Professional Documents

Culture Documents

Aiche J 47 - 2001 - 929-934

Uploaded by

Darwin Barra TorresOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aiche J 47 - 2001 - 929-934

Uploaded by

Darwin Barra TorresCopyright:

Available Formats

Gypsum Nucleation into Sodium Chloride

Solutions

Marina Prisciandaro

` dell’Aquila, 67040 L’Aquila, Italy

Dipt. di Chimica, Ingegneria Chimica e Materiali, Universita

Amedeo Lancia

` di Napoli ‘‘Federico II,’’ 80125 Napoli, Italy

Dipt. di Ingegneria Chimica, Universita

Dino Musmarra

Istituto di Ricerche sulla Combustione, CNR, 80125 Napoli, Italy

The nucleation of gypsum into a NaCl solution was studied within a supersaturation

range of 2 ] 4 at 25-708C. The experiments were carried out using a lab-scale apparatus

consisting of a batch crystallizer with the related measurement de®ices. Signals of scat-

tered and transmitted light coming from a He ] Ne laser source were analyzed to mea-

sure the induction period, that is, the time delay necessary for homogeneous nucleation

to take place. Comparison of the experimental results with those pre®iously obtained in

the absence of added NaCl in solution showed that NaCl strongly affects gypsum precip-

itation. They were compared in terms of the acti®ation energy and the interfacial tension

between crystals and the surrounding aqueous solution.

Introduction

The precipitation of calcium sulfate dihydrate represents In a previous article ŽLancia et al., 1999. this research group

an important issue in a number of different industrial appli- had devised a new method, based on a laser light scattering

cations, and for this reason a great deal of attention has been technique, for measuring nucleation induction period Ž t ind .,

given in the literature to the study of gypsum crystal nucle- that is, the time delay necessary for homogeneous nucleation

ation and growth, with both a fundamental and an operating to take place. More precisely, the induction period Žor induc-

approach. Several authors devoted their researches to under- tion time. is defined as the time elapsed between the onset of

standing the gypsum crystallization phenomena involved in supersaturation and the first changes in the system’s physical

nucleation and growth processes, and to the estimation of properties due to the formation of a solid phase ŽSohnel ¨ and

significant parameters such as activation energy Ž Eat t . and Garside, 1992.. In fact, the true induction period Ž tU , with

interfacial tension Žgs . ŽHe et al., 1994; Nielsen, 1964; Lancia tU F t ind ., as pointed out by Sohnel

¨ and Mullin Ž1978., cannot

et al., 1999.. On the other hand, the study of the practical be experimentally measured, since it refers to the detection

application of gypsum precipitation covers different fields, for of critical nuclei Žor embryos, such as clusters of loosely ag-

example, the wet limestone]gypsum scrubbing process, for gregated molecules.; in order to perform the measurement,

which the evaluation of the best conditions for carrying out however, it is necessary that such nuclei grow until they reach

the precipitation step focuses mainly on how to reduce the a detectable size. The only possible determination is there-

byproduct water content, making sludge disposal less expen- fore simply referred to as the induction period, which de-

sive ŽEtherton and Randolph, 1981.; several scale control ap- pends on the technique employed to measure it. Neverthe-

plications, such as desalination and industrial water treat- less, the knowledge of t ind and of its relationships with the

ment, for which many researchers have tested the capability process parameters, such as the temperature and the super-

of disparate additives of retarding the unwanted gypsum pre- saturation, can give some important information about the

¨

cipitation process ŽOner et al., 1998.. ¨

crystallization process ŽSohnel and Mullin, 1988.; obviously,

the more accurate the technique, the more reliable the infor-

Correspondence concerning this article should be addressed to A. Lancia. mation obtained. A detailed review of the effect of organic

AIChE Journal April 2001 Vol. 47, No. 4 929

and inorganic additives on the induction period for gypsum

nucleation was presented elsewhere ŽPrisciandaro et al.,

1999.. Analyses in the literature showed that most of the arti-

cles ŽLiu and Nancollas, 1975; Amjad and Hooley, 1986. con-

cerned the effects that specific additives have on the growth

kinetics of gypsum crystals, especially from seeded solutions

Žsuch as with a secondary nucleation mechanism., while a

much smaller number of articles ŽHe et al., 1994. have been

published on the effect of additives on the primary nucle-

ation kinetics of gypsum, and therefore on induction time.

