Professional Documents

Culture Documents

Torque N Tension of Bolt

Uploaded by

Ganesh Konar0 ratings0% found this document useful (0 votes)

275 views2 pagesA Torqued Bolt Isn't Necessarily a tight bolt, says Field Bolting Specialist. RCSC banned torque not tight. Why is it then that everybody's torquing bolts if tension 8.2.2. Is the goal? RCSC bans torque not tight.

Original Description:

Original Title

Torque n Tension of Bolt

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA Torqued Bolt Isn't Necessarily a tight bolt, says Field Bolting Specialist. RCSC banned torque not tight. Why is it then that everybody's torquing bolts if tension 8.2.2. Is the goal? RCSC bans torque not tight.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

275 views2 pagesTorque N Tension of Bolt

Uploaded by

Ganesh KonarA Torqued Bolt Isn't Necessarily a tight bolt, says Field Bolting Specialist. RCSC banned torque not tight. Why is it then that everybody's torquing bolts if tension 8.2.2. Is the goal? RCSC bans torque not tight.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Lessons From the Field — Lesson 1: A

Torqued Bolt Isn’t Necessarily a Tight Bolt

By Chris Curven, Field Bolting Specialist, Applied Bolting Technology

O ut in the field, I sometimes hear, “Those bolts

are tight. I torqued ‘em up.”

One of the biggest field bolting issues is still the

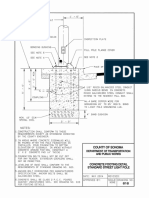

bolts left in the steelwork too long (see figures 1 and

2). Also, changes to the air wrench, including the op-

erator, compressor and hoses. Using a predetermined

confusion on torque being thought of as tight, whether torque value was such a problem for achieving bolt

for installation or inspection. As you tension in the field bolt that the

may have heard before, torque is Research Council on Structural Con-

not tight. Well, why is it then that nections (RCSC) banned torque

everybody’s torquing bolts if tension tables over 50 years ago. See Sec.

is the goal? The confusion comes 8.2.2.

from the nuts — the nuts must be Even before you make it to

torqued, spun along the threads of the field, brand new bolts can have

a bolt for bolt tension to be induced. a +/-40% variation in the torque to

Pop quiz: What’s torque? What’s achieve the same amount of ten-

tension? Well, come on now. You’ve sion. What that means is, after you

been using the word “torque” like you do the required testing in a

know what it means. It’s not easy is Figure 1: An open keg of galvanized nuts Skidmore on 1-1/8” A325 bolts and

it? Now try telling a bolt installer with without any visible dye lubricant with rusty figure it takes a 1,000 ft-lbs. of

20 years experience that torque isn’t threads. This will definitely increase the turn- torque to get to the minimum re-

tight. They look at you with that dis- ing resistance making the bolt assemblies quired tension of 56,000 pounds,

tant gaze, nodding their heads “yes” more difficult to tension. the next bolt could take 1,400 ft-

all the wile in disbelief. lbs. of torque to hit 56,000 pounds

Maybe this will clear things up. of tension. The downside: You’ve

Torque is the amount of energy set your air wrench to deliver 1,000

it takes to spin the nut up along the ft-lbs. and you’ll only achieve 40,000

threads of a bolt. Force x Distance pounds of tension; well below the

that is, put a 200-pound ironworker required 56,000 pounds.

on the end of a two-foot spud and Look at torque this way —

you have 400 foot-lbs. of torque. while cruising on a flat stretch of

Tension is the stretch or elonga- road, you can go 55 mph in a car

tion in a bolt that provides the clamp- and get 25 mpg, but once that road

ing force in a joint. A325 and A490 goes uphill, to maintain that same

Figure 2: Kegs left unprotected in the weather

bolts are actually made to stretch a will increase the torque needed as well. Did 55 mph, you’ll only get 15 mpg. It

few hairs. This Stretch is a good you notice the water in the keg? just takes more effort.

