Professional Documents

Culture Documents

Ultrasonic Monitoring Photoresist Prebake Using TOF Measurement

Uploaded by

Vi6enaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Monitoring Photoresist Prebake Using TOF Measurement

Uploaded by

Vi6enaCopyright:

Available Formats

Ultrasonic Monitoringof Photoresist Prebake

Using TOF Measurement

S.L. Morton, *A. Hansson, andB.T. Khuri-Yakub

Edward L. Ginzton Laboratory, Stanford University, Stanford, CA 94305

*Information Systems Laboratory

Abstract - We have measured the time of flight (TOF) 1994) applied ultrasonicthermometry to measure the

through a 4" silicon wafer with and without a 1 . 8 ~ m effect of thin films on this ultrasonic measurement of

coating of Shipley 1813 positive photoresist. The TOF wafer temperature.Thistechnology will be useful in

change from hare to coated wafer was measured three monitoring resist prehake since the wafer temperature

times on a singlewafer; theaverageofthethree and resistfilmthickness will change as thewaferis

experiments was a TOF of 14.311s (+/-Z.Sns), consistent heated and the solvent evaporates.

with the calculated expected results. In order to increase

the precision of the TOF measurement to the level needed METHOD

for prehake monitoring, we have applied a least squares First,

we conductedexperiments in orderto

algorithm to estimate the transfer function between the characterize the wave velocity in the coated and prehaked

echoandreceived waveforms. Results of pulsed data wafer.Thenweidentifiedcontinuous-timetransfer

studies indicate that we can get a decrease in the standard functions that described the relationship between the echo

deviation of the TOF measurement from 2.93ns to 2.5311s and received acoustic signals. The transfer function was

by determiningtheTOFfrom the estimatedtransfer used to calculate an estimated TOF that was expected to

function. he more precise than the current zero crossing technique

INTRODUCTION for determining TOF.

In currentI-line and deep-UVlithography, in situ

monitoring of photoresist processing is not required to &sist Characterization BY Time of Flieht Measurement

meet designobjectives.However,asfeaturesize In order to characterize the effect of a thin film of

surpasses sub-quarter micron, it is expected that the resist photoresist on Lambwavepropagationvelocity in

materials will be more sensitive to processing conditions silicon, we measured the TOF change before and after the

such as prebake and postbake time and temperature. It is wafer was coated with resist.The methodfor TOF

necessarytoprehakephotoresistpriortolithographic measurement was describedpreviously by Lee, et al.

exposure so that the solvent initially added to decrease (1996). Briefly, Lamb waves were excited in a silicon

resist viscosity can he evaporated, and the resin polymer wafer by aquartzpinpiezoelectrictransducerand

chains can relax into an ordered array. If the solvent isn't detected by an identicaltransducer.The TOF was

fully evaporated or if the prehake time is too long, then determined by the time differencebetween a chosen zero

the feature size may not he as small as expected. crossing in the echo waveform reflected from the

There has been some research in endpoint detection of pin/waferinterfaceandthereceivedwaveformthat

the prebake process. Metz, et al. (1991) performed real- propagates through the wafer to the second transducer. A

time measurement of resistfilmthicknessonsilicon StanfordResearch SystemsSR620UniversalTime

wafers using multi-wavelength reflection interferometry. Interval Counter was used to measure the time difference

They determined resist thickness versus spin and bake between the two zero crossings.

time. This method was used to monitor non-uniformities

forstatisticalprocesscontrol. In 1992,Metz, et al.

reported on similar experimentswithreal-time

photoresist monitoring to optimize the hake time and spin

speed.

At the Edward L. Ginzton Laboratory, several authors

haveappliedultrasonictechnology tomonitoring

semiconductorprocesses.Lee, et al. (1993, 1996)

developed an ultrasonic technique in order to measure

temperatureduring rapidthermalprocessing.Lamb

waves were excited in the wafer, and the change in wave

velocity was monitored as the wafer temperature varied.

Thewavevelocitydecreasedlinearlyastemperature Figure I: Experimental setup with two quartz transducer

increased. In relatedwork,Degertekin, et al. (1993, pins contacting a 4" wafer placed on an aluminum plate.

