Professional Documents

Culture Documents

Food Manufacturing Operations Policies, Procedures, and Standards Manual

Uploaded by

Len Villamoya Simpas0 ratings0% found this document useful (0 votes)

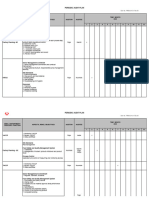

155 views2 pages1. This document provides policies, procedures, and standards for food manufacturing operations. It includes sections on management, quality assurance and control, HACCP plans, prerequisite programs, and facility cleaning and sanitation.

2. The table of contents outlines topics such as recalls, traceability, corrective actions, training programs, equipment calibration, sanitation solutions, and microbial testing.

3. Forms and logs are provided in the enclosures to document areas like temperature monitoring, sanitizer verification, training records, and cleaning checklists.

Original Description:

Original Title

HACCP Guidelines

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. This document provides policies, procedures, and standards for food manufacturing operations. It includes sections on management, quality assurance and control, HACCP plans, prerequisite programs, and facility cleaning and sanitation.

2. The table of contents outlines topics such as recalls, traceability, corrective actions, training programs, equipment calibration, sanitation solutions, and microbial testing.

3. Forms and logs are provided in the enclosures to document areas like temperature monitoring, sanitizer verification, training records, and cleaning checklists.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

155 views2 pagesFood Manufacturing Operations Policies, Procedures, and Standards Manual

Uploaded by

Len Villamoya Simpas1. This document provides policies, procedures, and standards for food manufacturing operations. It includes sections on management, quality assurance and control, HACCP plans, prerequisite programs, and facility cleaning and sanitation.

2. The table of contents outlines topics such as recalls, traceability, corrective actions, training programs, equipment calibration, sanitation solutions, and microbial testing.

3. Forms and logs are provided in the enclosures to document areas like temperature monitoring, sanitizer verification, training records, and cleaning checklists.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

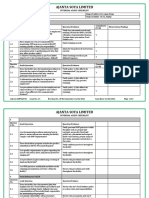

FOOD MANUFACTURING OPERATIONS

POLICIES, PROCEDURES, AND STANDARDS MANUAL

Table of Contents

PREFACE Recalls 13. Corrective action report

Traceability 14. System capability monthly audit

Log of changes to the manual

Enclosures (A) 15. USDA HACCP evaluation criteria

Food HACCP definitions

1. Employee-customer report of quality or 16. HACCP reassessment

References

hazard problem and disposition

Training Program

2. Foodborne illness information form

Training plan

3. Analysis of an alleged foodborne illness

SYSTEM AND OPERATIONS DESCRIPTION Training for performance mastery

4. Usual incubation / onset period ranges for

New employee training

Operation description select foodborne disease

Cross training

Products meet regulatory standards

QA, QC, and HACCP Team Continuing education and correct procedure

Organization and job responsibilities

QA, QC reinforcement

Environment and facilities description

Control of non-conformity Employee training records

Methods for adequate grounds

Facilities, equipment, and procedures Enclosures (C)

maintenance

MAP (Modified Atmosphere Packaging) 1. Training plan

Plant construction and design

Thermometer calibration 2. Lesson plan form

Water supply

Slush ice calibration 3. New employee training record

Plumbing

High-temperature calibration 4. Continuing education training record

Sewage disposal

Verifying refrigerator temperatures

Toilet facilities for employees

Sanitizing solutions

Hand washing facilities

Microbiological testing PREREQUISITE PROCESSES (SSOP /

Waste disposal

New product formulation and development GMP)

Facility plan and food flow

Enclosures (B)

Equipment and utensils Personal Hygiene

1. Equipment / instrument calibration and

Major equipment items Employee personal hygiene policies

verification log

Design, construction and use Individual illness and disease control

2. Refrigerator temperature log

Processes and controls Cuts and abrasions

3. Sanitizing solution verification log

Enclosures Personal cleanliness

4. Microbiological testing of production plant

1. Operation description Fingernails

food items

2. (a-c) USDA- / FDA- / FDA Fisheries- Hair restraint

5. Sample identification sheet

inspected products Jewelry and hard objects in pockets

6. Microbiological environmental testing

3. Organization chart and job responsibilities Handkerchiefs and facial tissues

report

4. Environment surrounding the facility Chewing gum, smoking, and eating

7. Product formulation (recipe) change

5. Facility plan and food flow Gloves

8. Product formulation (recipe) change

6. Major equipment items How to use gloves

checklist

Disposable gloves

9. New product development project

Heavy-duty gloves

schedule

MANAGEMENT Hand washing

10. New product / process development

Employee hand washing policies

AMC-HACCP Management HACCP Team

Double hand wash

Food safety policy Self-inspection and food hazard control

Single hand wash

Control of documents checklists

Medicines

Management responsibility and commitment HACCP team operations

First aid

Food safety management plan Member code of conduct

Hand cuts and abrasions

Evaluation of unit performance; HACCP team functioning

Contact with blood or body fluids from

management review Team membership

another person

Food safety improvement program Team leader

Enclosures (A)