Moreover the only article concerning the effect of dissolved

impurities on the induction period for gypsum nucleation in

conditions typical of a flue-gas desulfurization process is that

by Lancia et al. Ž1999., in which by applying the optical tech-

nique just reported, the authors measured the induction pe-

riod for gypsum nucleation as a function of temperature and

supersaturation. They evaluated the interfacial tension be-

tween CaSO4 ? 2H 2 O and the surrounding aqueous solution Figure 1. Experimental apparatus.

by using the dependence of t ind on supersaturation, while the

dependence of t ind on temperature was used to estimate the

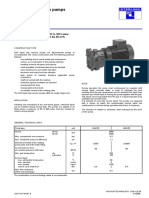

activation energy for gypsum crystallization. Subsequently, the splitter is provided in order to divide the laser beam into two

same measurement technique was applied to study the effect parts: one to illuminate the measure cell, while the other,

of calcium and sodium chloride salts on the calcium sulfate collected by a photodiode, to check the stability and intensity

dihydrate induction period ŽPrisciandaro et al., 1999., show- of laser beam Ž Io .. The signal of the scattered light Ž Isc a . is

ing that Cly ions have a strong effect on gypsum precipita- collected by two lenses of focal 120 and 50 mm, at 908 with

tion by retarding nucleation kinetics. The intensity of this ef- respect to the laser beam; this signal is sent, through a quartz

fect depended on the kind ŽCaCl 2 ? 2H 2 O or NaCl. and the optical fiber that ends on an interferential filter, to a photo-

concentration of salt added in solution to increase chlorine multiplier tube, connected to a power supply with voltage that

concentration with respect to equimolar conditions. is variable in the 0]1000 V range. The signal of the transmit-

The purpose of the present article is to report the evalua- ted light Ž Itrans . is collected by a photodiode located beyond

tion of the activation energy and the interfacial tension for the cell, at 08 with respect to the laser beam. The two analog

gypsum nucleation in a solution containing a fixed amount of signals of scattered and transmitted light, together with Io ,

sodium chloride. Such values are also compared with those are collected by a recorder device ŽPrisciandaro, 1998..

previously obtained ŽLanica et al., 1999., when the NaCl dis- Supersaturated solutions of calcium sulfate were prepared

solved into the gypsum mother liquor was exclusively caused by using two clear aqueous solutions of reagent-grade CaCl 2 ?

by the presence of Naq and Cly ions in the feed solution 2H 2 O and Na 2 SO4 in bidistilled water. The dissolved Ca2q

salts. ion concentration was measured by EDTA titration using

Idranal Pellets ŽRiedel-de Haen. as an indicator, while SO42y

ion concentration was measured by means of turbidity mea-

surements carried out in a spectrophotometer Ž Hach,

Experimental Apparatus and Procedure DRELr5.. After their preparation the two solutions were fil-

The experimental apparatus consists of a stirred reactor tered by using a 0.22-m m filter ŽMillipore. and a vacuum

with a related optical device, and is shown in Figure 1. The pump, in order to eliminate all foreign material inevitably

reactor is a batch cylindrical crystallizer, made of glass, with present in the solution, and then mixed directly into the reac-

a working volume of 1.0=10y3 m3 and diameter of 0.09 m. tor. The concentration of CaCl 2 ? 2H 2 O and Na 2 SO4 varied

The crystallizer is surrounded by a water jacket for tempera- between 38 molrm3 and 94 molrm3. Excess of chlorine ion

ture control; stirring is provided by a two-blade polypropy- with respect to the equimolar feed was obtained by adding an

lene stirrer, with rotation rate ranging between 1 and 10 sy1. amount of NaCl, whose concentration in the reactor solution