0-7803-3615-1/96/$5.00 0 1996 IEEE 1996 WEE ULTRASONICS SYMPOSIUM - 1013

The wave propagation velocity can then be determined 8 bit digitizer. In the time domain, the modelis set up as

from the TOF and the spacing between the pins. follows:

Fortheseexperiments,200kHztransducerswere A ( p ) d r ) = B(p)u(r - T ) + E(f)

fabricated by epoxy bonding a cylinder of 5H PZT, 5mm

in height and 3mm in diameter, to a 4" long quartz pin

3mm in diameter. The tip of the quartz pins were cut to a

radius of curvature of lOcm to provide good contact for

high signal transmission without the problemof multiple

contact sites. The pin was designed to be4" long so that

there would be at least5 cycles of 2M)kHz signal before

reflections from the pidwafer contact would be seen.

The experimental setup is shown in Figure 1. A 4"

silicon wafer <]M)> doped with boron to a resistivity of

8-12 ohm-cmwasplaced on an aluminumplateand

contacted from above by the two transducers. A voltage

-3

pulse (-4M)V) was applied to the transmitting transducer 0 10 20 30 40 50 60

and the echo and received signals monitored. The TOF Time (vs)

was then determined using the zero crossing method; Figure 2: Sample echo signal for modeling

measurements were taken with the transducers raised and

lowered between each data point. The wafer was then

coatedwithl.8pmofShipley1813photoresistto a

planarityof +/- SO,& alongthesignalpath.Afterthe

waferwasprebaked,itwastransferredfromthe

cleanroom to the measurement setup in a dark container

to prevent exposure. The resist side was placed down

onto the aluminum plate with the pins contacting the

opposite side. Double-side polished wafers were used to

maintain a reproducible contact. The measurement was

repeated and the delta TOF from hare wafer to resist-

coated wafer calculated. The wafer was then stripped of

resistandtheexperimentrepeatedtwomoretimes. 0 10 20 10 40 50 60

Results were compared with expected results calculated Time (bs)

fromtheory.Waferthicknesswasmeasuredusing a Figure 3: Sample received signal for modeling

Leitz height gauge with 1M)mm range and l p m accuracy.

Thicknesswasmeasuredat S locationsalongthe

wherepisthederivativeoperator, ~ ( t )is theresidual

propagation path and averaged.

The goal of these measurements is to determine the error and, where:

change in TOF through a wafer with and without resist; ~ ( p=)p n + LI, p"-' +...+a,

expected values are in the range of 12-14ns, depending B ( p ) = b,,p" + b,p"-' + ... + b,

on the wafer thickness.

In the Laplace domain:

Transfer Function Estimation

B($)

Our goal is to measure the change in TOF as the resist Y ( s )= G(s)e'"'U(s) + E ( s ) , where C(s) = -

changesfrom a liquidtosolidduringprebake.The A(s)

expected change i n TOF for this 90 second process is - Theparameters to beestimatedare .=[R, ...

2ns, much lower than the change from bare wafer to T

resist above. The 2ns includes changesin resist thickness b = [b,__.

b,] , and Z. The input and output signals will

and changes in the elastic propertiesof the resist. A TOF be filtered with a bandpass filterC,(s) to give:

resolution of lessthan0.lnsec will berequired to

distinguish this change.

u,(t) = C,fp)u(f)

InordertoincreasetheprecisionoftheTOF

measurement, we have developeda Least Squares fit to a Y,(d = C,(P)Y(C

continuous-time transfer

functionmodel of the

relationship between the echo and received signals.A set The filtered equation reads:

of sample signals to be modeled are shown i n Figures 2

and 3. The echo signal in Figure 2 will bethemodel A(P,)Y,(I)=B(P)LI,(I-~T)+&,(~)

input. u(t), and the received signal in Figure 3 will be the

model output, y(t). Data was collected with a at 2SOMHz and can berewritten as a linear regression:

1014 - 1996 IEEE ULTRASONICS SYMPOSIUM

experiments on the same 530pm thick wafer was 14.3ns

witha variation of +/-2Sns. Errors from the expected

valuewere within the noise rangedeterminedabove.

