Professional Documents

Culture Documents

Hemp Report Canada

Uploaded by

Christopher L BubnyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hemp Report Canada

Uploaded by

Christopher L BubnyCopyright:

Available Formats

The Ontario Hemp Report

Fall 2006

Message from the OHA Industrial hemp has taken me to Vancouver, Ottawa,

President Chicago, China, several times to Germany and to

Romania. I have become a faithful user of hemp oil and

other food products and it has a strong presence in our

In the summer of 1997, Noble Villeneuve, former Ontario family’s wardrobe. I am an original member of the OHA

Minister of Agriculture, described the reappearance of and have maintained my membership since it’s founding.

industrial hemp in Canada as an agricultural "Rip Van Winkle. It is still the central focus of my professional career and

He is waking up! It is time to wake up to industrial hemp and personal life. I envision the successful establishment of

its potential within the agricultural and food industry." industrial hemp in Ontario as an integral part of the

commercial crop rotation and a prosperous viable hemp

Industrial hemp fibre and grain industry to Ontario. I am not prepared to

production has give up until this vision is fulfilled. My cup continues to

experienced a global remain "half full".

"renaissance". This

renaissance has been Those of us who have journeyed with industrial hemp in Ontario,

largely due to the have experienced an incredible roller coaster ride and have learned

increased demand for many valuable lessons along the way. We have had great losses

biodegradable products, and many painful discouragements. Today we have realistic

the rapidly increasing expectations that hemp will be reintroduced to Ontario as

global demand for annual successful a new crop. For Ontario growers, we finally have

renewable fibre, the availability of Ontario-adapted hemp fibre and grain varieties,

rapidly increasing cost of which will perform competitively with other commercial crops.

non-renewable natural Processing industries for grain and fibre are emerging with

resources for energy, high commercial scale capacities and markets which will demand a

quality health food strong stable acreage of several thousand acres production per

products and an indescribable romance with hemp. year. Industrial hemp is "waking up" to a whole new generation of

markets not conceived 65 years ago. Ontario has the quality

Industrial hemp is a most unique plant that God has created for producers, production capacity, processing technologies, industry

mankind. Hemp produces several types of high quality bast and marketing experts to establish a state of the art industry

fibres as well as grain with very high nutritional value. Hemp demonstrating to the global audience ....“It can be done!”

seed is sometimes touted as ‘nature's most completely

balanced plant oil” and is packed with essential fatty and

amino acids necessary for human health

INSIDE:

No other agricultural crop in recent history has sparked such a The Ontario Hemp Propagation

level of romantic attention and controversy as industrial hemp. Agency (OHPA) Report p2

A new industry is emerging as the "Rip Van Winkle is waking

up" to a complete new millennium. Straw Bales for House Construction

p3-5

I was first introduced to industrial hemp by Mr. Joe Strobel in Tribute To Peter Dragla 1942-2006

the fall of 1994 when he gave a professional presentation to p5

my class of college students at Ridgetown College.

In the spring of 1995, the vision for this plant as a viable crop Things We Learned Combining

and industry for Ontario was painted for me by Mr. Claude Hemp p6

Pinsonneault, founder of Kenex Ltd. I was motivated by Canadian National Report p7

Claude's enthusiastic vision to obtain a research license in OHA Hemp Family Fun Field Day

1995 and thus begin my professional journey with this

exciting plant. p8

The Ontario Hemp Report Fall 2006

1

The Ontario Hemp Propagation

Agency (OHPA) Report

by Gordon Scheifele

This project is under contract with the University of

Guelph/Ridgetown Campus (UG/RC) and 50% funding from

Can Adapt and 50% from in kind and industry partners.

Breeder seed plot of Anka south of Tavistock, Ontario on

June 25/06.

The only existing 500 pounds of Carmen Registered

Pedigreed Seed from 2004 propagation was planted this

spring (2006) by Grant Kime for Certified seed

production. The OHPA has contracted Hempline to

maintain Carmen variety and continue

propagation and marketing of Carmen. The OHPA is

Gunhild Scheifele inspecting commercial Anka south of looking for partnership with someone to contract

Aylmer, Ontario on June 25/06. propagation and marketing of Anka and new grain

variety.

