Professional Documents

Culture Documents

Dessicant Properties

Uploaded by

Reena ThakurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dessicant Properties

Uploaded by

Reena ThakurCopyright:

Available Formats

How Are "Adsorption" And "Absorption"

Different?

You may have run across some terms used in the description of the

Moisture Control System's operation that are unclear to you. You may

for instance wonder at the term "adsorption" and think it a typo where

we meant to write “absorption". In actuality these terms represent two

very different scientific concepts. For the answers to this and other

questions on desiccant operation, read on.

Absorption is when a substance is chemically integrated into another.

When you drink a glass of water, you are absorbing it, as the water

becomes part of you.

Adsorption is when one substance is being held inside another by

physical bonds. If you spill a glass of water on your shirt, it is

adsorbed as the fibers will hold the water until heat dries out the shirt.

Most desiccants don't chemically combine with water or the other

substances they're present to protect against. They capture them

through adsorption, and stow them away where they can't cause harm

to the product.

How Do Desiccants Work?

It is important to understand how the desiccant does its job of

protecting the product. Most porous adsorbents, such as silica gel,

activated clay or molecular sieves rely upon physical adsorption rather

than chemical adsorption to accomplish their function.

Physical adsorption involves relatively weak intermolecular forces (van

der Waals forces and electrostatic interactions) between the moisture

and surface of the desiccant.

Chemisorbents, such as calcium oxide, involve an actual chemical

bond. Physical adsorption of moisture is typically exothermic. The

strength of the adsorptive bonds can thus be measured by the heat of

adsorption. The higher the heat of adsorption for moisture on the

desiccant, the stronger the bonding and the less easily that moisture

can be subsequently removed.

In a porous desiccant such as the silica gel used by Dri-Box, water is

removed from the airspace by:

1) multi-layer adsorption, which is the attraction of thin layers of water

molecules to the surface of the desiccant. Because the desiccant is

very porous, the surface area is high and significant amounts of water

can be attracted and adsorbed;

2) by capillary condensation in which the smaller pores become filled

with water.

Capillary condensation occurs because the saturation water vapor

pressure in a small pore is reduced by the effect of surface tension.

How Are Desiccants Rated?

Packaging engineers face a confusing array of variables when selecting

moisture adsorbents partly because moisture control is a multifaceted

challenge.

There are four sources of water contamination in a closed container or

package:

the water vapor in the air inside the package;

the water vapor adsorbed by the materials inside the package;

the water vapor on the walls of the package;

and the permeation of water vapor into the package.

Historically, desiccants are chosen by application-testing, commonly

known as trial and error. The variables can be classified into two main

groups:

those pertaining to the product, its package and its environment;

and the various properties of commercially available desiccants.

Through firsthand testing and published research, the packaging

engineer determines the conditions surrounding optimum product

preservation and performance.

In attempting to meet and maintain these conditions, one often

encounters moisture and its accompanying hazards: corrosion, rust,

mold, mildew, fungus, swelling and other undesirable factors affecting

product integrity. Where can one turn for answers?

Based upon its wartime experience in the development of food and

drug drying agents, the US Department of Defense developed

specifications addressing the elimination of corrosion and mildew by

adsorbing the moisture from the air of an enclosed space.

In November 1963, the DOD released MIL-D-3464C, covering the use

of bagged desiccants for packaging and static dehumidification.

Three years later, MID-D-3464D served to update the original

specification, creating a uniform standard of comparison in a wide

variety of areas: adsorption capacity and rate, dusting characteristics

of the package, strength and corrosiveness of the package and particle

size of the desiccant.

In 1973, the DOD followed with specifications for cleaning, drying,

preserving, and packaging of items, equipment and materials for

protection against corrosion, mechanical and physical damage and

other forms of deterioration. MIL-D-3464 and MIL-P-116 have long

been the only objective source for packaging engineers. The strength

of these specs lies in determining a uniform unit of drying capacity,

enabling one to compare desiccant effectiveness on a common scale.

The specifications, however, fail to deal specifically with variables,

such as product environment, packaging of the product itself, and the

type of desiccant suitable for a specific need.

Also, other important factors are defined but not applied: desiccant

packaging form, cover stock, adsorption rate and adsorption capacity.

These specifications seem only to compare the conformance of the

desiccant selected to Defense Department standards.

As a result, the packaging engineer may be at a loss to choose with

confidence which particular desiccant is best for each application.

Thus, the engineer must move outside the limited scope of military

specifications and into the real world of moisture-proof packaging: the

product's environment and package.

For more information, see the entries and charts on our selection

page.

How Does Moisture Cause Damage To A

Product?

Moisture trapped within a product package or leaking into it during

storage and shipping can cause many harmful effects. The stability of

many pharmaceutical formulations and diagnostic reagents, as well as

the maintenance of their physical product integrity, is often closely tied

to the moisture conditions of the package environment.

