Professional Documents

Culture Documents

A Case Study of ERP Implementation

Uploaded by

Dharti Sarage0 ratings0% found this document useful (0 votes)

234 views25 pagesERP (Enterprise resources Planning) has become the focus of corporate operation and management. This study aims to help enterprises successfully implement ERP system by proposing strategies and tactics to tackle the common problems encountered in implementing ERP system.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentERP (Enterprise resources Planning) has become the focus of corporate operation and management. This study aims to help enterprises successfully implement ERP system by proposing strategies and tactics to tackle the common problems encountered in implementing ERP system.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

234 views25 pagesA Case Study of ERP Implementation

Uploaded by

Dharti SarageERP (Enterprise resources Planning) has become the focus of corporate operation and management. This study aims to help enterprises successfully implement ERP system by proposing strategies and tactics to tackle the common problems encountered in implementing ERP system.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 25

A Case Study of ERP Implementation

for Opto-Electronics Industry

1Chan-Hsing Lo, 2Chih-Hung Tsai, and 1Rong-Kwei Li

1 Department of Industrial Engineering and Management

National Chiao-Tung University, Hsinchu, Taiwan, ROC.

2 Department of Industrial Engineering and Management

Ta-Hwa Institute of Technology, Hsin-Chu, Taiwan, ROC

E-mail: ietch@thit.edu.tw

Abstract

The corporate competitive environment

is being liberalized and globalized, therefore

product life cycle is shortening. Markets

are undertaking globalization and because

of rapid changes in recent years, companies

need to act more responsively to the market

and customer demand as well as strengthen

information exchange and communication

systems in order to survive the highly

competitive and speed-oriented industrial

environment. In such a global competition

era, ERP (Enterprise Resources Planning)

has become the focus of corporate operation

and management. The pricey ERP system

does not only tackle information technology

(IT) issues but also attempt to solve problems

related to human resource, enterprise

culture, and organizational restructuring

and so on. Hence, successful implementation

of appropriate ERP system can improve

enterprise performance significantly. This

study aims to help enterprises successfully

implement ERP system by proposing

strategies and tactics to tackle the common

problems encountered in implementing ERP

system.

Keywords: Enterprise Resources Planning

(ERP), Supply Chain Management (SCM),

Material Requirements Planning (MRP),

Application Implementation Methodology

(AIM), Customer Relationship Management

(CRM)

1. Introduction

APICS (American Production and

Inventory Control Society) [1, 19] defines

ERP (Enterprise Resources Planning) as an

accounting-oriented computer information

system that assists enterprises to define and

plan on the resources required during the

operation process of purchase, production,

distribution, and strategic planning to satisfy

customers’ orders. It also effectively

integrates and manages these resources so as

to enhance overall performance and reduce

costs. ERP covers a wide range of fields, for

Chan-Hsing Lo, Chih-Hung Tsa & Rong-Kwei Li

14

example, purchase and sale management in

distribution; production management, MRP

(Material Requirements Planning), quality

control, management of products in process,

cost management, material management, and

project design change management, which

represents a complete manufacturing process

including research and development,

production, product management, and total

quality control. In addition, ERP also

involves accounting, human resource, and

decision-making resource management. The

ultimate goal of ERP is to improve

enterprises’ operating cycle of planning,

implementing, auditing, and improving, and

to strengthen corporate internal control and

auditing capabilities [14, 21].

In a global market, companies are

exposed to competition from not only

traditional or local competitors but also

worldwide players in the industry. Therefore,

it is imperative companies develop a

responsive, integrated, and succinct

management procedure [4] to respond to any

future challenges from global competition in

21st century. The Opto-Electronics industry

has been growing rapidly, and even the

industrial internal competition has become

quite intense. Only companies that can make

right decisions in a timely fashion based on

market trends can sustain their profitability

in fierce competition, hence, more and more

enterprises in Opto-Electronics industry have

implemented ERP system to increase their

competitiveness. However, ERP system

implementation process involves a wide

range of complicated resources and issues.

