Professional Documents

Culture Documents

Est TK Emiss

Uploaded by

AZDOLMANOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Est TK Emiss

Uploaded by

AZDOLMANCopyright:

Available Formats

Environmental Protection < Discuss This Article!

>

To join an online discussion about this article

with the author and other readers, go to the

Estimate Storage ProcessCity Discussion Room for CEP articles

at www.processcity.com/cep.

Tank Emissions Use this shortcut to quickly

Jimmy Peress,

Tritech Consulting

determine emissions from

Engineers fixed-roof storage tanks.

F

ixed-roof storage tanks containing organic liquids increases and air will be expelled from the tank. As the tem-

are widely used in all industries that produce or con- perature falls during the night, pressure in the tank decreases

sume organic liquids. Emissions from fixed-roof and fresh air flows into the tank.

storage tanks consist of working losses and breath- The simplified method for calculating the breathing losses

ing losses (often referred to as standing losses). is an adaptation of an EPA method published in Ref. 1.

Engineers often need to estimate emissions from the stor- Consider a tank with a volume of VT and a liquid level LT.

age tanks to prepare air permits or develop emission esti- The vapor space of the tank is:

mates. The EPA has published a detailed method for calculat-

ing losses from storage tanks (1). However, it is quite tedious Vv = VT(100 – LT)/100 (2)

and time-consuming to the occasional user.

To assist industry, the EPA has developed a software The vapor expansion factor due to day-night temperature

program to calculate storage tank losses. The software fluctuation is defined as:

program, entitled TANKS 4.09, is available for download-

ing from the EPA Web site (2). Other commercial software KE = TR/T (3)

is also available (see the CEP Software Directory at

www.aiche.org/software). where the average ambient temperature is T and the day-

This article presents an adaptation of the conventional night temperature fluctuation is TR,.

EPA method tgo provide a quick estimate of the emissions The total air displaced per day is calculated by:

from fixed-roof storage tanks.

Mair = (Vv)(1/359)(KE)(273.15/T) (4)

Simplified procedure — working losses

Working losses occur when the vapor in the vapor space The breathing losses can now be estimated from:

over the liquid is displaced from the tank by the addition of

organic liquid during tank filling. Working losses depend on Lb = 365Mair(VP/760)(MW) (5)

the annual amount of material pumped, the vapor pressure of

the material stored, and the ambient temperature. Conventional EPA methodology

The working losses can be estimated by: The EPA procedure for estimating working losses as-

sumes a constant temperature of 15°C (59°F), but it is other-

Lw = Qw (1/359)(273.15/T)(VP/760)(MW)(KN)(Kp) (1) wise identical to the shortcut method described above.

The method adopted by the EPA to estimate breathing

KN, the turnover factor, is based on the number of losses is described in full in Ref. 1. The basic equation is:

turnovers per year, N, which is defined as N = Qw/VT. KN =

(180 + N)/6N for N > 36 and KN = 1 for N < 36. Kp, the work- Ls = 365(Vv)(Wv)(KE)(Ks) (6)

ing loss product factor, is defined as Kp = 0.75 for crude oils

and Kp = 1.0 for organic liquids. In general terms, the vapor space expansion factor (KE)

represents the combined effect of the day-night temperature

Simplified procedure — breathing losses fluctuation on the volume of the vapors and on the vapor

Breathing losses occur because differences in temperature pressure of the liquid in the tank.

(such as changes between day and night temperatures) affect The vented vapor saturation factor (Ks) can be viewed as

the vapor space pressure inside storage tanks. Vapors expand the approach to saturation of the liquid in the vapor space. It

with an increase in temperature and contract with a decrease is governed by the vapor pressure of the liquid and the tank

in temperature. In addition, the saturated vapor concentration outage (height of the vapor space in the tank). The saturation

of a substance in air increases with increasing temperature factor approaches 1.0 when the vapor pressure is low or the

and decreases with decreasing temperature. As the outside tank outage is small.

temperature rises during the day, the pressure inside a tank Ref. 1 provides detailed guidelines for evaluating each of

44 www.cepmagazine.org August 2001 CEP

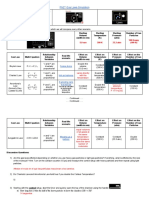

Table. Comparison of shortcut procedure and EPA method.

