Professional Documents

Culture Documents

Cogeneration

Uploaded by

grpalemOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cogeneration

Uploaded by

grpalemCopyright:

Available Formats

Aspen Plus Cogeneration Model

Contents

1 Introduction..............................................................................1

2 Components..............................................................................1

3 Process Description...................................................................1

4 Physical Properties....................................................................3

5 Chemical Reactions....................................................................3

6 Simulation Approaches...............................................................3

7 Simulation Results.....................................................................4

8 Conclusions...............................................................................7

References..................................................................................8

Aspen Plus Example Library i

Proprietary Information of AspenTech

Unauthorized duplication or distribution strictly prohibited without prior written permission

1 Introduction

This model simulates an Integrated Cogeneration process. It includes the following features:

• A set of conventional chemical species for this process.

• Typical process areas including: burning, compression, heat exchange, power generation, and the

main streams connecting these units.

• Property methods and unit operation models used in this process.

2 Components

The table below lists the components modeled in the simulation.

Component

ID Type Component name Formula

H2O CONV WATER H2O

N2 CONV NITROGEN N2

O2 CONV OXYGEN O2

CO CONV CARBON-MONOXIDE CO

CO2 CONV CARBON-DIOXIDE CO2

ARGON CONV ARGON AR

METHANE CONV METHANE CH4

ETHANE CONV ETHANE C2H6

PROPANE CONV PROPANE C3H8

3 Process Description

An outline of the cogeneration process which includes the letdown, Gas Turbine and Steam Generation

sections is shown in Figure 1.

Proprietary Information of AspenTech 1

Unauthorized duplication or distribution prohibited without prior written permission

W

POWER MIX W

POWER 1 POWER OU T

POWER2 M IX ER

WATER 1

WATER 14

POWER 3X

STEAM-A

LETDOWN GASTURB STMGEN

N ATGAS N ATGAS2 H OTGAS1 STEAM-B

HIERA RCH Y H IERA RCHY HIERARCH Y

STEAM-C

RC

AIR H OTGAS9

WATER 24

RC

N OXSTEAM

Figure 1: Cogeneration Overall Process

The feedstock of this cogeneration process is natural gas, which contains Methane (83.62%wt), Ethane

(7.33%wt), Propane (7.25%wt) and Argon (1.8%wt).

Firstly, a turbine is used in the letdown area to utilize the internal energy of the natural gas to generate

electrical power. After expanding, the gas pressure drops from 19.5 bar to 8 bar while generating 0.60MW

of power.

Secondly, mixed with steam (8 bar) and compressed air (1324000kg/hr), the gas is burned completely in

the burner to produce hot gas at 979℃. The hot gas is passed through a gas turbine to produce 103.4 MW

of electrical power. As a result, its temperature drops to 551℃ and its pressure drops from 8 bar to 1.1 bar.

Thirdly, the hot gas is passed to the steam generation area to recover heat. The gas runs through 5 heat

exchangers and is cooled down by water or steam as follows:

• E100 - cooled from 551to 492 ℃

• E101 - cooled from 492 to 320 ℃

• E102 - cooled from 320 to 238 ℃

• E103 - cooled from 238 to 234 ℃

• E104 - cooled from 234 to 175 ℃

Then the outlet stream HOTGAS6 from E104 is split into HOTGAS7A and HOTGAS7B. HOTGAS7A is

cooled to 108 ℃ in E106 and HOTGAS7B is cooled to 131℃ in E105. Afterwards these two streams are

mixed again and are vented out of the process. The BFW (boiler feed water) used in this area includes two

pressure grades, one at 76.5 bar and the other at 6.9 bar. Heated by the hot gas, BFW turns to steam.

Then the steam is let down through a turbine to produce electrical power. Finally, three steam products,

each at different pressure grades, are obtained and 37.6MW of electrical power is generated.

Proprietary Information of AspenTech 2

Unauthorized duplication or distribution prohibited without prior written permission

Process summary

Area Purpose

Let Down Uses the internal energy of the natural gas to generate electrical power

Gas Turbine Burns the natural gas to generate electrical power using a gas turbine

Steam Generation Recovers the heat from the hot gas to generate steam and electrical power using

steam turbines

4 Physical Properties

The PR-BM property method (Peng-Robinson equation of state with Boston-Mathias modifications) is used

for the properties of the natural gas and combustion products. For the steam system in the steam

generation area the STEAMNBS property method is used.

5 Chemical Reactions

The only reactor unit in this process is the burner modeled with RGibbs which uses the Gibbs free energy

minimization method. This determines the equilibrium composition of the products resulting from the many

reactions that can occur.

6 Simulation Approaches

Unit Operations – The major unit operations are represented by Aspen Plus models as shown in the

following table:

Aspen Plus Unit Operation Models Used in the Model

Unit Operation Aspen Plus Model Comments / Specifications

Heat exchanger HeatX Simplified shortcut design calculations.

Flash Flash2 Rigorous simulation of gas-liquid equilibrium.

Compressor/Turbine Compr Calculates electric power required or produced.