Three lines from the 2004 project with high GLA (5%) levels

were selected for the 2005 project. These cross lines were

selected for high yield (over 2,000#/a), large seed, high GLA UPCOMING:

(over 5%) and low THC (less than 0.1%). These cross lines

(F1) were planted in individual isolated plots the 18th of April. OHA Fall post harvest

Symposium in

Two lines are being developed as monoecious for dual

(grain/fibre) production and one as dioecious grain. Their

November

heights are expected to be between 1-2 metres. Each of the F1

cross lines were rouged for plant uniformity and low THC and

preferred plant types were tagged for harvest. The tagged

plants were harvested and a composite seed sample obtained Date and location

from each plot for another Fatty Acid (FA) and THC analysis.

The 2005 harvested seed of the 3 lines are planted in 2006, in to be confirmed.

4-5 variety performance trials with ANKA, Crag and ESTA-1

as check entries. The three lines are also planted separately in

isolated plots for further selection and breeder seed

production. The best performing line will be selected for

promotion and registered as Variety X for the OHA. The

remaining two lines remain property of the OHA and will be The Ontario Hemp Report is

for sale. This seed can be planted in 2007 for Foundation

Pedigreed Seed production. published on a semi regular basis

by the Ontario Hemp Alliance

ANKA and Carmen varieties were planted in 2005 under

contract with the UG/RC for Breeder Seed Production. Editors: Gordon Scheifele (OHA),

Breeder seed from each variety is planted in 2006. The OHA Arthur Hanks (CHTA)

is producing breeder and foundation Seed of both varieties in

2006. © 2006 Ontario Hemp Alliance

www.ontariohempalliance.org

Mr. Dan Scheele, Ingersoll, was contracted in 2005 to grow

Certified Pedigreed Seed of ANKA. 8,000 pounds of Certified

seed was available for sale in the spring of 2006.

The Ontario Hemp Report Fall 2006

2

by Dr. Colin MacDougall, Queen’s University

There has been renewed interest in using natural construction of the Haliburton, Ontario 4C’s Food

materials for construction in Ontario in the past Bank and Thrift Store building as part of the

decade. Much of the interest to date has focused on inaugural offering of the Sustainable Building

using baled fibre such as straw for residential Design and Construction program at Fleming

construction. This form of construction uses straw College.(see

bales stacked and then plastered on both sides to http://www.flemingc.on.ca/SustainableBuilding/pro

form the load-bearing walls of the home. There are jects/ )

now over 100 approved homes or buildings in

Ontario using straw bale construction. The culmination of the course was the construction

of the 1800 square foot building using load-bearing

A more recent development has been the use of walls of hemp fibre bales stacked and plastered on

hemp bales in place of straw. An on-going program both sides with an earth based plaster. Because of

of research by Dr. Colin MacDougall at Queen’s the unusual materials used in the construction, the

University Department of Civil Engineering is design needed to be approved by a professional

investigating the use of hemp as part of plastered engineer. In this case, the engineer requested a full-

wall construction, and extending its use for a wide scale structural test of a wall similar to that

variety of other applications in the construction proposed for the Haliburton food bank. The

field. required capacity of the wall was 23.5 kN/m in axial

compression.

An example of this research is a test conducted by

Dr. MacDougall and PhD student, Steve Vardy at About a dozen students from Fleming

Queen’s University in May 2005. Well known strawCollege constructed the wall in the Queen’s

bale builder Chris Magwood designed and led the University Structures Lab.

Hemp Straw Bale 4C’s Food Bank Haliburton,

Ontario

The Ontario Hemp Report Fall 2006

3

food bank were provided by Moorcroft

Farms of Madoc, Ontario (see

www.hemphomes.ca ). The wall was

carefully instrumented so that total applied

loads and wall deflections could be

measured. The picture to the left shows the

wall in the loading frame. The final wall

measured 2.4 metres x 2.4 metres

The Graph below shows the total applied to

the wall in kN/m versus the total axial

deflection.

Up to about 10 kN/m, the behaviour of the

wall was relatively linear. With increased

loading beyond this point, cracking in the

plaster was observed. The maximum load on

the wall was measured as approximately 30

kN/m, well above the required 23.5 kN/m.

. Little debonding between the plaster and

Hemp bale test wall prior to testing. hemp was noted. Based on these positive

results, the engineer gave his approval for

The hemp bales for this test wall and the construction to proceed.