With no plan or supporting procedure,

companies may spend tons of money,

resource, and time on ERP implementation

but not enjoy a bit of the benefit ERP system

should have brought out [2, 3, 7, 8, 10, 11,

15, 16, 17]. In particular, implementing ERP

in Taiwan costs dearly but few cases have

succeeded. Due to industrial difference, the

applicability of ERP system and the

opportunities it presents are the critical

factors for consideration in ERP

implementation [13]. The T Opto-Electronics

Company is analyzed in this case study

focusing on the following three aspects: (1)

how to assess appropriate ERP software and

the applicability of ERP software to

enterprises in Taiwan; (2) ERP system

implementation strategy and methodology;

and (3) problems that may be encountered

during implementation process and the

solutions. The results are intended to provide

future reference to the related enterprises in

implementing ERP system.

2. Literature Review

The APICS’s definition of ERP can be

summarized as: (1) ERP system is

accounting-oriented; (2) ERP system focuses

on satisfying customer demand; (3) ERP

system plans on all corporate resources,

which is similar to the typical MRPII; and (4)

ERP system utilizes many mature

information technologies in 1990s. The

concept of “ERP” was first introduced by

Gartner Group [6, 22] in early 1990s. The

Group believes ERP’s functions exceed

MRP II’s. In addition to information

technology included in APICS’s definition,

ERP employs artificial intelligence, has

simulation capability, and can be applied to

project management, integration of internal

functions, quality control, and external

integration with clients and suppliers.

Various reports can be produced as needed.

From operational perspective, based on

supply chain management (SCM) and

customer relationship management (CRM),

ERP effectively integrates enterprise internal

and external resources in order to reduce

operating costs and satisfy market demands.

In other words, ERP takes advantage of

information technology to effectively utilize,

share, and allocate such corporate internal

A Case Study of ERP Implementation for Opto-Electronics Industry

International Journal of The Computer, the Internet and Management Vol. 13#1 (January – April, 2005) pp 13 - 30

15

resources as finance, accounting,

manufacturing, quality control, material

purchase, sales, and human, aiming to satisfy

customer needs and utilize enterprise

resources more effectively while meet

product quality and specification

requirements based on timely analyses, thus

ultimately increase profitability. Based on

the changes in market characteristics and

demand for the period from 1970s to 21st

century, we can study the needs and sources

of information system and technology

evolution by understanding the focus

adjustment of enterprise operation and

management. The ERP system’s evolution

course can be divided into four stages (as

shown in Table 1) [20]:

Table 1: The ERP System Evolution Course

1970s 1980s 1990s 2000s

Market

Characteristics

Mass Market Segments Niche Market Individuals

Demand Focus Cost Quality Flexibility Timeliness

Manufacturing

Method

Mass production of

limited product lines

Small-scale production

of various product

lines

Mass production of

various product lines

Mass production of

customized products

Structure Centralized Decentralized Decentralized Virtual

Management

System MRP II JIT/TQC ERP + SCM EERP + SCM

Management

Focus

Focuses on sales,

production,

materials, and

financial

management,

planning and

implementation of

manufacturing

material integration.

Focuses on cost,

quality, efficiency, and

promptness of material

supply.

Focuses on research and

development, sales,

production allocation and

distribution, service,

integration and optimal

utilization of internal

financial resources.

Focuses on a global

operating model that

combines internal

and external

customers and

manufacturers.

Application

Territory

Large area Large area Worldwide Worldwide

Operation

Cycle

Periodic Periodic Periodic/Ad hoc Ad hoc

Prior to 1998, ERP system was referred

to as enterprise ‘internal’ decision-making

support system. However, after 1999, ERP

represents an operation and management

system integrating enterprise both ‘internal’

and ‘external’ information. Some people just

call it extended ERP (i.e. EERP). ERP

system’s evolution and functions are shown

in Figure 1. ERP has been promoted and

applied in Taiwan for almost 20 years.

