Professional Documents

Culture Documents

Niosh 6013

Uploaded by

Frank OspinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Niosh 6013

Uploaded by

Frank OspinaCopyright:

Available Formats

HYDROGEN SULFIDE 6013

H2S MW: 34.08 CAS: 7783-06-4 RTECS: MX1225000

METHOD: 6013, Issue 1 EVALUATION: FULL Issue 1: 15 August 1994

OSHA : C 20 ppm; P 50 ppm/10 min PROPERTIES: gas; d (liq) 1.54 g/mL @ 0 °C;

NIOSH: C 10 ppm/10 min BP - 60 °C; VP 20 atm @ 25 °C;

ACGIH: 10 ppm; STEL 15 ppm vapor density (air=1) 1.19;

(1 ppm = 1.39 mg/m 3 @ NTP) explosive range 4.3 to 46% v/v in air

SYNONYMS: sulfuretted hydrogen; hydrosulfuric acid; hepatic gas; stink damp

SAMPLING MEASUREMENT

SAMPLER: FILTER + SOLID SORBENT TUBE TECHNIQUE: ION CHROMATOGRAPHY,

(Zefluor, 0.5 µm; coconut shell CONDUCTIVITY

charcoal, 400 mg/200 mg)

ANALYTE: sulfate ion

FLOW RATE-RANGE: 0.1 to 1.5 L/min

-RECOMMENDED: 0.2 L/min DESORPTION: 2 mL 0.2 M NH 4OH + 5 mL

30% H 2O 2

VOL-MIN: 1.2 L @ 10 ppm

-MAX: 40 L INJECTION VOLUME: 50 µL

SHIPMENT: routine ELUENT: 40 mM NaOH, 1.5 mL/min

SAMPLE COLUMN: Ion-Pac AS4A separator, AG4A

STABILITY: at least 30 days @ 25 °C [1] guard

BLANKS: 2 to 10 field blanks per set CALIBRATION: SO 2

4 in deionized water

RANGE: 17 to 200 µg per sample

ACCURACY

ESTIMATED LOD: 11 µg per sample

RANGE STUDIED: 1.4 to 22.0 mg/m 3 [1]

(20-L samples) PRECISION (Sr): 0.031 [1]

BIAS: 0.23% [1]

OVERALL PRECISION (SrT): 0.059 [1]

ACCURACY: ± 11.8%

APPLICABILITY: The working range is 0.6 to 14 ppm (0.9 to 20 mg/m 3) for a 20-L air sample [1]. The method is applicable to

15-min samples taken at 1 L/min and 10-min samples taken at 1.5 L/min. The upper limit of loading depends on the

concentrations of hydrogen sulfide and other substances in the air, including water vapor. High relative humidity (80%) increases

the capacity of the sampler four-fold, relative to dry air. Some lots of charcoal have excessively high sulfur backgroun ds and/or

poor desorption efficiencies; therefore, screening of each lot should be done before field use.

INTERFERENCES: SO 2 is a positive interference, equivalent to H 2S by approximately twice the SO 2 concentration by weight.

Methyl and ethyl mercaptans do not interfere [1].

OTHER METHODS: Alternate methods are S4 [2] which uses impinger collection, and P&CAM 296 [3] which uses a molecular

sieve sampler but has poor stability.

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition, 8/15/94

HYDROGEN SULFIDE: METHOD 6013, Issue 1, dated 15 August 1994 - Page 2 of 4

REAGENTS: EQUIPMENT:

1. Ammonium hydroxide solution, 25%. 1. Sampler: glass tube, 10 cm long, 8-mm OD,

2. Hydrogen peroxide, 30%.* 6-mm ID, flame-sealed ends with plastic caps,

3. Sodium hydroxide, 50% (w/v).* containing 20/40 mesh activated (600 °C)

4. Extraction soln: 0.2 M NH 4OH. coconut shell charcoal (front = 400 mg, back

5. Eluent: 40 m M NaOH. Dilute 4.16 mL of 50% = 200 mg) separated by a 6-mm urethane

NaOH to 2 L with deionized water (degassed). foam plug. A silanized glass wool plug