The Ontario Hemp Report Fall 2006

4

Early stages of construction are shown

below. In Memorium: Peter Dragla

(1943-2006)

Construction of the 4C’s Food Bank

Born November 15,

1943 in Romania.

Married in 1968

Graduated from

University in Romania

with a MSC degree in

agricultural

engineering. Worked in

Romania as Technical

Director of large

communist field crop

systems. Fled Romania

The bales are stacked

in 1982 arrived in

Canada and in 1984

was reunited with wife Anka and daughter.

Worked in Corn breeding as assistant

breeder in the Chatham, ON region, as

technician with Agriculture & Agri-Food

Canada in Harrow and then with Ridgetown

College In 1995 he began research work on

industrial Hemp with Mr. Gordon Scheifele.

1997 became employed by Ridgetown

College and contracted as the first Industrial

Hemp breeder in Canada since 1939 by

Kenex Ltd. and started Industrial Hemp

the walls after plaster has been applied. SEED Development Company. Breed,

developed and registered the first

This project is an excellent example of the monoecious industrial hemp grain variety

use of hemp for construction applications. A (ANKA) in North America in 1999 with

longer term goal of the research at Queen’s Health Canada. Successfully registered:

is to understand and the structural Anka, Carmen, Denny, Ida, Alisa. Created a

performance of various bio-fibre highly valuable gene resource of breeding

construction components and to provide materials for hemp grain and fibre and

guidance for designers on their use. resourced modern industrial hemp genetics

from many eastern European and Russian

hemp breeders.

Peter was a very serious and hard working

person.

Died on Wednesday August 23, 2006 after 1

½ years battle with cancer. Funeral was on

Saturday August 26, 2006 at Alexander

funeral Home, Chatham.

The Ontario Hemp Report Fall 2006

5

Things We Learned Combining wait probably one week. After giving it one

week the stalks were starting to dry out and

Hemp

the dockage wasn’t nearly as wet. It flowed

by Harry Biermans Chesley

into the combine much better. There is a

compromise between moisture and seed

We used a 9650 John Deere Combine with a

maturity – the later you harvest, the more

30’ Head and an Air Reel. and Conventional

field shelling you will have, but the stalks

cylinder. We have listed our results as

are easier to work with. That is something

follows:

you have to monitor. The Combine was set

with the concave pretty much wide open.

Helps to have a high capacity Combine for

The hemp was so ripe that there was little

hemp to prevent plugging. Unplugging straw

threshing to do. The idea is to get the hemp

is very difficult and time consuming.

into the Combine and out as quickly as

possible so it

doesn’t get a

chance to wrap.

The sieves are set

very close to the

same settings as

wheat. The

ground speed was

approx. 2 mph. It

is very important

to have the same

reel speed as

ground speed. All

the reel needs to

do is just touch

the crop. Be

careful not to

thresh the hemp

Dan Scheele harvesting Anka in 2005 with on the reel. The air reel also helps to get the

his International rotary combine. Rotary

cylinder was modified. There were no hemp flowing into the head. It should look

problems with intake or going thru cylinder. like the hemp is coming into the Combine

The small grain real knocked down taller gradually without any bunching. We left

heads. Lost considerable grain out rear with stubble just below the last seed pods

straw due to too wet straw. Should have (approx. 2 feet). Do not put any more of the

waited another week to let the green straw

and heads dry down more. plant than you have to through the combine.

We tried to combine the hemp when the In the bin, we are able to get the sample

seed was just ready but the stalks were still about 1 - 1.5% Dock which was clean

green. This did not work. The hemp enough for the end user to take.

wrapped everywhere. It wouldn’t flow into We dried the hemp right away at 90 - 100°

the Combine and the dockage was still with lots of air. It’s important to dry the

green. When this happens you’re best to hemp as soon as possible.

The Ontario Hemp Report Fall 2006

6

Canadian National It’s reasonable to assume that increased demand

and increased supply will see farm gate prices

Report decline over time. Thus adding value through

Arthur Hanks, Executive processing fibre, turning what is now an agri-

Director, CHTA waste into another source of farm revenue

stream, will become very important. .