During this period of time, our discussions

and concerns have centered on the fact that

the applications of ERP in Taiwan were

not successful, thus could not achieve

predetermined goals. Many researches and

practices have provided us sufficient proof

that the failure of ERP applications in

Taiwan is not attributable to technology,

fund, Internet, application software, or

software implementation but enterprise

mindset. To inspire enterprises’ sponsorship

by improving their knowledge and

understanding, increase their proactive

capabilities, and fully exert their functions as

the sponsor, shall improve the success in

ERP applications in Taiwan fundamentally

[9, 12, 14].

Chan-Hsing Lo, Chih-Hung Tsa & Rong-Kwei Li

16

1970’s 1980’s 1990’s 2000’s

Figure 1: The ERP’s Evolution and Functions [19]

In implementing ERP system, business

process reengineering (BPR) is a

requirement [4]; therefore, how to use

process reengineering to drive success is

worth deep thinking. A successful

implementation of process reengineering is

determined by:

1. Human resource: strong leadership,

promotion and coordination across

functions, top-down delegation, and

outsourcing (e.g. management

consulting firm).

2. Organizational structure: analyze

corporate objectives and core

strategies, build the organization’s

business structure, define functions

and mechanism, assess shortfalls in the

functions of current structure, and

adjust operating process to meet the

requirements by ERP system’s

functions.

3. Objective and performance evaluation:

set measurable indexes or data,

predetermine the expected ERP’s

effect on enterprise operation and

profitability, produce checklist,

evaluate the return on investment and

benefit of ERP implementation, and

examine implementation process.

To summarize it, ERP system planning

smoothes out the whole system’s operation,

which doesn’t produce any immediate effect

MRP MRP II

Accounts Receivable

Accounts Payable

Salary System

Finance and Accounting

General Ledger

Human Resource

Planning

Scheduling

EDI

Enterprise Resource Planning

(ERP)

Sales and Shipping

Supply Chain Management

(SCM)

E-Commerce

Sales Force Automation

(SFA)

Customer Relationship

Management (CRM)

Extended ERP

(EERP)

A Case Study of ERP Implementation for Opto-Electronics Industry

International Journal of The Computer, the Internet and Management Vol. 13#1 (January – April, 2005) pp 13 - 30

17

but improves enterprise perpetual operating

capacity significantly, thus becomes

enterprise intangible asset. Nowadays, many

big foreign companies placing orders in

Taiwan list the adoption of ERP system as

one of the assessment criteria. Apparently, a

key to future success for information

enterprises lies in timely establishment and

effective implementation of ERP system.

3. Applicability Evaluation of ERP Software

What functions or modules should be

included in an ERP system is determined by

enterprise operating strategies, environment,

and needs, and the capacity of the integrated

software supporting such functions and

modules. This study provides a simple and

easy software system evaluation and

checklist (as shown in Table 2).

Table 2: The Software System Evaluation and Checklist

Factors Evaluation Items

□ Production by project □ Alternating production □ Process

1. Production Mode

□ Repetitive assembly □ Mixed machinery □ Streamline production

□ Electronics □ Semi-conductor □ Automobile

2. Applied Industry □Machinery □Gasoline and chemicals □Medical/Biochemistry

□ Food □ Other

3. Product Strategy □Manufacture to stock

(MTS) □ Manufacture to order

(MTO) □ Assemble to order (ATO,

BTO)

□ Customer order

management □ Customer relationship

management □ Production and sales

planning

□ Forecast □ Master schedule □ MRP/MRP II

□ Production capacity vs.

demand planning □ Manufacturing

implementing system □ Distribution vs. demand

planning

□ Purchase □ Warehouse management □ Human resource

management

4. Function/Module

□ Cost accounting □ Finance

5. Production

Schedule □ Support advanced planning

schedule □ Limited production

capacity schedule

□ Contract purchase □ Comprehensive purchase □ Quote inquiry

6. Purchase □Supplier’s schedule □EDI □Electronic payment

□ Supplier’s performance

□ Order/Invoice □ Accounts Receivable

(A/R) □ Accounts Payable (A/P)