An offtake tube, placed at half of the working height of the varied between 19 and 60 molrm3, therefore the concentra-

vessel, allows the removal of samples of the suspension; the tion of Cly ranged from 57 molrm3 to 180 molrm3.

position of the tube has been chosen to ensure that the con- The supersaturation was calculated considering the follow-

y

tent of the exit stream is the same as the content of the reac- ing liquid]solid equilibrium between Ca2q and SO42 ions

tor ŽZacek et al., 1982.. and solid CaSO4 ? 2H 2 O:

The stream removed by the offtake tube is sent by a peri-

y

staltic pump to an analysis flowthrough cell, and then is con- Ca2q qSO42 q2H 2 OsCaSO4 ? 2H 2 O Ž1.

veyed again to the crystallizer. The cell, made of quartz, is

0.07 m long, with a square section of 0.01 m and 0.0025 m so that it is

thickness. A 10-m W He]Ne laser beam Ž I0 s632.8 nm. is

focused on the cell, orthogonal to its walls; the beam is verti- aCa2q aSO42 y a2w

cally polarized with a diameter of 2 mm. On the path of the ss , Ž2.

K ps

laser, placed at 458 with respect to beam direction, a beam

930 April 2001 Vol. 47, No. 4 AIChE Journal

where a I is the activity expressed as the product of the molal-

ity Ž m I . and the activity coefficient Žg I . of the I species Ž I s

Ca2q, SO42y, and water., and K p s is the solubility product of

gypsum. The value of K ps was calculated as a function of

temperature by means of the following relationship:

ln Ž K ps . s 390.9619y152.6246 log T y12545.62rT

q0.0818493T Ž3.

obtained by Marshall and Slusher Ž1966. for calcium sulfate

dihydrate in aqueous sodium chloride solutions from 08C to

1108C Žsee also Barba et al., 1982; and Budz et al., 1986.. The

activity coefficient calculations in the supersaturated solution

were performed by using the Bromley Ž1973. approach and

are reported in a previous work ŽLancia et al., 1999..

The excess of Cly ions has been defined as follows:

w Cly x y Cly

eqm

Es , Ž4. Figure 2. Intensities of the scattered ( Isca ) and trans-

Cly

eqm mitted ( Itrans ) light as a function of time for

different values of supersaturation.

where Cly is the molar concentration of chlorine in solution, T s 258C, E s 0, no additives; A curves; s s 2.6, B curves:

and Cly s s 2.4.

eqm is the chlorine introduced in solution through the

equimolar feed as CaCl 2 ? 2H 2 O.

All experiments have been carried out for a fixed value of

chlorine excess, namely Es 0.5. Supersaturation was varied the case of Es 0 ŽLancia et al., 1999. and reported in Figure

in the 2]4 range and four temperature levels were explored, 5 Ždotted line., still remains. However, the slope of the straight

specifically 25, 35, 50 and 708C. lines is higher when Es 0.5, suggesting that when a chlorine

The induction period was evaluated by measuring the in- excess is present in the solution, the effect of T on t ind is

tensity of scattered and transmitted light as a function of time stronger than in the case of equimolarity ŽLancia et al., 1999..

and by adopting two parallel procedures, one graphical and Figure 6 shows the dependence of the induction period on

the other one numerical, as described in detail elsewhere supersaturation for three temperature levels}that is, 25, 50

