Professional Documents

Culture Documents

Specification Blindside Waterproofing With Bentonite

Uploaded by

Baugh Graphic DesignOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification Blindside Waterproofing With Bentonite

Uploaded by

Baugh Graphic DesignCopyright:

Available Formats

SPECIFICATION BLINDSIDE WATERPROOFING WITH BENTONITE SECTION 07124 COLD FLUID-APPLIED WATERPROOFING SYSTEM III PLUS PART 1 GENERAL

AL 1.1 RELATED DOCUMENTS A. Drawings and general provisions of the Contract, including General and Supplementary Conditions and Division 1 Specification Sections, apply to this Section.

1.2

SUMMARY A. This Section includes the following: 1. 2. 3. 4. 5. 6. B. Surface preparation and substrate treatment. Waterproofing/gas membrane. Auxiliary materials. Base course moisture/gas barrier. Waterproofing/Protection course. Prefabricated drainage mat.

Related Sections: The following Sections contain requirements that relate to this Section: 1. 2. 3. 4. Division 2 Sections Soil and Rock Anchors for placement and Sub-drainage Systems for installation. Division 3 Section Specially-Placed Concrete for concrete placement, curing, and finishing. Division 5 Section Expansion Joint Cover Assemblies, for expansion-joint covers assemblies and installation. Division 7 Section Joint Sealant for joint sealant materials and installation.

1.3

PERFORMANCE REQUIREMENTS A. General: Provide a waterproofing system that prevents the passage of liquid water under hydrostatic pressure and complies with physical requirements as demonstrated by testing performed by an independent testing agency of manufacturers current waterproofing formulations and system design.

1.4

SUBMITTALS A. Submit Product Data for each type of waterproofing specified, including manufacturers printed instructions for evaluating, preparing, and treating the substrate, technical data, and tested physical and performance properties. Project Data - Submit Shop Drawings showing locations and extent of waterproofing, including details for substrate (drainage mat) installation and preparation, including sheet flashing, penetrations, and other termination conditions. Samples Submit representative samples of the following for approval: 1. 2. 3. 4. 5. Waterproofing/gas membrane. Base course moisture/gas barrier. Waterproofing/protection course. Geo-textile and detailing sheet as required. Prefabricated drainage mat.

B.

C.

D.

Installer Certificates Submit certificates signed by manufacturer certifying that Installers comply with requirements under the Quality Assurance Article.

1.5

QUALITY ASSURANCE A. Installer Qualifications: Engage an experienced Installer who is certified in writing and approved by waterproofing manufacturer EPRO Services, Inc. for the installation of the SYSTEM III Plus Waterproofing System. Manufacturer Qualification: Obtain waterproofing materials and system components from a single manufacturer EPRO Services, Inc. Field Sample: Apply waterproofing system field sample to 100 sq./ft. (9.3 sq./m.) of deck or wall to demonstrate surface preparation, joint and crack treatment, thickness, texture, and standard of workmanship. 1. 2. 3. Notify Architect one week in advance of the dates and times when field sample will be prepared. If Architect determines that field sample, does not meet requirements; reapply waterproofing until field sample is approved. Retain and maintain approved field sample during construction in an undisturbed condition as a standard for judging the completed waterproofing. An undamaged field sample may become part of the completed Work.

B.

C.

D.

Pre-installation Conference: A pre-installation conference shall be held prior to application of the waterproofing system to assure proper substrate and installation conditions, to include contractor, applicator, architect/engineer and special inspector (if any). Installation inspections by manufacturer representative or other qualified independent third party may be required.

E.

1.6

DELIVERY, STORAGE, AND HANDLING A. Deliver materials to Project site as specified by manufacturer labeled with manufacturers name, product brand name and type, date of manufacture, shelf life, and directions for storing and mixing with other components. Store materials as specified by the waterproofing manufacturer in a clean, dry, protected location and within the temperature range required by waterproofing manufacturer. Protect stored materials from direct sunlight. Remove and replace material that cannot be applied within its stated shelf life.

B.

C. 1.7

PROJECT CONDITIONS A. Protect all adjacent areas not to be waterproofed. Where necessary, apply masking to prevent staining of surfaces to remain exposed wherever membrane abuts to other finish surfaces. Perform work only when existing and forecast weather conditions are within manufacturers recommendations for the material and application method used. Minimum clearance of 24 inches is required for application of product. For areas with less than 24inch clearance, the product may be applied by hand using ECOLINE-R. Ambient temperature shall be within manufacturers specifications. (Greater than +19F/-7C.)

B.

C.

D.

E.

All plumbing, electrical, mechanical and structural items to be under or passing through the waterproof membrane shall be positively secured in their proper positions and appropriately protected prior to membrane application. Waterproof membrane shall be installed before placement of reinforcing steel. When not possible, all exposed reinforcing steel shall be masked by General Contractor prior to membrane application. All sharp and irregular protrusions should be removed from shoring walls.