Organic Liquid EPA Method Simplified Method Discrepancy

Working Breathing Total Working Breathing Total Working Breathing Total

Losses, lb/yr Losses, lb/yr Losses, lb/yr Losses, lb/yr Losses, lb/yr Losses, lb/yr Losses Losses Losses

Toluene 603.9 319.7 923.6 584.3 317.2 901.6 –3.2% –0.8% –2.4%

o -Xylene 147.1 85.1 232.2 141.2 76.7 217.9 –4.0% –9.9% –6.2%

Methanol 915.9 413.8 1,329.7 885.4 481.0 1,366.4 –3.3% +16.2% +2.8%

Cumene 111.9 65.5 177.4 107.1 58.2 165.3 –4.3% –11.1% –6.8%

Acetone 3,443.7 1,338.3 4,782.0 3,360.4 1,825.7 5,186.1 –2.4% +36.4% +8.5%

o -Dichlorobenzene 42.3 25.1 67.4 40.4 22.0 62.4 –4.5% –12.4% –7.4%

Notes:

1. Storage tank is 40 ft high x 20 ft dia., and on average is half full.

2. Total annual throughput is 939,967 gal/yr (125,664 ft3/yr). Comparing the methods

3. Daily average temperature is 54.55˚F (12.53˚F). The table summarizes the results of emissions calculations

4. Daily average temperature range is 15.3˚F (8.5˚F). for the example and for the same storage tank containing

other organic liquids. In most cases, the simplified procedure

the above terms. The EPA method recognizes that the tem- presented here yields results that are in reasonable agreement

perature of the liquid and the temperature of the vapor space with the results obtained using the conventional EPA method-

may be different from the ambient temperature. Empirical ology. Depending on the assumed ambient temperature, the

formulas are provided to determine the temperatures of the discrepancy for working losses between the two methods is

liquid and the vapors if the ambient temperature and the daily in the order of 2–3 %.

range are given. The shortcut technique for breathing losses incorporates

some simplifications that may lead to a somewhat larger dis-

Example crepancy. As illustrated in the table, the difference is within

A fixed-roof vertical tank contains toluene (MW = 92.14). 10% for liquids such as toluene, o-xylene, cumene, or o-

The tank has a volume of 93,997 gal (40 ft dia. by 20 ft high) dichlorobenzene, where the vapor pressure is up to about 30

and is half full. The total annual throughput is 939,967 gal/yr mm Hg. For more volatile liquids, such as acetone or

(125,664 ft3/yr). From meteorological data, the daily average methanol, the shortcut method may lead to overly conserva-

ambient temperature is 54.55°F (12.53°C) and the daily aver- tive values for breathing losses.

age temperature range is 15.3°F (8.5°C). The toluene vapor

pressure at the daily average temperature is 14.40 mmHg. Program available

From Eq. 1, working losses are determined to be Lw = 584.3 A template to estimate emissions via the simplified pro-

lb/yr. From Eqs. 2–5, breathing losses are calculated to be cedure and the EPA method is available on an Excel spread-

Lb = 317.3 lb/yr. The total losses are the sum of Lw and Lb, or sheet. Readers interested in obtaining a copy of the template

901.6 lb/yr. free of charge may contact the author at

peressj@nyc.rr.com. CEP

Nomenclature

Literature Cited

KE = vapor space expansion factor, dimensionless

KN = annual turnover factor, dimensionless 1. U.S. Environmental Protection Agency, “Supplement E to AP-42,

Kp = working loss product factor, dimensionless Compilation of Air Pollutant Emission Factors, Volume 1,” U.S.

Ks = vented vapor saturation factor, dimensionless EPA, Office of Air Quality Planning and Standards, Research

Lb = breathing losses, lb/yr Triangle Park, NC (Oct. 1992).

Ls = standing storage loss, lb/yr 2. U.S. Environmental Protection Agency, “TANKS 4.09 Software

LT = liquid level in tank, % of total height zProgram,” U.S. EPA, Office of Air Quality Planning and Standards,

Lw = working losses, lb/yr Research Triangle Park, NC, available at www.epa.gov/ttn/chief/

Mair = air displaced from tank due to expansion, lbmole/d software/tanks.