It’s an interesting new era for

Canada’s hemp industry. Nine Currently, fibre is moving slowly, but definite

years in, companies are making progress is being made. Ontario’s Hempline is

money, new products continue an emerging company in technical fibres, while

to reach the market, and for the out west, three companies -- Avanti Polymers,

fifth year running, cultivated Parkland BioFibre, and Naturally Advanced

acreage is increasing. Technologies (formerly Hemptown) ~ are taking

the necessary steps to implement fibre

Currently, the North American market for processing on the prairies. This all will come.

hempseed-derived products is calculated to be

about $40 million. The Canadian Hemp Trade Association (CHTA)

Some companies has been working on the farm, food and fibre

have been growing fronts since 2003. Since beginning with a core of

sales at 50% more a about a dozen food and fibre manufacturers, the

year. association has now grown to include a talented

and creative group of 100 members ~ including

In 2006, last year’s researchers, farmers, marketers, processors and

24000 licensed entrepreneurs. OHA has proven to be a

acres have grown to particularly valuable member of CHTA

an estimated 35000

acres. Experienced hemp farmers have increased With membership’s active participation, CHTA

acreage to meet processor demand. The has accomplished a lot, including:

proportion of certified organic acres continues to our 2003-2004-media/marketing campaign for

climb. Supplies of certified planting seed are hemp foods in the USA; our ongoing nutritional

keeping pace and new varieties are being research on hempseed; hosting regional

developed across the country. workshops and field days; and producing an

unsurpassed national hemp conference (2006

Most production remains out west, where land CHTA Hemp Conference and AGM will be held

costs are cheapest: half of national production is in Winnipeg, November 17th, 2006). We have

in Manitoba, and Saskatchewan holds about one also facilitated dozens of media articles about

third. Weak prices of other commodities and hemp and have responded to many inquires from

strong prices for hemp are creating a lot of the public and professional spheres, ably assisted

interest in our crop. Farm gate prices are in all ways by our website (www.hemptrade.ca ;

maintaining at generally $0.45/lb conventional www.infochanvre.ca).

(Ontario $0.75/lb); organic at $0.85/lb.

The establishment and the growth of the national

As hemp grain prices are set by the free market, association reflects the growing vigor of the

there is a risk that an increase in production will national industry, and gives us a tool with which

negatively impact prices, and over the longer to realize the promise that hemp holds for our

term, supply stability. For a specialized industry country. From the baby steps we took in our

such as hemp, it’s important for farmers to first, tentative years, we seem to be finally

secure a contract. This will help maintain prices hitting our stride.

AND allow steady supply and expansion of the

market. Arthur Hanks

Regina Saskatchewan

The Ontario Hemp Report Fall 2006

7

OHA Hemp Family Fun Field Day Report

Saturday, Aug 26, 2006, the farm of Dan Scheele, Ingersoll, Ontario.

Saturday, Aug 26 turned out to be a great day for the OHA’s Family Fun Field Day contrary to

the weather forecast.

There were 10 vendors, 2 live demonstrations (paper making and spinning), touring the hemp

maze, which had 12 stations with vital information about industrial hemp and a program/harvest

clinic in the afternoon.

Children and adults were given a token metal whistles at registration.

Mr. Helmut Becker and Mrs. Diny Warren attracted much attention demonstrating paper making

and spinning with raw hemp fibre. We had 250 paid adults (over 16) plus many children

attending. It was a

very busy and fun

event. The

Agricultural

Adaptation Council

sponsored the

program speakers.

During the program,

tribute was given to

Mr. Joe Strobel

(deceased May 7,

2006) and Mr. Peter

Dragla (deceased

Aug 23, 2006). A

minute of silence

was held in respect

of Mr. Peter Dragla.

Mr. Claude

Pinsonneault was

also recognized for

outstanding

contributions to the

Hemp industry

since 1995. Claude

retired from the

Aerial View of the Hemp Maze, Scheele Farm OHA directorship in

spring of 2006.

Mr. John Baker (Stonehedge Phytomedicinals, Stirling, Ontario) and Gilles Gagne (Quebec)

gave an excellent harvesting report from attending the Hemp Harvest Clinic, Parkland Hemp

Growers, in July. The whole event far exceeded any of our expectations.~ OHA

The Ontario Hemp Report Fall 2006

8

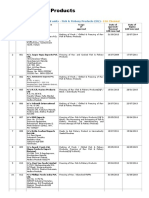

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Project Report On Importance of Hygiene in The Cottage IndustryDocument41 pagesProject Report On Importance of Hygiene in The Cottage Industryalfinmantony67% (3)