□ General ledger □ Fixed assets □ Multinational trade/

exchange

7. Accounting

□ Consolidation

□ Bill-of-Materials for

project/manufacturing 8. Bill-of-Materials □Project design adjustment □Product components

Management

(BOM) □ Modulated bill-of-materials

(BOM) □ On-line consumer product

components □ Shared material

components

□ Timely reports □ Various financial analysis

reports □ Response to problems/

9. Management issues

Report

□ Dollar value of production volume

An ERP system implementation is very

expensive costing from millions to billions

NT dollars. However, very few cases were

successful. In many cases, the system was

unable to deliver the expected performance

after implementation. A checklist as shown

Chan-Hsing Lo, Chih-Hung Tsa & Rong-Kwei Li

18

in Table 3 can be used to determine if an

ERP system has been successfully

implemented.

Table 3: The ERP Checklist

ERP Checklist Yes No

1. The basic information including material No., name, and specifications has

been completely and correctly filed. □ □

2. The information of Bill of Materials (BOM) and Routing has been filed. □ □

3. The accounting accuracy for the materials in stock is at least 95%. □ □

4. The accuracy of Bill of Material (BOM) is above 98%. □ □

5. The Master Production Schedule (MPS) has been established and will be

updated at least once a week. □ □

6. The forecast (when manufacture to stock) or the order (when manufacture to

order) is highly accurate. □ □

7. Hold periodic (at least once a month) production and sales meetings and

enter the finalized plans into the system. □ □

8. Periodically check the rationale underneath such parameters as preparation

time, safety inventory level, and lot sizes. □ □

9. Material requirements planning (MRP) needs to be updated at least once a

week. □ □

10. Replace manufacturing order and purchasing order (PO) with production

schedule and suppliers’ schedule. □ □

11. The users of the system must have been well educated and trained. □ □

12. The business process has been re-engineered when implementing the

system. □ □

13. The data of modules in the system is integrated, which doesn’t require

repetitive key-in. □ □

14. The output data of the system is for users and management to make

strategic decisions and judgment. □ □

15. The senior management supports ERP system and uses the system in

practice. □ □

4. Implementation Plan

4.1 Company Background

The T Opto-Electronics Co., Ltd. was

founded in Taiwan Hsinchu Science Park

Industry in September 1996. The company is

devoted to developing super bright Light

Emitting Diode (LED) series products by

using self-developed Metal Organic

Chemical Vapor Deposition (MOCVD)

technology. Large volume production of

Aluminum Gallium Indium Phosphide

(AlGaInP) (red, orange, and yellow) serial

Epitaxy wafer and dice officially started in

the fourth quarter of 1997. The R&D team is

made up of the experts from the Opto-

Electronics and Systems Laboratories (OESL)

of Industrial Technology Research Institute

(ITRI) and the experts who studied or

worked in Opto-Electronics area in USA.

The company, with NT$ 220 million capital,

A Case Study of ERP Implementation for Opto-Electronics Industry

International Journal of The Computer, the Internet and Management Vol. 13#1 (January – April, 2005) pp 13 - 30

19

has shown its strong competitive advantage

in optimizing the integration of product

design technology and mass production

capacity. The current product lines in

manufacturing include: AlGaInP and

Aluminum Gallium Arsenic (AlGaAs)

Lighting Emitting Diode Epitaxy wafer and

dice, which have the features of small size,

economic electricity consumption, and

extended life span. They can be widely

applied to such consumer electronic products

as indicator light, source light of fax machine

and scanner, backlight module of Liquid

Crystal Display (LCD), indoor or outdoor

information display, automobile light, and

traffic light.

4.2 Application Implementation

Methodology

This case employs the application

implementation methodology (AIM) and

makes modifications to it according to

individual needs. The AIM is an operating

methodology derived from numerous

implementation practices, which has helped

more than 6,000 enterprises around the world

successfully implement ERP system [8, 19].

