Professional Documents

Culture Documents

Aadg18080qr412s 3 W2

Uploaded by

pacote8920Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aadg18080qr412s 3 W2

Uploaded by

pacote8920Copyright:

Available Formats

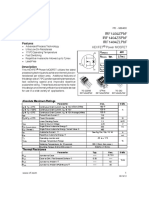

AADG18080QR412S/3 SERIES

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

DISCHARGE

SENSITIVE

DEVICES

Features

●Super high flux output and high luminance.

●Designed for high current operation.

●Low thermal resistance. Applications

●Silicone resin with glass lens. z Substitution of micro incandescent lamps.

●Compatible with IR-reflow processes. z Portable light source.

z Signal and symbol luminaire for orientation.

●ESD protection .

z Marker lights (e.g. steps, exit ways, etc).

●Package : 500pcs / reel.

z Decorative and entertainment lighting.

●RoHS compliant.

z Commercial and residential lighting.

z Emergency-vehicle lighting.

Application Note

Static electricity and surge damage the LEDS.

It is recommended to use a wrist band or anti-electrostatic

glove when handling the LEDs.

All devices, equipment and machinery must be electrically

Package Dimensions grounded.

Notes:

1. All dimensions are in millimeters (inches).

2. Tolerance is ±0.25(0.01") unless otherwise noted.

3. Specifications are subject to change without notice.

4. The device has a single mounting surface. The device must be mounted according to the specifications.

SPEC NO: DSAK4167 REV NO: V.2 DATE: APR/27/2010 PAGE: 1 OF 9

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.F.Lv

Flux Characteristics at 700mA Ambient Temperature, Ta = 25°C

Typical Luminous

Luminous Flux (lm)

Erp Color Part No. Flux (lm) [1]

@ 700mA [1]

Code. Min. Max. Typ.

C2 120 140

Cool White C3 140 160

1201200318 AADG18080QR412S/3-C1 160

(InGaN) C4 160 180

C5 180 210

C1 100 120

Neutral White C2 120 140

1201200326 AADG18080QR412S/3-N1 140

(InGaN) C3 140 160

C4 160 180

C1 100 120

Warm White C2 120 140

1201200328 AADG18080QR412S/3-W2 140

(InGaN) C3 140 160

C4 160 180

Note:

1. Minimum luminous flux performance guaranteed within published operating conditions.Kingbright maintains tolerance of +/-15% on flux.

Optical Characteristics at 700mA Ambient Temperature, Ta = 25°C

Typical

Correlated Color Viewing

Color Temperature CCT Angle [1]

(degrees)

Min. Typ. Max. 2θ1/2

Cool White 5310K 6000K 7040K 100°

Neutral White 3710K 4500K 5310K 100°

Warm White 2580K 3000K 3710K 100°

Note:

1.Viewing angle is the off axis angle from lamp centerline where the luminous intensity is 1/2 of the peak value.

SPEC NO: DSAK4167 REV NO: V.2 DATE: APR/27/2010 PAGE: 2 OF 9

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.F.Lv

Electrical Characteristics at 700mA Ambient Temperature, Ta = 25°C

Typical Temperature

Typical

Forward Voltage Vf [1] Coefficient of

Thermal

(V) Forward

Part No. Resistance

Voltage [2]

(°C/W)

(mV/°C)

Rth j-slug

ΔVf /ΔT

Min. Typ. Max.

AADG18080QR412S/3-C1 - 4.6 5.2 -4.3 7

AADG18080QR412S/3-N1 - 4.6 5.2 -4.3 7

AADG18080QR412S/3-W2 - 4.6 5.2 -4.3 7

Notes:

1.Kingbright maintains a tolerance of +/- 0.1V on forward voltage measurements.

2.Measured between 25 °C < TJ < 130 °C at IF = 700 mA.