F.

G. 1.8

WARRANTY A. General Warranty: The special warranty specified in this Article shall not deprive the Owner of other rights the Owner may have under other provisions of the Contract Documents, and shall be in addition to, and run concurrent with, other warranties made by the Contractor under requirements of the Contract Documents. Special Warranty: Submit a written warranty signed by waterproofing manufacturer and Installer agreeing to repair or replace waterproofing that does not meet requirements or that does not remain watertight within the specified warranty period. Warranty does not include failure of waterproofing due to failure of soil substrate prepared and treated according to requirements or formation of new joints and cracks in the specially applied concrete that exceed 1/16 inch (1.6 mm) in width. 1. Warranty Period: 5-years after date of Substantial Completion.

B.

PART 2 PRODUCTS 2.1 MANUFACTURERS A. SYSTEM III Plus; EPRO Services, Inc., Wichita, KS, 800-882-1896 1. 2. 3. 4. Fluid Applied waterproofing/gas membrane ECOLINE-S or ECOLINE-R. Base course moisture/gas barrier ECOSHIELD-P. Waterproofing/protection course ECOSHIELD-PB Prefabricated drainage mat ECODRAIN-E or ECODRAIN-S.

2.2 WATERPROOFING MATERIALS A. Fluid applied waterproofing system ECOLINE-S; a single course, high build, polymer modified, asphalt emulsion. Waterborne and spray applied at ambient temperatures. Apply to a thickness of 60 dry mils, unless specified otherwise. Non-toxic and odorless. ECOLINE-R has similar properties with greater viscosity and is roller or brush applied. Manufactured by EPRO Services, Inc. Fluid applied waterproofing physical properties.

B.

ECOLINE-S TYPICAL CURED PROPERTIES (MEMBRANE ONLY) TYPICAL UNCURED PROPERTIES Specific Gravity ASTM D 244 1 Viscosity ASTM D 1200 > 25 centipoise PH 12.3 Flammability ASTM D 3143 500 F Color Brown to Black Non-Toxic No Solvents Shelf Life 6 months TYPICAL CURED PROPERTIES Tensile Strength ASTM 412 32 psi Elongation ASTM 412 4140% Resistance To Decay ASTM E 154 Section 13 4% Perm Loss Accelerated Aging ASTM G 23 No Effect Moisture Vapor Transmission ASTM E 96 0.088 g/sq. ft. /hr. Hydrostatic Water Pressure ASTM D 751 26 psi Perm Rating (US PERMS) ASTM E 96 (US Persm) 0.21 Methane Transmission Rate ASTM D 1434 0 Adhesion To Concrete & Masonry ASTM C 836 & ASTM C 704 11 lbf./inch Hardness ASTM C 836 80 Crack Bridging ASTM C 836 No Cracking Low Temp. Flexibility No Cracking @ -20 ASTM C 836-00 C Resistance To Acids: Acetic 30% Sulfuric and Hydrochloric 13%

ECOLINE-R TYPICAL CURED PROPERTIES TYPICAL UNCURED PROPERTIES Specific Gravity Viscosity PH Flammability Color Non-Toxic Shelf Life TYPICAL CURED PROPERTIES Initial Cure Final Cure* Tensile Strength Elongation Resistance to Decay

ASTM D 244 ASTM D 1200 ASTM D 3143

1.034 9m-13m centipoise 11.5 270 F Brown to Black No Solvents 6 months 10 minutes 24 -48 hours 32 psi 3860% 9% Perm Loss

ASTM 412 ASTM 412 ASTM E 154 Section 13

Accelerated Aging Moisture Vapor Transmission Hydrostatic Water Pressure Perm rating (US Perms) Methane transmission rate Adhesion to Concrete & Masonry Hardness Crack Bridging Low Temp. Flexibility Resistance to Acids: Acetic Sulfuric and Hydrochloric *See curings, protection and cleaning sections for further explanation. 2.3 AUXILIARY MATERIALS A. B. C.

ASTM G 23 ASTM E 96 ASTM D 751 ASTM E 96 ASTM D 1434 ASTM C 836 ASTM C 836 ASTM C 836 ASTM C 836-00

No Effect .071 g/sq. ft. /hr. 28 psi 0.17 0 7 lbf./inch 85 No Cracking No Cracking at 20C 30% 13%

Sheet Flashing: 60-mil reinforced modified asphalt sheet good with double-sided adhesive. Reinforcing Strip: Manufacturers polyester fabric. Joint/Penetration Detailing Material: ECOLINE-T, a high viscosity polymer modified water based asphalt material or ECOLINE-R. 1. 2. ECOLINE-T. ECOLINE-R.