Proprietary Information of AspenTech 3

Unauthorized duplication or distribution prohibited without prior written permission

7 Simulation Results

The Aspen Plus simulation flowsheet is shown in Figures 2, 3, and 4.

POWER1 POWER1(OUT)

NATGA S(IN) NATGA S

EXP1

NATGA S2 NATGA S2(OUT)

Figure 2: Flowsheet of Letdown area

BURN1

NATGA S2(IN) NATGA S2 MIX 1

HOTGA S

NOXSTEAM MIX GAS

EXP2

POWER2A

A IR1

A IR2

HOTGA S1

A IRCOMP

WORKMIX

HOTGA S1(OUT)

A CPOWER POWER2 POWER2(OUT)

Figure 3: Flowsheet of Gas Turbine area

Proprietary Information of AspenTech 4

Unauthorized duplication or distribution prohibited without prior written permission

WATER17

HOTGAS9

MIX1

HOTGAS8A HOTGAS8B

WATER1 WATER14

E106 E105

HOTGAS4

HOTGAS7B

Water & Steam

SPLIT1

WATER15

E104

HOTGAS6 V101

Hot Gas STM18

WATER2

Power Generated HOTGAS5

WATER16

E103 P103

STEAM-C(OUT)

STM19

SPL103

STM21 STEAM-B(OUT)

STM23

STM20

STM22 MIX103

V100

WATER3 E102

STM13 V102

STM12

HOTGAS3

WATER4

SPL102 STM11

WATER4A P101 STM10

K102

E101

STM5 WATER24

HOTGAS2

STM8 K101 POWER5

STM9

STM6 STM7

STEAM-A(OUT) POWER3X

E100 POWER4

HOTGAS1(IN) HOTGAS1 K100 POWER3X(OUT)

POWER3

POWMIX

Figure 4: Flowsheet of Steam Generation area

Proprietary Information of AspenTech 5

Unauthorized duplication or distribution prohibited without prior written permission

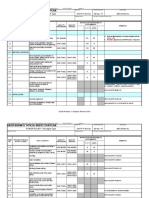

No errors occur in the simulation. Key simulation results are shown in the following table:

Key Stream Simulation Results

Flowsheet Variable Value Unit

NATGAS total 25000 kg/hr

NATGAS-Methane 20905 kg/hr

NATGAS-Ethane 1832.5 kg/hr

NATGAS-Propane 1812.5 kg/hr

NATGAS-Ar 450 kg/hr

Steam for Burner 45000 kg/hr

Boiler feed water (High Pressure) 180800 kg/hr

Boiler feed water (Low Pressure) 42600 kg/hr

Feed Air for Burner 1324000 kg/hr

Steam 9 (24bar) 27120 kg/hr

Steam 21 (5bar) 6390 kg/hr

Steam 23 (1bar) 185659 kg/hr

Product Electrical Power 141689.7 kW

Water 5125 kg/hr

Waste Exhaust Hot Gas 1394000 kg/hr

Key Process Simulation Results

Key Process Variable Value Unit

Temperature of Burner 978 ℃

Pressure of Burner 8 bar

Discharge Pressure of the NATGAS Turbine 8 bar

Discharge Pressure of the HOTGAS Turbine 1.1 bar

Discharge Pressure of High Pressure Steam Turbine 24 bar

Discharge Pressure of Medium Pressure Steam Turbine 5 bar

Discharge Pressure of Low Pressure Steam Turbine 1 bar

Proprietary Information of AspenTech 6

Unauthorized duplication or distribution prohibited without prior written permission

Heat Balance in Steam Generation Area

Heat Balance of Steam Generation Process Value Unit

Inlet Enthalpy of Hotgas(hotgas1) -309485 kW

Outlet Enthalpy of Hotgas(hotgas9) -495631 kW

Heat Energy Supply of Hotgas 186146 kW

Enthalpy of Inlet Water 1 -786876 kW

Enthalpy of Inlet Water 14 -185583 kW

Enthalpy of Outlet Water 24 -18290 kW

Enthalpy of Outlet Steam 9 -96704 kW

Enthalpy of Outlet Steam21 -23231 kW

Enthalpy of Outlet Steam 23 -686151 kW

Heat Energy Absorption of Water in total 148083 kW

Electrical Power Generated in STMGEN Process 38067 kW

Steam and Power Generation per 1 kg of Natural Gas

Product Name Product Quantity

1.085 kg

Steam at 24bar pressure

Steam at 5 bar pressure 0.256 kg

Steam at 1 bar pressure 7.426 kg

Electrical Power 20404.8 kJ

8 Conclusions

The Cogeneration model provides a useful description of the process. The simulation takes advantage of

Aspen Plus’s capabilities for modeling. The model may be used as a guide for understanding the process

and the economics, and also as a starting point for more sophisticated models for plant design and process

equipment specification and purchase.

Proprietary Information of AspenTech 7

Unauthorized duplication or distribution prohibited without prior written permission

References

V. I. Dlugosel’skii, V. E. Belyaev, N. I. Mishustin and V. P. Rybakov,

"Gas-turbine units for cogeneration", Thermal Engineering, 54:1000-1003, 2007.

