Professional Documents

Culture Documents

Nuva SRCN Liq - e

Uploaded by

peterchang12Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nuva SRCN Liq - e

Uploaded by

peterchang12Copyright:

Available Formats

___________________________________________________________________________________

Technical Information

Nuva SRCN liq.

Nuva® SRCN liquid

Nuva SRCN liq. gives cotton and cotton/polyester blends a very good soil-release and oil-repellent

finishing with good durabilities.

Nuva SRCN liq. displays a improved viscosity.

Nuva SRCN liq. displays low sensitivity to residues on the goods.

Nuva SRCN liq displays very good stabilities in combination with glyoxal resins (Arkofix types) and the

needed catalysts as well as selected softeners (e.g. Ceralube JW liq).

Clariant International AG 1 206922.07.05.e

1 Properties

Appearance Liquid, nearly colourless dispersion

Composition Dispersion of a fluorine compound

Ionicity Weakly cationic

pH (5% as it is; DIN EN 1262) about 5,5

density (25 °C; DIN 51 757) about 1,1 g/cm³

viscosity (25 °C; DIN/ISO 6388) about 100 mPas

Flash point (DIN 51 755) > 100°C

Dilutability Miscible in all proportions with (cold) water

Compatibility with other finishing products Compatible with numerous crosslinking agents,

catalysts, softeners and other textile auxiliaries.

Preliminary trials should in principle be carried out.

Storage Can be kept for at least 6 months if stored correctly

(between 5°C and 40°C).

2 Application properties

Soil release effect Reduces the soil retentivity of articles made of cellulosic

fibres and their blends.

Oleophobic effect Very good values of high durability are achieved if the

product is used in accordance with the recipe.

Stability to washing Withstands several home launderings if the product is

used in accordance with the recipe

3 Application

Nuva SRCN liq. can be applied by padding.

Depending on the type of fibre and requirements, the amounts used are 40 - 100 g/l for padding.

The pH of the finishing liquor should be 4 - 5 and may need to be adjusted with 0.5 - 1.0 ml/l acetic

acid 60 %.

The soil release and oil-repellent effects can be impaired by residues of auxiliaries on the goods being

finished such as fibre finish oils, sizes, surfactants or dyeing assistants. This is also the case when

silicone-containing finish oils or softeners are used. We therefore recommend preliminary washing with

1 g/l Ladiquest® 1097N liq. followed by rinsing and acidification with 1 ml/l acetic acid 60 %.

Clariant International AG 2 206922.07.05.e

4 Finishing examples

100% Co or PES/Co

0 - 1 ml/l acetic acid 60%

40 - 100 g/l Nuva SRCN liq.

• pad, dry at 110 - 130°C

• cure for 3 min. at 150°C or 30 - 40 s at 170 - 180°C*.

or

0- 1 ml/l acetic acid 60%

40 - 60 g/l Arkofix NES liq conc.

12 - 16 g/l Catalys NKC liq or

6- 8 g/l MgCl2

60 - 100 g/l Nuva SRCN liq

20 - 50 g/l Ceralube JW liq

0- 3 g/l Fluowet UD liq

• pad, dry at 110 - 130°C

• cure for 3 min. at 150°C or 30 - 40 s at 170 - 180°C*.

Wovens and knitwear

0- 1 ml/l acetic acid 60%

50 - 100 g/l Arkofix NDK liq.

10 - 30 g/l Ceralube PHD liq. c.

50 - 120 g/l Nuva SRCN liq.

• pad, dry at 110 - 130°C

• cure for 3 min. at 150°C*.

* In some cases higher curing temperatures have a very beneficial effect on wash fastness.

Many of their dyestuffs, pigments and chemicals are patented by Clariant Ltd or its affiliates in numerous industrial countries.

® Trademark registered by Clariant Ltd or Clariant GmbH in numerous countries.

* Trademark licensed to Clariant Ltd in numerous countries.

+ Manufacturer’s registered trade mark

The signs Ò, * and + appear only at the first mention of the product.