D.

EPROSTOP HDPL waterstop.

2.4 BASE COURSE MOISTURE/GAS BARRIER A. ECOSHIELD-P Physical Properties Grab Tensile Strength Grab Tensile Elongation PP Tear Puncture UV Resistance Light Reflectance 2.5 WATERPROOFING/PROTECTION COURSE A. ECOSHIELD-PB. PROPERTIES Membrane Puncture-Propagation Tear Resistance Tensile Strength: Membrane (psi) % Elongation at break Bentonite

ASTM D 882 ASTM D 882 ASTM D 2582 ASTM D 1709 ASTM D 4355 ASTM E 97

24 lb/in 500% 17.6 lbs 1.1 lbs 70% (after 150 hrs. exposure) 70%

TEST METHOD White HDPE/fabric geomembrane 7.7 lbs. (3,500 gm) 6,100 psi (42 Mpa) 100% Sodium Montmarilonite

ASTM D 2582 ASTM D 882 ASTM D 882

Overall Weight Resistance Crack Bridging Water Vapor Permeability

ASTM D 751 Procedure A ASTM E 96

Adhesive Odor Solids Ph Viscosity Cohesion Track HDPE (N/sqin) Flash Point Hazardous reactions Freeze/thaw stability Usage SF Application INSTALLED SYSTEM Puncture Resistance of membrane Puncture Resistance of composite Tensile Strength of composite Elongation-Ultimate failure (of rubberized asphalt) Water Vapor Transmission Permeance 2.6 PREFABRICATED DRAINAGE MAT A. ECODRAIN-E Physical Properties CORE Color Weight Compressive Strength Thickness Filter Fabric (Polypropylene) Grab Tensile Strength Elongation Trapezoidal Tear Puncture Strength Apparent Operating Size Mullen Burst Permittivity Water Flow Rate

(>90%) 0.6 per sq. ft. (2.44 kg/m_ ) 174 ft. (52.9m) of water 1/8" (.032 cm) crack 0.53 x 10 _ cm/sec 0.84 ng/m_.s Pa 0.033 Perms (grains/ft_. hr. iinHg) White Acrylic 65%

ASTM D 781 ASTM E 154 ASTM D 412 Modified Die C ASTM D 412 Modified Die C ASTM E 96 Method B

110 Kg/CM 40 Min. LBS 750 PSI Min. 400% Min. 0.1 Max. Grains/SF/Hr in HG

ASTM D 3776 ASTM D 1621 ASTM D 1777

HDPE Brown 1.90 oz/ft_ 5,200 lbs/ft_ 0.31 in.

ASTM D 4632 ASTM D 4632 ASTM D 4533 ASTM D 4833 ASTM D 4751 ASTM D 3786 ASTM D 4491 ASTM D 4491

130 lbs. 60% 60 lbs. 40 lbs. 70 sieve size 140 psi 0.7 sec. 55 gpm/ft_

Weight Typical UV Resistance Composite System Water Flow Rate (V) Water Flow Rate (H) Roll Size Roll Weight B. ECODRAIN-S6000 Physical Properties Core Color Weight Compressive Strength Thickness FILTER FABRIC Grab Tensile Strength Elongation Trapezoidal Tear Punchture Strength Apparent Operating Size Mullen Burst Permittivity Water Flow Rate Weight Typical UV Resistance COMPOSITE SYSTEM Water Flow Rate (V) Water Flow Rate (H) Roll Size Roll Weight PART 3 EXECUTION 3.1 EXAMINATION A.

ASTM D 5261 ASTM D 4355

4.0 oz/yd_ 70% (500 hrs.)

ASTM D 4716 ASTM D 4716 ASTM D 4716 ASTM D 4716

5.1 gal/min/ft 6.0 ft x 65.5 ft, 8.0 ft x 65.5 ft 60 lbs, 73 lbs

ASTM D 3776 ASTM D 1621 ASTM 1777 ASTM D 4632 ASTM D 4632 ASTM D 4533 ASTM D 4833 ASTM D 4751 ASTM D 4751 ASTM D 4491 ASTM D 4491 ASTM D 5261 ASTM D 4355 ASTM D 4716 ASTM D 4716 ASTM D 4716 ASTM D 4716

Polypropylene Black 2.85 oz/ft_ 17,000 psf 0.40 in. 160 lbs. 50% 65 lbs. 90 lbs. 80 sieve size 315 psi 1.6 sec 110 gpm/ft_ 6.0 oz/yd 70% (500 hrs.) 17 gal/min/ft 2.8 gal/min/ft. 6.0 ft. x 50 ft. 65 lbs.

Examine soil substrates, areas, and conditions under which waterproofing systems will be applied, with Installer present, for compliance with requirements. Do not proceed with installation until unsatisfactory conditions have been corrected.