thing. It’s what clamps the steel plies Installing dry rusty bolts is

together. just like driving your car straight

When a bolt is inserted into the uphill. While your ultimate goal of

steel, the underside of the bolt head cruising 55 mph hasn’t changed, the

bears against the steel; it can’t travel amount of energy needed to get

any further because the steel is in there has changed dramatically. The

the way. Then the nut is put on the steeper the hill, the harder your car

threaded end and run up the threads will have to work. The dryer and

to the steel until it can’t go any fur- rustier the bolt the more energy it

ther either. So, as the nut is turned takes to properly tension the bolt

(torqued) along the threads beyond (see Figure 3). On construction

this point, the steel gets pinched Figure 3: The rust increases the turning force sites, the workers often go at it as

together between each end of the (torque) needed by causing more friction or if all the roads in the world are flat.

bolt assembly causing the bolt to resistance between the threads. They forget to consider all the hills

stretch: E-L-O-N-G-A-T-I-O-N.

So what is the downside of measuring torque to get Greasy Bolt Dry Bolt Rusty Bolt

tension? There are lots of things that upset the torque-

to-tension relationship in the field. Field circumstances Torque in ft-lbs. 300 500 800

that can cause torque make-up issues are changed in Tension 39,000 39,000 25k before

lubrication or deterioration caused by exposure to dirt, torsional

heat, moisture, open kegs, tarps used to cover kegs, failure

Reprinted from Distributor’s Link Magazine, Fall 2004

(dry and rusty bolts) en route that will affect the amount ber bolt tightness is actually measured in TENSION

of energy consumed (torque) to maintain 55 mph (bolt (stretch), not TORQUE (twist). This 7/8” A325 bolt has

tension). experienced only 25,000 pounds of tension before it

Consider this for a moment — a good greasy 7/8” broke in torsion (twist) while someone applied 800 ft-

A325 bolt might take as little as 325 ft-lbs. (energy lbs. of torque. Not because the bolt was over-tightened,

consumed) to reach the minimum required tension of but because there was enough resistance between the

39,000 pounds (ultimate goal), but threads so the nut couldn’t run up

as soon as the bolt starts to dry out, the threads any further and the twist-

you’re going to need more energy to ing force was more than the bolt

get up that hill. Instead of 325 ft-lbs. could handle.

you might need as much as 500 ft- What was that middle part

lbs. to get to the same bolt tension again? Torque is not actually a mea-

of 39,000 pounds. Once the same surement of bolt tightness. Torque

bolt is left out in the steel work or in is only the amount of energy is

an open keg for a week, or worse, takes to spin (think twisting force)

two weeks, it could take 700 ft-lbs. the nut along the threads of a bolt.

to reach 39,000 pounds of tension Torque must be applied to tension a

— if the bolt doesn’t break! Figure 4: How to identify a torsional failure; bolt. Bolt torque is usually greater

Another concern using torque for conical shape and a spiraling to the grain of affected by lube, thread condition

measuring bolt tightness is that you the bolt. and exposure to weather.

might believe that the broken bolt Tension is what we’re actually

(see Figure 4) has been tightened TOO much. In the after here. This is how bolt tightness is measured. Ten-

field, they would say the bolt was “over-tightened.” They sion is the actual load caused by stretching the bolt

believe the bolt has seen too much load and has bro- that clamps the joint together.

ken due to that load. It’s going to take a while to get used to saying “ten-

What they don’t realize is that the bolt has been sion” instead of “torque” when you talk about bolting —

over-torqued not over-tightened (see Figure 2). Remem- but just give it some time.