The information and recommendations presented here were compiled with the utmost care, but cannot be extended to cover

every possible case. They are intended to serve as non-binding guidelines and must be adapted to the prevailing conditions.

Clariant International AG 3 206922.07.05.e

You might also like

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Leaflet Nuva n4547Document3 pagesLeaflet Nuva n4547Reski Alya PradiftaNo ratings yet

- Solusoft WA Liq - eDocument3 pagesSolusoft WA Liq - esuvrodev812No ratings yet

- Tds 55Document3 pagesTds 55ShripadNo ratings yet

- TDS 2.2.2 PDFDocument2 pagesTDS 2.2.2 PDFShripadNo ratings yet

- Solusoft SE1 Liq - e TIDocument3 pagesSolusoft SE1 Liq - e TIekoyonatanNo ratings yet

- ChemicalDocument2 pagesChemicalFiaz jutt100% (1)

- Ceilcote 6650 Ceilcrete+ds+engDocument4 pagesCeilcote 6650 Ceilcrete+ds+engMohamed NouzerNo ratings yet

- Sandoclean LFDI LiqDocument2 pagesSandoclean LFDI Liqriqpwri1120% (1)

- Sanitile 120 PDSDocument3 pagesSanitile 120 PDSNguyễn PhướcNo ratings yet

- Complete Technical Information For DyeingDocument28 pagesComplete Technical Information For DyeingKhandaker Sakib Farhad100% (1)

- RTV 566Document3 pagesRTV 566Aero solutionsNo ratings yet

- Lnci Technical Information: Altranol-NoviDocument4 pagesLnci Technical Information: Altranol-Novithe griffendorsNo ratings yet

- Carboguard 60 LH PDSDocument4 pagesCarboguard 60 LH PDSRicardo SantosNo ratings yet

- Fixapret F ECODocument4 pagesFixapret F ECOSajida Hafeez0% (1)

- Sanitile 655: Selection & Specification DataDocument3 pagesSanitile 655: Selection & Specification DataIndraNo ratings yet

- Hostapal MRN Liq C - eDocument4 pagesHostapal MRN Liq C - eRobin felderNo ratings yet

- Ceilcote 282 Flakeline+ds+engDocument4 pagesCeilcote 282 Flakeline+ds+engMohamed NouzerNo ratings yet

- Ceilcote 242 FlakelineDocument4 pagesCeilcote 242 Flakelineyoonchankim0911No ratings yet

- Carboguard 690 GF PDSDocument4 pagesCarboguard 690 GF PDSgilbertjerryNo ratings yet

- Silcolapse 426R: DescriptionDocument2 pagesSilcolapse 426R: DescriptionherryNo ratings yet

- Ceilcote 140 Flakeline+ds+engDocument4 pagesCeilcote 140 Flakeline+ds+englivefreakNo ratings yet

- Synolac 4103 WD 85Document2 pagesSynolac 4103 WD 85monrmNo ratings yet

- RCL-59 - Reduction Clearning Agent For TextilesDocument6 pagesRCL-59 - Reduction Clearning Agent For Textilessusheel deoraNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interseal - 670HS - Eng - Usa - LTR - 20170927Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interseal - 670HS - Eng - Usa - LTR - 20170927Thanh Toan LeNo ratings yet

- 696044carboset® CR-717Document9 pages696044carboset® CR-717Charles Buerger Jr.No ratings yet

- Carbothane 134 HPDocument4 pagesCarbothane 134 HPsrinath vNo ratings yet

- Clariant - Hydroperm RPU New Liq C - FTDocument4 pagesClariant - Hydroperm RPU New Liq C - FTAna AntunesNo ratings yet

- Painting Sop Rev 2 Krm0201 A Guf 422 16Document4 pagesPainting Sop Rev 2 Krm0201 A Guf 422 16saiful anwarNo ratings yet

- Cloverdale - (Data Sheet) Clovaprimer h20-0020Document3 pagesCloverdale - (Data Sheet) Clovaprimer h20-0020PubcrawlNo ratings yet