3.2 SHEET PILE PREPARATION A. Sheet pile installation. 1. Sheet piles are affixed using anchors or soil compaction. 2. Sheet piles are spaced no greater than _ apart. Lagging spikes that cannot be removed need to be covered with appropriate protective material to prevent damage to drainage composite.

B.

3.3 DRAINAGE MAT INSTALLATION

A.

Place and secure drainage panels to the soil substrate with the geo-textile facing the soil or soil retention. Place soil anchors through the drainage mat by slitting vertically and sliding it over the anchor. Overlap edges of dimpled core and ends of geo-textile on both horizontal and vertical seams a minimum of 6 to maintain continuity. Protect ECODRAIN-E during subsequent construction. Fasten ECODRAIN-E with approved fasteners a minimum of every 24 on center on seams and terminations and a minimum of every 48 on center in field.

B. C.

D. E.

3.4 BASE COURSE MOISTURE/GAS BARRIER INSTALLATION A. Install ECOSHIELD-P over ECODRAIN or other approved substrate in one direction with 6-inch overlaps. B. Fasten with manufacturer approved fasteners a minimum of 48-inches on center. C. Secure ECOSHIELD-P seams by applying a 60-mil coat of ECOLINE-S between the overlapped sheets. D. Each fastener should be treated with polyester fabric and ECOLINE-R. 3.5 PREPARATIONS AND TREATMENT AT TERMINATIONS AND PENETRATIONS A. Prepare of ECODRAIN-E at terminations; penetrations; expansion joints; drains; sleeves and soil nails according to ASTM C 898 and manufacturers recommendations. 1. Apply two coats of ECOLINE-T or ECOLINE-R (30-mil each). Embed a joint reinforcing polyester in preparation coat and apply a second coat over embedded joint reinforcing polyester ensuring its complete saturation and covering. Terminations should be treated 3-inches up vertical and 3-inches on horizontal. Penetrations should be treated in a 3-inch radius around penetration and 3 inches onto penetrating object.

2. 3.

B.

Prepare tie-backs per manufacturers recommendations.

**Optional design for water table conditions. 1. 2. 3. Install prefabricated galvanized or plastic cap. Inject cap with expandable close cell foam. Treat 3 onto cap and 3 onto ECODRAIN-E.

3.6 FLUID APPLIED WATERPROOFING/GAS MEMBRANE APPLICATION A. B. C. Set up spray equipment according to manufacturers instructions. Mix materials according to manufacturers instructions. Start installing waterproofing in presence of manufacturers technical representative or approved 3rd party inspector. Apply waterproofing/gas membrane, according to manufacturers recommendations, by spray (ECOLINE-S) or roller (ECOLINE-R).

D.

E.

Apply one spray coat of ECOLINE-S or four coats of ECOLINE-R waterproofing/gas membrane to obtain a seamless membrane free of entrapped gases, with a dry film thickness of 60 mils (1.5 mm). Apply waterproofing/gas membrane in and around soil anchor penetrations and cavities (Bird Beaks) copiously to ensure the formation of monolithic gasket to receive the specially placed concrete. Apply waterproofing/gas membrane to prepared wall terminations and vertical surfaces to heights indicated according to manufacturers recommendations and details. Verify film thickness of waterproofing every 100 sq./ft. (9.3 sq./m).

F.

G.

H.

3.7 WATERPROOFING/PROTECTION COURSE INSTALLATION A. Install ECOSHIELD-PB waterproofing/protection course perpendicular to the ECOSHEILD-P base over nominally cured membrane no later than recommended by manufacturer and before starting subsequent construction operations. B. Secure ECOSHIELD-PB protection course seams by applying ECOLINE-S between overlapped sheets as recommended by the manufacturer. C. Fasten with manufacturer approved fasteners a minimum of every 24-inches on center. D. Each fastener should be treated with polyester fabric and ECOLINE-R. 3.8 FIELD QUALITY CONTROL A. Membrane may be checked for coverage with a lightly oiled, needle nose depth gauge, taking four (4) readings over a one square inch area, every 500 square feet. Record the minimum reading. Mark the test area for repair. Test areas are to be patched over with ECOLINE-S to an 80-mil minimum dry thickness, extending a minimum of one inch (1) beyond the test perimeter.

B.

3.9 CURING, PROTECTING, AND CLEANING A. Cure waterproofing according to manufacturers recommendations. It should be noted normal curing time is 24 to 48 hours to achieve a permanent water barrier. However, in some conditions such as a saturated substrate, extremely cold conditions and/or high humidity, the full adhesion of the membrane may be delayed. The length of delay may be subject the membrane thickness and severity of conditions. Take care to prevent contamination and damage during application stages and curing. Clean spillage and soiling from adjacent construction using cleaning agents and procedures recommended by manufacturer of affected construction.