6. Suppressor regenerant: 0.025 N H2SO 4. Dilute precedes the front section and a 6-mm

1.4 mL concentrated H 2SO 4 to 2 L with urethane foam plug follows the back section.

deionized water.* Pressure drop across the tube at 1 L/min

7. Calibration Stock solution: 1 mg/mL (as airflow must be less than 3.4 kPa. Tubes are

anion). Dissolve 0.1814 g K 2SO 4 in 100 mL commercially available. Zefluor PTFE prefilter,

deionized water. 0.45-µm, 25-mm, with porous plastic support

8. H2S, calibration gas mixture, or permeation pad in 25-mm cassette.

device. NOTE: Some lots of charcoal have

excessively high sulfur backgrounds,

* See Special Precautions and/or desorption efficiencies. Screen

each lot before field use.

2. Personal sampling pump, 0.1 to 1.5 L/min,

with flexible connecting tubing.

3. Ion c hromatograph, conductivity detector,

integrator and columns (page 6013-1).

4. Centrifuge tubes, 15-mL, plastic with screw

caps.

5. Syringes, 10-mL, polyethylene with luer tip.

6. Syringe filters, 13-mm, 0.45-µm pore size.

7. Vials, autosampler, 4-mL, PTFE-lined caps.

8. Micropipettes, disposable tips.

9. Pipettes, 2-, 3-, 5-mL.

10. Volumetric flasks, 10-, 25-mL.

11. Vortex mixer (optional).

SPECIAL PRECAUTIONS: Hydrogen peroxide is a strong oxidizer causing burns to skin and mucous

membranes. Sulfuric acid and sodium hydroxide are extremely corrosive to all body tissue. Wear

protective clothing and eye protection. All work should be performed in a fume hood.

SAMPLING:

1. Calibrate each personal sampling pump with a representative sampler in line.

2. Break the ends of the sampler and attach prefilter with a small piece of flexible tubing immediately

before sampling. Attach sampler to personal sampling pump with flexible tubing.

3. Sample at an accurately known flow rate between 0.1 and 1.5 L/min for a total sample size of 15 to

40 L.

4. Cap the sorbent tubes with plastic caps and plug prefilter cassettes. Pack securely for shipment.

NOTE: The prefilters may be discarded or analyzed for particulate sulfates by, e.g., Method 6004.

SAMPLE PREPARATION:

5. Place the front and back sorbent sections of the sampler tube in separate screw-top centrifuge

tubes. Discard the glass wool and foam plugs.

6. Add 2.0 mL of 0.2 M NH 4OH and 5.0 mL H 2O 2 to each centrifuge tube. Attach screw cap and

loosen 1/4 turn.

7. Allow to react at least 10 min. Tighten cap and shake for 30 s or vortex 10 s.

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition, 8/15/94

HYDROGEN SULFIDE: METHOD 6013, Issue 1, dated 15 August 1994 - Page 3 of 4

8. Dilute to 10 mL with 3 mL of deionized water. Cap and shake vigorously.

9. Transfer sample to 10-mL plastic syringe fitted with in-line filter.

CALIBRATION AND QUALITY CONTROL:

10. Calibrate daily with at least six working standards over the range 0.1 to 20 µg sulfate ion per mL of

sample (1 to 200 µg per 10 mL).

a. Add known amounts of calibration stock solution to deionized water in 10- or 25-mL volumetric

flasks and dilute to the mark. Prepare fresh working standards biweekly.

b. Analyze together with samples and blanks (steps 14 and 15).

c. Prepare calibration graph (peak height vs. µg SO 2 4 per sample).