You might also like

- Averaging Wind Over Time - Durst CurveDocument4 pagesAveraging Wind Over Time - Durst CurveGanesh KonarNo ratings yet

- PT6C-67C MM Chap 4-5Document39 pagesPT6C-67C MM Chap 4-5anony810388% (8)

- Unit 6Document13 pagesUnit 6VeronicaNo ratings yet

- Pile Cap DesignDocument25 pagesPile Cap DesignGanesh Konar100% (5)

- Design Berths Quay Construction SystemsDocument44 pagesDesign Berths Quay Construction SystemsGanesh Konar100% (4)

- Reinforced ConcreteDocument13 pagesReinforced ConcreteRenukadevi Rpt17% (18)

- DiodeDocument22 pagesDiodeSaurabh Mittal100% (1)

- 2011 Guide To Vehicle Weight and Dimension in OntarioDocument227 pages2011 Guide To Vehicle Weight and Dimension in Ontariodennis_dizon_6No ratings yet

- Structural Capacities of H-Shaped RC Core Wall Subjected To Lateral Load and Torsion PDFDocument8 pagesStructural Capacities of H-Shaped RC Core Wall Subjected To Lateral Load and Torsion PDFpatricklim1982No ratings yet

- Profiled Sheeting AssemblyDocument24 pagesProfiled Sheeting Assemblyfhoria_20No ratings yet

- Klip-Lok 406 - NewDocument2 pagesKlip-Lok 406 - NewRajeev SharanNo ratings yet

- Simply SupportedDocument9 pagesSimply Supportedpackya7191No ratings yet

- 'Voebnfoubm 1sjodjqmft PG .Fdibojdbm &ohjoffsjoh: '-&/%&3 ESJWFTDocument150 pages'Voebnfoubm 1sjodjqmft PG .Fdibojdbm &ohjoffsjoh: '-&/%&3 ESJWFTraul carvajal rozasNo ratings yet

- 20kl 4compartment Petrol Tanker SpecDocument3 pages20kl 4compartment Petrol Tanker SpecPido VillaruelNo ratings yet

- KKKH3353 - Structural Steel Design - Design of Restrained BeamsDocument47 pagesKKKH3353 - Structural Steel Design - Design of Restrained BeamsZeyad Tareq Al SaroriNo ratings yet

- Aa Spec 371002Document5 pagesAa Spec 371002JDNo ratings yet

- C P & C I .: Cema B4, B5, C5, C6, D6 & E7 Class IdlersDocument20 pagesC P & C I .: Cema B4, B5, C5, C6, D6 & E7 Class IdlersArdian20No ratings yet

- SABS Idlers 2008 PDFDocument29 pagesSABS Idlers 2008 PDFJay Ryan SantosNo ratings yet

- HSS CatalogueDocument56 pagesHSS CataloguenenmilNo ratings yet

- SOUDAL Product Catalogue 2016 129171Document68 pagesSOUDAL Product Catalogue 2016 129171Candice Diaz100% (1)

- Aac Spec 373001 PDFDocument13 pagesAac Spec 373001 PDFJakesNo ratings yet

- Cap Screws: Sae J429 Grade IdentificationDocument6 pagesCap Screws: Sae J429 Grade IdentificationHomer SilvaNo ratings yet

- Corrosion Resistance of MiTek Metal ConnectorsDocument4 pagesCorrosion Resistance of MiTek Metal ConnectorsEduardo Depiné TarnowskiNo ratings yet

- Manual Técnico de Parafusos - BOSSARDDocument85 pagesManual Técnico de Parafusos - BOSSARDRenato Caldas100% (1)

- Totten CatalogDocument19 pagesTotten CatalogxpertsteelNo ratings yet

- Murray Roberts calculation sheet for Eskom Medupi crawl beamDocument23 pagesMurray Roberts calculation sheet for Eskom Medupi crawl beamMbalekelwa MpembeNo ratings yet

- Parallel Flange Channels (ALL Sections) : DiagramDocument1 pageParallel Flange Channels (ALL Sections) : Diagramalvin_tanNo ratings yet

- Mcnichols Master CatalogDocument56 pagesMcnichols Master CatalogULISES MONTANONo ratings yet