MW = molecular weight of the liquid stored

N = number of turnovers per year J. PERESS, P.E., is director of Tritech Consulting Engineers, Jamaica, NY (Phone:

Qw = annual throughput of organic liquid pumped to the tank, ft3/yr (718) 454-3920; Fax: (718) 454-6330; E-mail: peressj@nyc.rr.com). He has over

T = ambient temperature, K 30 years of professional experience in process engineering, process

TR = day-night temperature fluctuation, K troubleshooting, software development, and regulatory compliance (emission

VP = vapor pressure of the organic liquid at the ambient temperature, inventories and air permitting). Prior to starting his consulting practice in 1983,

mmHg he was a process development manager and a senior consultant for Chem

VT = tank capacity, ft3 Systems, Inc. He earned a BSChE from the Israel Institute of Technology and

an MSChE from the City University of New York. He is a Professional Engineer

Vv = vapor space in tank, ft3

registered in New York, New Jersey, and Delaware, and he holds seven U.S.

Wv = vapor density, lb/ft3

patents. He is a member of AIChE and the American Chemical Society.

CEP August 2001 www.cepmagazine.org 45

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Evaporative Rates of A SpillDocument3 pagesEvaporative Rates of A SpillkurtbkNo ratings yet

- Hydrodealkylation Plant Economic AnalysisDocument5 pagesHydrodealkylation Plant Economic AnalysisVinayak PathakNo ratings yet

- Catalytic Dehydration of Isopropyl Alcohol: AcetoneDocument6 pagesCatalytic Dehydration of Isopropyl Alcohol: AcetoneKharkhodaNo ratings yet

- Simulation and Evaluation of A Flare Gas Recovery Unit For RefineriesDocument8 pagesSimulation and Evaluation of A Flare Gas Recovery Unit For RefineriesRikiNo ratings yet

- Uj 36637+SOURCE1+SOURCE1.1Document7 pagesUj 36637+SOURCE1+SOURCE1.1pulezanele11No ratings yet

- Enhanced Recycle Split VapourDocument19 pagesEnhanced Recycle Split VapourMaythee SaisriyootNo ratings yet

- Note 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Blue or GreenDocument9 pagesNote 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Blue or GreenrakamechNo ratings yet

- Simulation and Evaluation of Flare Gas Recovery Unit For RefineriesDocument7 pagesSimulation and Evaluation of Flare Gas Recovery Unit For RefineriesJohnNo ratings yet

- Psych Process 09Document9 pagesPsych Process 09arul skpNo ratings yet

- Process Modifications For Solvent-Based Post Combustion CO CaptureDocument8 pagesProcess Modifications For Solvent-Based Post Combustion CO CaptureMaria RomeroNo ratings yet

- Simulation and Optimization of The Air Inlet SysteDocument5 pagesSimulation and Optimization of The Air Inlet Systeأحمد العقوريNo ratings yet

- Geclearning: Step 1. Choose or Calculate Inert O Concentration Required (Vol%)Document4 pagesGeclearning: Step 1. Choose or Calculate Inert O Concentration Required (Vol%)sandy4u2k2No ratings yet

- Solution Manual For Principles of Chemical Engineering Processes (Instructor Resources)Document132 pagesSolution Manual For Principles of Chemical Engineering Processes (Instructor Resources)Navapon PittayapornNo ratings yet

- Material Balance Fundamentals PresntationDocument50 pagesMaterial Balance Fundamentals Presntationsohaib_ali_13No ratings yet

- SPE-173598-MS A Simplified Approach To Sizing 2 and 3 Phase Separators PDFDocument21 pagesSPE-173598-MS A Simplified Approach To Sizing 2 and 3 Phase Separators PDFRicardo VargasNo ratings yet

- Accepted Manuscript: Separation and Purification TechnologyDocument36 pagesAccepted Manuscript: Separation and Purification Technologyeti apriyantiNo ratings yet

- Best Practice Tewi June2012Document21 pagesBest Practice Tewi June2012Lao ZhuNo ratings yet

- Studying Effect of Feed Vapor Fraction On Consumption Energy in Distillation ProcessDocument5 pagesStudying Effect of Feed Vapor Fraction On Consumption Energy in Distillation ProcessStive BrackNo ratings yet

- Sciencedirect: Co Absorption Efficiency and Heat Consumption Measured at High Gas To Liquid Ratios in Laboratory RigDocument9 pagesSciencedirect: Co Absorption Efficiency and Heat Consumption Measured at High Gas To Liquid Ratios in Laboratory RigYovaniNissiMKetarenNo ratings yet

- Q044114119 PDFDocument6 pagesQ044114119 PDFpeNo ratings yet

- Distillation Handbook 10004 01-08-2008 USDocument52 pagesDistillation Handbook 10004 01-08-2008 USzuhalelbarqiNo ratings yet