B. C.

You might also like

- Specifications Vapor Barrier/Dampproofing (Ecodamp)Document6 pagesSpecifications Vapor Barrier/Dampproofing (Ecodamp)Baugh Graphic DesignNo ratings yet

- Specifications Dampproofing (Ecodamp)Document7 pagesSpecifications Dampproofing (Ecodamp)Baugh Graphic DesignNo ratings yet

- Specification Concrete and Cmu Walls (Reinforced)Document6 pagesSpecification Concrete and Cmu Walls (Reinforced)Baugh Graphic Design100% (1)

- Specification Concrete and Cmu WallsDocument6 pagesSpecification Concrete and Cmu WallsBaugh Graphic DesignNo ratings yet

- Specification Concrete and Cmu Walls With BentoniteDocument8 pagesSpecification Concrete and Cmu Walls With BentoniteBaugh Graphic DesignNo ratings yet

- Specification Beneath Slab Moisture BarrierDocument5 pagesSpecification Beneath Slab Moisture BarrierBaugh Graphic DesignNo ratings yet

- SYS3PDocument6 pagesSYS3PBaugh Graphic DesignNo ratings yet

- Specifications Waterproofing Tunnels/Underground StructuresDocument14 pagesSpecifications Waterproofing Tunnels/Underground StructuresBaugh Graphic DesignNo ratings yet

- Specifications Concrete Deck/Thin Set Tile OverlaymentDocument8 pagesSpecifications Concrete Deck/Thin Set Tile OverlaymentBaugh Graphic DesignNo ratings yet

- Specification Beneath Slab Gas Vapor BarrierDocument5 pagesSpecification Beneath Slab Gas Vapor BarrierBaugh Graphic Design100% (1)

- Specification Plywood Deck WaterproofingDocument5 pagesSpecification Plywood Deck WaterproofingBaugh Graphic DesignNo ratings yet

- Specification Concrete Deck/Between Slab (Reinforced)Document6 pagesSpecification Concrete Deck/Between Slab (Reinforced)Baugh Graphic DesignNo ratings yet

- Specification Concrete Deck/Between SlabDocument6 pagesSpecification Concrete Deck/Between SlabBaugh Graphic DesignNo ratings yet

- Specification: Concrete Deck/Green Roof (Reinforced)Document7 pagesSpecification: Concrete Deck/Green Roof (Reinforced)Baugh Graphic DesignNo ratings yet

- Section 07141 Cold Fluid Applied WaterproofingDocument6 pagesSection 07141 Cold Fluid Applied WaterproofingMØhãmmed ØwięsNo ratings yet

- SYS3BSWDocument6 pagesSYS3BSWBaugh Graphic DesignNo ratings yet

- Specification System Iii Icf WaterproofingDocument8 pagesSpecification System Iii Icf WaterproofingBaugh Graphic DesignNo ratings yet

- EBVMBDocument5 pagesEBVMBBaugh Graphic DesignNo ratings yet

- CsiDocument9 pagesCsiyamanta_rajNo ratings yet

- 298 Hydropack SpecificationsDocument4 pages298 Hydropack SpecificationsMinton JPNo ratings yet

- Section 07131 Self-Adhering Sheet Waterproofing Part 1Document72 pagesSection 07131 Self-Adhering Sheet Waterproofing Part 1jacksondcplNo ratings yet

- CCCC Et Ha Spec ST 650 00 Reply BDocument5 pagesCCCC Et Ha Spec ST 650 00 Reply B黄赛赛No ratings yet

- 134Document5 pages134ali razaNo ratings yet

- University of Houston Master Construction Specifications Insert Project NameDocument5 pagesUniversity of Houston Master Construction Specifications Insert Project NameTaher AmmarNo ratings yet

- Waterproofing (Cementitious+HDPE)Document12 pagesWaterproofing (Cementitious+HDPE)masahinNo ratings yet

- Guide Specification: NeoflexDocument4 pagesGuide Specification: NeoflexruloNo ratings yet

- 13 WaterProofDocument4 pages13 WaterProofadel agustiNo ratings yet

- Sikaproof A - Suggested Master SpecificationsDocument7 pagesSikaproof A - Suggested Master SpecificationsSindayiheba PatrickNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07100-1 WaterproofingDocument5 pagesITCC in Riyadh Residential Complex J10-13300 07100-1 WaterproofinguddinnadeemNo ratings yet

- Div 07Document108 pagesDiv 07mfkmughalNo ratings yet

- Guide Specifications: Kemperol 2K-Pur Roofing & Waterproofing System Master Guide SpecificationDocument23 pagesGuide Specifications: Kemperol 2K-Pur Roofing & Waterproofing System Master Guide SpecificationLong An DoNo ratings yet