- Khowpa Engineering College: Purbancal UniversityDocument8 pagesKhowpa Engineering College: Purbancal UniversitySudan ShresthaNo ratings yet

- Table 10.1 - Man/ Equipment - Hours For Steel FabricationDocument6 pagesTable 10.1 - Man/ Equipment - Hours For Steel FabricationJyles SirabNo ratings yet

- Sl. No. Title Page No.: B. M. S. College of EngineeringDocument26 pagesSl. No. Title Page No.: B. M. S. College of EngineeringBn SharathNo ratings yet

- Masonry AnchorsDocument17 pagesMasonry AnchorsjeanniemanaloNo ratings yet

- British Steel Universal Beams PFC DatasheetDocument2 pagesBritish Steel Universal Beams PFC DatasheetArjun S SanakanNo ratings yet

- Mould 99 Correct NoDocument2 pagesMould 99 Correct NonephembaniNo ratings yet

- Introduction To The Economics of Structural SteelworkDocument156 pagesIntroduction To The Economics of Structural SteelworkCharles AjayiNo ratings yet

- Is 2645 2003 PDFDocument16 pagesIs 2645 2003 PDFlittle gloryNo ratings yet

- Piling Codes of Practice in Southern AfricaDocument7 pagesPiling Codes of Practice in Southern AfricaMfanelo MbanjwaNo ratings yet

- Bolt Grip Length PDFDocument1 pageBolt Grip Length PDFmatthewwalls4386100% (2)

- 04 Engineering Mechnical Production January 2017 PDFDocument116 pages04 Engineering Mechnical Production January 2017 PDFAbhijeet SinghNo ratings yet

- En 19Document1 pageEn 19Parvee K Nakwal100% (1)

- Dynamic Stiffness and Design of Rubber SteelDocument5 pagesDynamic Stiffness and Design of Rubber SteelAngga Fajar SetiawanNo ratings yet

- IIT Hyderabad Faculty Housing Design CalculationsDocument33 pagesIIT Hyderabad Faculty Housing Design CalculationssmijusNo ratings yet

- Chapter 5CDocument6 pagesChapter 5Cnishant361No ratings yet

- MiTek PG 83Document1 pageMiTek PG 83Sam LeungNo ratings yet

- Column SpliceDocument1 pageColumn SpliceBun KunNo ratings yet

- 24226.lotsizing and Scheduling For Production Planning (Lecture Notes in Economics and Mathematical Systems)Document126 pages24226.lotsizing and Scheduling For Production Planning (Lecture Notes in Economics and Mathematical Systems)Simplice KengneNo ratings yet

- 2.CALENBERG Vibration Insulation Bearings - Ciparall - Sliding - Bearing - en PDFDocument8 pages2.CALENBERG Vibration Insulation Bearings - Ciparall - Sliding - Bearing - en PDFAlexandra SanduNo ratings yet

- 7.2 Webb Overhead Power Free Components PDFDocument32 pages7.2 Webb Overhead Power Free Components PDFGiovanni Jiménez Reyes100% (1)

- Handbook of Mechanical Design PDFDocument286 pagesHandbook of Mechanical Design PDFHernán H.No ratings yet

- Welcome To E-Z-Slab 2001Document18 pagesWelcome To E-Z-Slab 2001dakotaaaNo ratings yet

- KL UHP Catalog 2011-02 PDFDocument30 pagesKL UHP Catalog 2011-02 PDFaconibet9040No ratings yet

- EXPANSION JOINTS: WHERE, WHEN AND HOWDocument4 pagesEXPANSION JOINTS: WHERE, WHEN AND HOWdnl_vicarsNo ratings yet

- As 4100Document1 pageAs 4100shiruhanNo ratings yet

- Architecture Design Handbook - Flashings and Copings - Coping CoversDocument5 pagesArchitecture Design Handbook - Flashings and Copings - Coping CoversDukeNo ratings yet