- Matecconf Aigev2017 01073 PDFDocument7 pagesMatecconf Aigev2017 01073 PDFNadiedaNo ratings yet

- Optimización de TECHNIP TEALARC Ie100081jDocument10 pagesOptimización de TECHNIP TEALARC Ie100081jAyrton TorrezNo ratings yet

- Simulation, Calculation and Possibilities of Energy Saving in Spray Drying ProcessDocument14 pagesSimulation, Calculation and Possibilities of Energy Saving in Spray Drying ProcessVenu Gopal TallojuNo ratings yet

- Optimization of Multiple Effect Evaporators Designed For Fruit Juice Concentrate PDFDocument7 pagesOptimization of Multiple Effect Evaporators Designed For Fruit Juice Concentrate PDFFrancoNo ratings yet

- Ayo ProposalDocument17 pagesAyo ProposalakintundeakinboladeNo ratings yet

- ReportDocument5 pagesReportAniruddhaDuttaNo ratings yet

- CPL and CTL CalculationDocument9 pagesCPL and CTL CalculationnoxleekNo ratings yet

- Material and Energy BalancesDocument9 pagesMaterial and Energy BalancesAbdulkudus AbdulshukurNo ratings yet

- Flue Gas AnalysisDocument41 pagesFlue Gas AnalysisKingrad1100% (1)

- Tech Data 8APPENDIXAPolymerQuenchingDocument13 pagesTech Data 8APPENDIXAPolymerQuenchingBalram JiNo ratings yet

- Accepted ManuscriptDocument27 pagesAccepted ManuscriptJesse Haney IIINo ratings yet

- Asme PTC4 1Document26 pagesAsme PTC4 1Surya MustafaNo ratings yet

- 128 Basic Aeration Design CalculationsxDocument4 pages128 Basic Aeration Design CalculationsxErno RuzsaNo ratings yet

- Design Project (1) FinalDocument38 pagesDesign Project (1) FinalJasonNtsako100% (3)

- ErwerDocument9 pagesErwerPriska Jesika MonanginNo ratings yet

- LNG RegasificationDocument16 pagesLNG RegasificationCal100% (1)

- Triple Effect EvaporatorDocument9 pagesTriple Effect Evaporatorjnmanivannan100% (1)

- Elecnrtl Rate Based Tea ModelDocument26 pagesElecnrtl Rate Based Tea ModelGodstandNo ratings yet

- Simulation of Methanol Production From Synthesis Gas: KeywordsDocument14 pagesSimulation of Methanol Production From Synthesis Gas: KeywordsJiawen ChongNo ratings yet

- Optimization of Multiple Effect Evaporators Designed For Fruit Juice ConcentrateDocument7 pagesOptimization of Multiple Effect Evaporators Designed For Fruit Juice Concentratekaterin Yanac TelloNo ratings yet

- Simulation Using PFR (Aspen Plus)Document10 pagesSimulation Using PFR (Aspen Plus)Cik Tiem NgagimanNo ratings yet

- Module-2-Hysys Simulation Manual CE-603Document29 pagesModule-2-Hysys Simulation Manual CE-603Zain ShahjeeNo ratings yet

- 1ethanol To Ethylene B1 - ProcessdesignDocument7 pages1ethanol To Ethylene B1 - ProcessdesignAdi PutraNo ratings yet

- ACT 5 SheetDocument5 pagesACT 5 SheetshaiNo ratings yet

- 1 s2.0 S1876610214008881 Main PDFDocument10 pages1 s2.0 S1876610214008881 Main PDFSanaNo ratings yet

- Latent Heat QueriesDocument20 pagesLatent Heat QueriesYeditha Satyanarayana MurthyNo ratings yet

- EEMG ManualDocument100 pagesEEMG ManualLakshmi Narayan100% (5)

- Lab 7 Determination of KLa in Bioreactor 231029 024751Document32 pagesLab 7 Determination of KLa in Bioreactor 231029 024751Nurain UbaidahNo ratings yet

- Design of Triple Effect Evaporator Developed by A Program in CDocument5 pagesDesign of Triple Effect Evaporator Developed by A Program in CDeepakNo ratings yet

- PID Tuning RulesDocument4 pagesPID Tuning RulesChristy PhillipsNo ratings yet

- 1 s2.0 S1876610214031749 MainDocument4 pages1 s2.0 S1876610214031749 MainNurWahyuningNo ratings yet