Absolute Maximum Ratings

Parameter Cool White / Neutral White / Warm White

DC Forward Current (mA) [1] 700

Peak Pusled Forward Current (mA) 1000

Average Forward Current (mA) 700

Reverse Voltage (V) 5

ESD Sensitivity 8000V HBM

LED Junction Temperature (°C) 130

Operation Temperature (°C) -40 to+100

Storage Temperature (°C) -40 to+110

Soldering Temperature (°C) 260 For 5 Seconds

Notes:

1. Proper current derating must be observed to maintain junction temperature below the maximum.

Moisture Sensitivity

AADG18080 LEDs are packaged in airtight and moisture-resistant bags to prevent moisture absorption which may lead to

catastrophic failure in reflow soldering process. Kingbright recommends that the devices must be baked before soldering if

they are removed from the original package, and are exposed to environmental conditions for longer than the durations

(unit: days) defined in the table below. Recommended baking conditions are 24 hours at 80ºC.

Maximum Percent Relative Humidity

Temperature

30% 40% 50% 60% 70% 80% 90%

30°C 9 5 4 3 1 1 1

25°C 12 7 5 4 2 1 1

20°C 17 9 7 6 2 2 1

Storage Conditions

After being removed from the original sealed package, AADG18080 LEDs should be stored at a temperature of 25 ºC with a

relative humidity lower than 10%. Under such conditions, storage duration is excluded from the exposure duration as defined

in the Moisture Sensitivity section.

SPEC NO: DSAK4167 REV NO: V.2 DATE: APR/27/2010 PAGE: 3 OF 9

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.F.Lv

Wavelength Characteristics Ta = 25°C

Light Output Characteristics

SPEC NO: DSAK4167 REV NO: V.2 DATE: APR/27/2010 PAGE: 4 OF 9

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.F.Lv

SPEC NO: DSAK4167 REV NO: V.2 DATE: APR/27/2010 PAGE: 5 OF 9

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.F.Lv

CCT 2500-7000 K Bin Code

0.44

3000 K 2500 K

4000 K

0.42 1

3

5

7

9

0.40 4 2

11 6

5000 K 13 8

15 10 W1

0.38 12

17 14 W2

y

6000 K 16 W3

19

0.36 21 18

20

N1

7000 K 23

22

0.34 25

24 N2

27

26

0.32

28

C1

0.30

0.28 0.30 0.32 0.34 0.36 0.38 0.40 0.42 0.44 0.46 0.48 0.50

x

CCT (K)

Color Group Chromaticity Regions

Min. Typ. Max.

W1 1, 2, 3, 4 2580 2700 2870 Notes:

Warm White W2 5, 6, 7, 8 2870 3000 3220 Shipment may contain more than one chromaticity

W3 9, 10, 11, 12 3220 3500 3710 regions.

Orders for single chromaticity region are

N1 13, 14, 15, 16 3710 4000 4260

Neutral White generally not accepted.

N2 17, 18, 19, 20, 21, 22 4260 4700 5310 Measurement tolerance of the chromaticity coordi-

Cool White C1 23, 24, 25, 26, 27, 28 5310 6000 7040 nates is ±0.02.