ŽLancia et al., 1999., which gave quite similar Ž"10%. re- and 708C}for Es 0.5. It can be observed that the induction

sults. period for gypsum nucleation continuously decreases with in-

creasing supersaturation. By using the following semiempiri-

Results and Discussion

In Figures 2 and 3 the smoothed curves of IscarI0 and

ItransrI0 are reported as a function of time for T s 258C and

for two different values of supersaturations Ž s s 2.4 and 2.6.;

in particular, Figure 2 refers to stoichiometric conditions Ž E

s 0., while Figure 3 refers to a condition in which an excess

of chlorine ions has been added in the solution as NaCl

Ž c NaCl s 56 molrm3, curves C; c NaCl s 50 molrm3, curves D .,

for which Es 0.5. Figures 2 and 3 show the strong influence

exerted by supersaturation on the induction period Žsee

Mullin, 1993.. The comparison among curves in Figure 2 and

those in Figure 3 shows well that when a chlorine excess is

present in solution ŽFigure 3., with respect to equimolar con-

ditions, it inhibits gypsum nucleation kinetics with respect to

the case of Es 0 ŽFigure 2. ŽLancia et al., 1999..

In Figure 4 the smoothed curves of IscarI0 and ItransrI0 are

reported as a function of time for s s 2.6, Es 0.5, and for

three different temperature values ŽT s 25, 50 and 708C..

These figures clearly show the strong effect of temperature

on the induction period, which decreases as the temperature

increases. Figure 3. Intensities of the scattered ( Isca ) and trans-

Figure 5 reports the logarithm of t ind vs. 1rT for three mitted ( Itrans ) light as a function of time for

different levels of supersaturation Ž Es 0.5; s s 2.4, 2.6, 3.0.. different values of supersaturation.

The linear relationship existing between the logarithm of t ind T s 258C, E s 0.5; C curves: c NaCl s 56 molrm 3, s s 2.6; D

and the inverse of the absolute temperature, already found in curves: c NaCl s 50 molrm 3, s s 2.4.

AIChE Journal April 2001 Vol. 47, No. 4 931

Figure 4. Intensities of the scattered ( Isca ) and trans-

Figure 6. Induction period as a function of supersatura-

mitted ( Itrans ) light as a function of time for

tion.

different values of temperature.

Es 0.5; `: T s 258C; I: T s 508C; D: T s 708C.

s s 2.6, E s 0.5.

istic parameters of primary nucleation, such as the activation

cal correlation to correlate experimental data ŽPackter, 1974.,

energy and the interfacial tension.

For this purpose or aim, the following equation derived

K from homogeneous nucleation equations, was considered ŽHe

t ind s , Ž5.

sr et al., 1994.:

A2

where K and r are empirical constants, the curves sketched log Ž t ind . s A1 q , Ž6.

2

in Figure 6 are obtained. In particular, a nonlinear regression T 3 Ž log s .

analysis gives K s1.1=10 5, 5.1=10 4 and 3.8=10 4 s for T s

25, 50 and 708C, respectively; while r is almost independent where A1 is an empirical constant and A 2 is given by

of temperature and equal to 5.0 A similar behavior was previ-

ously obtained for the case of Es 0 by Lancia et al. Ž1999.. hgs3m2 NA f

Experimental data of the induction period plotted as a A2 s , Ž7.

function of supersaturation levels can be adequately used, as Ž 2.3 R . 3

¨

suggested by Sohnel and Garside Ž1992., to distinguish be-

tween homogeneous and heterogeneous nucleation phenom- in which h is a shape factor, g S is the surface energy, NA is

ena. This is worth noting in the estimation of some character- the Avogadro number, R is the gas constant, m the molecular

volume, and f is a correction factor that takes into account

the heterogeneous nucleation; in particular, according to

¨

Sohnel and Mullin Ž1988., when purely homogeneous nucle-

ation takes place, it is f s1, while when heterogeneous nu-

cleation occurs, it is f -1. Consequently, a change in the slope

of the experimental results could indicate a transition from

homogeneous to heterogeneous nucleation mechanisms. In

Figure 7a, 7b, 7c, the distinction between the two nucleation

mechanisms is reported for the temperatures T s 258C, 508C,

and 708C. In Figure 7a, the passage from homogeneous to

heterogeneous nucleation is quite visible, and following the

¨

approach of Sohnel and Garside Ž1992., the experimental data

in the middle part of the plot have not been taken into ac-

count in the interpolation of the experimental results, but are

considered to belong to a ‘‘transition zone.’’