Ligang Zheng and Edward Furimsky, “ASPEN simulation of cogeneration plants”,

Energy Conversion and Management, 44: 1845-1851, 2003

Proprietary Information of AspenTech 8

Unauthorized duplication or distribution prohibited without prior written permission

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Ies 2003 - IDocument19 pagesIes 2003 - Iharioo7No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- GEK28126-Leak Detection For Fuel Gas PipingDocument4 pagesGEK28126-Leak Detection For Fuel Gas Pipingkarim karimNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Cold Start UpDocument31 pagesCold Start UpJijo JoseNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Osaka Tubular Technical Data SheetDocument5 pagesOsaka Tubular Technical Data SheetAbdul BasitNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- IIT Madras Professors Explain Mercury-Steam Binary Vapor Power CycleDocument3 pagesIIT Madras Professors Explain Mercury-Steam Binary Vapor Power CycleSekhar Babu PendyalaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Heat ExchangerDocument82 pagesHeat ExchangerMahe MahendiranNo ratings yet

- Arthur R. Bergen, Vijay Vittal Power Systems Analysis (OCR)Document628 pagesArthur R. Bergen, Vijay Vittal Power Systems Analysis (OCR)really100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Chapter 1 - CANDU ManualDocument106 pagesChapter 1 - CANDU ManualGeoff Momin100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- AC Solar Pumping System MNE-3PH-SJ8 - Solar Powered Water Pump System, Off Grid Solar Power System, Solar Powered Inverter - MNE Technology Co.,LtdDocument1 pageAC Solar Pumping System MNE-3PH-SJ8 - Solar Powered Water Pump System, Off Grid Solar Power System, Solar Powered Inverter - MNE Technology Co.,LtdSuman Resolved NeupaneNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Presentation 1Document12 pagesPresentation 1cak kaconkNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Student Guide: Exploring Solar EnergyDocument16 pagesStudent Guide: Exploring Solar EnergyirfangelenNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Simulasi Boiler SpreadsheetDocument5 pagesSimulasi Boiler SpreadsheetNHSNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- FT8 - Cold Air Buffer - P&W FT8 - Solar Turbines Technical BLOGDocument7 pagesFT8 - Cold Air Buffer - P&W FT8 - Solar Turbines Technical BLOGLibyanManNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Claude System: A Process For Liquefying Air On A Commercial Basis. Air Under Pressure Is Used As TheDocument2 pagesClaude System: A Process For Liquefying Air On A Commercial Basis. Air Under Pressure Is Used As Thekaushal1977No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Sodium Borohydride Fuel Cell AVRCDocument25 pagesSodium Borohydride Fuel Cell AVRCSriharsha GaniNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Heavy Manufacturing of Power PlantsDocument16 pagesHeavy Manufacturing of Power PlantsCemil GüneşNo ratings yet

- Doosan Posiflow technology improves boiler efficiency and reliabilityDocument12 pagesDoosan Posiflow technology improves boiler efficiency and reliabilityKarthick VelayuthamNo ratings yet

- Planning & Business Development Alternate Energy VendorsDocument26 pagesPlanning & Business Development Alternate Energy VendorsCold ExecuTionNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- IbrDocument4 pagesIbrJayesh100% (1)

- API PLAN "11" / "61" Api Plan "11" API PLAN 11/52: by VendorDocument1 pageAPI PLAN "11" / "61" Api Plan "11" API PLAN 11/52: by VendorTien Tran Kha Tien100% (1)

- Unit 2 RacDocument40 pagesUnit 2 Racozair arshadNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Basics of Power System ProtectionDocument17 pagesBasics of Power System Protectionmuaz_aminu14220% (1)

- Pico-Hydro Power from Residential Water TanksDocument6 pagesPico-Hydro Power from Residential Water Tanksdinesh sharmaNo ratings yet

- Satip F 001 04Document13 pagesSatip F 001 04Rijwan MohammadNo ratings yet

- RHOURDE EL BAGUEL LPG EXTRACTION PLANT FEED PLANNINGDocument2 pagesRHOURDE EL BAGUEL LPG EXTRACTION PLANT FEED PLANNINGZakari LOUNISNo ratings yet

- 919/919B - PTFE Hose: FeaturesDocument1 page919/919B - PTFE Hose: Featureshoussem houssemNo ratings yet

- CT Design ParametersDocument6 pagesCT Design ParametersMike Rowen BanaresNo ratings yet

- (Question) Module Praktikum GTE - Performance (20141209)Document3 pages(Question) Module Praktikum GTE - Performance (20141209)DieniarNurRamadhaniNo ratings yet

- Chilled Water Pumps Calculation for Irbed City CenterDocument3 pagesChilled Water Pumps Calculation for Irbed City CenterMohamed Elarabi100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- MFI Control System-01Document1 pageMFI Control System-01AUTOMOTRIZ TIPO SPCANo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)