x y x y x y x y

0.4582 0.4099 0.4147 0.3814 0.3702 0.3722 0.3481 0.3557

0.4687 0.4289 0.4221 0.3984 0.3736 0.3874 0.3370 0.3472

1 8 15 22

0.4813 0.4319 0.4342 0.4028 0.3869 0.3958 0.3364 0.3328

0.4700 0.4126 0.4259 0.3853 0.3825 0.3798 0.3466 0.3411

0.4483 0.3919 0.4080 0.3916 0.3670 0.3578 0.3376 0.3616

0.4582 0.4099 0.4146 0.4089 0.3702 0.3722 0.3260 0.3512

2 9 16 23

0.4700 0.4126 0.4299 0.4165 0.3825 0.3798 0.3265 0.3371

0.4593 0.3944 0.4221 0.3984 0.3783 0.3646 0.3370 0.3472

0.4465 0.4071 0.4017 0.3751 0.3736 0.3874 0.3370 0.3472

0.4562 0.4260 0.4080 0.3916 0.3616 0.3788 0.3265 0.3371

3 10 17 24

0.4687 0.4289 0.4221 0.3984 0.3592 0.3641 0.3270 0.3230

0.4582 0.4099 0.4147 0.3814 0.3703 0.3726 0.3364 0.3328

0.4373 0.3893 0.3941 0.3848 0.3703 0.3726 0.3260 0.3512

0.4465 0.4071 0.3996 0.4015 0.3592 0.3641 0.3144 0.3408

4 11 18 25

0.4582 0.4099 0.4146 0.4089 0.3568 0.3495 0.3160 0.3274

0.4483 0.3919 0.4080 0.3916 0.3670 0.3578 0.3265 0.3371

0.4342 0.4028 0.3889 0.3690 0.3616 0.3788 0.3265 0.3371

0.4430 0.4212 0.3941 0.3848 0.3496 0.3702 0.3160 0.3274

5 12 19 26

0.4562 0.4260 0.4080 0.3916 0.3481 0.3557 0.3175 0.3139

0.4465 0.4071 0.4017 0.3751 0.3592 0.3641 0.3270 0.3230

0.4259 0.3853 0.3825 0.3798 0.3592 0.3641 0.3144 0.3408

0.4342 0.4028 0.3869 0.3958 0.3481 0.3557 0.3028 0.3304

6 13 20 27

0.4465 0.4071 0.4006 0.4044 0.3466 0.3411 0.3055 0.3177

0.4373 0.3893 0.3950 0.3875 0.3568 0.3495 0.3160 0.3274

0.4221 0.3984 0.3783 0.3646 0.3496 0.3702 0.3160 0.3274

0.4299 0.4165 0.3825 0.3798 0.3376 0.3616 0.3055 0.3177

7 14 21 28

0.4430 0.4212 0.3950 0.3875 0.3370 0.3472 0.3081 0.3049

0.4342 0.4028 0.3898 0.3716 0.3481 0.3557 0.3175 0.3139

SPEC NO: DSAK4167 REV NO: V.2 DATE: APR/27/2010 PAGE: 6 OF 9

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.F.Lv

Reflow soldering is recommended and the soldering profile is shown below.

Other soldering methods are not recommended as they might cause damage to the product.

Heat Generation:

1.Thermal design of the end product is of paramount importance.Please consider the heat generation of the LED when making

the system design. The coefficient of temperature increase per input electric power is affected by the thermal resistance of the

circuit board and density of LED placement on the board ,as well as other components. It is necessary to avoid intense heat gen-

eration and operate within the maximum ratings given in this specification.

2.Please determine the operating current with consideration of the ambient temperature local to the LED and refer to the plot

of Permissible Forward current vs. Ambient temperature on CHARACTERISTICS in this specification. Please also take meas-

ures to remove heat from the area near the LED to improve the operational characteristics on the LED.

3.The equation ① indicates correlation between Tj and Ta ,and the equation ② indicates correlation between Tj and Ts

Tj = Ta + Rthj-a *W ……… ①

Tj = Ts + Rthj-s *W ……… ②

Tj = dice junction temperature: ℃

Ta = ambient temperature:℃

Ts = solder point temperature:℃

Rthj-a = heat resistance from dice junction temperature to ambient temperature : ℃ /W

Rthj-s = heat resistance from dice junction temperature to Ts measuring point : ℃ /W

W = inputting power (IFx VF) : W

SPEC NO: DSAK4167 REV NO: V.2 DATE: APR/27/2010 PAGE: 7 OF 9

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.F.Lv

Recommended Soldering Pattern

(Units : mm ; Tolerance: ± 0.1)

Tape Dimensions

(Units : mm)

Reel Dimension

SPEC NO: DSAK4167 REV NO: V.2 DATE: APR/27/2010 PAGE: 8 OF 9

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.F.Lv

PACKING & LABEL SPECIFICATIONS AADG18080QR412S/3 SERIES

SPEC NO: DSAK4167 REV NO: V.2 DATE: APR/27/2010 PAGE: 9 OF 9

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.F.Lv

You might also like

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Why Why Analysis Presentation-TPm-training-materialDocument43 pagesWhy Why Analysis Presentation-TPm-training-materialsaravanananusha67% (6)

- Hydrogen EngineDocument4 pagesHydrogen EnginerajmehaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- ABB Motors for Hazardous AreasDocument65 pagesABB Motors for Hazardous Areaslaem269No ratings yet

- D92 02 Ultar Fest PDFDocument5 pagesD92 02 Ultar Fest PDFCicero MelloNo ratings yet

- D000-EL-701 Rev 4Document19 pagesD000-EL-701 Rev 4Sardar PerdawoodNo ratings yet