- EARVIN JINANG..... O0oDocument16 pagesEARVIN JINANG..... O0oJohnmarvin Sace SeñoNo ratings yet

- Dissolved Gas Concentration in Water: Computation as Functions of Temperature, Salinity and PressureFrom EverandDissolved Gas Concentration in Water: Computation as Functions of Temperature, Salinity and PressureNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsRating: 4 out of 5 stars4/5 (9)

- Thermal Power Plant: Pre-Operational ActivitiesFrom EverandThermal Power Plant: Pre-Operational ActivitiesRating: 4 out of 5 stars4/5 (4)

- Split Deliveries PDFDocument18 pagesSplit Deliveries PDFAZDOLMANNo ratings yet

- PNG Energy ConferenceDocument9 pagesPNG Energy ConferenceAZDOLMANNo ratings yet

- Identification of Equipment For MaintenanceDocument14 pagesIdentification of Equipment For MaintenanceAZDOLMANNo ratings yet

- Toolbox Talks CompleteDocument103 pagesToolbox Talks CompleteBinay Kumar Pradhan94% (16)

- Chevron RichmondDocument4 pagesChevron RichmondAZDOLMANNo ratings yet

- Chevron RichmonDocument2 pagesChevron RichmonAZDOLMANNo ratings yet

- Chevron RichmondDocument55 pagesChevron RichmondAZDOLMANNo ratings yet

- Refining Human FactorsDocument6 pagesRefining Human FactorsAZDOLMANNo ratings yet

- Chevron Asia PacificDocument18 pagesChevron Asia PacificAZDOLMANNo ratings yet

- 2-Chevron Australia OverviewDocument17 pages2-Chevron Australia OverviewAZDOLMANNo ratings yet

- LNG PNG Pipe DreamsDocument76 pagesLNG PNG Pipe DreamsAZDOLMANNo ratings yet

- IP 570-2009 RR Research ReportDocument30 pagesIP 570-2009 RR Research Reportkrunalb@inNo ratings yet

- Volume CalculationDocument45 pagesVolume CalculationAZDOLMANNo ratings yet

- Building World Class LNG Operations: Chevron AustraliaDocument8 pagesBuilding World Class LNG Operations: Chevron AustraliaAZDOLMANNo ratings yet

- Engineering HandBookDocument80 pagesEngineering HandBookFranklyn FrankNo ratings yet

- Reliability Availability and Maintainability RAMDocument20 pagesReliability Availability and Maintainability RAMShawqi MohammedNo ratings yet

- 20 Gas Properties and CorrelationsDocument18 pages20 Gas Properties and CorrelationsAZDOLMANNo ratings yet

- Critical Environmental ElementsDocument82 pagesCritical Environmental ElementsAZDOLMANNo ratings yet

- 11 Oil StorageDocument14 pages11 Oil StorageAZDOLMANNo ratings yet

- 06 Hydraulic PumpingDocument71 pages06 Hydraulic PumpingAZDOLMANNo ratings yet

- Aviation Fuel 2007Document40 pagesAviation Fuel 2007AZDOLMANNo ratings yet

- Top 10 CareerDocument3 pagesTop 10 CareerAZDOLMANNo ratings yet

- Employee EffDocument5 pagesEmployee EffAZDOLMANNo ratings yet

- Special Report More Product-Sulfur Reduction On HorizonDocument8 pagesSpecial Report More Product-Sulfur Reduction On HorizonAZDOLMANNo ratings yet

- Documents StackDocument1 pageDocuments StackDan MNo ratings yet

- Proct 09Document43 pagesProct 09AZDOLMANNo ratings yet

- ISA S84.01 On ESD Valve TestingDocument21 pagesISA S84.01 On ESD Valve TestingAZDOLMANNo ratings yet

- Documents StackDocument1 pageDocuments StackDan MNo ratings yet

- Refining Human FactorsDocument6 pagesRefining Human FactorsAZDOLMANNo ratings yet

- VW Polo 5 2014 Heating Air Conditioner EngDocument153 pagesVW Polo 5 2014 Heating Air Conditioner Engjose reirizNo ratings yet

- Sunbeam Generator Internship ReportDocument16 pagesSunbeam Generator Internship ReportChibi Raja100% (2)

- Cambridge IGCSE™: Physics 0625/62 May/June 2022Document9 pagesCambridge IGCSE™: Physics 0625/62 May/June 2022AdilNo ratings yet