Transfer Function Esiimation

Results indiiate that the use of transferfunction

o=[-aT b'] estimationcangive an estimateof 7 with a standard

deviation that is less than that associated with the use of

For a fixed Z : the zero crossing method for determining the TOF. The

standard deviation of the Z estimates for 10 sets of echo

and received signal waveforms was foundto be as low as

2.53ns. This is compared with a value of 2.96ns standard

is a leastsquaresproblemwhichcanbesolved in a deviation found by applying the zero crossing method to

straightforward way (Johansson 1993). the same waveforms. It should be noted that the values

The functionV(Z) has several local minima, but it is of 7 andTOFarenotexpected to bethesame.

locally quasi-convex. By evaluating Figures 2 and 3, it is However, the actual value of the estimated TOF was

possible to determine in which interval there exists a calculated from separate theory not presented here and

local minimum that captures the time-delay Z between resulted in the same standard deviation as that ofT .

theechoandreceivedsignals.Tofindthelocal

minimum once theinterval is known, a polynomial CONCLUSIONS

interpolationmethodcombinedwithGoldenSearch Results of photoresistcharacterizationstudies

m

techniques was used (Gill et al., 1981). The filtration of indicate that the measured change in TOF of 14.311s+/-

the signals was performedin Matlab using a Runge-Kutta 2.5ns is withinmeasurementnoiserange of the

ordinary differential equation (ODE) solver. Data points expected value of about 13.2ns for the530wm 4" wafer,

inbetweenthoseproduced by theODEsolverwere Results of transfer functionestimation indicate that

obtainedbylinearinterpolation.Optimizationof 7,

U , and b was performed for pulsed transducer excitation

signals. The model order used here was n = m = 4, and 16.245

8000 points were included in the estimation. The number

of pointswaslimitedtopreventtheinclusion of 16.24

reflections. In Figures 2 and 3, the primary signal and the h

onset of unwanted reflections from thepin and the wafer 3 16.235

E

1

edge are

identified.

The

reflections occurring

16.225

16.23 Della TOF = 14 ns

immediatelyafterthesignaloriginatefromthe pin

geometry and are included in the estimation. In Figure 3,

I , ~ and C,?,& are the initial and final values used in the

estimation. The former was counted from the beginning 16.22

0 4 8 I2 16 20

of the received signal atabout 2 0 ~ s .The final value was Trial #

chosen based on the point at which edge reflections were Figure 4: TOF results from single wafer, first 10 trials

seen in the signal. The total number of points in each arewithoutresist,second I O are after resist has been

signal as plottedis 15,000. coatedhaked.

RESULTS

Resist Characteriaztion

Figure 4 shows the change in TOF through 4.5cm of

a single wafer before and after it was coated with resist.

The first ten trials are measurements without resist and

the second ten trials were obtained after the wafer was

coated with resist and prebaked. Noise of about +/-3ns

was measured. An abrupt change in TOF of about 1411s

occurred when the 1.8$m film of resist was spun onto the

wafer.Thisvaluewasclosetothatexpectedfrom

theoreticalcalculations(Figure

thickness of this wafer.

5) forthe530pm 13

12s

l,,

, , ,-, ,

, ,, , , , , , :, ,

, I ,y

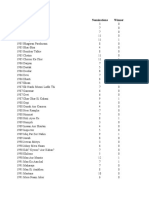

Figure S is a plot of expected change in TOF upon 510 515 520 525 530 535 540

addition of photoresist for different wafer thicknesses. WuferTlickne% Urn)

This plot was used to determine the expected value for Figure 5: Results of three experiments on same wafer,

the 53Opm thick wafer. The expected increase can be theoreticalandexperimentalresultsareshown.Each

seentobeabout 13.211s. Theaverageof

three experimental result is the average of ten measurements.

1996 IEEE ULTRASONICS SYMPOSIUM - 1015

determining TOF by transfer function estimation can

predictthe value of TOF with greater precisionthan

when it is determined by the zero crossing technique.

The standard deviation was decreased by 14% with the

least squares tit estimation. The deviations obtained were

for data digitized with an 8 bit digitizer and would be

expected to be lower in both cases with an increase in

signal to noise ratio. The analog measurement is still

more precise (to <0.5ns) but we hope to improve the

digitization and signal processing to obtain digital results

that

are

better

thanthe

corresponding analog

measurements.

ACKNOWLEDGEMENTS

We would like to acknowledge F.L. Degertekin for

developingthetheoreticalanalysis of Lambwave

propagation that was used in this research. This research

was supported by a multidisciplinary research initiative

grant from ARPA and by the Swedish Research Council

for Engineering Science contract #S-838.

REFERENCES

[ I ] Degertekin, F.L., et al. Proc. 1993 IEEE

UItrusonics Symposium, Part 1, Vol. I , 1993, pp.

375-377.