Supervisor / Person In Charge (PIC) Roles individuals play in groups

Holding subordinates responsible Some major areas for HACCP team action Facility and Equipment Cleaning,

Product complaints Problem solving Sanitation, and Pest Control

Foodborne illness complaints and hoaxes HACCP team meeting, report, and Substances used in cleaning and sanitizing;

Food security corrective action storage of toxic materials

Management Filling the report Cleaning and sanitation GMPs

Human element – staff HACCP team's measures of success Pest control GMPs

Human element – public Operational improvement Pest control program

Facility HACCP reassessment Enclosures (B)

Operations Enclosures (B) 1. Cleaning and sanitizing schedule and

Food sabotage 11. Daily QA checklist pre-operations report

Emergencies 12. HACCP team monthly meeting report 2. Sanitation procedures and standards

F:ppsm-HITM: mfg-ppsm-2008-Mar tofc-3-08 rev 3/26/08 12:26 PM print 7/30/08 Table of contents 1

3. Chemicals list and material safety data FOOD PROCESS HACCP (USDA; FDA; FDA APPENDIX

sheets FISH / FISHERIES) HACCP plans

4. Pest control schedule and report HACCP recipes

General

5. Floor plan / bait placement Product specifications

Determination if a production step is a CCP

Validation studies

Facility and Equipment Maintenance Quality control operations

Technical reports

Maintenance plan and schedule, including Methods of verification

equipment calibration Ingredient hazards

Food contact surface equipment construction Food products HACCP control groups

Non-food contact surface equipment Chemical additives

construction Allergies and adverse food reactions

Equipment operation HACCP recipe, group process flow charts, and

Gaskets HACCP plans

Cooling and refrigeration units Physical hazards

Freezers Chemical hazards

Surplus equipment and items for repair Food manufacturing hazard and control rules

Dunnage racks, shelving, pallets, dollies, etc. Unprotected food items

Backflow prevention valves for plumbing Physical (hard foreign) objects

CO2 backflow prevention valves pH

Warewashing equipment Ice

Enclosures (C) Food tasting

1. Preventive maintenance schedule Surface heat blanching

2. Maintenance procedures and standards Food washing

Pasteurization

Supplies

Production process control log

Qualified suppliers

Cooling

Hazard identification of food items

Assembly and packaging

Ingredient specification

Handling

Defect action levels

Labeling

Natural or unavoidable defects at low levels

Finished products

Mixing food

Unused food

Receiving and storage

Use-by date

Receiving

Discards

Storage

Water activity

Adulteration

Shelf life validation

Aflatoxin

Frozen food

Contamination

Refrigeration units

Raw materials and other items

Thawing

Shelf-stable products

Batters, breading, sauces, gravies,

Cold storage products

dressings, and other similar preparations

Dating and use

Metal detection

Single-service articles

Food transport

Finished product storage

Hold program

Shipping

Rework

Enclosures (D)

Returned product

1. Major suppliers of products used in the

Non-human food

operation and their HACCP qualification

Packaging

2. Supplier letter – example

Enclosures

3. Supplier hazard control of items

1. Food products HACCP control groups

4. Cook controls for safe products

2. Five USDA-based food process flows

5. Supplier controls for safe products

3. Quality-assured HACCP recipe

6. Food item allergen analysis

procedures

7. Detailed list of food allergens and food

4. Food control group process flow charts

intolerance

5. Food HACCP plans

8. Ingredient specifications

6. Production schedule

9. Receiving report

7. Production process control log

10. Receiving quality control

8. Cooked product monitoring form

9. Assemble / package production record

10. Product specifications

11. Product disposal record

F:ppsm-HITM: mfg-ppsm-2008-Mar tofc-3-08 rev 3/26/08 12:26 PM print 7/30/08 Table of contents 2