The AIM divides system implementation

into: implementation strategy, operation

analysis, solution design, solution

development, documentation, transition, and

production run, so that it can conveniently

coordinate with operation process and

workflow improvement. The AIM flow is

shown in Figure 2 as below:

Computerized operation and

management process

improvement

Implementation Strategy

Implementation Strategy

Implementation Team Structure

and Plan

Kick-Off Meeting

Operation Analysis (Training)

(OA)

Solution Design (BRM)

(Application System Configuration)

(SOP)

(Decision on Customization)

Solution Development (SOP Walkthrough) Documentation (Documentation)

(CRP)

(Customized Operation)

(End-User Training)

(End-User CRP)

(Data Preparation)

Transition

Production Run

(Production)

(Post Support)

Figure 2: The AIM Flow

4.3 Team Structure

This case especially emphasizes

teamwork, which is deemed critical to the

success of the implementation [5]. The

implementation team comprises T Company

employees involved and the consultants from

ERP Software Company, whose goal is to

Chan-Hsing Lo, Chih-Hung Tsa & Rong-Kwei Li

20

help clients handle various problems in the

maximum feasible scope under

predetermined time schedule. The ERP

software consultants encourage the

interaction among team members by means

of shared working area and responsive

mutual support between team members. The

implementation team in this case is

structured as shown in Figure 3:

Figure 3: The Implementation Team Structure

Senior Management Decision-Making

Committee (T Company/Software Company)

Project Manager (T Company Project Manager/

Software Company Project Manager)

T Company

(Information Department)

Finance Distribution

Software

Company

Consultant

T

Company

Key-User

Software

Company

Consultant

T

Company

Key-User

Software

Company

Consultant

T

Company

Key-User

A Case Study of ERP Implementation for Opto-Electronics Industry

International Journal of The Computer, the Internet and Management Vol. 13#1 (January – April, 2005) pp 13 - 30

21

4.4 Job Tasks at Different System

Implementation Stages

This case employs the application

implementation methodology (AIM). The

job tasks at different stages of the process are

illustrated as follows:

1. Operation Analysis Stage: As

shown in Table 4, T Company

provides and explains the current

operation process and the

expectations of future

computerization, helps consultants

fully understand operational needs

for analysis in order to determine

the focus of later system

implementation.

2. Solution Design Stage: After

operation analysis results are

released and discussed, consultants

will design solutions to how to

satisfy T Company’s future needs

by appropriate software

applications, propose the blueprint

for overall future structure, and

define the scope of customization

to the benefit of follow-up

customization jobs (as shown in

Table 5).

3. Solution Development Stage: After

variance analysis results review

meeting, based on the new process

and function structure proposed at

the early stage of solution design,

consultants will build a test

environment for simulation and

further confirm the future new

system standard operation process

(as shown in Table 6).

4. Customer Documentation Stage:

The User will write the operation

manual and education/training

manual. This way ensures the

User’s knowledge and

understanding of the new system’s

functions. Meanwhile, the manuals

can be used for reference when

roles change or alternate at T

Company (as shown in Table 7).

5. Transition Stage: At this stage, the

preparation work for transition

must be completed, including

environment and data setup and

transition training for End-User (as

shown in Table 8).

6. Production Run Stage: At this stage,

the system will officially start

running in production (as shown in

Table 9).

Chan-Hsing Lo, Chih-Hung Tsa & Rong-Kwei Li

22

Table 4: The Operation Analysis Stage

Job Task Operating Methodology Deliverab

les

Analyze

current

operation

process and

needs

Overview: The consultants explain the system’s functions and structure to

help the Key-User refresh his/her knowledge and develop correct

perception and understanding of the system. This also provides an

opportunity for the management who is unable to attend the full-length

course or the Key-User and MIS staff of the peripheral systems to build

the overall comprehensive concept of various modules.

Operation Analysis Preparation Work Description: The consultants of various

systems explain the preparation work and matters to the Key-User of the

systems before any operation analysis starts so that the operation analysis

meetings can achieve their goals more efficiently and effectively.