- The Application of Na-K-Mg, Na-K/Mg-Ca and K-Mg/Quartz Diagrams To Evaluate Water Geochemistry in West Java Geothermal Prospects, IndonesiaDocument8 pagesThe Application of Na-K-Mg, Na-K/Mg-Ca and K-Mg/Quartz Diagrams To Evaluate Water Geochemistry in West Java Geothermal Prospects, IndonesiaReinhard DanangNo ratings yet

- 02 Penetration PDFDocument8 pages02 Penetration PDFraulNo ratings yet

- PhET - Gas Laws - StudentDocument3 pagesPhET - Gas Laws - Studentx0% (1)

- T2900 Manual Rev 5Document113 pagesT2900 Manual Rev 5brucelirockNo ratings yet

- Quiz BowlDocument60 pagesQuiz BowlApril Mae BaldozaNo ratings yet

- Departamento de Química Facultad de Ciencias Exacta y Naturales Universidad de NariñoDocument3 pagesDepartamento de Química Facultad de Ciencias Exacta y Naturales Universidad de NariñoGabrielNo ratings yet

- Enthalpy of An Ideal Gas Is A Function Only of A. Entropy B. Internal Energy C. Temperature D. PressureDocument150 pagesEnthalpy of An Ideal Gas Is A Function Only of A. Entropy B. Internal Energy C. Temperature D. PressureTed Mana-ayNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument12 pagesPDF Created With Pdffactory Pro Trial VersionAws HasanNo ratings yet

- Bypass Thermostats: Installation InstructionsDocument1 pageBypass Thermostats: Installation InstructionsBassieNo ratings yet

- Chart+table From Ashrae PDFDocument3 pagesChart+table From Ashrae PDFSurooshNo ratings yet

- Boyles Law and Charles LawDocument7 pagesBoyles Law and Charles Lawpeepee poopooNo ratings yet

- Microbiol Incubators 6000 ImlabDocument11 pagesMicrobiol Incubators 6000 ImlabTatit Aji WijayaNo ratings yet

- The Advantages of Using Ambient Air Vaporizers Throughout The Entire LNG MarketDocument3 pagesThe Advantages of Using Ambient Air Vaporizers Throughout The Entire LNG MarketPranav MishraNo ratings yet

- Legend: Saudi Arabian Oil CompanyDocument1 pageLegend: Saudi Arabian Oil CompanyWaqarNo ratings yet

- TKS Rtcurves PDFDocument15 pagesTKS Rtcurves PDFOihane GomezNo ratings yet

- Q13&14Document2 pagesQ13&14Dhenil ManubatNo ratings yet

- Grade 9 Thermal Energy TransferDocument2 pagesGrade 9 Thermal Energy TransferR4iDNo ratings yet

- ASTM D 445 - UnprotectedDocument14 pagesASTM D 445 - UnprotectedEdgar100% (1)

- Thermal Chemical Process Safety Calcs - VeraDocument3 pagesThermal Chemical Process Safety Calcs - VeracymyNo ratings yet

- Sample Paper-02 Physics (Theory) Class - XI Time Allowed: 3 Hours Maximum Marks: 70 General InstructionsDocument3 pagesSample Paper-02 Physics (Theory) Class - XI Time Allowed: 3 Hours Maximum Marks: 70 General InstructionsKabir BiswalNo ratings yet

- The Effect of Elevated Inlet Air Temperature and Relative Humidity On Cogeneration SystemDocument11 pagesThe Effect of Elevated Inlet Air Temperature and Relative Humidity On Cogeneration SystemAdrian Arauco CarhuasNo ratings yet

- MEK Plant DesignDocument112 pagesMEK Plant Designtarhuni100% (3)

- Method 17 - Determination of Particulate Matter Emissions From Stationary SourcesDocument7 pagesMethod 17 - Determination of Particulate Matter Emissions From Stationary SourcesElizabeth Cares LiraNo ratings yet

- Pompe de Caldura PDFDocument21 pagesPompe de Caldura PDFLiviuNo ratings yet

- YORK. YMC2-S1196AA PerformanceDocument2 pagesYORK. YMC2-S1196AA PerformanceMIGUELNo ratings yet

- Compact Thermal Energy Storage StudyDocument46 pagesCompact Thermal Energy Storage StudyRaif QelaNo ratings yet

- MECH3423 - 1516 - 08-Mechanical and Natural VentilationDocument53 pagesMECH3423 - 1516 - 08-Mechanical and Natural Ventilationahtin618No ratings yet