[2] Degertekin,F.L.,et al. 1994 IEEE Ultrasonics

Symp, Vol. 3, 1994, pp. 1337-1341.

[3] Gill, P.E., et al. vs, Academic

Press, London: 1981, p. 92.

[4] Johansson, R. “LinearRegression,” Chapter 5 in

1dentification.Prentice Hall,

Inc., Englewood Cliffs,NJ, 1993..

[S] Lee, Y.J., et al. 1993 IEEE In?Electron Devices

Meeting, pp. 187-190.

[6] Metz, T.E.. et al. Process Module Metrology,

Control, and Clustering, SPIE, Vol. 1594, 1991,

pp. 146-152.

[7] Metz, T.E., et al. Semic. InternationaI, Feb 1992,

pp. 68-9.

[8] Lee, Y.J.. et al. IEEE Trans Semic Munuf, Vol. 9,

No. 1,Feb 1996,pp. 115-121.

1016 - 1996 IEEE ULTRASONICS SYMPOSIUM

You might also like

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Rating: 4.5 out of 5 stars4.5/5 (5)

- Denoising DataDocument7 pagesDenoising DataTugba ÖzacarNo ratings yet

- Nasa SST Meeting 2013 2Document1 pageNasa SST Meeting 2013 2api-253017850No ratings yet

- New Implementation of High-Precision and Instant-Response Air Thermometer by Ultrasonic SensorsDocument7 pagesNew Implementation of High-Precision and Instant-Response Air Thermometer by Ultrasonic Sensorshamza_qayyumNo ratings yet

- Sound VelocityDocument13 pagesSound VelocityLinthish PulickoolNo ratings yet

- Nicholson Ross Extraction MethodDocument6 pagesNicholson Ross Extraction MethodTom SebastianNo ratings yet

- Raman Nath Diffraction ManualDocument8 pagesRaman Nath Diffraction ManualPratik PatnaikNo ratings yet

- Thetaprobe PrinciplesDocument20 pagesThetaprobe PrinciplesMuhammad ArifinNo ratings yet

- znse Single Crystals: Rapid CommunicationDocument3 pagesznse Single Crystals: Rapid CommunicationAlexanderNo ratings yet

- Analysis of Channels Impulse Response Due To Transducer Movements in Underwater Acoustic CommunicationDocument8 pagesAnalysis of Channels Impulse Response Due To Transducer Movements in Underwater Acoustic CommunicationMaria MargaretaNo ratings yet

- Avila SomDocument12 pagesAvila SomPablo DruettaNo ratings yet

- 01 0302031 L Norgren PDFDocument37 pages01 0302031 L Norgren PDFkrishnaNo ratings yet

- Aip Advances 2011Document12 pagesAip Advances 2011Adriano Philippe BustorffNo ratings yet

- Determining The Speed of Sound Invoking The Phenomenon of Wave Interference in A Close-Ended PipeDocument4 pagesDetermining The Speed of Sound Invoking The Phenomenon of Wave Interference in A Close-Ended PipeJesse CenizaNo ratings yet

- 2003 Epl 63Document7 pages2003 Epl 63A94leo14hsetmaNo ratings yet

- Photon Scanning Tunneling Microscope: Detection of Evanescent WavesDocument5 pagesPhoton Scanning Tunneling Microscope: Detection of Evanescent Wavescuongtran_siegenNo ratings yet

- Merical Met Od For Transit 'Fimc MeasurementDocument6 pagesMerical Met Od For Transit 'Fimc Measurementemild_03No ratings yet

- A Model of High Frequencies HF Channel Used To Design A Modem ofDocument5 pagesA Model of High Frequencies HF Channel Used To Design A Modem ofASM AAS ASSASNo ratings yet

- A Ces: Send.i, 980 J.P.NDocument4 pagesA Ces: Send.i, 980 J.P.Nhaden tetwNo ratings yet

- Orthogonal Time Frequency Space OTFS Modulation For Millimeter-Wave Communications SystemsDocument3 pagesOrthogonal Time Frequency Space OTFS Modulation For Millimeter-Wave Communications Systemsdileep bapatlaNo ratings yet

- Fuzzy BasedDocument7 pagesFuzzy BasedHüseyin YükselNo ratings yet

- Physlca ®: Scaling Law For Vortex Dynamics in SuperconductorDocument5 pagesPhyslca ®: Scaling Law For Vortex Dynamics in SuperconductorpietrasekNo ratings yet