You might also like

- GMP, Haccp, KPDocument27 pagesGMP, Haccp, KPannaNo ratings yet

- Activity 1Document5 pagesActivity 1Raina JainNo ratings yet

- HAZARD ANALYSIS CRITICAL CONTROL POINT (HACCP) Version 5Document47 pagesHAZARD ANALYSIS CRITICAL CONTROL POINT (HACCP) Version 5Danessa LlagasNo ratings yet

- FSMS Awareness Final PRINTDocument92 pagesFSMS Awareness Final PRINTIbnu Hasan SunandarNo ratings yet

- Training GMPDocument14 pagesTraining GMPGeeshani SilvaNo ratings yet

- Farmhouse Cheesemakers Workbook FINALDocument67 pagesFarmhouse Cheesemakers Workbook FINALIshan PoudelNo ratings yet

- Food Safety and Hygiene FinalDocument5 pagesFood Safety and Hygiene FinalBiệnCôngTrungNo ratings yet

- Quality Assurance: (PHTC 941)Document31 pagesQuality Assurance: (PHTC 941)LAZKILLERNo ratings yet

- 05 Food Safety Plan Template and Sample For FSCODocument4 pages05 Food Safety Plan Template and Sample For FSCOTeacher JoanNo ratings yet

- Haccp SopDocument20 pagesHaccp SopNor Adila Norhasmie hassanNo ratings yet

- HACCPDocument66 pagesHACCPAbubakker SiddiqNo ratings yet

- FSQ - mdl.004 ISO TS 22002-1 Awareness V BahasaDocument66 pagesFSQ - mdl.004 ISO TS 22002-1 Awareness V BahasaErmawati WidodoNo ratings yet

- Ice Cream Haccpguidelines 150405040301 Conversion Gate01Document158 pagesIce Cream Haccpguidelines 150405040301 Conversion Gate01IrisNo ratings yet

- Haccp Plan For Spice IndustryDocument7 pagesHaccp Plan For Spice IndustryOtana ENOPA100% (2)

- Haccp & Its Implementation in Food Industry: Dr. H. K. SharmaDocument58 pagesHaccp & Its Implementation in Food Industry: Dr. H. K. Sharmaankita pathaniaNo ratings yet

- FRM - mr.03.02 DaftarHadil Tinjauan ManajemenDocument4 pagesFRM - mr.03.02 DaftarHadil Tinjauan ManajemenMardhiana Sari mardhianaNo ratings yet

- FoodDocs - BRC Audit ChecklistDocument1 pageFoodDocs - BRC Audit Checklistpvmali.roshNo ratings yet

- Sample Audit Checklist For HACCPDocument16 pagesSample Audit Checklist For HACCPAprilJoyBascosNo ratings yet

- Of Methods: CompendiumDocument12 pagesOf Methods: CompendiumTesa Norberte67% (3)

- Materi Training ISO 22000 - 2018Document50 pagesMateri Training ISO 22000 - 2018Dedeq AiiyaNo ratings yet

- Haccp EmeDocument9 pagesHaccp EmeMaria Joana Abueva TabadaNo ratings yet

- 12 Steps To HACCP Defined by The Codex Alimentarius - EnglishDocument1 page12 Steps To HACCP Defined by The Codex Alimentarius - EnglishDiana RestrepoNo ratings yet

- FSSAI-manual For Edible OilDocument84 pagesFSSAI-manual For Edible Oilsrikumar75% (4)

- ECA Contamination ControlDocument6 pagesECA Contamination ControlSathish KumarNo ratings yet

- Hazard Analysis and Critical Control Points Lecture NotesDocument12 pagesHazard Analysis and Critical Control Points Lecture NotesDarlyn Denise PruebasNo ratings yet

- Quality Assurance in Food Microbiology - A Novel Approach: F.J. BoltonDocument5 pagesQuality Assurance in Food Microbiology - A Novel Approach: F.J. BoltonCalidad CODITEV SACNo ratings yet

- Audit Checklist TemplateDocument16 pagesAudit Checklist TemplateManasa Ravi100% (3)

- Sample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorDocument16 pagesSample Audit Checklist: Company Name: Luscious Bites Date of Audit: AuditorMonica SinghNo ratings yet

- Quality Assurance and AuditDocument38 pagesQuality Assurance and AuditBantuinAku KakNo ratings yet

- Quality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodDocument1 pageQuality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodMia AgustinNo ratings yet

- 4.0 Food Safety and Quality SystemDocument44 pages4.0 Food Safety and Quality SystemSiti Aisyah MahamudNo ratings yet