- Draft VTUSA Conveyor Bridge Report v4Document219 pagesDraft VTUSA Conveyor Bridge Report v4ken stanleyNo ratings yet

- Fortress Timber & Metal SDS Screws 2017 WebDocument36 pagesFortress Timber & Metal SDS Screws 2017 WebGabriel MacedoNo ratings yet

- Discussion - Yield Line Analysis of Bolted Hanging ConnectionsDocument1 pageDiscussion - Yield Line Analysis of Bolted Hanging ConnectionsRob TamaccioNo ratings yet

- Fasten BoltDocument1 pageFasten BoltSara BookerNo ratings yet

- Rectangular Bin Designs - Steve AshDocument3 pagesRectangular Bin Designs - Steve AshVictor BoderoNo ratings yet

- Beam Bridge Ethereum Part Security AnalysisDocument9 pagesBeam Bridge Ethereum Part Security AnalysisBeamPrivacyNo ratings yet

- Staatskoerant: Van Dierepubliek Van Suid-AfrikaDocument17 pagesStaatskoerant: Van Dierepubliek Van Suid-AfrikaMmamoraka Christopher MakhafolaNo ratings yet

- Wrought Carbon Steel Sleeve-Type Pipe Couplings: Standard Specification ForDocument5 pagesWrought Carbon Steel Sleeve-Type Pipe Couplings: Standard Specification ForDeen ew100% (1)

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600No ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Modern Industrial Statistics: with applications in R, MINITAB and JMPFrom EverandModern Industrial Statistics: with applications in R, MINITAB and JMPNo ratings yet

- GRE Analytical Writing Sample Paper 2014Document4 pagesGRE Analytical Writing Sample Paper 2014Kumardeep MukhopadhyayNo ratings yet

- ASTM Nut - Proof StressDocument14 pagesASTM Nut - Proof StressGanesh KonarNo ratings yet

- Analysis of Torsion in Prestressed Concrete StructuresDocument11 pagesAnalysis of Torsion in Prestressed Concrete StructuresNeil DuldulaoNo ratings yet

- Chord Sheet PDFDocument1 pageChord Sheet PDFGanesh KonarNo ratings yet

- Chapter 11Document36 pagesChapter 11sharathr22No ratings yet

- Flow DesignDocument37 pagesFlow DesignHeang BorinNo ratings yet

- Sheet Pile 1Document13 pagesSheet Pile 1belacewNo ratings yet

- 9 Design For EarthquakeDocument3 pages9 Design For EarthquakedhawanaxitNo ratings yet

- Chapter 11Document36 pagesChapter 11sharathr22No ratings yet

- Fujairah Municipality - New Rules For Document SubmissionDocument6 pagesFujairah Municipality - New Rules For Document SubmissionGanesh Konar0% (1)

- Seismic Analysis and Design of Structures Using Response Spectra Time History MotionsDocument60 pagesSeismic Analysis and Design of Structures Using Response Spectra Time History MotionsGanesh KonarNo ratings yet

- Blank Ukulele Chord Sheet PDFDocument1 pageBlank Ukulele Chord Sheet PDFGanesh Konar100% (1)

- API Steel GradeDocument2 pagesAPI Steel GradeGanesh KonarNo ratings yet

- Unrestrained BeamDocument3 pagesUnrestrained BeamGanesh Konar100% (1)

- Retaining StructuresDocument1 pageRetaining StructuresGanesh KonarNo ratings yet

- Steel Table BS4Document42 pagesSteel Table BS4Ganesh Konar0% (1)

- 543R-12 Guide To Design PilesDocument69 pages543R-12 Guide To Design PilesGanesh Konar0% (2)

- 616 PDFDocument1 page616 PDFAnonymous qMToncNo ratings yet

- Steel Table BS4Document42 pagesSteel Table BS4Ganesh Konar0% (1)

- Bending and TorsionDocument29 pagesBending and TorsionGanesh KonarNo ratings yet