- Gourmet LAB MenuDocument13 pagesGourmet LAB MenuOmar Alameri100% (1)

- Mtap GR2Document23 pagesMtap GR2Roslyn JusayanNo ratings yet

- California Pizza Kitchen Case SolnDocument8 pagesCalifornia Pizza Kitchen Case Solnkiller dramaNo ratings yet

- The Ultimate Guide To The Best Road Trips in AustraliaDocument16 pagesThe Ultimate Guide To The Best Road Trips in AustraliaTravellersAutobarnNo ratings yet

- Meal Prep For Summer Downshiftology PDFDocument2 pagesMeal Prep For Summer Downshiftology PDFMaira VergouNo ratings yet

- Tibetan Language PDFDocument72 pagesTibetan Language PDFDiana Nicoleta100% (1)

- Copper Kettle Catering 2Document4 pagesCopper Kettle Catering 2t4thilini100% (2)

- AP Economy in BriefDocument77 pagesAP Economy in Briefdarimadugu100% (1)

- Natural Glow BookDocument112 pagesNatural Glow Bookalejandra9roper9cond100% (1)

- List of Approved Units - FFP ProductsDocument8 pagesList of Approved Units - FFP ProductsBajaj AlchemNo ratings yet

- Ip in ScienceDocument36 pagesIp in SciencePhoebe ArriolaNo ratings yet

- FageDocument8 pagesFageapi-282903171No ratings yet

- Sahara Trading - ProfileDocument7 pagesSahara Trading - ProfileronyforhadNo ratings yet

- Strangities - The More Mundane Adventures of Blue Stahli (Ep 01)Document13 pagesStrangities - The More Mundane Adventures of Blue Stahli (Ep 01)AishaGrewalNo ratings yet

- Golden Rum Cake The Irresistible Charm of Rum Cake UK - Jamaica VibezDocument3 pagesGolden Rum Cake The Irresistible Charm of Rum Cake UK - Jamaica Vibezpeter parkerNo ratings yet

- Quantitative Determination OF AND: Vitamin A Vitamin EDocument20 pagesQuantitative Determination OF AND: Vitamin A Vitamin EAras RafiqNo ratings yet

- FinalThesis - Adugna GessesseDocument114 pagesFinalThesis - Adugna Gessesseemunkiros100% (1)

- Devoir de Synthèse N°1 Collège Pilote - Anglais - 7ème (2019-2020) MR Bechir FraouaDocument3 pagesDevoir de Synthèse N°1 Collège Pilote - Anglais - 7ème (2019-2020) MR Bechir FraouaMesmed NacNo ratings yet

- Time: 3.00 HR Marks:100 6 Class Grand Skill - 2Document9 pagesTime: 3.00 HR Marks:100 6 Class Grand Skill - 2Rama Mohana Rao BhandaruNo ratings yet

- Welcome On BoardDocument46 pagesWelcome On BoardLohayne LimaNo ratings yet

- Family Resources and Needs and Sources of Family IncomeDocument12 pagesFamily Resources and Needs and Sources of Family IncomeJeffrey VigonteNo ratings yet

- Bok:978 81 322 0958 4 PDFDocument304 pagesBok:978 81 322 0958 4 PDFSamiNo ratings yet

- Sexton Plath ExtrasDocument12 pagesSexton Plath ExtraschrissiemavNo ratings yet

- What's Cooking? Preparing and Sharing Food in Ambai's Tamil Short StoriesDocument1 pageWhat's Cooking? Preparing and Sharing Food in Ambai's Tamil Short Storiesusernaga84No ratings yet

- Why It Is Important To Take Care Our HairDocument3 pagesWhy It Is Important To Take Care Our HairKennedy KenNo ratings yet

- Theory 4-3 Centrifugal SeparationDocument21 pagesTheory 4-3 Centrifugal SeparationRaika100% (1)

- Tle BPP10-Q3-M3Document10 pagesTle BPP10-Q3-M3ShekinahJewelNo ratings yet

- FNF Media23-32 Attached Map - Fall23 - RXfiresDocument1 pageFNF Media23-32 Attached Map - Fall23 - RXfiresNBC MontanaNo ratings yet

- Utilisation of Red Palm Olein in Formulating Functional Chocolate SpreadDocument6 pagesUtilisation of Red Palm Olein in Formulating Functional Chocolate SpreadRod LopNo ratings yet