Professional Documents

Culture Documents

Design of Tension Members

Uploaded by

Thebe SetshediOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Tension Members

Uploaded by

Thebe SetshediCopyright:

Available Formats

CAN/CSA-S16-01 S.F.

Stiemer

Design of Tension Members

ties ties

Summary

applications as principal structural members in trusses, bridges, transmission

towers, bracing systems

applications as secondary members such as sag rods, bracing of OWSJs bracing system

most efficient because limit of usefulness not reduced by stability problems

roof truss

single shape most economical in applications, when doubling up use tie

advantages of symmetry

limiting slenderness ratio exists because of potential of vibrations hanger

design member in two steps: ties

select tentative cross section using approximate formulae

check design according to code requirements

failure modes: buildings

1. excessive elongation (Fy governs)

2. rupture in net area (Fu governs) ties

3. rupture in effective net area (considers shear lag effects)

use “s2/4g - rule” for staggered bolt patterns

composite members need to be evaluated for minimum ratio of gyration of

individual elements, stitch fasteners may help bridge truss

bolt hole size:

punched bolt hole diameter need to be increase by 2 mm for

analysis purposes, because of material damage at the hole edge by main cables

punching process

deck hangers

hole should be 2 mm lager than bolt shafts

therefore take bolt diameter + 4 mm for analysis purposes of net

sections

Welded connections of tensile member require an investigation of the size,

length and orientation of the individual weldlines cable stay bridge suspension bridge

pin-ended tension members = eye-bars need to be treated differently

tension rods are not covered by this section, use specifications and fasteners

according to fabricator’s catalog Figure T-1: Use of Tension Members in Structures

design_of_tension_members.docx 1/2/2010 page 1 of 13

CAN/CSA-S16-01 S.F.Stiemer

General Load Deflection Behaviour

Tension members can be found in most steel structures where they are used as

principal structural members in trusses, bridges, transmission towers, bracing

systems in single and multistory buildings. Other applications are secondary

members in roof and wall systems e.g. sag rods for purlins or girts.

The tension member is the most efficient structural member as it can be stressed

up to and beyond the yield limit in most cases without being susceptible to

stability problems or other limiting states. It may consist of a single structural

shape or be built up from several shapes. The use of a single member is usually

preferred because of economical reasons. Built-up members are used when a

single member would not be sufficient or when the slenderness ratio is too high

and resulting in excessive vibrations or when a built-up member would reduce the

complexity of

the connection.

Figure T-2: rolled shapes

typical Cross

Sections of

Tension

Members

composite shapes

welded shapes

rods, bars

cables

design_of_tension_members.docx 1/2/2010 page 2 of 13

CAN/CSA-S16-01 S.F.Stiemer

General Design Steps (ref. Clause 13.2)

design member in two steps:

select tentative cross section using approximate formulae and check

slenderness ratio limit

o Tr = Φ Ag Fy

check design according to code requirements (least of the following):

o Tr = Φ Ag Fy or

o Tr = 0.85Φ An Fu or

o Tr = 0.85Φ Ane Fu

failure modes:

excessive elongation (Fy governs)

rupture in net area (Fu governs)

rupture in effective net area (considers shear lag effects)

Effective Net Area, Ane (ref. Clause 12.3.3)

use “s2/4g - rule” for staggered bolt patterns

applicable when critical net area includes the net area of unconnected elements

2

bn = b - ∑D + ∑s /(4g)

For bolted connections:

where Ane = 0.60 to 0.90 An (refer to S16.1)

d = bolt diameter

D = d + 2mm for drilled holes For welded connections:

D = d + 4mm for punched holes Ane = An1 + An2 + An3

Note: if shear block failure is involved, reduce shear path by a factor of 0.6

where

An1 for elements connected by transverse welds

An2 for elements connected by longitudinal welds along two

parallel edges

An3 for elements connected by a single longitudinal weld

Slenderness Ratio Limit

(ref. Clause 10.4.2.2)

The value of slenderness ratio (KL/r) limit of 300 stems from experience and

parallels values from foreign steel standards (i.e. German, Russian, American).

design_of_tension_members.docx 1/2/2010 page 3 of 13

CAN/CSA-S16-01 S.F.Stiemer

Design Selection

Now the designer can select an appropriate trial cross section following the

guidance given by the tentative cross section; or one can find the shape

designation by the required mass per length and the required radius of gyration.

