Professional Documents

Culture Documents

Operating Case Trunnion Calculation Sheet: Input Data

Uploaded by

Jagadish Jas0 ratings0% found this document useful (0 votes)

2K views1 pageOriginal Title

trunion_cal[1].1122

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2K views1 pageOperating Case Trunnion Calculation Sheet: Input Data

Uploaded by

Jagadish JasCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

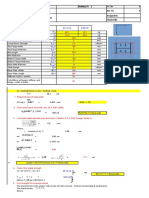

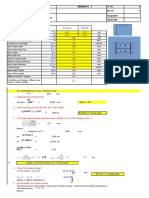

TRUNNION CALCULATION SHEET Operating Case

Client: Yanbu National Petrochemical Co. Pipe Support Number: GS70-76B-632

Project: HDPE Project By: jagadish Chkd:

Location: Yanbu , Saudi Arabia Date: 21/01/2008 Date:

Job №: 119784 Area: 46 Line Number: 46-SM-1111-1CS1S02H1-4"-IH

GA №: Stress Sketch Number:

INPUT DATA: Metric or Imperial Sizes : IMP

Nominal Pipe Size = 16" (400) Diameter (D) = 406.4 mm Radius (R) = 203.2 mm

(inc. rolling

Nominal Thickness (T) = 12.7 mm Pipe Minimum Thickness = 9.513 mm tolerance)

Corrosion Allowance = 1.6 mm Effective Wall Thickness (t) = 9.513 mm

Nom.Trunnion Size = 14" (350) Diameter (d) = 355.6 mm Radius (r) = 177.8 mm

Trunnion Wall Thickness = 9525 mm Longitudinal Force (Fl) = 2360 N

Pad Nominal Thickness = 0 mm Circumferential Force (Fc) = 2434 N

Moment Arm (L) = 700 mm Direct Axial Load (Fa) = 33256 N

Max Design Pressure (P) = 28 bar Maximum Operating Temp. = 150 C°

Material Type = CS Allowable Stress (Sh) =. 137 N/mm²

SUMMARY: 16" HEADER 14" TRUNNION(NO REPAD REQUIRED)

HEADER STRESS = 49% OF ALLOWABLE UNITY CHECK = 0% OF ALLOWABLE

HEADER STRESSES OK TRUNNION UNITY CHECK OK

CALCULATION: fl = [ ( Fl x L ) / πr² ] = 16.634 N/mm (longitudinal lineal load)

(Using Kellogg's Method) fc = [ ( Fc x L ) / πr² ] = 17.1556 N/mm (circumferential lineal load)

fa = [ Fa / 2πr ] = 29.7686 N/mm (direct lineal load)

f1 = [ ( 1.5 fa ) + fl ] = 61.3 N/mm f2 = [ 1.5 ( fc + fa ) ] = 70.386 N/mm

Sbl = ( 1.17 x f1 x √ R ) / t1.5 =. 34.8396 N/mm² (longitudinal bending stress)

Sbc = ( 1.17 x f2 x √ R ) / t1.5 =. 40.0123 N/mm² (circumferential bending stress)

Spl = P x R / 20t =. 29.9059 N/mm² (longitudinal primary stress)

Sph = P x R / 10t =. 59.8118 N/mm² (hoop primary stress)

Sl = Sbl + Spl =. 64.7455 N/mm² (combined longitudinal stress)

Sc = Sbc + Sph =. 99.8241 N/mm² (combined circumferential stress)

Sh = 137 N/mm² (allowable stress) 1.5 x Sh = 205.5 N/mm² 99.8

Maximum Combined Stress (Sc or Sl)