In order to gain values relative to the homogeneous nucle-

ation region solely, experiments at higher temperature ŽT s

50 and 708C. have been carried out for a very high value of

Figure 5. Dependence of the induction period on the in- supersaturation Žsuch as for very low values of 1rŽlog s . 2 ..

verse of temperature. In particular, considering the influence of temperature on the

Es 0.5; `: s s 2.4; I: s s 2.6; D: s s 3.0. induction period Žsee Figure 4., at a high temperature the

932 April 2001 Vol. 47, No. 4 AIChE Journal

surrounding aqueous solution can be easily performed. The

following empirical relationship, proposed by Liu and Nan-

collas Ž1975., was used to correlate data of t ind vs. T :

Eatt

t ind st exp ž / , Ž8.

RT

where t is a constant, Eatt is the activation energy for the

process, and R is the gas constant. In particular, Eq. 8 was

reported as continuous lines in Figure 5, and from the slopes

of these straight lines the value of 49.7 kJrmol was deter-

mined for the activation energy. This value is higher than

that previously found Ž Eatt s 30 kJrmol; Lancia et al., 1999.,

leading to a slower nucleation kinetic.

As regards the interfacial tension values, from the slopes

of the straight lines reported in Figure 7a, 7b, 7c, relative to

the homogeneous nucleation region, the average value of 37.8

mJrm2 was evaluated win Eq. Ž7. it was considered that h s

16pr3, assuming spherical particles, and m s 74.69 cm3rmolx.

The comparison among the interfacial tension values ob-

tained for different temperature levels in the presence Žgs s

37.8 mJrm2 . and in the absence of excessive chlorine Žgs s

36.8 mJrm2 ., indicates that the interfacial tension between

gypsum crystals and the aqueous solution is not influenced by

the presence of NaCl.

Conclusions

The induction period for gypsum nucleation has been ex-

perimentally measured by using an optical technique for a

supersaturation ranging from 2 to 4, a temperature varying

between 25 and 708C, and with a chlorine excess E, added as

NaCl, that is equal to 0.5. Activation energy for gypsum crys-

tallization and the interfacial tension between gypsum crys-

tals and the aqueous solution have been calculated by means

of the experimental measurements of induction time. These

values have been compared with those previously estimated

in the absence of a chlorine excess, and the following conclu-

Figure 7. Induction period as a function of supersatura- sions have been reached:

tion. v The temperature has a strong accelerating effect on gyp-

E s 0.5; Ža . T s 258C; Žb . T s 508C; Žc . T s 708C; `: homo-

geneous nucleation; I: transition zone; D: heterogeneous

sum nucleation kinetics, by reducing the induction period val-

nucleation. ues, and this effect is stronger when Es 0.5 with respect to

the case of Es 0;

v The supersaturation is indeed able to accelerate the pre-

cipitation phenomenon, and the intensity of its effect is higher

passage from homogeneous to heterogeneous nucleation

at low temperature;

mechanism takes place at low values of s Žthat is, at the high

v The effect of NaCl on the induction period is more

value of 1rŽlog s . 2 ., therefore in the plot log Ž t ind . vs. 1rŽlog

marked at low temperature values than at high temperatures;

s . 2 , the transition region moves toward the right. For this

v The delay of the primary nucleation of gypsum in the

reason, a supersaturation level higher than 3 Žthat is, 1rŽlog

s . 2 - 4.5. appeared sufficient to restrict the experimental re- presence of a chlorine excess is confirmed by the activation

sults to the desired homogeneous region. Figure 7b and 7c energy value, which is higher when Es 0.5 Ž49.7 kJrmol. with

show experimental results relative to T s 50 and 708C, re- respect to the case of Es 0 Ž30 kJrmol.;

v The interfacial tensions between crystal and solution is

spectively; in these figures it is possible to recognize the ho-

mogeneous region, as well as some experimental data belong- of 37.8 mJrm2 , which does not vary significantly in the tem-

ing to the transition region toward the heterogeneous nucle- perature interval explored, and that is not influenced by the

ation mechanism. presence of NaCl in solution.