- Self PublishingDocument84 pagesSelf PublishingFrancesco CusumanoNo ratings yet

- Commander SK Size 2 To 6 Getting Started GuideDocument80 pagesCommander SK Size 2 To 6 Getting Started GuidesunhuynhNo ratings yet

- 3.5X3.5 MM SMD Chip Led Lamp: AttentionDocument6 pages3.5X3.5 MM SMD Chip Led Lamp: AttentionAbel GaunaNo ratings yet

- High Frequency DiodeDocument12 pagesHigh Frequency DiodeCarlos IbaNo ratings yet

- ET-3528-C 1W White Datasheet: PLCC SeriesDocument11 pagesET-3528-C 1W White Datasheet: PLCC SeriesconganthonNo ratings yet

- LM4702Document16 pagesLM4702lynx12155100% (1)

- 497 3542 5 DatasheetzDocument7 pages497 3542 5 DatasheetzOmar MelchorNo ratings yet

- Everlight Elec 99 213UMC 384947D TR8 T - C192920Document15 pagesEverlight Elec 99 213UMC 384947D TR8 T - C192920trollkfhNo ratings yet

- DMTH6016LSDQ: 60V 175°C Dual N-Channel Enhancement Mode MosfetDocument7 pagesDMTH6016LSDQ: 60V 175°C Dual N-Channel Enhancement Mode MosfetFarhan HanifNo ratings yet

- Lava DoraDocument13 pagesLava DoraRay Zander FebresNo ratings yet

- Description Features: Maximizing IC PerformanceDocument6 pagesDescription Features: Maximizing IC PerformanceHernan De OtoNo ratings yet

- STTH1R02_200V_1.5A_U-FastDocument15 pagesSTTH1R02_200V_1.5A_U-Fastrara221122raraNo ratings yet

- STTH1R02: 200 V - 1.5 A Ultrafast Recovery DiodeDocument15 pagesSTTH1R02: 200 V - 1.5 A Ultrafast Recovery DiodeAlex Nicole SanchezNo ratings yet

- T1635h-6i, T1635H-6T, T1635H-6G T1650h-6i, T1650H-6T, T1650H-6GDocument13 pagesT1635h-6i, T1635H-6T, T1635H-6G T1650h-6i, T1650H-6T, T1650H-6Gemanuel viniciusNo ratings yet

- Apbda3020Surkcgkc-Gx: 3.0 X 2.0 MM Right Angle SMD LEDDocument5 pagesApbda3020Surkcgkc-Gx: 3.0 X 2.0 MM Right Angle SMD LEDpmusNo ratings yet

- BTA12, BTB12, T12xx: 12 A Snubberless™, Logic Level and Standard TriacsDocument12 pagesBTA12, BTB12, T12xx: 12 A Snubberless™, Logic Level and Standard Triacsالعقار امين عيسىNo ratings yet

- STTH1602C: DescriptionDocument15 pagesSTTH1602C: DescriptionAndrea MartinezNo ratings yet

- SMD LED Product Data SheetDocument12 pagesSMD LED Product Data SheetHemantkumarNo ratings yet

- AL8805 Description Pin Assignments: Not Recommended For New Design USE ORDocument18 pagesAL8805 Description Pin Assignments: Not Recommended For New Design USE ORlakshmananNo ratings yet

- Stps 10120 CDocument9 pagesStps 10120 CLEWIS RODRIGUEZNo ratings yet

- STTH2002C: High Efficiency Ultrafast DiodeDocument16 pagesSTTH2002C: High Efficiency Ultrafast DiodeAseng saputraNo ratings yet

- LED Bar DesignDocument2 pagesLED Bar DesignAbir AhmedNo ratings yet

- Static / Dynamic Resistance Measurement Accessory For TM1800 / TM1600 / EGILDocument2 pagesStatic / Dynamic Resistance Measurement Accessory For TM1800 / TM1600 / EGILNilesh MahajanNo ratings yet

- Trial TVDocument18 pagesTrial TVronal lopezNo ratings yet

- Erz-E 8 11Document8 pagesErz-E 8 11Pușcă MartinNo ratings yet

- Fsp-A: Surge Protective Device (AC SPD)Document1 pageFsp-A: Surge Protective Device (AC SPD)khuongNo ratings yet