- HydroStop System Spec PDFDocument21 pagesHydroStop System Spec PDFRafaelNo ratings yet

- PVC Roofing System DetailsDocument23 pagesPVC Roofing System DetailsJuanPaoloYbañezNo ratings yet

- SECTION 07 54 23 Thermoplastic Polyolefin (Tpo) RoofingDocument23 pagesSECTION 07 54 23 Thermoplastic Polyolefin (Tpo) RoofingJuanPaoloYbañezNo ratings yet

- ASP U91S42 30 10 GacoFlex U91 S4200 Over AsphaltDocument6 pagesASP U91S42 30 10 GacoFlex U91 S4200 Over Asphaltwebhareggebru06No ratings yet

- Acrylic Liquid Applied Over Mod BitDocument10 pagesAcrylic Liquid Applied Over Mod BitTaher AmmarNo ratings yet

- VOL-2-SEC-06-PART02-Torch-Applied Protected Membrane RoofingDocument9 pagesVOL-2-SEC-06-PART02-Torch-Applied Protected Membrane RoofingAdamNo ratings yet

- Modif Bitum Sheet Air BarriersDocument5 pagesModif Bitum Sheet Air BarriersTaher AmmarNo ratings yet

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Document5 pagesSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530No ratings yet

- 07 16 13 - Polymer Modified Cement WaterproofingDocument4 pages07 16 13 - Polymer Modified Cement WaterproofingMutaz Hashim MirganyNo ratings yet

- SECTION 07 18 13 Pedestrian Traffic CoatingsDocument4 pagesSECTION 07 18 13 Pedestrian Traffic CoatingsJuanPaoloYbañezNo ratings yet

- Sikafloor Chemical Resistant Solvent Based Aliphatic Urethane Esd SystemDocument7 pagesSikafloor Chemical Resistant Solvent Based Aliphatic Urethane Esd SystemHaytham ElsayedNo ratings yet

- Waterproofing Specifications for BridgesDocument6 pagesWaterproofing Specifications for BridgesAbdul Wahab JamilNo ratings yet

- Fluid Applied WaterproofingDocument8 pagesFluid Applied WaterproofingHamza MamiNo ratings yet

- F - A F Key Quartz B-125 1/8" Epoxy Decorative Quartz Resinous Flooring UV Light Resistant Epoxy Grout/SealerDocument7 pagesF - A F Key Quartz B-125 1/8" Epoxy Decorative Quartz Resinous Flooring UV Light Resistant Epoxy Grout/SealerUmerNo ratings yet

- Central Business District of the New Administrative CapitalDocument5 pagesCentral Business District of the New Administrative Capitallf chNo ratings yet

- 09 25 13 - Acrylic Plastering PDFDocument8 pages09 25 13 - Acrylic Plastering PDFmasoodaeNo ratings yet

- SECTION 07 13 52 Modified Bituminous Sheet WaterproofingDocument7 pagesSECTION 07 13 52 Modified Bituminous Sheet WaterproofingJuanPaoloYbañezNo ratings yet

- 1.1 A. 1.2 A. B. C. 1.3 A. B. C. D. E. F. G. H. I.: Click HereDocument5 pages1.1 A. 1.2 A. B. C. 1.3 A. B. C. D. E. F. G. H. I.: Click HereRiksa AsNo ratings yet

- Employer's Representative's: E18066-0100D-SD-SPC-15A-ST-01 REV ADocument4 pagesEmployer's Representative's: E18066-0100D-SD-SPC-15A-ST-01 REV Alf chNo ratings yet

- 2013 12 09 NIH - 07 Div Thermal Moisture PDFDocument105 pages2013 12 09 NIH - 07 Div Thermal Moisture PDFNathalie ReyesNo ratings yet

- 03 05 00iseDocument5 pages03 05 00isemp4 ghad mp4No ratings yet

- Concrete Waterproofing ProceduresDocument5 pagesConcrete Waterproofing ProceduresCire Lop CastroNo ratings yet

- Platon 3 Part SpecDocument4 pagesPlaton 3 Part SpecQuevara AntonNo ratings yet

- Joint Sealant SpecificationsDocument7 pagesJoint Sealant SpecificationsMØhãmmed ØwięsNo ratings yet

- 09 30 00 Interior Wall Tile SpecDocument5 pages09 30 00 Interior Wall Tile Specalex_geus5080No ratings yet

- KOSTER NB1 Grey Specification For Cementitious Crystallizing WaterproofingDocument7 pagesKOSTER NB1 Grey Specification For Cementitious Crystallizing WaterproofingMosul SpaceNo ratings yet