Once the distinction between homogeneous and heteroge-

neous nucleation data have been made, the estimation of the Notation

activation energy for the primary nucleation of gypsum and asactivity, molrm3

the interfacial tension between the gypsum crystals and the A1 sconstant in Eq. 6, dimensionless

AIChE Journal April 2001 Vol. 47, No. 4 933

A 2 sconstant in Eq. 6, K 3 ties on the Continuous Precipitation of Calcium Sulphate

csconcentration, molrm3 ŽGypsum.,’’ J. Chem. Tech. Biotechnol., 36, 153 Ž1986..

Eschlorine excess as defined by Eq. 4, dimensionless Etherton, D. L., and A. D. Randolph, ‘‘NucleationrGrowth Rate Ki-

Eatt sactivation energy, Jrmol netics of Gypsum in Simulated FGD Liquors: Some Process Con-

f scorrection factor in Eq. 7, dimensionless figurations for Increasing Particle Size,’’ AIChE Symp. Ser., 77, 87

I sintensity of light, Wrm2 Ž1981..

K sconstant in Eq. 5, s He, S., J. E. Oddo, and M. B. Tomson, ‘‘The Nucleation Kinetics of

K p s ssolubility product, mol 4rkg 4 Calcium Sulfate Dihydrate in NaCl Solutions up to 6 m and 908C,’’

NA sAvogadro number, moly1 J. Colloid Interface Sci., 162, 297 Ž1994..

r sconstant in Eq. 5, dimensionless Lancia, A., D. Musmarra, and M. Prisciandaro, ‘‘Measurement of

Rsgas constant, Jrmol K the Induction Period for Calcium Sulfate Dihydrate Precipitation,’’

t stime, s AIChE J., 45, 390 Ž1999..

t ind sinduction period, s Liu, S. T., and G. H. Nancollas, ‘‘A Kinetic and Morphological Study

tU strue induction period, s of the Seeded Growth of Calcium Sulfate Dihydrate in the Pres-

T sabsolute temperature, K ence of Additives,’’ J. Colloid Interface Sci., 52, 593 Ž1975..

V svolume, m3 Marshall, W. L., and R. Slusher, ‘‘Thermodynamics of Calcium Sul-

fate Dihydrate in Aqueous Sodium Chloride Solutions, 0]1108,’’ J.

Greek letters Phys. Chem., 70, 4015 Ž1966..

Mullin, J. W., Crystallization, 3rd ed., Butterworth-Heinemann, Ox-

g sactivity coefficient, dimensionless ford Ž1993..

gs ssurface energy, Jrm2 Nielsen, A. E., Kinetics of Precipitation, Pergamon Press, Oxford

h sshape factor, dimensionless Ž1964..

l0 swavelength, m ¨

Oner, M., O.¨ Dogan, and G. Oner,

¨ ‘‘The Influence of Polyeletrolytes

m smolecular volume, m3rmol Architecture on Calcium Sulfate Dihydrate Growth Retardation,’’

s ssupersaturation, dimensionless J. Cryst. Growth, 186, 427 Ž1998..

t sconstant in Eq. 8, s Packter, A., ‘‘The Precipitation of Calcium Sulphate Dihydrate from

Aqueous Solution}Induction Period, Crystal Numbers and Final

Subscripts Size,’’ J. Cryst. Growth, 21, 191 Ž1974..

Prisciandaro, M., ‘‘Crystallizzazione del Solfato di Calcio Biidrato

abs sabsorption

nel Processo di Desolforazion ad Umido dei Fumi della Combus-

eqm sequimolar

tione,’’ PhD Diss. Univ. of Naples ‘‘Federico II,’’ Naples, Italy

sca sscattering Ž1998..

trans stransmitted

Prisciandaro, M., A. Lancia, and D., Musmarra, ‘‘The Influence of

w swater

Typical FGD Impurities on Gypsum Nucleation,’’ Proc. Symp. on

0 srelative to incident light

Industrial Crystallization, Cambridge, UK Ž1999..