- Fire Research Corporation: TOLL FREE 1.800.645.0074Document2 pagesFire Research Corporation: TOLL FREE 1.800.645.0074sebastianrockNo ratings yet

- TRANSISTOR - IRF1404ZPbFDocument12 pagesTRANSISTOR - IRF1404ZPbFFelipe FerreiraNo ratings yet

- MT7842 MaxicTechnologyDocument6 pagesMT7842 MaxicTechnologyHeart of mountainNo ratings yet

- EPS 901-123 - Rev R - IOPDocument2 pagesEPS 901-123 - Rev R - IOPFarhan YassarNo ratings yet

- LED Bar DesignDocument2 pagesLED Bar DesignAbir AhmedNo ratings yet

- STTH2003CT/CG/CF/CR/CFP: High Frequency Secondary RectifierDocument8 pagesSTTH2003CT/CG/CF/CR/CFP: High Frequency Secondary RectifierPușcă MartinNo ratings yet

- Zone Defender SquaredDocument2 pagesZone Defender SquaredJagadesh C S NadarNo ratings yet

- Lighted Pushbutton Switch: Ordering InformationDocument6 pagesLighted Pushbutton Switch: Ordering InformationHeru susantoNo ratings yet

- Model ETR-9200 Automatic Tuning Smarter Logic ControllerDocument26 pagesModel ETR-9200 Automatic Tuning Smarter Logic ControllervhelectronicaNo ratings yet

- DVP-ES2 Series PLC Electrical Specifications GuideDocument19 pagesDVP-ES2 Series PLC Electrical Specifications Guidetoanck86No ratings yet

- Littelfuse Thyristor C106 D Datasheet PDFDocument5 pagesLittelfuse Thyristor C106 D Datasheet PDFExodia RaNo ratings yet

- Oval Bi-Color Led Lamp Features: Package DimensionsDocument3 pagesOval Bi-Color Led Lamp Features: Package Dimensionsrrr2013No ratings yet

- Oval Bi-Color Led Lamp Features: Package DimensionsDocument3 pagesOval Bi-Color Led Lamp Features: Package Dimensionsrrr2013No ratings yet

- BBBBBB PDFDocument3 pagesBBBBBB PDFrrr2013No ratings yet

- LED Spec Sheet ApprovalDocument20 pagesLED Spec Sheet ApprovalAnonymous G1iPoNOKNo ratings yet

- Metal Foil Low Resistance Chip Resistors: KRL 1220E - C - R010 - F - T1Document3 pagesMetal Foil Low Resistance Chip Resistors: KRL 1220E - C - R010 - F - T1Adrian SalazarNo ratings yet

- Edison Opto - PLCC 2835 HE Series - Eng - V2Document20 pagesEdison Opto - PLCC 2835 HE Series - Eng - V2Adrian Evangelist SantificNo ratings yet

- STTH 102Document12 pagesSTTH 102Abel GaunaNo ratings yet

- BTA/BTB16 and T16 Series: 16A TriacDocument7 pagesBTA/BTB16 and T16 Series: 16A TriacTarik OnalNo ratings yet

- DatasheetDocument3 pagesDatasheetStuxnetNo ratings yet

- Littelfuse Thyristor C106 D Datasheet - pdf-1372503Document6 pagesLittelfuse Thyristor C106 D Datasheet - pdf-1372503Abraham IbarraNo ratings yet

- BTA08, BTB08 T810, T835: Snubberless™, Logic Level and Standard 8 A TriacsDocument12 pagesBTA08, BTB08 T810, T835: Snubberless™, Logic Level and Standard 8 A TriacsMuhammad YunusNo ratings yet

- LCDSPLN-S-18-CDL_LCDSPLN-R-18-CDL - 16072019 (1)Document2 pagesLCDSPLN-S-18-CDL_LCDSPLN-R-18-CDL - 16072019 (1)Anilkumar KolpuruNo ratings yet

- 1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enDocument2 pages1LE1502-1EA23-4AA4-Z D22+D47 Datasheet enmohamed gomaaNo ratings yet

- AL6562ADocument16 pagesAL6562ASibi DhayalanNo ratings yet

- AT1526 GlobalMixed ModetechnologyDocument2 pagesAT1526 GlobalMixed ModetechnologyFafa MangstabNo ratings yet

