesTi 5al 2.5feNiraNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- 6060 PropertiesDocument3 pages6060 Propertiesinterpon07No ratings yet

- SEMIKRON DataSheet SKN 94 02644150Document3 pagesSEMIKRON DataSheet SKN 94 02644150Vítor Dias JavornikNo ratings yet

- Bohler AWS ER308LDocument1 pageBohler AWS ER308LbrayanNo ratings yet

- Bohler Aws Er308lDocument1 pageBohler Aws Er308lJuan ShunaNo ratings yet

- X8CrNiS18-9 austenitic stainless steel technical cardDocument1 pageX8CrNiS18-9 austenitic stainless steel technical cardshahid khanNo ratings yet

- 10 HMMIK329 DDDDocument2 pages10 HMMIK329 DDDg1ann1sNo ratings yet

- Torrent Pumps: Deep Well Vertical Turbine Pumps 1/16Document2 pagesTorrent Pumps: Deep Well Vertical Turbine Pumps 1/16g1ann1s100% (1)

- Torrent Pumps: 6 KNB 2900 6 - 0702 5 " K 2,4Document1 pageTorrent Pumps: 6 KNB 2900 6 - 0702 5 " K 2,4g1ann1sNo ratings yet

- Torrent Pumps: Deep Well Vertical Turbine PumpsDocument2 pagesTorrent Pumps: Deep Well Vertical Turbine Pumpsg1ann1sNo ratings yet

- Torrent Pumps: 8 KNM/K 2900 8 - 0203Document4 pagesTorrent Pumps: 8 KNM/K 2900 8 - 0203g1ann1sNo ratings yet

- 18MPM717Document1 page18MPM717g1ann1sNo ratings yet

- Torrent Pumps: Deep Well Vertical Turbine Pumps 1/2Document1 pageTorrent Pumps: Deep Well Vertical Turbine Pumps 1/2g1ann1sNo ratings yet

- Torrent Pumps: Deep Well Vertical Turbine PumpsDocument2 pagesTorrent Pumps: Deep Well Vertical Turbine Pumpsg1ann1sNo ratings yet

- Torrent Pumps: 10 Hmm-I 1480 10 - 0637Document2 pagesTorrent Pumps: 10 Hmm-I 1480 10 - 0637g1ann1sNo ratings yet

- 10 HMMIK329 DDDDocument2 pages10 HMMIK329 DDDg1ann1sNo ratings yet

- Max. power centrifugal pump performance curveDocument2 pagesMax. power centrifugal pump performance curveg1ann1sNo ratings yet

- 12KM719Document1 page12KM719g1ann1sNo ratings yet

- Torrent: Low Lift PumpsDocument1 pageTorrent: Low Lift Pumpsg1ann1sNo ratings yet

- Increased efficiency and head for a single-stage deep well pumpDocument1 pageIncreased efficiency and head for a single-stage deep well pumpg1ann1sNo ratings yet

- Torrent Pumps: Deep Well Vertical Turbine Pumps 1/2Document1 pageTorrent Pumps: Deep Well Vertical Turbine Pumps 1/2g1ann1sNo ratings yet

- Torrent Pumps: 6 KNB 2900 6 - 0702 5 " K 2,4Document1 pageTorrent Pumps: 6 KNB 2900 6 - 0702 5 " K 2,4g1ann1sNo ratings yet

- Increased efficiency and head for a single-stage deep well pumpDocument1 pageIncreased efficiency and head for a single-stage deep well pumpg1ann1sNo ratings yet

- Torrent Pumps: Deep Well Vertical Turbine PumpsDocument1 pageTorrent Pumps: Deep Well Vertical Turbine Pumpsg1ann1sNo ratings yet

- Torrent Pumps: Deep Well Vertical Turbine Pumps 1/2Document1 pageTorrent Pumps: Deep Well Vertical Turbine Pumps 1/2g1ann1sNo ratings yet

- Pump Curve MNB 3x12768Document1 pagePump Curve MNB 3x12768g1ann1sNo ratings yet

- 12HM520Document1 page12HM520g1ann1sNo ratings yet

- 36 Pump Industry: RPM TRIMMING (R) : R 201 Curve No: 50 HZ SUC: 65 Disch: 40Document2 pages36 Pump Industry: RPM TRIMMING (R) : R 201 Curve No: 50 HZ SUC: 65 Disch: 40g1ann1sNo ratings yet

- 24PR704Document1 page24PR704g1ann1sNo ratings yet

- Centrifugal pump performance curveDocument1 pageCentrifugal pump performance curveg1ann1sNo ratings yet

- 10PR720Document1 page10PR720g1ann1sNo ratings yet

- 12KM719Document1 page12KM719g1ann1sNo ratings yet

- Performance curves for multi-stage pumpsDocument2 pagesPerformance curves for multi-stage pumpsg1ann1sNo ratings yet