- Interlac 665 PDFDocument4 pagesInterlac 665 PDFEngTamerNo ratings yet

- AquaCool Processing Guide v2.2Document3 pagesAquaCool Processing Guide v2.2metal.rockeangelNo ratings yet

- Viscofluid Product Data CharDocument3 pagesViscofluid Product Data CharSyed Omar SayreNo ratings yet

- Ceilcote 6640 Ceilcrete+ds+engDocument4 pagesCeilcote 6640 Ceilcrete+ds+englivefreakNo ratings yet

- Curran® Granules: Your Biobased Solution For Improved Water Based CoatingsDocument2 pagesCurran® Granules: Your Biobased Solution For Improved Water Based CoatingsWendell SanchezNo ratings yet

- Acrolon 7300: Acrylic Urethane Gloss FinishDocument2 pagesAcrolon 7300: Acrylic Urethane Gloss FinishOswaldo SantoyoNo ratings yet

- Devthane 379H: Aliphatic Urethane Gloss EnamelDocument2 pagesDevthane 379H: Aliphatic Urethane Gloss EnamelBikeBook EnsenadaNo ratings yet

- Ceilcote 380 PrimerDocument4 pagesCeilcote 380 Primeryoonchankim0911No ratings yet

- XF-GL EngDocument4 pagesXF-GL EngWedas TechnicNo ratings yet

- RoClean P112 DATASHEETDocument1 pageRoClean P112 DATASHEETramonmzaNo ratings yet

- Phenoline 385 PDSDocument5 pagesPhenoline 385 PDSNsidibe EtimNo ratings yet

- Clariant Moist CareDocument20 pagesClariant Moist CareHrishikesh Dhawadshikar100% (1)

- Contavan GalDocument3 pagesContavan Galraju_hosssenNo ratings yet

- Carbothane 8832: Selection & Specification DataDocument4 pagesCarbothane 8832: Selection & Specification Dataluisbarrios104No ratings yet

- Tricolev Tan eDocument2 pagesTricolev Tan egzintechNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Ceilcote - 6640 - Ceilcrete - Eng - A4 - 20150818 PDFDocument4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Ceilcote - 6640 - Ceilcrete - Eng - A4 - 20150818 PDFCuong Nguyen Manh100% (1)

- TL - English - Felosan NKB PDFDocument3 pagesTL - English - Felosan NKB PDFRezoanul Haque100% (2)

- B ImpressionDocument44 pagesB ImpressionMenna AmrNo ratings yet

- Carbomastic 15 PDSDocument2 pagesCarbomastic 15 PDSAnonymous 4fVUDODNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Synolac 4100: Product Application DetailsDocument2 pagesSynolac 4100: Product Application DetailsmonrmNo ratings yet

- Korepox Topcoat ET6572Document2 pagesKorepox Topcoat ET6572Isabelo AbaoNo ratings yet

- Synolac 60 WD 70Document2 pagesSynolac 60 WD 70monrmNo ratings yet

- Kieralon JETDocument4 pagesKieralon JETKalpesh BhatiaNo ratings yet

- Synolac 755 WD 60Document2 pagesSynolac 755 WD 60monrmNo ratings yet

- MSDS Mounting MediaDocument47 pagesMSDS Mounting MediaermaNo ratings yet

- INTERSEAL 670HS TemperateDocument4 pagesINTERSEAL 670HS TemperatePamungkasNo ratings yet

- Ful-Base Basecoat (IF Quality) : GeneralDocument3 pagesFul-Base Basecoat (IF Quality) : GeneralsikgmcNo ratings yet

- Geneva IntrotoBankDebt172Document66 pagesGeneva IntrotoBankDebt172satishlad1288No ratings yet

- Analyze Oil Wear DebrisDocument2 pagesAnalyze Oil Wear Debristhoma111sNo ratings yet

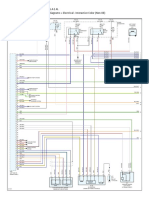

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument4 pagesEngine Controls (Powertrain Management) - ALLDATA Repairmemo velascoNo ratings yet