- Ultrafast Terahertz Faraday Rotation in GrapheneDocument6 pagesUltrafast Terahertz Faraday Rotation in GrapheneAnonymous 5NJsCTjBNo ratings yet

- Patch PhotodetectorDocument6 pagesPatch PhotodetectorHabibe DurmazNo ratings yet

- LTSKAR009 PHYLAB2 Speed of Sound PracDocument5 pagesLTSKAR009 PHYLAB2 Speed of Sound PracKarabo LetsholoNo ratings yet

- McWilliams - SM Revised PDFDocument31 pagesMcWilliams - SM Revised PDFUmberto GenoveseNo ratings yet

- Drakhlis Boris - Calculate Oscillator Jitter by Using Phase-Noise Analysis Part 1Document6 pagesDrakhlis Boris - Calculate Oscillator Jitter by Using Phase-Noise Analysis Part 1beppes66No ratings yet

- E.A. Donley Et Al - A Quantum-Based Microwave Power Measurement Performed With A Miniature Atomic FountainDocument3 pagesE.A. Donley Et Al - A Quantum-Based Microwave Power Measurement Performed With A Miniature Atomic FountainOppekeeNo ratings yet

- Dielectric Permittivity MeasurementsDocument4 pagesDielectric Permittivity MeasurementsHussein KassemNo ratings yet

- Brown, T. R. Kincaid, B. M. Ugurbil, K. - NMR Chemical Shift Imaging in Three Dimensions.Document4 pagesBrown, T. R. Kincaid, B. M. Ugurbil, K. - NMR Chemical Shift Imaging in Three Dimensions.Isra RMNo ratings yet

- Science - Abo4297 SMDocument37 pagesScience - Abo4297 SMKen DarghiNo ratings yet

- 1996experimental Investigation of A Surface Plasmon-Based Integrated-Optic Humidity Sensor - WeissDocument2 pages1996experimental Investigation of A Surface Plasmon-Based Integrated-Optic Humidity Sensor - WeisspillaiyarmuruganNo ratings yet

- A Numerical Study On Time-Reversal Electromagnetic Wave For Indoor Ultra-Wideband Signal TransmissionDocument14 pagesA Numerical Study On Time-Reversal Electromagnetic Wave For Indoor Ultra-Wideband Signal TransmissionpoketupiNo ratings yet

- Efficient Model-Free Deconvolution of Measured Femtosecond Kinetic Data Using A Genetic AlgorithmDocument31 pagesEfficient Model-Free Deconvolution of Measured Femtosecond Kinetic Data Using A Genetic AlgorithmXuân PhươngNo ratings yet

- Cleo 1995Document2 pagesCleo 1995Armando Humberto Nolasco PintoNo ratings yet

- Greve 2005Document12 pagesGreve 2005Emotional V.I.PNo ratings yet

- Wavelet Estimation MVDBDocument13 pagesWavelet Estimation MVDBdig_itNo ratings yet

- Progress in Electromagnetics Research, Vol. 113, 103-110, 2011Document8 pagesProgress in Electromagnetics Research, Vol. 113, 103-110, 2011Rasheduzzaman SifatNo ratings yet

- Detection of Interface Failure in A Composite Structural T - Joint Using Time of FlightDocument3 pagesDetection of Interface Failure in A Composite Structural T - Joint Using Time of Flightedcam13No ratings yet

- Microwave Spectroscopy of Thermally Excited Quasiparticles in Yba Cu ODocument12 pagesMicrowave Spectroscopy of Thermally Excited Quasiparticles in Yba Cu OPinder DosanjhNo ratings yet

- Wide-Angle Perfect Absorber/thermal Emitter in The Terahertz RegimeDocument4 pagesWide-Angle Perfect Absorber/thermal Emitter in The Terahertz RegimehesoyamyecgaaaNo ratings yet

- Acoustic Dispersion and Attenuation Measurement Using Both Transmitted and Re Ected PulsesDocument6 pagesAcoustic Dispersion and Attenuation Measurement Using Both Transmitted and Re Ected PulsesKishorePrabakaranKumarNo ratings yet

- 63-No.4-2008 - 04-Svilainis, MotiejunasDocument5 pages63-No.4-2008 - 04-Svilainis, MotiejunasriannataNo ratings yet