Required Mass for Tension Member

Inputs: Outputs:

Fu 480 MPa reqMass 0.037 kg/mm

Fy 350 MPa

Tf 1500 kN density of steel

gSteel 7.85e-6 kg/mm^3 7.85e-6 kg/mm^3 factored tensile load

phi 0.9 1500 kN

required gross area, failure mode: elongation

Tf performance factor

An1 =

phi * Fy phi = 0.9

required mass / length 4762 mm^2

reqMass = gSteel * MAX( An1, An2 ) yield strength

0.037 kg/mm 350 MPa

factored tensile load

Tf = 1500 * kN

required net area, failure mode: fracture in net area

Tf performance factor

An2 =

0.85 * phi * Fu phi = 0.9

4085 mm^2

ultimate strength

480 MPa

design_of_tension_members.docx 1/2/2010 page 4 of 13

CAN/CSA-S16-01 S.F.Stiemer

Slenderness Ratio

Once a particular shape has been chosen, one should perform all checks of code

compliance. Before going through the somewhat lengthy process of checking for

connection and cross sectional resistance, it is advisable to examine the

slenderness of the member first. The standard provides the reasoning for this

check.

The value of slenderness limit of 300 stems from experience and parallels values

from foreign steel standards (i.e. German, Russian, American).

If one has to deal Design Check of Slenderness Ratio

with non-(point)-

symmetrical Inputs:

members, the effective length factor

Kx 1

highest slenderness Kx = 1.0

Ky 1 slenderness about x-axis

ratio corresponds to Kz 1 Kx * Lx unbraced member length

slx =

the smallest radius Lx 1500 mm rx Lx = 1.5 * m

of gyration. Thus we Ly 1500 mm 75

Lz 750 mm radius of gyration about x-axis

have to evaluate the

rx 20 mm rx = 20 * mm

three principal radii ry 25 mm

for a double angle rz 50 mm effective length factor

arrangement. Ky = 1.0

slenderness about y-axis

Ky * Ly unbraced member length

sly =

ry Ly = 1.5 * m

checked slenderness ratio 60

radius of gyration about y-axis

checked_sl = IF( MAX( slx, sly, slz )max_slr, "all o.k.", "too slender")

ry = 25 * mm

all o.k.

effective length factor

Kz = 1.0

slenderness about z-axis

Kz * Lz unbraced member length

slz =

rz Lz = .75 * m

15

radius of gyration about z-axis

rz = 50 * mm

maximum slenderness ratio, $10.2.2

max_slr = 300

design_of_tension_members.docx 1/2/2010 page 5 of 13

CAN/CSA-S16-01 S.F.Stiemer

Failure Modes Inputs: Outputs:

Although the design of a tension member is Ag 10000 mm^2 Tr 715 kN

considered to be one of the simplest and Ane 2078 mm^2

most straightforward problems in structural Fu 450 MPa

engineering, we still have to deal with a few Fy 300 MPa performance factor

peculiarities. Ln 484 mm phi = 0.9

Before considering the failure modes one Load_Transfer_Type 1 yielding in gross cross section

gross cross section

must understand the basic assumption of the c_Type 1 Tri = phi * Ag * Fy

10000 mm^2

2700 kN

standard for the load carrying mechanism. dh 24 mm

yield strength

When one designs a tension member e 30 mm

300 MPa

without perforations, one can assume a g1 80 mm

uniform stress distribution over the full g2 80 mm performance factor

s1 80 mm

cross section. For members with holes, as tensile resistance

phi = 0.9

t 6 mm

required by bolted connections, one can Tr = MIN( Tri, Trii, Triii ) rupture in net cross section net cross section