11. Determine desorption efficiency (DE) at least once for each lot of charcoal used for sampling in the

calibration range (step 10). Prepare four tubes at each of three levels plus three media blanks.

a. Generate concentrations of H 2S from a calibration gas mixture or a permeation device. Mix with

dilution air as necessary.

b. Collect samples at a flow rate of 1 L/min for 30 min.

c. Cap the tubes and allow to stand overnight.

d. Desorb (steps 5 through 9) and analyze together with working standards (steps 14 and 15).

e. Prepare a graph of DE vs. µg sulfate recovered.

12. Analyze three quality control blind spikes and three analyst spikes to insure that the calibration

graph is in control.

MEASUREMENT:

13. Set ion chromatograph according to manufacturer's recommendations and to conditions given on

page 6013-1.

14. Inject a 50-µL sample aliquot manually or with autosampler.

15. Measure peak height.

NOTE: If peak height is above the linear range of the working standards, dilute with deionized

water, reanalyze, and apply the appropriate dilution factor in calculations.

CALCULATIONS:

16. Determine the mass, µg (corrected for DE) of sulfate ion found in the sample front (W f) and back

(W b) sorbent sections, and in the average media blank front (B f) and back (B b) sorbent sections.

NOTE: If W b > W f/10, report breakthrough and possible sample loss.

17. Calculate concentration, C, of hydrogen sulfide in the air volume sampled, V (L), applying the factor

0.3548 (MW H 2S/MW SO 2 2

4 ) for the conversion of SO 4 to H 2S:

EVALUATION OF METHOD:

The method was evaluated by sampling generated test atmospheres of H 2S in air [1]. Time-weighted

average samples were taken at four concentration levels over a range of 1.4 to 22 mg/m 3 (1 to 16 ppm).

For ceiling concentrations or short-term exposure limits, 15-L samples were collected at 1 L/min.

Breakthrough was determined for coconut charcoal from a generated atmosphere at a concentration of

20 ppm (2 x PEL) and at both low (~20%) and high (~80%) relative humidity (RH). Breakthrough volumes

for low and high RH were 21 L and 84 L, respectively, corresponding to capacities of 588 µg of H 2S (low

RH) and 2352 µg of H 2S (high RH). At 1 x PEL, the equivalent breakthrough volume is 42 L (low RH)

and 164 L (high RH). Large coconut charcoal tubes have sufficient capacity to collect a 4-h sample at

the PEL of 10 ppm, as well as STEL samples (15 ppm for 15 min). H 2S samples are stable for at least

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition, 8/15/94

HYDROGEN SULFIDE: METHOD 6013, Issue 1, dated 15 August 1994 - Page 4 of 4

30 days. Recoveries, based on mass of H 2S found on samples analyzed on day 1, were 97.2% for

ambient storage and 98.9% for refrigerated storage. The overall method for H 2S has a limit of detection

of 11 µg per sample and a limit of quantitation of 17 µg per sample. A mean bias of -0.17% was

determined from the recoveries of six samples generated at each of four concentration levels (0.1, 0.5, 1

and 2 x PEL) with a precision ( Sr) of 0.031. The method had a total precision including pump error ( SrT)

of 0.059, and an estimate of overall error of ±11.6%.

REFERENCES:

[1] Cassinelli, ME, Backup Data Report, NMAM 6013, Hydrogen Sulfide. NIOSH/DPSE (1992).

[2] NIOSH Manual of Analytical Methods, 2nd ed., V. 2, S4, U.S. Department of Health, Education, and

Welfare, Publ. (NIOSH) 77-157-B (1977).

[3] NIOSH Manual of Analytical Methods, 2nd ed., V. 6, P&CAM 296, U.S. Department of Health and

Human Services, Publ. (NIOSH) 80-125 (1980).

METHOD WRITTEN BY:

Mary Ellen Cassinelli, NIOSH/DPSE.