= 0.49 < 1.0 HEADER STRESSES OK

1.5 x Sh

UNITY CHECK: Pc = 80 N/mm² Area (a) = ### mm²

Pbc = 100 N/mm² Section Modulus (Z) = ### mm3

fbc xx = ML / Z = 0.00 N/mm²

fbc zz = MC / Z = 0.00 N/mm²

f dir = Fa / a = 0.00 N/mm²

f dir fbc xx + fbc zz

+ = 0.00 < 1.0 UNITY CHECK OK

Pc Pbc

You might also like

- Trunion Calc Node 2000&2010Document4 pagesTrunion Calc Node 2000&2010Naveen RaoNo ratings yet

- Trunnion Calc SHTDocument1 pageTrunnion Calc SHTAtty Atty100% (1)

- Trunnion Calc r6Document4 pagesTrunnion Calc r6Chirag Shah50% (2)

- Master Trunnion CalcDocument4 pagesMaster Trunnion CalcgenergiaNo ratings yet

- Structural TrunnionDocument4 pagesStructural TrunnionecsalomNo ratings yet

- Pipe Support CalculationDocument2 pagesPipe Support Calculationjsmnjasmines86% (7)

- DummyDocument1 pageDummythopa_nath100% (2)

- Saddle Support Calculation PD 5500,2000 Annex.G)Document26 pagesSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Load Check For Shoe Welded SupportDocument313 pagesLoad Check For Shoe Welded Supportscrbdgharavi100% (2)

- Expansion Loop Flexibility Analysis (Weaver)Document3 pagesExpansion Loop Flexibility Analysis (Weaver)bakelly100% (1)

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Trunnion Calculation SheetDocument2 pagesTrunnion Calculation SheetIshu Vohra0% (1)

- Pipe SupportDocument11 pagesPipe SupportAditya Bagus M100% (3)

- Saddle SupportDocument12 pagesSaddle SupportrustamriyadiNo ratings yet

- Flange CalculationsDocument3 pagesFlange CalculationssanjaysyNo ratings yet

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- Trunnion CalculationDocument8 pagesTrunnion CalculationPrashant ChauhanNo ratings yet

- Nozzle Neck CalculationDocument4 pagesNozzle Neck CalculationAkshat JainNo ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysisPEJU0007No ratings yet

- Dummy Leg JacobsDocument1 pageDummy Leg Jacobsananyo_sengupta0% (1)

- Saddle Dimension CalculationDocument2 pagesSaddle Dimension Calculationrinabiswas50% (2)

- Standard Shoe Verification Rev - ADocument19 pagesStandard Shoe Verification Rev - AballisnothingNo ratings yet

- Sif B31.3Document10 pagesSif B31.3Rob Gillespie100% (1)

- Nozzle Reinf Calc (Rough)Document12 pagesNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Lifting Lug TutorialDocument20 pagesLifting Lug Tutorialmontie3No ratings yet

- Nozzle CalculationsDocument2 pagesNozzle CalculationsBaher Elsheikh100% (3)

- Saddle CalcDocument26 pagesSaddle CalcVamsi S100% (2)

- Trunnion & Shoe Temp. Calculation.Document27 pagesTrunnion & Shoe Temp. Calculation.Bharat Bellad100% (1)

- Design of Tail LugDocument34 pagesDesign of Tail LugPrajwal Shetty100% (1)

- Reinforcement CalculationDocument2 pagesReinforcement CalculationVekaymech100% (9)

- Nozzle Movement CalculationDocument23 pagesNozzle Movement CalculationPriyanathan Thayalan100% (4)

- 16147-Shoe With Gusset No RepadDocument5 pages16147-Shoe With Gusset No RepadRamesh Krishnan100% (1)

- Weldstrength Calc ProgDocument10 pagesWeldstrength Calc ProgSajal KulshresthaNo ratings yet

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocument1 page2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNo ratings yet

- Nozzle ReinforcementDocument8 pagesNozzle ReinforcementHafizi HZnumismatic0% (1)

- Flange From Plate - Asme 16.5Document1 pageFlange From Plate - Asme 16.5Rey Fiedacan100% (1)

- Design Practise Piping Support SystemDocument46 pagesDesign Practise Piping Support SystemOkondu Chiedu100% (1)