twelds True

experience stress concentrations in the 715 kN Trii = 0.85 * phi * Ane * Fu Ane = Ana + Anb + Anc

w 50 mm

vicinity of the hole of up to three times the 715.5 kN 2078 mm^2

wL 100 mm

average stress. The standard assumes a ultimate strength

x 0 mm

deformation of those overstressed fibres 450 MPa

beyond yield until the average stress is

evenly distributed over the complete cross shear lag effects considered

Triii = 0.85 * phi * A'ne * Fu

section at a magnitude of the yield stress Fy. 3443 kN

Stability is only of secondary concern and vibrational problems have been dealt

with above by taking care by the comparative value of slenderness ratio.

Basically one must provide sufficient cross-sectional area to resist the applied

loads with an adequate margin of safety. However, we must accommodate three

different types of failure (limit states) as shown in the following:

Excessive Elongation

Rupture in Net Area

Rupture in Effective Net Area

design_of_tension_members.docx 1/2/2010 page 6 of 13

CAN/CSA-S16-01 S.F.Stiemer

The “specified hole diameter” is 2 mm greater than the bolt diameter. This is the

Bolted Connections of Tension Members, Effective Net Area diameter to be specified on the shop drawings.

The bolt holes are punched into the steel members. During the punching process

In bolted connections, the net area Ane considered is equal to the anticipated

the edge of the hole is slightly deformed or damaged and cannot be expected to

fracture path. If the path is extending diagonally from a bolt hole of one gauge

carry the same load as the unaffected metal. From experience the standard allows

line to a hole of another gauge line, you could gain by having a longer path. On

for this local damage due to fabrication. Therefore, one must add a total of 4 mm

the downside, more holes are intercepted. Furthermore, an inclined path has less

to the bolt diameter to arrive at the “nominal hole diameter”, which is the value to

resistance to tensile failure than one which is transverse to the loading direction.

be used for the analysis.

A few researchers have dealt with this problem and the “s2/4g - rule” has evolved.

nominal hole diameter = spec. dia+4 [mm]

For a detailed treatment of fasteners and

their behaviour please see the appropriate

sections on bolted connections. The

previous considerations are based on

g1 connections, where the individual bolts

P P carry equal loads and are arranged

d symmetrically with respect to the

h g2 centroidal axial of the tension member and

thus, axis of load application.

Furthermore one needs to consider shear

lag effects, which can lead to a further

decrease of effective net area. However, it

is recommended to check if it is better to

replace requirements of this clause by

e s2 s1 another engineering approach: One can

Although it is not applicable for the full range of parameter variations of pitch, s, leave out the unconnected elements and consider the resistance of the connected

and gauge, g, it is quite accurate within the limits as stated by the standard. elements only, which can result in more efficient designs without reduction in the

The effective area is computed by adding all critical areas of all segments. safety margin.

Hereby one has to check all possible fracture paths in order to find the lowest

resistance.

In order to conveniently place the bolts for a connection in a structural member it

is necessary to have holes slightly bigger than the bolt diameter. The greater the

holes are, the easier is the erection of a building. However, in order to achieve a

behaviour of the connection, which can be predicted and modeled by simple

mathematical expressions one has to keep the bolt to hole tolerance in a certain

limit.

design_of_tension_members.docx 1/2/2010 page 7 of 13

CAN/CSA-S16-01 S.F.Stiemer

The effective net area must be calculated as follows:

gauge 2

80 mm

net width

wn2 = g2 - dh

nominal hole diameter

Ana = wn2 * t 24 mm

336 mm^2

plate thickness

end distance

6 mm

30 mm

net length

dh nominal hole diameter

Ln = 2 * e- + 8 * s1 - 8 * dh 24 mm

Anb = 0.6 * Ln * t 2

1742 mm^2 pitch 1

plate thickness

net cross section 6 mm

80 mm

gauge 1

Ane = Ana + Anb + Anc g1 = 80mm

2078 mm^2 wn1 = g1 - dh

56 mm

nominal hole diameter

24 mm

2

s1 * t plate thickness

Ans = wn1 * t + 6 mm

4 * g1

456 mm^2

pitch 1

80 mm

2

Anc = Ans, 0 * mm : pattern

0 mm^2 gauge 1

g1 = 80mm

stagger=1, parallel=2

pattern = 2

Bolted Connection at Ends of Tension Member

design_of_tension_members.docx 1/2/2010 page 8 of 13

CAN/CSA-S16-01 S.F.Stiemer

performance factor no connection considered

gross cross section

phi = 0.9 A0 = Ag

10000 mm^2

10000 mm^2

bolted WWF, W, M, or S-shapes

A1 = 0.9 * Ane

1871 mm^2

shear lag effects considered bolted angles, one leg, four lines and more

Triii = 0.85 * phi * A'ne * Fu A2 = 0.8 * Ane

3443 kN 1663 mm^2

bolted angles, one leg, less than four lines

A3 = 0.6 * Ane

reduced effective net area 1247 mm^2

A'ne = [ A0, A1, A2, A3, A4, A5, Aw ] : c_Type

10000 mm^2 bolted other shapes, three lines and more

A4 = 0.85 * Ane

ultimate strength 1767 mm^2

450 MPa

bolted other shapes, less than three lines

A5 = 0.75 * Ane

1559 mm^2

welded connection

Aw = Ane1 + Ane2 + Ane3

900 mm^2

selected member and connection case

c_Type = 1

Shear Lag Effect Consideration

due to Bolted Connection

design_of_tension_members.docx 1/2/2010 page 9 of 13

CAN/CSA-S16-01 S.F.Stiemer

Welded Connection of Tension Members

Welded connections of tensile member require an investigation of the size, length

and orientation of the individual weldlines. Any set (transverse, parallel and

longitudinal) weldlines will be considered as follows:

transverse welds plate width

twelds = TRUE when wL>= 2*w 50 mm

transverse welds Ane2i = w * t

plate width 300 mm^2 plate thickness

Ane1 = IF( twelds, w * t, 0 )

50 mm 6 mm

300 mm^2

plate thickness plate width

6 mm when 2*w > wL >= 1.5*w 50 mm

Ane2ii = 0.87 * w * t

two parallel longitudinal welds 261 mm^2 plate thickness

welded connection Ane2 = [ Ane2i, Ane2ii, Ane3iii ] : Load_Transfer_Type 6 mm

Aw = Ane1 + Ane2 + Ane3 300 mm^2

900 mm^2 plate width

weld eccentricity when 1.5*w > wL >= w 50 mm

x = 0 * mm Ane3iii = 0.75 * w * t

225 mm^2 plate thickness

one longitudinal weld weld length 6 mm

x 100 mm

Ane3 = 1 - *w*t method of load transfer (i=1, ii=2, iii=3)

wL plate width Load_Transfer_Type = 1

300 mm^2 50 mm

plate thickness

6 mm

design_of_tension_members.docx 1/2/2010 page 10 of 13

CAN/CSA-S16-01 S.F.Stiemer

Pin-Connected Tension Members

In pin-connected tension members, the non-uniform distribution of stress makes

it desirable that the net area across the pin hole be at least one third greater than

the area of the body of the member. In order to avoid end splitting, the area

beyond the pin hole within a 45 degree arc each side of longitudinal axis of the

member must be at least 90% of the area of the body of the member. Sag rods Roof truss

Purlins

Purlin

Purlin

Tension Rods

Ridge

Previous considerations are not applicable to tension rods, which are

quite common members in buildings, but usually used as secondary Roof

Sag rod Sag rod

members. The design stress is often rather small i.e. in sag rods for truss

purlins or wall girts. Special care must be taken in case the tension

rods are used as primary hangers for balconies or ties of structural Elevation view Top view

arches. The tie rods are connected by nuts on their threaded ends.