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition, 8/15/94

You might also like

- Standard methods for the examination of water and sewageFrom EverandStandard methods for the examination of water and sewageNo ratings yet

- 7906 FLUORIDES Aerosol and Gas, by IC: F MW: 18.998 CAS: (HF) 7664-39-3 RTECS: (HF) MW7875000Document4 pages7906 FLUORIDES Aerosol and Gas, by IC: F MW: 18.998 CAS: (HF) 7664-39-3 RTECS: (HF) MW7875000sonecuNo ratings yet

- LQ-F090 Niosh 7906Document6 pagesLQ-F090 Niosh 7906Marilu Tello PaucarNo ratings yet

- Niosh 6009 PDFDocument5 pagesNiosh 6009 PDFCaleb ConnerNo ratings yet

- Yodo - NIOSH 6005Document4 pagesYodo - NIOSH 6005Mario LagosNo ratings yet

- NIOSH 7903 - Acidos InorganicosDocument6 pagesNIOSH 7903 - Acidos InorganicosNoe Adrianzen MNo ratings yet

- Cloruro de Zinc PDFDocument3 pagesCloruro de Zinc PDFPaola RiveraNo ratings yet

- Niosh 6004 Dióxido de AzufreDocument4 pagesNiosh 6004 Dióxido de AzufreEverChumpisucaAlvarezNo ratings yet

- Niosh 7908-Ácidos No VolátilesDocument5 pagesNiosh 7908-Ácidos No VolátilesDiegoRossoNo ratings yet

- Formaldehyde On Dust (Textile or Wood) 5700: H C O MW: 30.03 CAS: 50-00-0 RTECS: 36172Document5 pagesFormaldehyde On Dust (Textile or Wood) 5700: H C O MW: 30.03 CAS: 50-00-0 RTECS: 36172alexdruppiNo ratings yet

- Hydrogen Cyanide 6010: HCN MW: 27.03 CAS: 74-90-8 RTECS: MW6825000Document5 pagesHydrogen Cyanide 6010: HCN MW: 27.03 CAS: 74-90-8 RTECS: MW6825000Ngọc Ánh LêNo ratings yet

- CH CHCH CL MW: 76.53 CAS: 107-05-1 RTECS: UC7350000: Allyl Chloride 1000Document3 pagesCH CHCH CL MW: 76.53 CAS: 107-05-1 RTECS: UC7350000: Allyl Chloride 1000Cristian Gutiérrez PeñaNo ratings yet

- CH CH BR MW: 108.97 CAS: 74-96-4 RTECS: KH6475000: Ethyl Bromide 1011Document4 pagesCH CH BR MW: 108.97 CAS: 74-96-4 RTECS: KH6475000: Ethyl Bromide 1011Patricia RoaNo ratings yet

- CH (CH) NH MW: 73.16 CAS: 109-73-9 RTECS: EO2975000: N-Butylamine 2012Document4 pagesCH (CH) NH MW: 73.16 CAS: 109-73-9 RTECS: EO2975000: N-Butylamine 2012Jayesh PanjabiNo ratings yet

- Niosh Naftas 1550Document6 pagesNiosh Naftas 1550Enrique Alejandro OvandoNo ratings yet

- CH CHCLCH CL MW: 112.99 CAS: 78-87-5 RTECS: TX9625000: Propylene Dichloride 1013Document4 pagesCH CHCLCH CL MW: 112.99 CAS: 78-87-5 RTECS: TX9625000: Propylene Dichloride 1013Patricia RoaNo ratings yet

- NIOSH 3502-1993 (Phenol)Document3 pagesNIOSH 3502-1993 (Phenol)apriliandiniNo ratings yet

- Niosh Method 1501Document7 pagesNiosh Method 1501Memet ganashpatiNo ratings yet

- Al MW: 26.98 (Al) CAS: 7429-90-5 (Al) RTECS: BD0330000 101.96 (Al 0) 1344-28-1 (Al 0) BD1200000Document4 pagesAl MW: 26.98 (Al) CAS: 7429-90-5 (Al) RTECS: BD0330000 101.96 (Al 0) 1344-28-1 (Al 0) BD1200000Huu Thanh NguyenNo ratings yet