- Food Safety Assurance SystemsDocument8 pagesFood Safety Assurance Systemsroseliz0807No ratings yet

- Test Food Safety 2Document7 pagesTest Food Safety 2Danial IqhwanNo ratings yet

- Manufacturing PharmacyDocument19 pagesManufacturing Pharmacydiadiaida100% (1)

- Internal Audit Checklist HR - AdminDocument3 pagesInternal Audit Checklist HR - AdminRavi Baghel100% (1)

- K To 12 CG - FISH PROCESSING - v1.0Document10 pagesK To 12 CG - FISH PROCESSING - v1.0Olive AsuncionNo ratings yet

- Audit Checklist TemplateDocument16 pagesAudit Checklist TemplateAsif HabibNo ratings yet

- Bai 1. Tong Quan Ve Xu Ly Nguy Co Va GMP - ck1Document23 pagesBai 1. Tong Quan Ve Xu Ly Nguy Co Va GMP - ck1chinhnguyen102No ratings yet

- Pas 220Document71 pagesPas 220JuwitaNo ratings yet

- Good Laboratory Practice: Presented To Presented byDocument39 pagesGood Laboratory Practice: Presented To Presented byaakash sahaNo ratings yet

- Course Content: No. Course Focus Skills & KnowledgeDocument1 pageCourse Content: No. Course Focus Skills & KnowledgeNadarajanNo ratings yet

- Modul-1 Industrial Pharmacy 2021 Rev1Document13 pagesModul-1 Industrial Pharmacy 2021 Rev1Fadhilah PalensiaNo ratings yet

- Case Study 3 - Remediation Aseptic Manufacturing PDFDocument3 pagesCase Study 3 - Remediation Aseptic Manufacturing PDFManish BhatkarNo ratings yet

- Chapter 4 Food Safety and Quality SystemDocument45 pagesChapter 4 Food Safety and Quality SystemIman Fatihah100% (1)

- HND in Applied Sciences Assignment Brief - 53 Industrial MicrobiologyDocument6 pagesHND in Applied Sciences Assignment Brief - 53 Industrial MicrobiologySewmini WanderNo ratings yet

- QC2 PrelimDocument9 pagesQC2 PrelimcalopemichelleNo ratings yet

- Objectives:: Applying HACCP and GMP in Food Preservation ProcessesDocument8 pagesObjectives:: Applying HACCP and GMP in Food Preservation Processesomelkhair amenNo ratings yet

- Agilent Maritime Seminar FDA-Methods Validations Guidelines PresentationDocument19 pagesAgilent Maritime Seminar FDA-Methods Validations Guidelines PresentationSunil Murkikar (GM - PMI Quality Operations)No ratings yet

- Contoh Company ProfileDocument28 pagesContoh Company ProfileSendy Rindi FebriyantoNo ratings yet

- FSSC Document List PDFDocument1 pageFSSC Document List PDFAbubakker SiddiqNo ratings yet

- HACCPDocument28 pagesHACCPShafakatNo ratings yet

- GMP Health Supplements NutraceuticalsDocument84 pagesGMP Health Supplements NutraceuticalsSol RejoiceNo ratings yet

- Group 4 - CGMPDocument30 pagesGroup 4 - CGMPCristine BellenNo ratings yet

- Mushroom 6Document3 pagesMushroom 6Fredrick MayakaNo ratings yet

- 3M Environmental Monitoring HandbookDocument122 pages3M Environmental Monitoring HandbookMarife Montes100% (1)

- QCDocument6 pagesQCLance RafaelNo ratings yet

- Food Safety in Shrimp Processing: A Handbook for Shrimp Processors, Importers, Exporters and RetailersFrom EverandFood Safety in Shrimp Processing: A Handbook for Shrimp Processors, Importers, Exporters and RetailersNo ratings yet

- Lesson 2 - Onset, Rime, Consonant Digrapg Blending, and SegmentingDocument12 pagesLesson 2 - Onset, Rime, Consonant Digrapg Blending, and SegmentingLen Villamoya SimpasNo ratings yet

- Scriptural RosaryDocument7 pagesScriptural RosaryLen Villamoya SimpasNo ratings yet

- World Food Safety Guidelines 2010Document91 pagesWorld Food Safety Guidelines 2010Len Villamoya SimpasNo ratings yet

- HACCP in Table Egg IndustryDocument36 pagesHACCP in Table Egg IndustryLen Villamoya Simpas100% (1)

