Professional Documents

Culture Documents

ASTM Material Specifications

Uploaded by

maz2340 ratings0% found this document useful (0 votes)

2K views6 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2K views6 pagesASTM Material Specifications

Uploaded by

maz234Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

ASTM Material Specifications

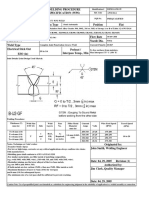

‘The following isa chart from ANSI 816.34 - 1996 Version; Table 1- Material Specification

Group 1 Materials

Material Product Form

Forgings Castings Plates Bars Tubular

[Group] Nominal

|Spec. No.| Grade | Spec. No, |Grade|Spec. No. | Grade |Spec. No.| Grade | Spec. No.| Grade

No. | Designation

ners | 70

©

asis | 70 | A105

ut csi A105 asr2 | a70

aze |wea} sie | 70 | asso | ure

CMnSi 350 asr2 | c70

asaz_ | cir | acs |

esi

ass2_| Lez

21aNi

12. ae ase | ics} azos | 8 ais | c

asso | irs | azie Jwoc] azos | & | asso | urs

CMn-Si

ass2_| Loc

©

esi sis | 65 as72 | B65

13 21/26 nos | A | 67s | 65

aas2_| ice

128i nzos |

CMnSi asis | 65 as72_| c8s

ners | 60

©

1 csi asis | 60 as | a

as72 | 860

asso. | uFt

CMn-Si asso | asis | 60 as72 | coo

acoa |

nai7_ [wer] aoa | A

1s | camo aisz | Fi aisz | Fi | asor | emo

ass2_| uct | sacs | 8

cae

Pt

16 | 12cr-12M0 ass? | 2011 asa | FPt

aser [20.2 acai | 112ce

rer-v/2Mo aser_|r2cit

cram

1120r-12Mo

a aoe | oc acer | cm75

Nitvace-trame | atez | F2 | aziz [wes aisa | Fe

SIANiMo-314Cr a2t7_ [wes

Terao nae? [2ci2 naar | 1cR

ass | pz

asso | pre

1KeCe-12Mo-Si var arc aso |1-amor

pn

ase | FPtt

2.4N4Cr-1Mo vae7 |22.c.1 aso 2amcr

ass | P22

asa | FP22

TortraMe aie2_ [rrzci2|

sacrvamo-si| A182 [F202 are2_ fen ciz|

area frrsciz var |arci2

s-4crt12Ma nai | wes araa_ | ant

2vaceime | _Ate2 |r22cis nse7_[22ci2|_Atez |r22cis

vai’ | wea ars |eazt0.2

screamo | arse | F21 vae7_|2rci2| arse | 21

Mrvil2Me nao [ABE

Ma.st/2Ma-12Ni asoz | ¢

M1/2Mo-SI4Ni sao2 | 0

Cosi aso7_| ci2

‘02M naa 50R

vae7 | 511 ass | 5

va7 | sc.2 asc | FPS:

50r-1/2Mo-Si A335 | PB

seesame | ANZ | F | nar | os ars | Fa

avez | Fs

‘crime | avez | Fa | aa [ore aaa | Fo

‘The following isa chart from ANSI 816.34 - 1996 Version; Table 1- Material Specification

ASTM Material Specifications (2)

Group 2 Materials

Material Product Form

Forgings Castings Plates: Bars Tubular

[Group] Nominal

[Spec. No.|Grade|Spec.No.| Grade |Spec. No. Grade |Spec. No. | Grade |Spec. No. | Grade

No. | Designation

asta | TP308

ais | eas | asta |reaosh

a1 | taceaw | A182 fra | asst | ces | ogo | 04 | tga |roosH] Aas | aoe

ats |rsosH| ssi | crs | Aza | sosy | aaa | soe | as76 | TPs0e

sara | sosn | aave |resosn

ago | Fang

ago |FPsoaH

6Cr-2N-2Mo

a2so | 16 asta | Tpst6

200 | 316H aat2_ [resto

ass | 316

ais2_| F316 | as76 | TPst6

2 awe2 | F316 ais2 |raicH| aa7e [resto

ate2 [rato sara | are | aaso. | Frais

180r-8N 351 | CF3A

nara | si6H | asso. |rpsten

351 | crBA

18 Cr-13N-aMo

160r-12N-2Mo 351 | cFsM

azo | 317 ast2_| TP317

ssi | crem

19Cr-10N-3Mo aas1_ | coem

‘Aie2 | Fa0dL

recren, | area [roost a2a0 | 304 asta |TPa9at

ara | 304.