- Torrent Pumps: Deep Well Vertical Turbine Pumps 1/2Document1 pageTorrent Pumps: Deep Well Vertical Turbine Pumps 1/2g1ann1s100% (1)

- 16PR628Document1 page16PR628g1ann1sNo ratings yet

- Torrent Pumps: Deep Well Vertical Turbine PumpsDocument1 pageTorrent Pumps: Deep Well Vertical Turbine Pumpsg1ann1sNo ratings yet

- MEN 321 Chapter 9 Flow Over Immersed BodiesDocument81 pagesMEN 321 Chapter 9 Flow Over Immersed BodiesGeo AyoubNo ratings yet

- 1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00Document107 pages1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00vhpatel67No ratings yet

- Shear Modulus at Room Temperature: Standard Test Method ForDocument5 pagesShear Modulus at Room Temperature: Standard Test Method ForROHITNo ratings yet

- ASME 2017 SA 312 Sublimentry RequirementsDocument2 pagesASME 2017 SA 312 Sublimentry RequirementsKathir VelNo ratings yet

- G-R 25Document27 pagesG-R 25Duncan VanderwallNo ratings yet

- Beep 2 CdevDocument1,241 pagesBeep 2 CdevIzio SilvaNo ratings yet

- TITUS Catalog - Grilles & RegistersDocument16 pagesTITUS Catalog - Grilles & RegistersZainul Abedin SayedNo ratings yet

- EJOT Crossfix Factsheet 2022 07 21 ENDocument1 pageEJOT Crossfix Factsheet 2022 07 21 ENEren GülayNo ratings yet

- AERODYNAMICS-II QUESTION BANKDocument8 pagesAERODYNAMICS-II QUESTION BANKhamdanforaero100% (1)

- Vahterus Plate and Ring Prhe-EnDocument4 pagesVahterus Plate and Ring Prhe-EnMartin CorkeryNo ratings yet

- FraceDocument12 pagesFraceIra MejiaNo ratings yet

- How To Size A Room Air Conditioner PDFDocument3 pagesHow To Size A Room Air Conditioner PDFKo PaukNo ratings yet

- Water Bound Macadam-WbmDocument11 pagesWater Bound Macadam-WbmCheng EngiNo ratings yet

- Rudawska 2016Document33 pagesRudawska 2016MochammadDzulFiqarNo ratings yet

- Alfa Laval Gphe Catalog 2022Document20 pagesAlfa Laval Gphe Catalog 2022JUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Bill 10 UG Water Tank and Pump RoomDocument92 pagesBill 10 UG Water Tank and Pump RoomLevy MalagambaNo ratings yet

- iRSVP 3100 Data Sheet.Document2 pagesiRSVP 3100 Data Sheet.Gỗ MộcNo ratings yet

- Philips Lighting 1Document45 pagesPhilips Lighting 1Manisankar DhabalNo ratings yet

- Shackelford 7e 13ADocument44 pagesShackelford 7e 13AaznapnNo ratings yet

- Building Envelope Testing Report by SGS Pak - Rev. 00Document45 pagesBuilding Envelope Testing Report by SGS Pak - Rev. 00muzammalNo ratings yet

- Proper Maintenance of InstrumentsDocument92 pagesProper Maintenance of InstrumentsDimi DimoNo ratings yet

- Plastering Checklist PDFDocument1 pagePlastering Checklist PDFabdelmjidNo ratings yet

- PDF Standard Construction Productivity Norms ManpowerDocument1 pagePDF Standard Construction Productivity Norms ManpowereldredvongaringNo ratings yet

- BanbgroupDocument59 pagesBanbgroupVenkata RajuNo ratings yet

- Georges Pompidou CenterDocument3 pagesGeorges Pompidou CenterGrendelle BasaNo ratings yet

- Column DesignDocument4 pagesColumn DesignRafsanjani AbasNo ratings yet

- Corrosion-Guide 1 Stainless Steel CategoriesDocument8 pagesCorrosion-Guide 1 Stainless Steel CategoriesMarc L'abbéNo ratings yet

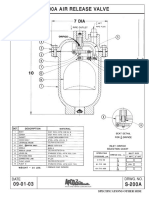

- APCO. S-200a Air Release ValveDocument2 pagesAPCO. S-200a Air Release ValveAlberto Diaz100% (2)

- SeaRox SL 620: improved fire safety and acousticsDocument2 pagesSeaRox SL 620: improved fire safety and acousticsAnh Le NgocNo ratings yet

- Geyser Mounting Horizontal Vs VerticalDocument1 pageGeyser Mounting Horizontal Vs VerticalRussell Collett0% (1)