- Internship Report On Supply Chain of Nestlé BangladeshDocument45 pagesInternship Report On Supply Chain of Nestlé BangladeshAbeera IslamNo ratings yet

- Global Operations Research PaperDocument8 pagesGlobal Operations Research Paperwalter chahwetaNo ratings yet

- Purity™ D: Supply Specification (Physical & Chemical Data)Document3 pagesPurity™ D: Supply Specification (Physical & Chemical Data)Thuy PhanNo ratings yet

- CoreInternational CatalogDocument21 pagesCoreInternational CatalogNathanaelPadmonobo100% (1)

- Chapter 4 Pulp and Paper IndustryDocument19 pagesChapter 4 Pulp and Paper IndustryLTE002No ratings yet

- Fishbone Cause and Effect DiagramDocument1 pageFishbone Cause and Effect DiagramsitimaezyarohNo ratings yet

- Fresh Produce Tomato Value Chain in Bangladesh: Md. Jasim UddinDocument36 pagesFresh Produce Tomato Value Chain in Bangladesh: Md. Jasim UddinAhnaf Rasid RefatNo ratings yet

- What To Do Now AARS (Last Month)Document41 pagesWhat To Do Now AARS (Last Month)tauseeqNo ratings yet

- Textile and Apparel Supply Chains For The 21 Century: Article Designation: Scholarly Jtatm Volume 6, Issue 4, Fall 2010Document10 pagesTextile and Apparel Supply Chains For The 21 Century: Article Designation: Scholarly Jtatm Volume 6, Issue 4, Fall 2010Shourya TripathiNo ratings yet

- Cadbury - Production Process PDFDocument33 pagesCadbury - Production Process PDFAshnaa Fauzan60% (15)

- Jagdev ParleDocument108 pagesJagdev Parlerahulsogani123No ratings yet

- Quality AssuranceDocument2 pagesQuality AssuranceChandni LalaNo ratings yet

- ARM0375 Lindt Brochure WebDocument5 pagesARM0375 Lindt Brochure WebmattdewieNo ratings yet

- Food Safety System Certification 22000: Jules Rojer, Technical Advisor FSSC 22000 Webinar, February 23, 2017Document33 pagesFood Safety System Certification 22000: Jules Rojer, Technical Advisor FSSC 22000 Webinar, February 23, 2017Chandra Nur KhalamNo ratings yet

- A Presentation On: "GD Birla"Document20 pagesA Presentation On: "GD Birla"Aditya BorkarNo ratings yet

- Food and Beverage CycleDocument4 pagesFood and Beverage CycleJoseph Louis BautistaNo ratings yet

- Chemical Petrochemical IndustryDocument8 pagesChemical Petrochemical IndustryArav SoniNo ratings yet

- WWW - Clariant.com Clariant International Ltd. Pigments & Additives DivisionDocument3 pagesWWW - Clariant.com Clariant International Ltd. Pigments & Additives Divisiontahera aqeelNo ratings yet

- Langfield-Smith7e IRM Ch05Document71 pagesLangfield-Smith7e IRM Ch05Rujun Wu100% (1)

- WT 2780Document88 pagesWT 2780Schmidt AngelisNo ratings yet

- KASEZ Working Unit List 2015 16Document25 pagesKASEZ Working Unit List 2015 16vanshikaNo ratings yet

- Evening Jasmine: Ann LoganDocument12 pagesEvening Jasmine: Ann LoganBlu Marie100% (1)

- Case 1Document2 pagesCase 1Aki WaliNo ratings yet

- Textile Finishing 1Document40 pagesTextile Finishing 1Mujahid MehdiNo ratings yet

- SL. No. Register Number Name Sector Mode ProgramDocument14 pagesSL. No. Register Number Name Sector Mode Programanish ashokkumarNo ratings yet

- The Textile and Apparel Industry in India PDFDocument11 pagesThe Textile and Apparel Industry in India PDFhoshmaNo ratings yet

- CH409 Organic Chemical Technology-1Document2 pagesCH409 Organic Chemical Technology-1rijintom100% (1)

- AVK Group of CompaniesDocument4 pagesAVK Group of CompaniesSathishkumar DhamodaranNo ratings yet

- Bounty ProfileDocument2 pagesBounty Profileredbutterfly_766No ratings yet

- Balaji Wafers QuestionnaireDocument5 pagesBalaji Wafers Questionnairemaa0007100% (1)