2a

ats2 | Fate.

te0r-12N-2Mo | area |F3i6l 2a | 316. asta |TPst6.

sara | s16.

aaa | 1321

asta |res2i

tz | F321

ass | 321

ate2 | Fa21 a

24 | tace10Ni-ri aare | Tpa21

ats2_|Fs21H azao | sath | area | Fs21H

sve |res2iH

nara | 21H

aso | FP321

aso |epaziH

‘ata | TP 347

area | F347

asta ready

ane2 | Faa7es

sss | TP347

Aisa | F348

area | F347 azo | sar are | Te3a7

are | Fass

aie2 |rae7H azso | a47H sare [ream

28 | t8ce-10N-ce nasi | crac nara | sar

are | F348 azo | 48 sare | Te3ee

Aiea |F34sH 280 | s48H aso | FP347

aava | 347H

aso |Fesa7H

aa7a | a8

asta | TP3es

aa7a | s4sH

asta [Tes

25Cr-12N

os ast | cHe

ssi | cao | Aza | 098, asta |TP309H

230r-12Ni

240 | s09H ase | 3098

‘azo | s108 | area [raton| asiz [resin

27 | ascrzon | are2 |raton] assr | ck20

20 | ston | aa7a | 3108

nara s10s | 4388 [3104

aaa [sa1254

2ocr-18NisMo | ats2 | Fas A280 |ssi254

358 | ss1254

aa7a |ss1254

asa | 831803

28 |22crswisMen] atez | Ft | aas1 |ckamcun] azdo |sare03] asza |ssta0a

A790 | sata03

area 832750

25Cr-7NiMON| A182 | F53 240 |832750| aa79_ |s32750

carga | 832750

ASTM Material Specifications (3)

‘The following isa chart from ANSI 816.34 - 1996 Version; Table 1- Material Specification

Group 3 Materials,

Material Product Form

Forgings Castings Plates Bars Tubular

[orove) Nominal No.| Grade |Spec. No.) Grade No.| Grade |Spec. No.| Grade |Spec. No.| Grad:

No. | Designation _[™ i ps is Ps

B5NFGBFe-20Cr-Cb aes _|x08020]

ase |nos020

462 |woso20| 8473 |Nosozo

468 |wos0z0

28Ni-19Cr-CurMo ass1_ [ONT

‘ret _[N02200

32 9 8160 8162 8160 |voz200

163 |No2200

33 | __99Nilowe wei60_| No2207 162 _|Noz20i| 6160 |NOZ200

‘7NF3O0u res No«A00

165. |Nossoo

34 564 |wossoo] 127 |wossoo]

163. |No«aoo

67Ni30CuS ssa} No‘aos 164 _|Nodaos

167 |NoB5o0|

35 | 7aniscrare | 3564 |woes00] 8168 |xoss00] 8165 |uoss0o|

163 |No8s00

36 | _sNid2reziGr | 8564 [Nows0o] 3409 _[Nosso0] 8408 nosso] Ni63 _|oBe09|

37 | _csN-28Mo-2Fe | 8335 [vi0566| 3333 _[Ni0s65] 8335 Jui066s] 6522 _|uioes5|

Baniciemo-tscr_ | B574 |vi027el 3575 |vioa7a) 8574 |uioa7e] 8622 |uioz76|

6oN-22¢r-9Mo-3.5¢0 | 564 |No8625 443 Jnoss2s] 8446 Jnose2s|

as | _S2NezeMosre | Baas 10009 88333 |v10001] 6335 |u10001] 8622 |wro001

ToN-16Mo-76r-5Fe | 8573 |\10003 434 |wi0003} 8573 $u10009|

BINi-t6Mo-t6cr | 8574 |NoB4s5| 8575 Jnosass] 8574 Jwossss] 8522 |nosass|

li2ni-21.5cr-3Mo-23cu] 6425 _|NoBe25 124 |Nose2s) 8425 |woss2s] 8423 |oss25|

39 | «7N-22GraMe-t8Fe | 8572 _|uos002| 435 _|uosoo2] 8572 _nosoo2] 8622 |Noso02|

3.10 | 25NiA7Fe-21Cr5Mo | 8572 _|NOB7O0 3599 _[x08700] 8672 _|NO87OO]

3.11 | 44Fe26N-210rMe | 8649 _|NoBso4 8625 _Jnosao«] 8649 Jnosa0s] 6677 _|NoBa04]

gia | 2NaFe22crsMo | B21 |NoBs20 3620 [Noas20] 8621 Juo8s20] 8622 |No8s20]

47N-226r-20Fe-7™Mo | 681 [Noss 582 |Nosgss] 8561 |vos9es] 8622 |nososs|

sig | “oN-28erteFeamo | eset |Nosars wa5e2 [vose7s) 8561 [vosa75] 5522 |uose7s|

NiFe-CrMo-Cu-Low 0 8564 _|N0803 625 |vos01] 8649 |vos031] 8622 |nosos1

374 | 47N-226r19Fe-amo | 8581 _|N08007 13562 _[Noso07| 8561 Jnosoo7| 6522 |Nosoo7|