Operation Analysis Meetings: The system supervisor from T Company should

collect and summarize the current operation process and needs, prepare

PowerPoint presentation, explain to Oracle consultants in detail the

current operation’s bottleneck and the needs and expectations of future

computerization, as well as answer any questions the consultants may

have. For those questions that require further research or explanation, the

system supervisor needs to coordinate with the parties involved to answer

the questions or provide requested information. T Company’s MIS staff

should take notes from the meetings and obtain confirmation signatures

from the parties concerned.

Operation Analysis Documentation: The consultants should produce an

“Operation Analysis Report” based on the notes and results of the

meeting, propose inter-module topics to module consultants for discussion

at application implementation meeting, and then summarize the results

concluded from the meeting and deliver the “Operation Analysis Report”.

Operation Analysis Review Meeting: The consultants educate T Company’s

Key-User and related management with the system’s future operational

requirements. Meanwhile, the Key-User should familiarize himself/herself

with the details of “Operation Analysis Report” before the meeting; feel

free to ask any questions as soon as possible in order to improve the

efficiency of communication.

Operation Analysis Confirmation: The Key-User of modules is responsible

for the confirmation of the “Operation Analysis Report”. He/she should

collect questions within five business days after the operation analysis

review meeting, prepare a written explanation for consultants to make any

modification or adjustment. Otherwise, it is deemed confirmation is

completed.

Operation

Analysis

Report

A Case Study of ERP Implementation for Opto-Electronics Industry

International Journal of The Computer, the Internet and Management Vol. 13#1 (January – April, 2005) pp 13 - 30

23

Table 5: The Solution Design Stage

Job Task Operating Methodology Deliverables

Define the

new

operation

process and

analyze the

needs/

requirements

Function vs. Need: The consultants are responsible for matching the

application system to enterprise need based on the “Operation Analysis

Report”.

Matching Enterprise Need Meeting: Based on the operation proposal,

output report, data converting plan, information transfer plan, and

customization plan provided by the consultants, T Company’s Key-

User should invite all parties involved to discuss the contents and

obtain agreement. T Company’s MIS staff should take notes of the

meeting and request meeting participants’ confirmation signatures.

Matching Enterprise Need Documents: The consultants should write up an

“Matching Enterprise Need Report” on the basis of the meeting

results, collect and summarize inter-module topics for discussion with

module consultants at project implementation meeting, and then

modify and submit the “Matching Enterprise Need Report” after the

meeting.

Matching Enterprise Need Presentation: The consultants present to T

Company’s Key-User and related management the framework of the

enterprise future process and proposed solutions. The Key-User should

read the “Matching Enterprise Need Report” in detail before the

meeting, and raise any questions or concerns as early as possible to

improve the efficiency in communication.

Matching Enterprise Need Confirmation: The Key-Users of individual

modules are responsible for the confirmation of “Matching Enterprise

Need Report”. They should summarize the questions, and provide a

written explanation within 5 business days after the meeting for the

consultants to make any modifications necessary. Otherwise, it will be

deemed as the confirmation job has been completed.

Matching

Enterprise

Need Report

Variance

Analysis

Variance Analysis Meeting: After the meeting that aims to match

enterprise needs, the consultants should further analyze the

disconnected portion between future requirements and application

system based on the plans and proposals in “Matching Enterprise Need

Report”, including new operation, process, information processing,

and report requirements etc. functions. This will help T Company

confirm the requirements for customization. The consultants should

discuss with T Company’s Key-User and MIS staff.

Variance Analysis Documents: The consultants should prepare a “Variance

Analysis Report” based on the meeting results.

Variance Analysis Explanation Meeting: The consultants present to T

Company’s Key-User and MIS staff any function variance and the

requirements for customization. MIS staff should read the “Variance

Analysis Report” in detail before the meeting and raise questions and

concerns as early as possible to improve communication efficiency.

Variance Analysis Confirmation: All systems’ MIS staff should assist Key-

User in “Variance Analysis Report” confirmation job by summarizing

the questions, and providing a written explanation within 5 business

days after the meeting for the consultants to make any modifications

necessary. Otherwise, it will be deemed as the confirmation job has

been completed.