When prestress is applied to the rods, the vibration can be reduced to (a) Roof truss

manageable amounts and requirements of slenderness ratios need not

be complied with.

A Tie Girts

Girt rods

Tie

rods Tie rod

Balcony

Col. Girt

Col.

A

Section A-A

(b) Wall system (c)

Figure T-3: Use of Tension Rods in Buildings

design_of_tension_members.docx 1/2/2010 page 11 of 13

CAN/CSA-S16-01 S.F.Stiemer

Examples of tension members in Structures

design_of_tension_members.docx 1/2/2010 page 12 of 13

CAN/CSA-S16-01 S.F.Stiemer

Gimme Five

Tension members fail in:

strength mode [_]

stability mode [_]

serviceability mode [_]

A tentative cross section is useful to:

determine the tensile capacity [_]

check a suitable shape [_]

select a suitable shape [_]

Shear lag effects:

improve the member resistance [_]

reduce the member resistance [_]

have no influence on the member resistance [_]

In order to check a connection capacity, one needs to consider:

the fracture image [_]

the fracture path [_]

the edge distance of the load [_]

The eccentricity of resultant force of the tension member is determined by:

the distance of shape edge from bolt [_]

the distance of centroid of bolt group from centre of member [_]

the distance of centroid of bolt group from centroid of cross section [_]

design_of_tension_members.docx 1/2/2010 page 13 of 13

You might also like

- Tension Member Design and TypesDocument6 pagesTension Member Design and TypesbaizubirajiNo ratings yet

- Design of Steel Structure - Steel Design Tension MembersDocument24 pagesDesign of Steel Structure - Steel Design Tension MembersshingkeongNo ratings yet

- Design of Tension Member LRFDDocument57 pagesDesign of Tension Member LRFDJerome Angelo B. Baybay100% (1)

- Tension MembersDocument35 pagesTension MembersVictor Carhuayo Paredes100% (1)

- ABB Seismic Report on Dry Vacuum TransformerDocument35 pagesABB Seismic Report on Dry Vacuum TransformerchandranmuthuswamyNo ratings yet

- Sliding Hinge Joint PDFDocument11 pagesSliding Hinge Joint PDFjcvalenciaNo ratings yet

- Design of Steel Bolted ConnectionsDocument34 pagesDesign of Steel Bolted ConnectionsManjunath Tontanal0% (1)

- Tension MembersDocument16 pagesTension MembersArnab DuttaNo ratings yet

- 02 - Design of Steel Tension MembersDocument15 pages02 - Design of Steel Tension MembersMagdy BakryNo ratings yet

- KKKH3353 - Structural Steel Design - Tension MembersDocument21 pagesKKKH3353 - Structural Steel Design - Tension MembersZeyad Tareq Al Sarori100% (2)

- Cables and ArchesDocument22 pagesCables and ArchesFouad KehilaNo ratings yet

- TowerDocument40 pagesTowerAthulvasnikNo ratings yet

- Design of Tension MembersDocument10 pagesDesign of Tension MembersSandgrouse RajNo ratings yet

- Worksheet 1 Tension Members: S S? S SDocument2 pagesWorksheet 1 Tension Members: S S? S SHaftom Gebreegziabiher100% (1)

- Chapter 7 BoltDocument38 pagesChapter 7 BoltRamesh P KoiralaNo ratings yet

- Mechanical Properties and Deformation Mechanisms in MetalsDocument31 pagesMechanical Properties and Deformation Mechanisms in Metalspoom2007No ratings yet

- Compression Members - Local Buckling and Section Classification PDFDocument15 pagesCompression Members - Local Buckling and Section Classification PDFAnonymous lswzqloNo ratings yet

- Bolted ConnectionDocument56 pagesBolted ConnectionScracher Sahil ChauhanNo ratings yet

- Design - of - Steel - Structure-I PDFDocument54 pagesDesign - of - Steel - Structure-I PDFNi Mesh100% (1)