- Experimental Results in Ultrasound Reflection Tomography For Nondestructive TestingDocument5 pagesExperimental Results in Ultrasound Reflection Tomography For Nondestructive Testingcal2_uniNo ratings yet

- Water Mark Research PaperDocument4 pagesWater Mark Research PaperKanish CbNo ratings yet

- Issue in Modeling UwbDocument6 pagesIssue in Modeling UwbVirang PatelNo ratings yet

- Fourier Transform Experiment ManualDocument10 pagesFourier Transform Experiment Manualf20212358No ratings yet

- High-Speed Tunable Photonic Crystal Fiber-Based Femtosecond Soliton Source Without Dispersion Pre-CompensationDocument8 pagesHigh-Speed Tunable Photonic Crystal Fiber-Based Femtosecond Soliton Source Without Dispersion Pre-CompensationManuel SalazarNo ratings yet

- A6,,,,,,,,,,,A MEMS-based Air Flow Sensor With A Free-Standing Microcantilever StructureDocument13 pagesA6,,,,,,,,,,,A MEMS-based Air Flow Sensor With A Free-Standing Microcantilever StructureyohannesNo ratings yet

- Blanc Benon1987Document8 pagesBlanc Benon1987vermashrey2122No ratings yet

- Wavelength Dispersion of Ti Induced Refractive Index Change in LiNbO3as A Function of Diffusion ParametersDocument9 pagesWavelength Dispersion of Ti Induced Refractive Index Change in LiNbO3as A Function of Diffusion ParametersYingPin TsaiNo ratings yet

- Mansard Funke 1980Document19 pagesMansard Funke 1980AzisNo ratings yet

- Article PDFDocument5 pagesArticle PDFlazarosNo ratings yet

- Confirmation of Ring Protons of 2 - ( (3 - (Trifluoromethyl) Phenyl) Amino) Nicotinic Acid Using Correlation Spectroscopy NMR TechniqueDocument7 pagesConfirmation of Ring Protons of 2 - ( (3 - (Trifluoromethyl) Phenyl) Amino) Nicotinic Acid Using Correlation Spectroscopy NMR TechniqueInternational Organization of Scientific Research (IOSR)No ratings yet

- POSTER 2011 - Foz de IguaçúDocument1 pagePOSTER 2011 - Foz de IguaçúrubensufpaNo ratings yet

- EE 612 Home Assignment No. 3 Nov. 08, 2009 Solutions To Copy Point On Nov. 11, 2009. Quiz 3 On Nov. 12, 2009Document1 pageEE 612 Home Assignment No. 3 Nov. 08, 2009 Solutions To Copy Point On Nov. 11, 2009. Quiz 3 On Nov. 12, 2009VishalPandeyNo ratings yet

- A Novel Microstrip Patch Antenna With Large Impedance Bandwidth in Vhf/Uhf RangeDocument11 pagesA Novel Microstrip Patch Antenna With Large Impedance Bandwidth in Vhf/Uhf RangealkeshkhatriNo ratings yet

- Pico Second Labs PDFDocument5 pagesPico Second Labs PDFVenkatesh KarriNo ratings yet

- By Forced Convection at The Front Pole of A Sphere: ReferenceDocument4 pagesBy Forced Convection at The Front Pole of A Sphere: ReferencelorencorumbaNo ratings yet

- Network UseAdministratorModeDocument1 pageNetwork UseAdministratorModeVi6enaNo ratings yet

- Cold SteelDocument189 pagesCold SteelJoão Eduardo Schleich UbertiNo ratings yet

- Licensing Windows Server 2012 R2 RDS and Desktop Apps For RDSDocument7 pagesLicensing Windows Server 2012 R2 RDS and Desktop Apps For RDSRafael Carmona ZendejasNo ratings yet

- DBVS ConstraintsDocument14 pagesDBVS ConstraintsVi6enaNo ratings yet

- Deathwatch Character Sheet Web QualityDocument2 pagesDeathwatch Character Sheet Web QualityGrid Reaper100% (2)

- Konu Anlatımı Week4Document45 pagesKonu Anlatımı Week4Ozel DersNo ratings yet

- ECONOMETRICS (2014 Version) by Bruce E. HansenDocument387 pagesECONOMETRICS (2014 Version) by Bruce E. HansenThuan ZitaNo ratings yet