‘SIN-2Fe21Cr

aaa | Netany

3.18 NeMo 584 |vossto] 409 |wossto] 8408 Juosst0] 5407 |oss1o|

aaa fow-12mv|

NiMo-Cr

376 | seneiacriiiasi | e511 _\NoBsa0 3536 _[Nowss0| 8511 nosso] 8535 _|owss0]

ASTM Material Specifications (4)

‘The following isa chart from ANSI 816.34 - 1996 Version; Table 1- Material Specification

Group 4 Materials,

Bolting Material Specifications [Note (1)]

‘Specification No. Grade Notes ‘Specification Ne. Grade Notes

Ai98 - (ae) as > ao)

1307 B : ys) M453 - (9,19)

320 2303)6) As40 -

A354 : A864 620 a

408 - 129073)

B16 : cr1yc1243) 3473 : on

2165 : (ora as74 Nio276 on

2905 Ni0665 a 8574 Nosozz on

8637 novris on

(GENERAL NOTES:

‘a, The user is responsible for assuring thal bolting material is nat used beyond the limits specified inthe governing code or

regulations,

b, ASME Boiler and Prossure Vessel Code Section II material that also meat the requirements of the listed ASTM specifcaton|

may also be used.

‘c. Materal imitation

restrictions, and special requirements are shown on pressure-temperalure tables

NOTES

1. Repair welding of bolting material's not permite.

2. Where austenitic bolting materials have been carbide solution treated but not strain hardened, they are designated Class 1

oF Class 1A in ASTM A193, ASTM A194 nuts of coresponding material are recommended.

3, Where austeritc bolting materials have been carbide solution treated and strain hardened, they are designated Class 2 in

ASTM A193. ASTM A194 nuls of coresponding material are recommended,

For imitations of usage and strength levels, see ASME 816.94 para. 5.1.1

Bolts with dried or undersize heads shail not be used,

4

6

6. For fertc bolting materials intended for service at low temperatures, ASTM A784 Gr. 4 or Gr. 7 nul are recommended

7. Acceptable nuts for use with these quenched and tampered steel bols are ASTM A194 Grade 2 and 2H.

‘8. Mechanical property requirements for studs shall be tha same as those for bolts.

9, These are bolting materials suitable for high temperature service with austenitic stainless steel valve materals.

10. Only Grades 651 and 660 shall be used.

11, Nuts may be of the same materal or may be of compalile grade of ASTM A184,

12. Forging quality not permitted unless the producer last heating or working these parts tests them as required for other

permitted conditions in the same specification and certifies their final tensile, yield, and slongation properties to equal or

‘2xc00d the requirements for one ofthe other permitted conitions,

18, Maximum operating temperature is arbitrary set at 800°F (260°C) unloss matenal has been annealed, solution annealed, oF

hot frished, because hard temper adversely affects design stress in the creep-uplure temperature range.

You might also like

- Filler Metal SelectionDocument7 pagesFiller Metal SelectionMidhun K ChandraboseNo ratings yet

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDocument1 pagePQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNo ratings yet

- Welding PositionsDocument116 pagesWelding PositionsASAPASAPASAPNo ratings yet

- Weld Filler Metal SelectionDocument7 pagesWeld Filler Metal SelectionsusanwebNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Inspection of Unusual Pipe Types With Eddy Current TechnologiesDocument25 pagesInspection of Unusual Pipe Types With Eddy Current Technologiesmaz234100% (1)

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Tech Manual Wire Rope Us NavyDocument126 pagesTech Manual Wire Rope Us NavydrunkwombatNo ratings yet

- KMI Batam - FPSODocument19 pagesKMI Batam - FPSOmaz234No ratings yet

- Welder Performance Qualification Record (WPQ) : Testing Condition and Qualification LimitsDocument9 pagesWelder Performance Qualification Record (WPQ) : Testing Condition and Qualification Limitsahmed mohamed100% (1)

- Aisi 4140 En8 En19Document1 pageAisi 4140 En8 En19Jose KurianNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Understanding Contractual Suspension TermsDocument9 pagesUnderstanding Contractual Suspension TermsHarish BabuNo ratings yet

- Manual CalidadDocument23 pagesManual CalidadGabriel GaraventaNo ratings yet

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72No ratings yet

- Valve MaterialsDocument1 pageValve MaterialsMarcel BolovedeaNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- The Suitability of CRA Lined Pipes For Flowlines Susceptible To Lateral BucklingDocument13 pagesThe Suitability of CRA Lined Pipes For Flowlines Susceptible To Lateral Bucklingmaz234No ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- ASTM Material SpecificationsDocument2 pagesASTM Material SpecificationssemsagroNo ratings yet