- D6950D6950M-04 (2012) E1 Standard Practice For Application of Heat Weldable Atactic Polypropylene (APP) Modified Bituminous Waterproofing Membranes Systems For New Building DecksDocument4 pagesD6950D6950M-04 (2012) E1 Standard Practice For Application of Heat Weldable Atactic Polypropylene (APP) Modified Bituminous Waterproofing Membranes Systems For New Building DecksSatya kaliprasad vangaraNo ratings yet

- Tremco 071416.01 - Cold Fluid-Applied Waterproofing, Vertical and Deck Tremproof 250gc - 20141031Document12 pagesTremco 071416.01 - Cold Fluid-Applied Waterproofing, Vertical and Deck Tremproof 250gc - 20141031ali razaNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Epro Bento-Pro PlusDocument2 pagesEpro Bento-Pro PlusBaugh Graphic DesignNo ratings yet

- Ecobase HVDocument2 pagesEcobase HVBaugh Graphic DesignNo ratings yet

- Epro Bento-Pro PlusDocument2 pagesEpro Bento-Pro PlusBaugh Graphic DesignNo ratings yet

- Ecoshield EBDocument2 pagesEcoshield EBBaugh Graphic DesignNo ratings yet

- Ecoshield PBDocument2 pagesEcoshield PBBaugh Graphic DesignNo ratings yet

- Ecoshield HDocument2 pagesEcoshield HBaugh Graphic DesignNo ratings yet

- System III GRBDocument2 pagesSystem III GRBBaugh Graphic DesignNo ratings yet

- Specifications Waterproofing Tunnels/Underground StructuresDocument14 pagesSpecifications Waterproofing Tunnels/Underground StructuresBaugh Graphic DesignNo ratings yet

- BSBEDocument6 pagesBSBEBaugh Graphic DesignNo ratings yet

- BB 1Document1 pageBB 1Baugh Graphic DesignNo ratings yet

- Sys3 LWBDocument2 pagesSys3 LWBBaugh Graphic DesignNo ratings yet

- Sys3 CWBDocument2 pagesSys3 CWBBaugh Graphic DesignNo ratings yet

- CDBSBEDocument9 pagesCDBSBEBaugh Graphic DesignNo ratings yet

- Sys3 RDBDocument2 pagesSys3 RDBBaugh Graphic DesignNo ratings yet

- EprostophplDocument2 pagesEprostophplBaugh Graphic DesignNo ratings yet

- Epro Services, System III - MBBDocument2 pagesEpro Services, System III - MBBBaugh Graphic DesignNo ratings yet

- R BaughDocument1 pageR BaughBaugh Graphic DesignNo ratings yet

- Polymer Mix Material Safety Data Sheet: 1. Product IdentificationDocument2 pagesPolymer Mix Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignNo ratings yet

- AS9100BDocument1 pageAS9100BBaugh Graphic DesignNo ratings yet

- Iso 13485Document1 pageIso 13485Baugh Graphic DesignNo ratings yet

- Fast Set Green Adhesive: General DescriptionDocument1 pageFast Set Green Adhesive: General DescriptionBaugh Graphic DesignNo ratings yet

- Eprosil Material Safety Data Sheet: 1. Product IdentificationDocument2 pagesEprosil Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignNo ratings yet

- AD55M Drum Pump: Sold Exclusively by Epro Services, Inc. Wichita, KS (800) 882-1896Document1 pageAD55M Drum Pump: Sold Exclusively by Epro Services, Inc. Wichita, KS (800) 882-1896Baugh Graphic DesignNo ratings yet

- MSDBSDocument2 pagesMSDBSBaugh Graphic DesignNo ratings yet

- Ecosil Series Material Safety Data Sheet: 1. Product IdentificationDocument2 pagesEcosil Series Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignNo ratings yet

- MSDPPDocument2 pagesMSDPPBaugh Graphic DesignNo ratings yet

- Eco TapeDocument1 pageEco TapeBaugh Graphic DesignNo ratings yet

- Eco Membrane Series Material Safety Data Sheet: 1. Product IdentificationDocument2 pagesEco Membrane Series Material Safety Data Sheet: 1. Product IdentificationBaugh Graphic DesignNo ratings yet

- Method Statement: Conbextra GP2Document5 pagesMethod Statement: Conbextra GP2diwakar1978No ratings yet

- API 5L GR.B SteelDocument2 pagesAPI 5L GR.B SteelYosua Rielys PNo ratings yet

- Inspiring The Next Generation - Proceedings of The International Conference On Spatial Structures 2020/21 (IASS2020/21-Surrey7) Available atDocument32 pagesInspiring The Next Generation - Proceedings of The International Conference On Spatial Structures 2020/21 (IASS2020/21-Surrey7) Available atRancho vonNo ratings yet

- Spending 2012 02Document123 pagesSpending 2012 02Mohammod KhanNo ratings yet

- Rain Water HarvestingDocument7 pagesRain Water HarvestingMithil KotwalNo ratings yet