¨

Sohnel, O., and J. Garside, Precipitation, Butterworth-Heinemann,

Literature Cited Oxford Ž1992..

¨

Sohnel, O., and J. W., Mullin, ‘‘A Method for the Determination of

Amjad, A. B., and J. Hooley, ‘‘Influence of Polyelectrolytes on the Precipitation Induction Periods,’’ J. Cryst. Growth, 44, 377 Ž1978..

Crystal Growth of Calcium Sulphate Dihydrate,’’ J. Colloid Inter- ¨

Sohnel, O., and J. W. Mullin, ‘‘Interpretation of Crystallization In-

face Sci., 111, 496 Ž1986.. duction Periods,’’ J. Colloid Interface Sci., 123, 43 Ž1988..

Barba, D., V. Brandani, and G. Di Giacomo, ‘‘A Thermodynamic Zacek, S., J. Nyvlt, J. Garside, and A. W. Nienow, ‘‘A Stirred Tank

Model of CaSO4 Solubility in Multicomponent Aqueous Solutions,’’ for Continuous Crystallization Studies,’’ Chem. Eng. J., 23, 111

Chem. Eng. J., 24, 191 Ž1982.. Ž1982..

Bromley, L. A., ‘‘Thermodynamic Properties of Strong Electrolytes

in Aqueous Solutions,’’ AIChE J., 19, 313 Ž1973..

Budz, J., A. G. Jones, and J. W. Mullin, ‘‘Effect of Selected Impuri- Manuscript recei®ed Dec. 8, 1999, and re®ision recei®ed Aug. 8, 2000.

934 April 2001 Vol. 47, No. 4 AIChE Journal

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Concrete CanvasDocument20 pagesConcrete CanvasJet Espejon JavierNo ratings yet

- Journal of Bacteriology 1991 Gormley 6705.fullDocument4 pagesJournal of Bacteriology 1991 Gormley 6705.fullDarwin Barra TorresNo ratings yet

- Spray Dry Manual: ©2005 BETE Fog Nozzle, IncDocument25 pagesSpray Dry Manual: ©2005 BETE Fog Nozzle, IncDarwin Barra TorresNo ratings yet

- T Carbopol 2016 UK 2Document4 pagesT Carbopol 2016 UK 2Darwin Barra TorresNo ratings yet

- MD0106E GE Series 170629Document8 pagesMD0106E GE Series 170629Darwin Barra TorresNo ratings yet

- HTSTDocument22 pagesHTSTDarwin Barra TorresNo ratings yet

- Molinos SkioldDocument227 pagesMolinos SkioldDarwin Barra TorresNo ratings yet

- Liquid ring vacuum pumps in compact designDocument7 pagesLiquid ring vacuum pumps in compact designDarwin Barra TorresNo ratings yet

- Modelling in Crystallography: What Is X-Ray Crystal Structure Analysis?Document49 pagesModelling in Crystallography: What Is X-Ray Crystal Structure Analysis?Darwin Barra TorresNo ratings yet

- 3-A Sanitary Standards, IncDocument81 pages3-A Sanitary Standards, IncDarwin Barra TorresNo ratings yet

- The New E-Series Fume Hoods CatalogDocument48 pagesThe New E-Series Fume Hoods CatalogDarwin Barra TorresNo ratings yet

- 2 - Cleaning and Shaping in EndodonticsDocument299 pages2 - Cleaning and Shaping in EndodonticsElisabeth MarofNo ratings yet

- Agoo Montessori Learning Center and High School Inc.: Fruit Waste As Biodegradable PlasticDocument6 pagesAgoo Montessori Learning Center and High School Inc.: Fruit Waste As Biodegradable PlasticAlejandro De la GarzaNo ratings yet