- Descripcion MetodoDocument4 pagesDescripcion MetodoAaron HernandezNo ratings yet

- Niosh 6010Document5 pagesNiosh 6010Mai Trung ToànNo ratings yet

- CH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Document4 pagesCH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Haryo SaputroNo ratings yet

- NIOSH 7907 - Ácidos VolátilesDocument6 pagesNIOSH 7907 - Ácidos VolátilesjosepthfrancisNo ratings yet

- CH CHCN MW: 53.06 CAS: 107-13-1 RTECS: AT5250000: Acrylonitrile 1604Document4 pagesCH CHCN MW: 53.06 CAS: 107-13-1 RTECS: AT5250000: Acrylonitrile 1604Huy MinhNo ratings yet

- Niosh Methanol 2000Document4 pagesNiosh Methanol 2000Endang MilahNo ratings yet

- Cloruro de MetilenoDocument4 pagesCloruro de MetilenoLuisa MinaNo ratings yet

- Niosh 1610Document4 pagesNiosh 1610MICROLABORATORIO S.A de C.VNo ratings yet

- Niosh 1610Document3 pagesNiosh 1610tio dameroNo ratings yet

- NIOSH 7900 Arsenico As PDFDocument3 pagesNIOSH 7900 Arsenico As PDFNicolas ZeballosNo ratings yet

- NIOSH 8310 Ed 94 Metales en OrinaDocument5 pagesNIOSH 8310 Ed 94 Metales en OrinaMario Rodrigo Ramirez MesaNo ratings yet

- TOLUENE (Diffusive Sampler) 4000: C H CH MW: 92.14 CAS: 108-88-3 RTECS: XS5250000Document4 pagesTOLUENE (Diffusive Sampler) 4000: C H CH MW: 92.14 CAS: 108-88-3 RTECS: XS5250000VaninaNo ratings yet

- 1600 PDFDocument4 pages1600 PDFHarold Alonso CFNo ratings yet

- Ca MW: Table 1 CAS: Table 1 RTECS: Table 1: CALCIUM and Compounds, As Ca 7020Document4 pagesCa MW: Table 1 CAS: Table 1 RTECS: Table 1: CALCIUM and Compounds, As Ca 7020Harold Alonso CFNo ratings yet

- NIOSH 1457-1994 Ethyl Acetate Udara Lingker GC FIDDocument4 pagesNIOSH 1457-1994 Ethyl Acetate Udara Lingker GC FIDFakhri MuflihNo ratings yet

- O CH (CH) CH O MW: 100.12 CAS: 111-30-8 RTECS: MA2450000Document4 pagesO CH (CH) CH O MW: 100.12 CAS: 111-30-8 RTECS: MA2450000Vinoth BabuNo ratings yet

- Table 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Alcohols I 1400Document4 pagesTable 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Alcohols I 1400Cristian Gutiérrez PeñaNo ratings yet

- (CH O) SO MW: 126.13 CAS: 77-78-1 RTECS: WS8225000: Dimethyl Sulfate 2524Document4 pages(CH O) SO MW: 126.13 CAS: 77-78-1 RTECS: WS8225000: Dimethyl Sulfate 2524Fauzan FebriyantoNo ratings yet

- (CLCH CH) O MW: 143.01 Cas: 111-44-4 Rtecs: Kn0875000: Dichloroethyl Ether 1004Document3 pages(CLCH CH) O MW: 143.01 Cas: 111-44-4 Rtecs: Kn0875000: Dichloroethyl Ether 1004Patricia RoaNo ratings yet

- Table 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 1301Document5 pagesTable 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 1301Nicolas ZeballosNo ratings yet

- Niosh Method 1501-Hc GC B IndoDocument8 pagesNiosh Method 1501-Hc GC B IndoMemet ganashpatiNo ratings yet