- Gattu Madhuri's Resume for ECE GraduateDocument4 pagesGattu Madhuri's Resume for ECE Graduatedeepakk_alpineNo ratings yet

- Introduction To Succession-1Document8 pagesIntroduction To Succession-1amun dinNo ratings yet

- Part I-Final Report On Soil InvestigationDocument16 pagesPart I-Final Report On Soil InvestigationmangjuhaiNo ratings yet

- E-TON - Vector ST 250Document87 pagesE-TON - Vector ST 250mariusgrosyNo ratings yet

- Discursive Closure and Discursive Openings in SustainabilityDocument10 pagesDiscursive Closure and Discursive Openings in SustainabilityRenn MNo ratings yet

- Indian Institute of Management KozhikodeDocument5 pagesIndian Institute of Management KozhikodepranaliNo ratings yet

- AKTA MERGER (FINAL) - MND 05 07 2020 FNLDocument19 pagesAKTA MERGER (FINAL) - MND 05 07 2020 FNLNicoleNo ratings yet

- Siemens Documentation - Modeling ComponentsDocument1 pageSiemens Documentation - Modeling ComponentsanupNo ratings yet

- 3838 Chandra Dev Gurung BSBADM502 Assessment 2 ProjectDocument13 pages3838 Chandra Dev Gurung BSBADM502 Assessment 2 Projectxadow sahNo ratings yet

- 01-Azeotropic Distillation (IL Chien)Document35 pages01-Azeotropic Distillation (IL Chien)Shivam Vinoth100% (1)

- Department of Labor: kwc25 (Rev-01-05)Document24 pagesDepartment of Labor: kwc25 (Rev-01-05)USA_DepartmentOfLaborNo ratings yet

- Learning HotMetal Pro 6 - 132Document332 pagesLearning HotMetal Pro 6 - 132Viên Tâm LangNo ratings yet

- BlueDocument18 pagesBluekarishma nairNo ratings yet

- Improvements To Increase The Efficiency of The Alphazero Algorithm: A Case Study in The Game 'Connect 4'Document9 pagesImprovements To Increase The Efficiency of The Alphazero Algorithm: A Case Study in The Game 'Connect 4'Lam Mai NgocNo ratings yet

- ITS America's 2009 Annual Meeting & Exposition: Preliminary ProgramDocument36 pagesITS America's 2009 Annual Meeting & Exposition: Preliminary ProgramITS AmericaNo ratings yet

- SAP ORC Opportunities PDFDocument1 pageSAP ORC Opportunities PDFdevil_3565No ratings yet

- Difference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDocument2 pagesDifference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDharma Teja TanetiNo ratings yet

- UW Computational-Finance & Risk Management Brochure Final 080613Document2 pagesUW Computational-Finance & Risk Management Brochure Final 080613Rajel MokNo ratings yet

- Weka Tutorial 2Document50 pagesWeka Tutorial 2Fikri FarisNo ratings yet

- Deed of Sale - Motor VehicleDocument4 pagesDeed of Sale - Motor Vehiclekyle domingoNo ratings yet

- Tyron Butson (Order #37627400)Document74 pagesTyron Butson (Order #37627400)tyron100% (2)

- Model S-20 High Performance Pressure Transmitter For General Industrial ApplicationsDocument15 pagesModel S-20 High Performance Pressure Transmitter For General Industrial ApplicationsIndra PutraNo ratings yet

- Benchmarking Guide OracleDocument53 pagesBenchmarking Guide OracleTsion YehualaNo ratings yet

- Group 4-Hospital Information System - His - QuizDocument2 pagesGroup 4-Hospital Information System - His - QuizGeeyan Marlchest B NavarroNo ratings yet

- HI - 93703 Manual TurbidimetroDocument13 pagesHI - 93703 Manual Turbidimetrojesica31No ratings yet

- Novirost Sample TeaserDocument2 pagesNovirost Sample TeaserVlatko KotevskiNo ratings yet

- Sta A4187876 21425Document2 pagesSta A4187876 21425doud98No ratings yet