- O-Rings: Back-Up Rings / P SeriesDocument1 pageO-Rings: Back-Up Rings / P SeriesRian PratamaNo ratings yet

- Sikalastic®-590: Product Data SheetDocument5 pagesSikalastic®-590: Product Data SheetKhin Sandi KoNo ratings yet

- Creep and Effective Stiffness of Early Age Concrete Slabs: H.G. Park & H.J. Hwang J.Y. Kim G.H. Hong J.H. Im & Y.N. KimDocument4 pagesCreep and Effective Stiffness of Early Age Concrete Slabs: H.G. Park & H.J. Hwang J.Y. Kim G.H. Hong J.H. Im & Y.N. KimAshwin B S RaoNo ratings yet

- Alliance-SMO QAF PreparationDocument14 pagesAlliance-SMO QAF PreparationMd FattahNo ratings yet

- Principles of Reinforced Concrete Design: Arlegui, Quiapo, ManilaDocument10 pagesPrinciples of Reinforced Concrete Design: Arlegui, Quiapo, ManilaMary Scarlette CenaNo ratings yet

- 002 - ITP Earthworks - Revision 2.0Document12 pages002 - ITP Earthworks - Revision 2.0randyNo ratings yet

- Shaikh ZaheerDocument4 pagesShaikh ZaheerMonika ShindeNo ratings yet

- A Script File For Mix Design of Structural Lightweight ConcreteDocument10 pagesA Script File For Mix Design of Structural Lightweight ConcreteMohamed Elshahat OudaNo ratings yet

- The Best Choice for Network Solutions - Zimmlink IndonesiaDocument21 pagesThe Best Choice for Network Solutions - Zimmlink IndonesiapuspitagdNo ratings yet

- Types of BoltsDocument7 pagesTypes of BoltsPranshu JainNo ratings yet

- Presentazione Per Progettisti ENG1 PDFDocument122 pagesPresentazione Per Progettisti ENG1 PDFAlexandra Lungu ROAD DESIGNNo ratings yet

- Megapower's Extensive Range of PVC Conduit Fittings and Wiring AccessoriesDocument8 pagesMegapower's Extensive Range of PVC Conduit Fittings and Wiring AccessoriesChia Woon LimNo ratings yet

- 8V396 PDFDocument627 pages8V396 PDFOsman Burak ÖzbekNo ratings yet

- Ref. Title No.: 10.1 Piling: GeneralDocument9 pagesRef. Title No.: 10.1 Piling: GeneralJithesh.k.sNo ratings yet

- Technical Guide JIBster KIT SWF 06 11 enDocument43 pagesTechnical Guide JIBster KIT SWF 06 11 enRonald FrancoNo ratings yet

- Water Infrastructure Design Standards and GuidelinesDocument111 pagesWater Infrastructure Design Standards and Guidelinesahmed zakiNo ratings yet

- Method Statement For Interlocking PavingDocument5 pagesMethod Statement For Interlocking Pavingdinidu3priyankara3saNo ratings yet

- Invitation To Bid: Republic of The Philippines Department of Public Works and Highways Region Xi Matiao, City of MatiDocument5 pagesInvitation To Bid: Republic of The Philippines Department of Public Works and Highways Region Xi Matiao, City of MatiMark Joseph ArellanoNo ratings yet

- Different Types of Wood JointsDocument6 pagesDifferent Types of Wood JointsNaharia Rangiris0% (1)

- Hardened ConcreteDocument3 pagesHardened ConcreteEng Aidaruos Abdi MatanNo ratings yet

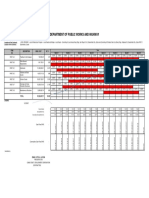

- Department of Public Works and Highway: Contract I.D. Location of The Contract: Location of The ContractDocument1 pageDepartment of Public Works and Highway: Contract I.D. Location of The Contract: Location of The ContractAdrian Louie Laganzo AquinoNo ratings yet

- Proofex GP TDSDocument2 pagesProofex GP TDSvinoth kumar SanthanamNo ratings yet

- Elastic critical moment for lateral torsional buckling00.20.4M0.60.81M<0End moments and concentrated load – Factor C1Document14 pagesElastic critical moment for lateral torsional buckling00.20.4M0.60.81M<0End moments and concentrated load – Factor C1Hamati RamiNo ratings yet

- WBS-Engineering Project PlanDocument3 pagesWBS-Engineering Project PlanM iqbalNo ratings yet

- Anna Schmookler Recognized As A Woman of The Month For November 2018 by P.O.W.E.R. (Professional Organization of Women of Excellence Recognized)Document2 pagesAnna Schmookler Recognized As A Woman of The Month For November 2018 by P.O.W.E.R. (Professional Organization of Women of Excellence Recognized)PR.comNo ratings yet