- Design and Analysis of Tension MemberDocument29 pagesDesign and Analysis of Tension MemberJhianne Dulpina RoqueNo ratings yet

- Design and Analysis of Steel BeamsDocument35 pagesDesign and Analysis of Steel BeamsLhee Ann Garbo100% (1)

- Design of Steel Structures IIDocument9 pagesDesign of Steel Structures IIIvan Jansen Saragih100% (2)

- 2006 Beam Column Joint ICJDocument9 pages2006 Beam Column Joint ICJvishalgoreNo ratings yet

- Chapter-5 Design of Steel BeamDocument36 pagesChapter-5 Design of Steel Beamzakai zakiNo ratings yet

- Ly and LZ Concept DiscussedDocument2 pagesLy and LZ Concept DiscussedalayshahNo ratings yet

- Unit-I Thin Plate Theory, Structural InstabilityDocument78 pagesUnit-I Thin Plate Theory, Structural InstabilityNirav LakhaniNo ratings yet

- Limit state deflection and cracking in reinforced concrete structuresDocument17 pagesLimit state deflection and cracking in reinforced concrete structuresRadhikaNo ratings yet

- Web Yielding Is The Compressive Crushing of A Bam Web Caused by A Force Acting On The Flange Directly AboveDocument3 pagesWeb Yielding Is The Compressive Crushing of A Bam Web Caused by A Force Acting On The Flange Directly AboveJohn Saniel J. EstacionNo ratings yet

- Tension MemberDocument58 pagesTension MemberD SRINIVASNo ratings yet

- Flat Slab DesignDocument2 pagesFlat Slab DesignKim ChanthanNo ratings yet

- 6.design of Connections in Steel Building ConstructionDocument50 pages6.design of Connections in Steel Building ConstructionNovember RainNo ratings yet

- Design of Columns and Struts in Structural SteelDocument20 pagesDesign of Columns and Struts in Structural SteelMaqsood83% (18)

- Biaxial Bending and Torsion of Steel Equal Angle Section BeamsDocument29 pagesBiaxial Bending and Torsion of Steel Equal Angle Section Beamsp_meulendijks108No ratings yet

- AISC LRFD Column DesignDocument4 pagesAISC LRFD Column Designwinlugue3059No ratings yet

- Class Lectures 4 - Flexural MembersDocument18 pagesClass Lectures 4 - Flexural MembersvrsafeNo ratings yet

- 3.1 Bolted Joint DesignDocument15 pages3.1 Bolted Joint Designssn MLNo ratings yet

- 3 - Compression Member PDFDocument43 pages3 - Compression Member PDFYetty Oktavianita100% (2)

- Elastic Stresses in Composite SectionsDocument39 pagesElastic Stresses in Composite Sectionsjshgfukwekkfu100% (1)

- Steel Cap Plate Connections DesignDocument18 pagesSteel Cap Plate Connections DesignVinoth KumarNo ratings yet

- Design Slip-Critical Steel ConnectionDocument9 pagesDesign Slip-Critical Steel ConnectionKURONo ratings yet

- Long Term Losses in Pre-Stressed Concrete Member As Per IS 1343:2012 and IS 1343:1980Document16 pagesLong Term Losses in Pre-Stressed Concrete Member As Per IS 1343:2012 and IS 1343:1980HemanthNo ratings yet

- Biaxial Bending of Steel Angle Section PDFDocument3 pagesBiaxial Bending of Steel Angle Section PDFImam NakhrowiNo ratings yet

- 1 Review - Seismic and Wind AnalysisDocument28 pages1 Review - Seismic and Wind Analysissaleem100% (1)

- Base Plate Design PDFDocument21 pagesBase Plate Design PDFdiajengangelNo ratings yet

- Chapter - 6. Bending Stress in BeamDocument0 pagesChapter - 6. Bending Stress in BeamAjay KumarNo ratings yet