- Tailing LugDocument12 pagesTailing LuguvarajmecheriNo ratings yet

- PV Elite Webinar 001Document23 pagesPV Elite Webinar 001MEC_GuiNo ratings yet

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocument4 pagesSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRNo ratings yet

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag0% (1)

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleNithin ZsNo ratings yet

- Steam Tracing Excel 2007Document74 pagesSteam Tracing Excel 2007cybermineNo ratings yet

- Calculation of Pipe SupportDocument8 pagesCalculation of Pipe SupportPhyu Mar Thein Kyaw67% (6)

- Saddle CalculationDocument7 pagesSaddle CalculationMichael HaiseNo ratings yet

- TRUNNION CHECK CN-0xxDocument2 pagesTRUNNION CHECK CN-0xxAkashNo ratings yet

- Dummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMDocument2 pagesDummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMashish shrivastavNo ratings yet

- Davit Design Calculation: L 1 D V H V H V DDocument2 pagesDavit Design Calculation: L 1 D V H V H V DSiva baalanNo ratings yet

- Dummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMDocument4 pagesDummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMashish shrivastav50% (2)

- Trunnion Calculation SheetDocument3 pagesTrunnion Calculation Sheetsudhisnair67% (3)

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarDocument3 pagesClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmaleNo ratings yet

- Trunnion Check Calculation (Onsite) : Page No: Contract No: System NoDocument2 pagesTrunnion Check Calculation (Onsite) : Page No: Contract No: System NoJ A S JAS0% (1)

- Design of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)Document30 pagesDesign of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)raman212No ratings yet

- Base Plate - LSDDocument14 pagesBase Plate - LSDrelu59No ratings yet

- Section Properties: Left Beam Member MC 400: Major MinorDocument12 pagesSection Properties: Left Beam Member MC 400: Major MinorshaimenneNo ratings yet

- Design of Sign Board Gantry 20.2 M SpanDocument10 pagesDesign of Sign Board Gantry 20.2 M SpanVrusha BendarNo ratings yet

- DesignOfFooting JOSDocument26 pagesDesignOfFooting JOSJhoe SamNo ratings yet

- Dental Prescription..Document2 pagesDental Prescription..Jagadish JasNo ratings yet

- Trun CalcsDocument2 pagesTrun CalcsJagadish JasNo ratings yet

- Questions Related To Stress Analysi1Document12 pagesQuestions Related To Stress Analysi1Jagadish JasNo ratings yet

- Fatigue AssessmentDocument9 pagesFatigue AssessmentroyalcomNo ratings yet

- Dec 92Document13 pagesDec 92chris110No ratings yet

- Piping - Nozzle LoadingDocument2 pagesPiping - Nozzle Loadingaap1100% (1)

- Flange LeakageDocument3 pagesFlange LeakageBuiVanHop100% (1)

- Global To LocalDocument1 pageGlobal To LocalJagadish JasNo ratings yet

- CVDocument8 pagesCVJagadish JasNo ratings yet

- 212 SteamHammerDocument9 pages212 SteamHammerJagadish JasNo ratings yet

- Asme B31.1, B31.4Document5 pagesAsme B31.1, B31.4Jagadish Jas50% (2)

- Pipe Support GlossoryDocument3 pagesPipe Support GlossoryJagadish JasNo ratings yet

- Solidworks Simulation Premiun DYNAMICSDocument142 pagesSolidworks Simulation Premiun DYNAMICSTarcio TomNo ratings yet

- Overview of ABAQUS ExplicitDocument11 pagesOverview of ABAQUS Explicittone_n_tune100% (1)

- Electronic DamperDocument10 pagesElectronic DamperRaja Sekaran SajjaNo ratings yet

- Report PDFDocument58 pagesReport PDFTiểu Bảo ViNo ratings yet

- Force and Motion Study GuideDocument7 pagesForce and Motion Study Guideapi-263168545No ratings yet