- Chapter-1 Classification of MaterialsDocument46 pagesChapter-1 Classification of MaterialstrfuawlachewNo ratings yet

- Dynamic Balancing of Hydronic SystemsDocument65 pagesDynamic Balancing of Hydronic Systems黃偉哲100% (4)

- Class 10 science lab exam MCQ questionsDocument4 pagesClass 10 science lab exam MCQ questionsDonkeyNo ratings yet

- Power Distribution at NFC EeeDocument70 pagesPower Distribution at NFC EeeTeEbhan ChAnthira SeEkaranNo ratings yet

- MotionDocument6 pagesMotionRobert willaimsNo ratings yet

- 2014 Ifa Phosphate Method PDFDocument21 pages2014 Ifa Phosphate Method PDFsanford siegelNo ratings yet

- Nucleic Acids BrochureDocument2 pagesNucleic Acids BrochureCring-cring NavarroNo ratings yet

- Standard dimensions and data for steel and stainless steel pipe sizesDocument7 pagesStandard dimensions and data for steel and stainless steel pipe sizesRSGatesNo ratings yet

- How buffers maintain pH levelsDocument4 pagesHow buffers maintain pH levelsManP13No ratings yet

- Cape Chemistry Unit Ii Module I Alkanes and Alkenes Worksheet and Revision GuideDocument5 pagesCape Chemistry Unit Ii Module I Alkanes and Alkenes Worksheet and Revision GuideDestinee SullivanNo ratings yet

- World Fertilizer Trends and Outlook To 2020Document38 pagesWorld Fertilizer Trends and Outlook To 2020SudhirNo ratings yet

- Rition Feeaing: Ruminant AnatomyDocument30 pagesRition Feeaing: Ruminant AnatomySMP SeriesNo ratings yet

- RN FDocument52 pagesRN Fhassan SardarNo ratings yet

- ASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire ApparatusDocument3 pagesASTM D 2821 - 00 Measuring The Relative Stiffness of Leather by Means of A Torsional Wire Apparatusalin2005No ratings yet

- Spontaneous Combustion ConversionDocument68 pagesSpontaneous Combustion ConversionRizwan Ullah BaigNo ratings yet

- E Booklet Feeding The ChakrasDocument20 pagesE Booklet Feeding The ChakrasVibrating PickleNo ratings yet

- Lightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiDocument6 pagesLightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiAfzalNo ratings yet

- Filter Elements, Parts for Compressors and EnginesDocument2 pagesFilter Elements, Parts for Compressors and Enginespgm900No ratings yet

- 109 Sodium ChlorideDocument6 pages109 Sodium Chlorideeng20072007No ratings yet

- (VESBO) Catalog en 100317Document55 pages(VESBO) Catalog en 100317AnhNguyen100% (1)

- UNIT III TheoryDocument6 pagesUNIT III TheoryRanchuNo ratings yet

- Chinese GMP 2010Document115 pagesChinese GMP 2010Atul SharmaNo ratings yet

- Adam Lechter: Resident Course in Confectionery TechnologyDocument73 pagesAdam Lechter: Resident Course in Confectionery TechnologyJulio KinenNo ratings yet

- Istory of Jellyfish Envenomation: 3.1.1. Class Cubozoa - Cubozoan JellyfishDocument16 pagesIstory of Jellyfish Envenomation: 3.1.1. Class Cubozoa - Cubozoan JellyfishRangsiyo BeabeoNo ratings yet

- Catalysis Norskov 05 15 02Document36 pagesCatalysis Norskov 05 15 02Rafael Ricardo Celin ManceraNo ratings yet

- Journal of Environmental ManagementDocument12 pagesJournal of Environmental ManagementAjeng FadillahNo ratings yet

- KaMin™ 2000C - Calcined Kaolin ClayDocument1 pageKaMin™ 2000C - Calcined Kaolin Claymarco_ravelo_10No ratings yet