- Tension MembersDocument11 pagesTension MembersJe EspenidaNo ratings yet

- Specific StepsDocument26 pagesSpecific StepsAbdul Hamid BhattiNo ratings yet

- Mechanical Columns Buckling FailureDocument19 pagesMechanical Columns Buckling FailurePraful Patil100% (1)

- Example Problems For Tension Members SteelDocument5 pagesExample Problems For Tension Members SteelTesfa HunderaNo ratings yet

- Steel Connection DesignDocument4 pagesSteel Connection Designpaul machariaNo ratings yet

- E26.To2 Steel PDFDocument10 pagesE26.To2 Steel PDFAmolsingh100No ratings yet

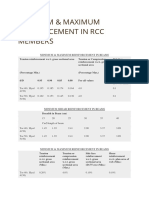

- Minimum & Maximum SteelDocument3 pagesMinimum & Maximum SteelSathishNo ratings yet

- DOS Web Cleat ConnectionDocument31 pagesDOS Web Cleat ConnectionArfat PatelNo ratings yet

- Bolted ConnectionsDocument3 pagesBolted ConnectionsandreiroscaNo ratings yet

- Aspects of Connection in Steel FramesDocument50 pagesAspects of Connection in Steel FramesChai Weng100% (2)

- Composite Deck Technical Manual: 3WH-36 Hi FormDocument33 pagesComposite Deck Technical Manual: 3WH-36 Hi FormVinod Kumar ReddyNo ratings yet

- Lecture10 PDFDocument8 pagesLecture10 PDFnihithNo ratings yet

- 2 Tension MembersDocument13 pages2 Tension MembersAbel MulugetaNo ratings yet

- Chapter 2 - Tension MembersDocument13 pagesChapter 2 - Tension MembersSami IGNo ratings yet

- Guidance Note Shear Connectors No. 2.11: ScopeDocument4 pagesGuidance Note Shear Connectors No. 2.11: ScopeDesigns3 ShreeprefabNo ratings yet

- Being Assertive PDFDocument35 pagesBeing Assertive PDFGaurav Inder Singh RahejaNo ratings yet

- 11 Communication SkillsDocument42 pages11 Communication SkillsPratyush Tripathi100% (2)

- The Young Entrepreneurs: A Report by Gerard DarbyDocument51 pagesThe Young Entrepreneurs: A Report by Gerard DarbyThebe SetshediNo ratings yet

- Guide DisplayDocument3 pagesGuide DisplayThebe SetshediNo ratings yet

- Experimental Study On Condition Monitoring of Low Speed Bearings: Time Domain AnalysisDocument6 pagesExperimental Study On Condition Monitoring of Low Speed Bearings: Time Domain AnalysisThebe SetshediNo ratings yet

- Why Invest?: Tools To Make Compound Interest WorkDocument3 pagesWhy Invest?: Tools To Make Compound Interest WorkThebe SetshediNo ratings yet

- Code10 Vol2Document45 pagesCode10 Vol2Thebe Setshedi67% (3)

- Slip Angle Adjustment 11Document13 pagesSlip Angle Adjustment 11Thebe SetshediNo ratings yet

- Solucionario de Diseño en Ingenieria Mecanica Capitulo 1Document5 pagesSolucionario de Diseño en Ingenieria Mecanica Capitulo 1arrchilNo ratings yet

- HP 49g+ User's Guide EnglishDocument865 pagesHP 49g+ User's Guide EnglishThebe SetshediNo ratings yet

- Strain Gage-WhatDocument16 pagesStrain Gage-WhatAshok JoshiNo ratings yet

- Motorized ShutterDocument38 pagesMotorized ShutterTanvi KhuranaNo ratings yet

- Electrovalvula Atos Dhi 610 23Document4 pagesElectrovalvula Atos Dhi 610 23daniloaderNo ratings yet

- Steel ConstructionDocument70 pagesSteel ConstructionTony PedaNo ratings yet

- Guide to Selecting the Right Lubricant for Ball ScrewsDocument10 pagesGuide to Selecting the Right Lubricant for Ball ScrewsDat RomanNo ratings yet