- C H O Toc H O MW: 316.4 To 372.4 Cas: 8003-34-7 Rtecs: Ur4200000Document4 pagesC H O Toc H O MW: 316.4 To 372.4 Cas: 8003-34-7 Rtecs: Ur4200000Boss VinaNo ratings yet

- Alkali Metal Cations Na, K, Li 7405: NIOSH Manual of Analytical Methods (NMAM), Fifth EditionDocument5 pagesAlkali Metal Cations Na, K, Li 7405: NIOSH Manual of Analytical Methods (NMAM), Fifth EditionLINDA IVON PARRADO SÁNCHEZNo ratings yet

- 6014-1 (NO y NO2)Document5 pages6014-1 (NO y NO2)Pablo Isaai Bracamonte CurielNo ratings yet

- HydrazineDocument3 pagesHydrazineSylab InstrumentsNo ratings yet

- 1,1,1,2-TETRACHLORO-2,2-DIFLUOROETHANE and 1016 (2) 1,1,2,2-TETRACHLORO-1,2-DIFLUOROETHANEDocument4 pages1,1,1,2-TETRACHLORO-2,2-DIFLUOROETHANE and 1016 (2) 1,1,2,2-TETRACHLORO-1,2-DIFLUOROETHANEPatricia RoaNo ratings yet

- Plastificanti Come DOPDocument5 pagesPlastificanti Come DOPMarco CorrengiaNo ratings yet

- CH C H Oh MW: 108.14 Cas: 1319-77-3 Rtecs: Go5950000 C H Oh 94.11 108-95-2 SJ3325000Document4 pagesCH C H Oh MW: 108.14 Cas: 1319-77-3 Rtecs: Go5950000 C H Oh 94.11 108-95-2 SJ3325000HectorNo ratings yet

- 6009Document5 pages6009Oktasari Dyah AnggrainiNo ratings yet

- NIOSH 0500-1994 (Total Dust As Inhalable Dust)Document4 pagesNIOSH 0500-1994 (Total Dust As Inhalable Dust)apriliandiniNo ratings yet

- NISOH 1401 ButanolDocument4 pagesNISOH 1401 Butanolluis norabuenaNo ratings yet

- NMAM 7302. 2014. Elements by ICP (Microwave Digestion) .Document9 pagesNMAM 7302. 2014. Elements by ICP (Microwave Digestion) .cesioNo ratings yet

- 5600 - OrganofosforadosDocument22 pages5600 - OrganofosforadosDanilo CostaNo ratings yet

- CBRF MW: 148.92 CAS: 75-63-8 RTECS: PA5425000: Trifluorobromomethane 1017Document4 pagesCBRF MW: 148.92 CAS: 75-63-8 RTECS: PA5425000: Trifluorobromomethane 1017Patricia RoaNo ratings yet

- Niosh 7301 PDFDocument8 pagesNiosh 7301 PDFAngelicaNo ratings yet

- CCL F MW: 120.91 Cas: 75-71-8 Rtecs: Pa8200000: Dichlorodifluoromethane 1018Document4 pagesCCL F MW: 120.91 Cas: 75-71-8 Rtecs: Pa8200000: Dichlorodifluoromethane 1018Patricia RoaNo ratings yet

- NIOSH - (Naoh) - KOH LIOH7401 PDFDocument4 pagesNIOSH - (Naoh) - KOH LIOH7401 PDFEnrique Alejandro OvandoNo ratings yet

- Methyl AcetateDocument3 pagesMethyl AcetatetranhungNo ratings yet

- Niosh 1405Document6 pagesNiosh 1405MICROLABORATORIO S.A de C.VNo ratings yet

- Acetona Niosh 1300 PDFDocument5 pagesAcetona Niosh 1300 PDFOscar Garcia GutierrezNo ratings yet