In unsterile or poorly sterilized situations, moisture can promote the

growth of mold, mildew and fungus. Products using some polymers are

prone to swelling in high humidity conditions as intermolecular bonding

between polymer chains can be weakened by the presence of water. In

some cases water can become an integral part of the bulk crystal

structure of a product through the formation of hydrates. If a solid is

very water soluble, such as a sugar coating, and the right conditions

exist, dissolution into the sorbed layer can trigger irreversible water

uptake and subsequent deliquescence.

In the case of electronics, the presence of moisture can cause not only

corrosion but also can lead to "short" circuits, wherein the electricity

powering the device reroutes through the water instead of its assigned

conductive path. These will not necessarily lead to cinematic instance

of panels blowing open and sparks flying. In fact, they will usually be

much more subtle and untraceable by making the device's operation

unreliable. Sometimes it works... sometimes it doesn't. At the very

least a situation like this is frustrating; at worst, life-threatening.

What Is "Saturation" And "Equilibrium

Capacity"?

Although technically they are different situations, for most practical

purposes these two terms cover the point at which a desiccant no

longer adsorbs moisture.

Saturation is when the desiccant is full and even if there were moisture

molecules to pick up, the desiccant could not adsorb them.

Equilibrium capacity is when the desiccant has pulled so much

moisture out of the air that the air retains a stronger hold on the

moisture molecules than the desiccant can exert. At equilibrium

capacity, adding more desiccant will not bring the relative humidity

any lower.

IRON AND STEEL

This page looks at the use of the Blast Furnace in the extraction of

iron from iron ore, and the conversion of the raw iron from the

furnace into various kinds of steel.

Extracting iron from iron ore using a Blast Furnace

Introduction

The common ores of iron are both iron oxides, and these can be

reduced to iron by heating them with carbon in the form of coke.

Coke is produced by heating coal in the absence of air.

Coke is cheap and provides both the reducing agent for the

reaction and also the heat source - as you will see below.

Iron ores

The most commonly used iron ores are haematite (US: hematite),

Fe2O3, and magnetite, Fe3O4.

Note: The two equations for the reduction of the ore on this page are for

haematite. In the fairly unlikely event that you need the equations for

magnetite, they aren't difficult to work out for yourself.

The Blast Furnace

The heat source

The air blown into the bottom of the furnace is heated using the hot

waste gases from the top. Heat energy is valuable, and it is

important not to waste any.

The coke (essentially impure carbon) burns in the blast of hot air to

form carbon dioxide - a strongly exothermic reaction. This reaction

is the main source of heat in the furnace.

The reduction of the ore

At the high temperature at the bottom of the furnace, carbon

dioxide reacts with carbon to produce carbon monoxide.

It is the carbon monoxide which is the main reducing agent in the

furnace.

In the hotter parts of the furnace, the carbon itself also acts as a

reducing agent. Notice that at these temperatures, the other

product of the reaction is carbon monoxide, not carbon dioxide.

The temperature of the furnace is hot enough to melt the iron which

trickles down to the bottom where it can be tapped off.

The function of the limestone

Iron ore isn't pure iron oxide - it also contains an assortment of

rocky material. This wouldn't melt at the temperature of the

furnace, and would eventually clog it up. The limestone is added to

convert this into slag which melts and runs to the bottom.

The heat of the furnace decomposes the limestone to give calcium

oxide.

This is an endothermic reaction, absorbing heat from the furnace. It

is therefore important not to add too much limestone because it

would otherwise cool the furnace.

Calcium oxide is a basic oxide and reacts with acidic oxides such

as silicon dioxide present in the rock. Calcium oxide reacts with

silicon dioxide to give calcium silicate.

The calcium silicate melts and runs down through the furnace to

form a layer on top of the molten iron. It can be tapped off from

time to time as slag.

Slag is used in road making and as "slag cement" - a final ground

slag which can be used in cement, often mixed with Portland

cement.

Cast iron

The molten iron from the bottom of the furnace can be used as

cast iron.

Cast iron is very runny when it is molten and doesn't shrink much

when it solidifies. It is therefore ideal for making castings - hence its

name. However, it is very impure, containing about 4% of carbon.

This carbon makes it very hard, but also very brittle. If you hit it

hard, it tends to shatter rather than bend or dent.

Cast iron is used for things like manhole covers, guttering and

drainpipes, cylinder blocks in car engines, Aga-type cookers, and

very expensive and very heavy cookware.

Note: It is quite difficult to find examples of uses for cast iron, because it

is nowadays often replaced by other materials. For example, although

guttering and drainpipes were once made of cast iron, apart from special

old buildings, it is now quite hard to find any which aren't made of plastic!