- Light Boxes PDFDocument98 pagesLight Boxes PDFKhadiga AbdallahNo ratings yet

- Kubara Lamina d22!10!01-n0Document5 pagesKubara Lamina d22!10!01-n0Faulhaber AdrianNo ratings yet

- STTH3002CDocument8 pagesSTTH3002Celad kotlovskiNo ratings yet

- DMN3350LDW DiodesDocument7 pagesDMN3350LDW DiodesJuan NunesNo ratings yet

- EL2020Document14 pagesEL2020api-3825669No ratings yet

- stps20s100cfp SCHOTTKY DIODEDocument7 pagesstps20s100cfp SCHOTTKY DIODEANDREASBOULNo ratings yet

- 01 Rude DoctypeDocument215 pages01 Rude DoctypeChristal Rae Tac-anNo ratings yet

- Pune University Simulation and Modeling Question PapersDocument2 pagesPune University Simulation and Modeling Question Paperspradeepkraj22No ratings yet

- ISO 15589 1 2015, Petroleum andDocument21 pagesISO 15589 1 2015, Petroleum andamr s0% (1)

- Bennett, Stuart Virk, Gurvinder S Computer Control of Real-Time ProcessesDocument322 pagesBennett, Stuart Virk, Gurvinder S Computer Control of Real-Time ProcessesPTR77No ratings yet

- Ijsec 1.0Document3 pagesIjsec 1.0Hagi ShahidNo ratings yet

- Application of PWM Speed ControlDocument7 pagesApplication of PWM Speed ControlJMCproductsNo ratings yet

- EHP 200A 11-10-NardaDocument7 pagesEHP 200A 11-10-NardaDrughinsNo ratings yet

- Basic Principles of Counseling ProcessDocument2 pagesBasic Principles of Counseling ProcessBhavna SinghalNo ratings yet

- District Sales Manager or Territory Manager or Regional ManagerDocument3 pagesDistrict Sales Manager or Territory Manager or Regional Managerapi-121327024No ratings yet

- Tarea 2. Design - of - Machinery NortonDocument10 pagesTarea 2. Design - of - Machinery Nortonbisiosote100% (1)

- Techrite Siemens Siemens Qra Uv Flame Detection 013060323409Document14 pagesTechrite Siemens Siemens Qra Uv Flame Detection 013060323409Ali Hadi100% (1)

- Bharat Institute of EngineeringDocument2 pagesBharat Institute of EngineeringdasarioramaNo ratings yet

- As 1172.2-1999 Water Closet (WC) Pans of 6 3 L Capacity or Proven Equivalent CisternsDocument7 pagesAs 1172.2-1999 Water Closet (WC) Pans of 6 3 L Capacity or Proven Equivalent CisternsSAI Global - APACNo ratings yet

- 09250.517.gypsum DrywallDocument7 pages09250.517.gypsum DrywallNguyen BachNo ratings yet

- RapidAnalytics ManualDocument23 pagesRapidAnalytics ManualansanaNo ratings yet

- 15 Step Guide to Build Simple Electric GeneratorDocument13 pages15 Step Guide to Build Simple Electric GeneratorSeindahNyaNo ratings yet

- Solar Home Lighting System 40 Watt: (GST Inclusive Price)Document5 pagesSolar Home Lighting System 40 Watt: (GST Inclusive Price)nachiNo ratings yet

- Dilg Joincircular 2018814 - 80736aa36cDocument10 pagesDilg Joincircular 2018814 - 80736aa36clexay.mangadosiervoNo ratings yet

- QMCS 16 - 2 Process CapabilityDocument27 pagesQMCS 16 - 2 Process CapabilityalegabipachecoNo ratings yet

- R6 Relay ValveDocument2 pagesR6 Relay ValveveereshNo ratings yet

- TH3122 004 PDFDocument14 pagesTH3122 004 PDFSasa MitrovicNo ratings yet

- Legendary Units 1.1Document5 pagesLegendary Units 1.1Alejandro Sanchez GarciaNo ratings yet

- Contoh Spoof TextDocument7 pagesContoh Spoof TextIndrayaniNo ratings yet

- Report Design (Human Generater Device)Document39 pagesReport Design (Human Generater Device)dadin85No ratings yet