- Hw11 SolutionDocument3 pagesHw11 Solutiono3428No ratings yet

- Fake Discounts Drive Real Revenues in Retail: Donald NgweDocument47 pagesFake Discounts Drive Real Revenues in Retail: Donald NgweSrikara AcharyaNo ratings yet

- Solved ProblemsDocument6 pagesSolved ProblemsChhanny SornNo ratings yet

- Answers Are Highlighted in Yellow Color: MCQ's Subject:Introductory EconometricsDocument74 pagesAnswers Are Highlighted in Yellow Color: MCQ's Subject:Introductory EconometricsSimran Simie100% (1)

- Sta - Chap 14Document4 pagesSta - Chap 14凱儀No ratings yet

- Chapter 14Document22 pagesChapter 14dungnt0406No ratings yet

- Statistics - Imp FormulaeDocument4 pagesStatistics - Imp FormulaeTSNo ratings yet

- Uji Normalitas Data SPSS - Puspita Utari D042202010Document7 pagesUji Normalitas Data SPSS - Puspita Utari D042202010Ahmad Hunain SupyanNo ratings yet

- Fig.1 Forestplot - Fixed and Random Effect Models: Js Chart by AmchartsDocument2 pagesFig.1 Forestplot - Fixed and Random Effect Models: Js Chart by Amchartsdaniel serraniNo ratings yet

- Lampiran 1. Syarat Mutu Dendeng Sapi (SNI 2908:2013. Dendeng Sapi) No. Kriteria Uji Satuan PersyaratanDocument21 pagesLampiran 1. Syarat Mutu Dendeng Sapi (SNI 2908:2013. Dendeng Sapi) No. Kriteria Uji Satuan PersyaratanImel DestiaraNo ratings yet

- Ordinal and Multinomial ModelsDocument58 pagesOrdinal and Multinomial ModelsSuhel Ahmad100% (1)

- Regresia Multipla (1) - Modelare, Interpretare Si TestareDocument10 pagesRegresia Multipla (1) - Modelare, Interpretare Si TestareDelia RaduNo ratings yet

- Verbeek e Nijman - Testing For Selectivity Bias in Panel Data ModelsDocument24 pagesVerbeek e Nijman - Testing For Selectivity Bias in Panel Data Modelsstehta16529No ratings yet

- A Lidsttiti F S Iti M KT Applied Statistics For Securities Markets CSMP@ NismDocument30 pagesA Lidsttiti F S Iti M KT Applied Statistics For Securities Markets CSMP@ NismAlok RustagiNo ratings yet

- Robust and Quantile Regression: OutliersDocument41 pagesRobust and Quantile Regression: OutliersMannyNo ratings yet

- Time Sereis Analysis Using StataDocument26 pagesTime Sereis Analysis Using Statasaeed meo100% (7)

- PROBABILITYDocument59 pagesPROBABILITYgunjanNo ratings yet

- Century National BanksDocument3 pagesCentury National BanksAsad Msa100% (3)

- T. Confidence Interval Estimates For The Population MeanDocument18 pagesT. Confidence Interval Estimates For The Population MeanBrian GarciaNo ratings yet

- Confidence Intervals (Cis) : DR Trevor BryantDocument13 pagesConfidence Intervals (Cis) : DR Trevor Bryantmohammed saadNo ratings yet

- Original PDF Business Statistics Abridged Australia New Zealand 7th PDFDocument41 pagesOriginal PDF Business Statistics Abridged Australia New Zealand 7th PDFtiffany.williamson504100% (33)

- Ang A. H-S, Probability Concepts in Engineering Planning and Design, 1984Document572 pagesAng A. H-S, Probability Concepts in Engineering Planning and Design, 1984Ionescu Paul86% (14)

- SPSS Statistics 20 Modules SpecificationsDocument5 pagesSPSS Statistics 20 Modules SpecificationsakashniranjaneNo ratings yet

- Forecasting Product Sales - Dataset 1Document9 pagesForecasting Product Sales - Dataset 1hiteshNo ratings yet

- Econometrics MadalaDocument1 pageEconometrics MadalaHimadri PalikheNo ratings yet

- ST5212: Survival Analysis: ScheduleDocument4 pagesST5212: Survival Analysis: ScheduleSnu Cho IDNo ratings yet

- Correlation and RegressionDocument1 pageCorrelation and RegressionRaman KulkarniNo ratings yet

- Econometrics ProofsDocument4 pagesEconometrics Proofsfernandesg11No ratings yet