Steel

Most of the molten iron from a Blast Furnace is used to make one

of a number of types of steel. There isn't just one substance called

steel - they are a family of alloys of iron with carbon or various

metals. More about this later . . .

Steel-making: the basic oxygen process

Impurities in the iron from the Blast Furnace include carbon,

sulphur, phosphorus and silicon. These have to be removed.

Removal of sulphur

Sulphur has to be removed first in a separate process.

Magnesium powder is blown through the molten iron and the

sulphur reacts with it to form magnesium sulphide. This forms a

slag on top of the iron and can be removed.

Removal of carbon etc

The still impure molten iron is mixed with scrap iron (from recycling)

and oxygen is blown on to the mixture. The oxygen reacts with the

remaining impurities to form various oxides.

The carbon forms carbon monoxide. Since this is a gas it removes

itself from the iron! This carbon monoxide can be cleaned and used

as a fuel gas.

Elements like phosphorus and silicon react with the oxygen to form

acidic oxides. These are removed using quicklime (calcium

oxide) which is added to the furnace during the oxygen blow. They

react to form compounds such as calcium silicate or calcium

phosphate which form a slag on top of the iron.

Types of iron and steel

Cast iron has already been mentioned above. This section deals

with the types of iron and steel which are produced as a result of

the steel-making process.

Wrought iron

If all the carbon is removed from the iron to give high purity iron, it

is known as wrought iron. Wrought iron is quite soft and easily

worked and has little structural strength. It was once used to make

decorative gates and railings, but these days mild steel is normally

used instead.

Mild steel

Mild steel is iron containing up to about 0.25% of carbon. The

presence of the carbon makes the steel stronger and harder than

pure iron. The higher the percentage of carbon, the harder the steel

becomes.

Mild steel is used for lots of things - nails, wire, car bodies, ship

building, girders and bridges amongst others.

High carbon steel

High carbon steel contains up to about 1.5% of carbon. The

presence of the extra carbon makes it very hard, but it also makes

it more brittle. High carbon steel is used for cutting tools and

masonry nails (nails designed to be driven into concrete blocks or

brickwork without bending). You have to be careful with high

carbon steel because it tends to fracture rather than bend if you

mistreat it.

Special steels

These are iron alloyed with other metals. For example:

iron mixed special

uses include

with properties

cutlery, cooking

utensils, kitchen

stainless chromium resists sinks, industrial

steel and nickel corrosion equipment for

food and drink

processing

withstands

titanium gas turbines,

titanium high

steel spacecraft

temperatures

rock-breaking

machinery, some

manganese

manganese very hard railway track (e.g.

steel

points), military

helmets

Some environmental considerations

This section is designed to give you a brief idea of the sort of

environmental issues involved with the extraction of iron and its

conversion to steel. I wouldn't claim that it covers everything!

Note: This is deliberately brief because a lot of it is just common sense,

and you will probably already have met it in detail in earlier chemistry

courses, in geography, in general studies, or wherever.

If you aren't sure about the various environmental problems like acid rain,

global warming and the like, the very best site to find out about them is the

US Environmental Protection Agency.

Environmental problems in mining and transporting the raw

materials

Think about:

• Loss of landscape due to mining, processing and

transporting the iron ore, coke and limestone.

• Noise and air pollution (greenhouse effect, acid rain)

involved in these operations.

Extracting iron from the ore

Think about:

• Loss of landscape due to the size of the chemical plant

needed.

• Noise.

• Atmospheric pollution from the various stages of extraction.

For example: carbon dioxide (greenhouse effect); carbon

monoxide (poisonous); sulphur dioxide from the sulphur

content of the ores (poisonous, acid rain).

• Disposal of slag, some of which is just dumped.

• Transport of the finished iron.

Recycling

Think about:

• Saving of raw materials and energy by not having to first

extract the iron from the ore.

• Avoiding the pollution problems in the extraction of iron from

the ore.

• Not having to find space to dump the unwanted iron if it

wasn't recycled.

• (Offsetting these to a minor extent) Energy and pollution

costs in collecting and transporting the recycled iron to the

steel works.

Where would you like to go now?

To the Metal Extraction menu . . .

To the Inorganic Chemistry menu . . .

To Main Menu . . .