- Mill Test Certificate: Customer Name/Address StampDocument1 pageMill Test Certificate: Customer Name/Address StampD S Sagar TripuramalluNo ratings yet

- Material Dissimilar JointsDocument7 pagesMaterial Dissimilar JointsPemburu JablayNo ratings yet

- Carbon and Alloy Steel PDFDocument52 pagesCarbon and Alloy Steel PDFmaz234100% (3)

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983No ratings yet

- Mechnical Property For Q235B Carbon SteelDocument3 pagesMechnical Property For Q235B Carbon SteelPritom Ahmed100% (1)

- Tungsten ElectrodesDocument2 pagesTungsten ElectrodesSyed Furqan Rehmani0% (2)

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- WPS & PQRDocument24 pagesWPS & PQRtulasirao.nammiNo ratings yet

- Lista de Equivalencias de Materiales enDocument1 pageLista de Equivalencias de Materiales enNattaya Chantapanich รักในหลวงNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNo ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- FCAW Electrode DesignationDocument3 pagesFCAW Electrode DesignationthedreampowerNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- Chemical DetailsDocument3 pagesChemical Detailsemmas18No ratings yet

- Astm A 516 Gr.60n Plate SpecificationDocument3 pagesAstm A 516 Gr.60n Plate Specificationharishbabuek100% (1)

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDocument50 pagesSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediNo ratings yet

- Casting Material WCBDocument8 pagesCasting Material WCBYusri WyeuserieyNo ratings yet

- Ferrous Metals: General Grade Cast IronsDocument8 pagesFerrous Metals: General Grade Cast IronskkamalakannaNo ratings yet

- IS Materail Specification For General ApplicationDocument1 pageIS Materail Specification For General Applicationravindranathanne100% (1)

- Preview - AWS+B2.1 8 214 +2001 (R2012)Document8 pagesPreview - AWS+B2.1 8 214 +2001 (R2012)Jaime0% (1)

- PreheatDocument2 pagesPreheatScott TrainorNo ratings yet

- Comp SA36, IS 2062, SA516 GR 60Document2 pagesComp SA36, IS 2062, SA516 GR 60RajendraNo ratings yet

- Guidelines For Specification, Welding and Inspection of Stainless Alloy PipingDocument19 pagesGuidelines For Specification, Welding and Inspection of Stainless Alloy Pipingafr5364No ratings yet

- TC VerificationDocument33 pagesTC VerificationmaheshNo ratings yet

- MSM Marketing SDN BHD: MIG Welding Electrodes !Document3 pagesMSM Marketing SDN BHD: MIG Welding Electrodes !namasralNo ratings yet

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Silvia CardenasNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Nip Material ComparsionDocument1 pageNip Material ComparsionRob WillestoneNo ratings yet

- Add02 1060.1Document14 pagesAdd02 1060.1Diego Calderón AlvaradoNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- AWS Classification System SAWDocument5 pagesAWS Classification System SAWperungguNo ratings yet

- Equivalent ASME en MaterialsDocument3 pagesEquivalent ASME en MaterialsChee WeiNo ratings yet

- Astm A36 Chapa Grossa Ate 19mm PDFDocument1 pageAstm A36 Chapa Grossa Ate 19mm PDFHugo RodriguezNo ratings yet

- Material Data Sheet For ValvesDocument1 pageMaterial Data Sheet For ValvesИлья БересневNo ratings yet

- EralpFintube CatalogDocument6 pagesEralpFintube Catalogparsiti unnesNo ratings yet

- Astm Material Specifications: Group 1 MaterialsDocument4 pagesAstm Material Specifications: Group 1 Materialsabdelkader benabdallahNo ratings yet

- Piping Material Selection TableDocument1 pagePiping Material Selection TablepchakkrapaniNo ratings yet

- MaterialSpec Pipe RawMatDocument1 pageMaterialSpec Pipe RawMatjittshong8072No ratings yet

- Material SpecificationDocument2 pagesMaterial SpecificationmasrooorNo ratings yet

- Valve Material Specifications: Forged Cast Key Physical PropertiesDocument1 pageValve Material Specifications: Forged Cast Key Physical PropertiesdenyNo ratings yet

- 1) Tube & Pipe Comparison TableDocument2 pages1) Tube & Pipe Comparison Tablevalli rajuNo ratings yet

- Autoclave - Tools, Installation. Operation and MaintenanceDocument16 pagesAutoclave - Tools, Installation. Operation and Maintenancemaz234No ratings yet

- Araldite - GT7074Document2 pagesAraldite - GT7074maz234No ratings yet