- 6015 RevDocument7 pages6015 RevAdem YildirimNo ratings yet

- Ob NotesDocument8 pagesOb NotesRahul RajputNo ratings yet

- Marketing FinalDocument15 pagesMarketing FinalveronicaNo ratings yet

- (500eboard) Version Coding Model 140 As of MY 1995Document1 page(500eboard) Version Coding Model 140 As of MY 1995Saimir SaliajNo ratings yet

- Unit 16 - Monitoring, Review and Audit by Allan WatsonDocument29 pagesUnit 16 - Monitoring, Review and Audit by Allan WatsonLuqman OsmanNo ratings yet

- Duavent Drug Study - CunadoDocument3 pagesDuavent Drug Study - CunadoLexa Moreene Cu�adoNo ratings yet

- LTE Networks Engineering Track Syllabus Overview - 23 - 24Document4 pagesLTE Networks Engineering Track Syllabus Overview - 23 - 24Mohamed SamiNo ratings yet

- Task 3 - LPDocument21 pagesTask 3 - LPTan S YeeNo ratings yet

- AntibioticsDocument36 pagesAntibioticsBen Paolo Cecilia RabaraNo ratings yet

- Modulo EminicDocument13 pagesModulo EminicAndreaNo ratings yet

- Farmer Producer Companies in OdishaDocument34 pagesFarmer Producer Companies in OdishaSuraj GantayatNo ratings yet

- Talking Art As The Spirit Moves UsDocument7 pagesTalking Art As The Spirit Moves UsUCLA_SPARCNo ratings yet

- AnticyclonesDocument5 pagesAnticyclonescicileanaNo ratings yet

- Radiation Safety Densitometer Baker PDFDocument4 pagesRadiation Safety Densitometer Baker PDFLenis CeronNo ratings yet

- Sba 2Document29 pagesSba 2api-377332228No ratings yet

- 15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsDocument42 pages15.053/8 February 7, 2013: More Linear and Non-Linear Programming ModelsShashank SinglaNo ratings yet

- Strucure Design and Multi - Objective Optimization of A Novel NPR Bumber SystemDocument19 pagesStrucure Design and Multi - Objective Optimization of A Novel NPR Bumber System施元No ratings yet

- German Atv-Dvwk Rules and StandardsDocument25 pagesGerman Atv-Dvwk Rules and StandardsMehmet Emre Bastopcu100% (1)

- Manual s10 PDFDocument402 pagesManual s10 PDFLibros18No ratings yet

- Unit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptDocument6 pagesUnit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptĐại học Bạc Liêu Truyền thông100% (1)

- E MudhraDownload HardDocument17 pagesE MudhraDownload HardVivek RajanNo ratings yet

- Spesifikasi PM710Document73 pagesSpesifikasi PM710Phan'iphan'No ratings yet

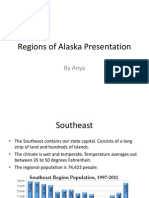

- Regions of Alaska PresentationDocument15 pagesRegions of Alaska Presentationapi-260890532No ratings yet

- Equivalent Fractions Activity PlanDocument6 pagesEquivalent Fractions Activity Planapi-439333272No ratings yet

- Report Card Grade 1 2Document3 pagesReport Card Grade 1 2Mely DelacruzNo ratings yet

- LetrasDocument9 pagesLetrasMaricielo Angeline Vilca QuispeNo ratings yet

- DPSD ProjectDocument30 pagesDPSD ProjectSri NidhiNo ratings yet

- Stearns 87700 Series Parts ListDocument4 pagesStearns 87700 Series Parts ListYorkistNo ratings yet

- From Philo To Plotinus AftermanDocument21 pagesFrom Philo To Plotinus AftermanRaphael888No ratings yet

- Developing Paragraphs: Test Section - Writing Task 2Document11 pagesDeveloping Paragraphs: Test Section - Writing Task 2Cengizhan AkdağNo ratings yet

- 05 x05 Standard Costing & Variance AnalysisDocument27 pages05 x05 Standard Costing & Variance AnalysisMary April MasbangNo ratings yet