© Jim Clark 2005

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Avengers (2012 Film)Document4 pagesThe Avengers (2012 Film)Matthew SusetioNo ratings yet

- Trends, Networks, and Critical Thinking in The 21st CenturyDocument22 pagesTrends, Networks, and Critical Thinking in The 21st CenturyGabrelle Ogayon100% (1)

- In The United States Bankruptcy Court For The District of Delaware in Re:) ) Mervyn'S Holdings, LLC, Et Al.) Case No. 08-11586 (KG) ) ) Debtors.) Affidavit of ServiceDocument19 pagesIn The United States Bankruptcy Court For The District of Delaware in Re:) ) Mervyn'S Holdings, LLC, Et Al.) Case No. 08-11586 (KG) ) ) Debtors.) Affidavit of ServiceChapter 11 DocketsNo ratings yet

- 6-Modul - PTI412 - IoT-1-2020Document17 pages6-Modul - PTI412 - IoT-1-202020200801015 Joko SulistyoNo ratings yet

- Bach Invention No9 in F Minor - pdf845725625Document2 pagesBach Invention No9 in F Minor - pdf845725625ArocatrumpetNo ratings yet

- SuccessDocument146 pagesSuccessscribdNo ratings yet

- Assessment of Hygiene Status and Environmental Conditions Among Street Food Vendors in South-Delhi, IndiaDocument6 pagesAssessment of Hygiene Status and Environmental Conditions Among Street Food Vendors in South-Delhi, IndiaAdvanced Research Publications100% (1)

- The Sweetheart Doctrine and Its InapplicabilityDocument4 pagesThe Sweetheart Doctrine and Its InapplicabilityJosiah BalgosNo ratings yet

- Design and Construction of Food PremisesDocument62 pagesDesign and Construction of Food PremisesAkhila MpNo ratings yet

- Keppel's lease rights and option to purchase land upheldDocument6 pagesKeppel's lease rights and option to purchase land upheldkdcandariNo ratings yet

- Chapter 3 - The Role of Multimedia in EducationDocument37 pagesChapter 3 - The Role of Multimedia in EducationGellie Ann Silvestre RapinNo ratings yet

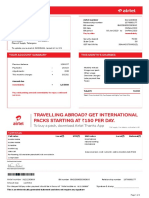

- Mobile Services Tax Invoice for Dr Reddys LaboratoriesDocument3 pagesMobile Services Tax Invoice for Dr Reddys LaboratoriesK Sree RamNo ratings yet

- Ecological Modernization Theory: Taking Stock, Moving ForwardDocument19 pagesEcological Modernization Theory: Taking Stock, Moving ForwardFritzner PIERRENo ratings yet

- Model Test Paper Maths CBSE Class IX - IIIDocument8 pagesModel Test Paper Maths CBSE Class IX - IIIAnanthakrishnan Tinneveli VNo ratings yet

- Public Policy For Nigerian EnviromentDocument11 pagesPublic Policy For Nigerian EnviromentAbishai Auta GaiyaNo ratings yet

- AIESEC - Exchange Participant (EP) GuidebookDocument24 pagesAIESEC - Exchange Participant (EP) GuidebookAnonymous aoQ8gc1No ratings yet

- Scholarship For Yemeni StudentsDocument45 pagesScholarship For Yemeni Studentshilal_lashuel80% (10)

- Final Portfolio Cover LetterDocument2 pagesFinal Portfolio Cover Letterapi-321017157No ratings yet

- MAT 1100 Mathematical Literacy For College StudentsDocument4 pagesMAT 1100 Mathematical Literacy For College StudentsCornerstoneFYENo ratings yet

- Eng 188 Change in Ap, Ae, and ErrorsDocument5 pagesEng 188 Change in Ap, Ae, and Errorsmkrisnaharq99No ratings yet

- Mini Lecture and Activity Sheets in English For Academic and Professional Purposes Quarter 4, Week 5Document11 pagesMini Lecture and Activity Sheets in English For Academic and Professional Purposes Quarter 4, Week 5EllaNo ratings yet

- Sarina Dimaggio Teaching Resume 5Document1 pageSarina Dimaggio Teaching Resume 5api-660205517No ratings yet

- January 2008 Ecobon Newsletter Hilton Head Island Audubon SocietyDocument6 pagesJanuary 2008 Ecobon Newsletter Hilton Head Island Audubon SocietyHilton Head Island Audubon SocietyNo ratings yet

- 5 Whys Analysis SheetDocument3 pages5 Whys Analysis SheetAjay KrishnanNo ratings yet

- इंटरनेट मानक का उपयोगDocument16 pagesइंटरनेट मानक का उपयोगUdit Kumar SarkarNo ratings yet

- I CEV20052 Structureofthe Food Service IndustryDocument98 pagesI CEV20052 Structureofthe Food Service IndustryJowee TigasNo ratings yet

- Connotative Vs Denotative Lesson Plan PDFDocument5 pagesConnotative Vs Denotative Lesson Plan PDFangiela goc-ongNo ratings yet

- Class 7 Summer Vacation PDFDocument4 pagesClass 7 Summer Vacation PDFPrince RajNo ratings yet

- Introduction To ResearchDocument5 pagesIntroduction To Researchapi-385504653No ratings yet

- Midterm Exam ADM3350 Summer 2022 PDFDocument7 pagesMidterm Exam ADM3350 Summer 2022 PDFHan ZhongNo ratings yet