- NL18x ManualDocument229 pagesNL18x Manualrazali1982No ratings yet

- Crastin PBT - Rynite Pet PDFDocument38 pagesCrastin PBT - Rynite Pet PDFkfaravNo ratings yet

- RE240821Document2 pagesRE240821libin francisNo ratings yet

- W SER 0502 AD Manual Flange Torque TighteningDocument8 pagesW SER 0502 AD Manual Flange Torque TighteningAnonymous IJBjI0No ratings yet

- Lighting System (Ipc 90-92-13-08a)Document5 pagesLighting System (Ipc 90-92-13-08a)jmam1992No ratings yet

- BAM-1020-9800 Manual Rev FDocument81 pagesBAM-1020-9800 Manual Rev F이민우No ratings yet

- '02-'04 Service Manual - AllDocument4,655 pages'02-'04 Service Manual - AllChristopher Anderson100% (1)

- 69NT40 551 500 To 599: Container RefrigerationDocument132 pages69NT40 551 500 To 599: Container Refrigerationsergio.floresNo ratings yet

- Specification of StrainerDocument3 pagesSpecification of StrainermishtinilNo ratings yet

- #Catalog Niedax 2015 enDocument276 pages#Catalog Niedax 2015 enmNiosuNo ratings yet

- Catalago Motor STX 200Document32 pagesCatalago Motor STX 200Moto Peças CruzeiroNo ratings yet

- Arrow 270 400 16 Inch MAXI FanDocument45 pagesArrow 270 400 16 Inch MAXI FanÖnder BüyükişcanNo ratings yet

- Engineering Drawing Textbook Intro by N D BhattDocument11 pagesEngineering Drawing Textbook Intro by N D BhattAizaz Shamshad100% (1)

- BallScrews and BallSplinesDocument160 pagesBallScrews and BallSplinesmattiaNo ratings yet

- VC6877 RRDocument31 pagesVC6877 RRSagar HarwaniNo ratings yet

- Master Data Sign off Document Organizational StructureTITLE Master Data Sign off Document Material Master DataDocument26 pagesMaster Data Sign off Document Organizational StructureTITLE Master Data Sign off Document Material Master DataVeera ManiNo ratings yet

- Pressure Vessel 1Document66 pagesPressure Vessel 1gst ajahNo ratings yet

- Electromagnetic Lock Installation Instruction (Waterproof Series)Document4 pagesElectromagnetic Lock Installation Instruction (Waterproof Series)Victor BitarNo ratings yet

- Sinajet Digital Cutter Manual-EnDocument40 pagesSinajet Digital Cutter Manual-EnMaulana YusufNo ratings yet

- 3415-FSL-003 - Corsusa - Fmm-100-S-Lp-3ee-1cs-32f150-S1-D1Document4 pages3415-FSL-003 - Corsusa - Fmm-100-S-Lp-3ee-1cs-32f150-S1-D1alvarito12100% (1)

- H501L5R Logic 5 Installation ManualDocument45 pagesH501L5R Logic 5 Installation ManualFOYLESKO HDZ.No ratings yet

- Giddings & Lewis Sect06 Rotary TableDocument14 pagesGiddings & Lewis Sect06 Rotary TableAngel AdautaNo ratings yet

- PM-965-041C Bell 204 - 205 - 210 - 212 - 412 WSPS MM and IplDocument30 pagesPM-965-041C Bell 204 - 205 - 210 - 212 - 412 WSPS MM and IplLuis Antonio HermozaNo ratings yet

- Bulletin Technical: CX, BEHR Heating Unit, Level 3 ModificationDocument8 pagesBulletin Technical: CX, BEHR Heating Unit, Level 3 Modificationjjam80No ratings yet

- Reed Thread Roll AttachmentDocument2 pagesReed Thread Roll AttachmentshawntsungNo ratings yet

- Sliding Gate Operator Manual (WJKMB201&202)Document13 pagesSliding Gate Operator Manual (WJKMB201&202)Ricardo FajardoNo ratings yet