- Design and Construction of Oil Expeller Press With Structural Analysis of Screw With AnsysDocument7 pagesDesign and Construction of Oil Expeller Press With Structural Analysis of Screw With AnsysBirjesh YaduvanshiNo ratings yet

- Biofluid Mechanics Chapter 1Document72 pagesBiofluid Mechanics Chapter 1AbcdNo ratings yet

- DLL Grade 7 3rd Quarter - EditedDocument23 pagesDLL Grade 7 3rd Quarter - EditedCindy Belmes92% (26)

- 6) 3-Hinged FramesDocument44 pages6) 3-Hinged FramesAdelisa AdrovicNo ratings yet

- Electrical Charges and Coulomb's Law: Physics II Note-1Document24 pagesElectrical Charges and Coulomb's Law: Physics II Note-1Helping purpose onlyNo ratings yet

- AspenPhysPropMethodsV7 3 RefDocument245 pagesAspenPhysPropMethodsV7 3 RefDarkLugiaNo ratings yet

- ACS Term Paper 5th SemDocument11 pagesACS Term Paper 5th SemdandeashritNo ratings yet

- Heat Calculation ReferenceDocument5 pagesHeat Calculation ReferenceCham SurendNo ratings yet

- Lab 1 B Force Polygon Report PrintDocument14 pagesLab 1 B Force Polygon Report Printkingtai lau75% (4)

- PhysicsDocument234 pagesPhysicsshugufta nazneenNo ratings yet

- GEOL - 3003 - Lecture 3 4 Rheology PDFDocument66 pagesGEOL - 3003 - Lecture 3 4 Rheology PDFMohammed HarrasiNo ratings yet

- Industrial Tank Model 3115 Dia 9.39 M Nominal Volume 253 MDocument2 pagesIndustrial Tank Model 3115 Dia 9.39 M Nominal Volume 253 MMohamedHussein MohamedHusseinNo ratings yet

- Tos Second Quarter Physical ScienceDocument15 pagesTos Second Quarter Physical ScienceEden Garin AmadorNo ratings yet

- Transverse Wave On A StringDocument7 pagesTransverse Wave On A StringYotin MaimanNo ratings yet

- KnjigaDocument671 pagesKnjigaIgor VasićNo ratings yet

- Assignment #1Document6 pagesAssignment #1Deniz GüneşNo ratings yet

- Laboratory Activity 7 Orifice and JetflowDocument12 pagesLaboratory Activity 7 Orifice and JetflowChardel Porlares100% (1)

- Shear-Flexible Element With Warping For Thin-Walled Open BeamsDocument19 pagesShear-Flexible Element With Warping For Thin-Walled Open BeamsnevinkoshyNo ratings yet

- Mechanics of The Metal Cutting Process. I. Orthogonal Cutting and A Type 2 ChipDocument15 pagesMechanics of The Metal Cutting Process. I. Orthogonal Cutting and A Type 2 ChipJosé María Flores RojasNo ratings yet

- Determination of Gas-Diffusion and Inter PDFDocument9 pagesDetermination of Gas-Diffusion and Inter PDFfarzadsadeghzadNo ratings yet

- Statistical Mechanics - Homework Assignment 1: Alejandro G Omez Espinosa February 5, 2013Document4 pagesStatistical Mechanics - Homework Assignment 1: Alejandro G Omez Espinosa February 5, 2013Ale Gomez100% (13)

- Hep THDocument453 pagesHep THMoeed_Paracha_395No ratings yet

- Subjective Questions: Center of MassDocument7 pagesSubjective Questions: Center of MassarnavNo ratings yet

- 4357r 85 PDFDocument14 pages4357r 85 PDFFred PrzNo ratings yet

- Maurer Seismic Isolation Systems With Lead Rubber Bearings (LRB)Document9 pagesMaurer Seismic Isolation Systems With Lead Rubber Bearings (LRB)BogdanBNo ratings yet