- Stiffened PlateDocument1 pageStiffened PlateGanesh KonarNo ratings yet

- Column Base Plates DesignDocument19 pagesColumn Base Plates Designccbserialk80% (5)

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- Caprani - Deflection To EC2Document3 pagesCaprani - Deflection To EC2emmetfureyNo ratings yet

- Stiffened PlateDocument1 pageStiffened PlateGanesh KonarNo ratings yet

- AWS D1.1 Prequalified WPS ProcessesDocument38 pagesAWS D1.1 Prequalified WPS ProcessesVel MuruganNo ratings yet

- Caprani - Deflection To EC2Document3 pagesCaprani - Deflection To EC2emmetfureyNo ratings yet

- Experion Scada PinDocument7 pagesExperion Scada PinKhalid AliNo ratings yet

- Aso Airfield Standards Quick ReferenceDocument66 pagesAso Airfield Standards Quick ReferenceRahul RanaNo ratings yet

- Asme B36.10M-2018Document36 pagesAsme B36.10M-2018امينNo ratings yet

- Dacnewppt p4Document21 pagesDacnewppt p4vmspraneethNo ratings yet

- V8fr-Ii V8r7-IiDocument1 pageV8fr-Ii V8r7-Iiaeroseb1No ratings yet

- 2022 Manufacture AnswerDocument8 pages2022 Manufacture AnswerChampika V SamarasighaNo ratings yet

- Devoir 2 Arsalan 2SM BIOFDocument3 pagesDevoir 2 Arsalan 2SM BIOFphytanjaNo ratings yet

- 3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFDocument6 pages3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFRene ParedesNo ratings yet

- Iraqi Code for Reinforced Concrete StructuresDocument71 pagesIraqi Code for Reinforced Concrete Structuresmamandawe50% (2)

- Quotation 615-4078 BabulalDocument14 pagesQuotation 615-4078 Babulaldevrajan631No ratings yet

- GD&T Training Levels and ServicesDocument1 pageGD&T Training Levels and ServicesdramiltNo ratings yet

- LMDQDocument601 pagesLMDQMohd Azamuddin Mohd SaifullizanNo ratings yet

- Mobiltech (Textile Used in Transportation, Automotive & Aerospace)Document12 pagesMobiltech (Textile Used in Transportation, Automotive & Aerospace)cario galleryNo ratings yet

- Wrangling Logs With Logstash and ElasticSearch PresentationDocument38 pagesWrangling Logs With Logstash and ElasticSearch PresentationMohammad Syafiq Bin HussainNo ratings yet

- DMD Documentation Error - Freetronics ForumDocument3 pagesDMD Documentation Error - Freetronics ForumapofviewNo ratings yet

- Filter DesignDocument4 pagesFilter Designhassan11783No ratings yet

- Sinusverteiler Multivalent SolutionsDocument13 pagesSinusverteiler Multivalent SolutionsIon ZabetNo ratings yet

- Switching Theory and Logic Design PDFDocument159 pagesSwitching Theory and Logic Design PDFSai TejaswiniNo ratings yet

- List of Linkages2016Document74 pagesList of Linkages2016engrwho0% (1)

- Bottom Ash HopperDocument8 pagesBottom Ash HopperBhargav ChaudhariNo ratings yet

- Ornl 2465Document101 pagesOrnl 2465jesusNo ratings yet

- Versys Parts Catalogue (UK)Document111 pagesVersys Parts Catalogue (UK)BaronBaz001No ratings yet

- Wireless Mouse m325 Quick Start GuideDocument2 pagesWireless Mouse m325 Quick Start GuideFabolos 9No ratings yet

- Electrical Measurements LabDocument40 pagesElectrical Measurements Labmdayyub100% (4)

- Portable Low-Frequency Acoustic Seismic System HMS-620Document2 pagesPortable Low-Frequency Acoustic Seismic System HMS-620AntoNo ratings yet