Variance

Analysis

Report

Chan-Hsing Lo, Chih-Hung Tsa & Rong-Kwei Li

24

Table 6: The Solution Development Stage

Job Task Operating Methodology Deliverables

Testing

Environment

Configuration

Testing Data Preparation: After the matching enterprise need meeting, ERP

software consultants should explain the corresponding testing data that need

to be prepared by T Company’s Key-User with MIS staff’s help. The practice

on real machines must be completed before testing environment is

configured.

System Configuration: The consultants configure the testing environment

parameters on T Company’s machines directly and explain them to the Key-

User. T Company’s Key-User is required to fill out the parameter

configuration table and prepare the “system parameter configuration

document”.

Test on Real Machines: ERP software company’s consultants should prepare the

test questions for function and operation practices.

The Blank

Table of

System

Parameter

Configuration

Function and

Operation

Practice

The consultants should explain to the Key-User the application system’s

main functions and operating methodology that are related to the future new

operating plan, and make sure the Key-User understand how to operate the new

process and the new system by practicing the testing data on real machines. The

Key-User should take the test prepared by the consultants in order to understand

his/her own knowledge level and practice more in the areas that need further

improvement.

Set up

Standard

Operating

Process (SOP)

Set up Standard Operating Process: With the consultants’ and MIS staff’s help, T

Company’s Key-User should standardize and document the future operating

process and document flow which can be used as operating standards when

the new system is in production.

Standard Operating Process Confirmation Meeting: The T Company’s Key-User

should try explaining the standard operating process to the consultants after

the documentation is finished so as to confirm the Key-User’s full knowledge

and understanding of the operating process and is ready to train End-User

before transition and help examine the correctness of SOP contents.

Standard Operation Analysis Confirmation: The consultants should include the

examination results from SOP meeting in the written memorandum

Memorandum

of Standard

Operating

Process

Confirmation

Meeting

New System

Function

Deduction

SOP Simulation Data Planning: The consultants should initiate a discussion of

simulation data contents according to SOP at implementation meeting. The

T Company should help provide simulation data in order to make sand table

exercise more accurately simulate future operation.

New System Function Integration and Deduction: The inter-module integrated

sand table exercise on real machines is intended to help Key-User learn

more about the future operating process.

A Case Study of ERP Implementation for Opto-Electronics Industry

International Journal of The Computer, the Internet and Management Vol. 13#1 (January – April, 2005) pp 13 - 30

25

Table 7: The Documentation Stage

Job Task Operating Methodology Deliverables

User

Documentation

User Documentation: The Key-User is responsible for the job

usually with the consultants’ assistance.

Table 8: The Transition Stage

Job Task Operating Methodology Deliverables

Operation Practice Education and Training: The Key-User will educate and train the

End-User, with the consultants’ help.

Configure

Transition

Environment

Transition Environment Configuration: The Key-User configures

the transition environment according to the “System

Parameter Configuration Documents” produced by

himself/herself early. The consultants will provide assistance

when needed.

Convert Data

Data Conversion Planning: The consultants should help T

Company develop data converting strategies and

methodology.

Data Conversion Coding: When writing codes to convert data, the

detailed design and program should follow customization

principles.

Data Conversion: The T Company’s MIS staff will conduct it.

Table 9: The Production Run Stage

Job Task Operating Methodology Deliverables

Online Support At early stages, the consultants can provide support as needed. Acceptance

Report

5. Case Analysis

During the ERP system implementation

process at T Company in study, sometimes

the predetermined goals cannot be met. The

problems encountered in this case study and

their solutions are illustrated in the following:

5.1 Insufficient Professional Experience of

Implementation Consultants

Problem Description: The ERP system

implementation consulting team is one of

critical factors to consider in selecting

software. The consultants are required to not

only possess software professional

knowledge but also a fair amount of

industrial experience. However, finding

appropriate consultants is not an easy but

rather big task. During application

implementation, if the consultants are not

familiar with industrial characteristics, it will

usually cause misunderstanding in

communication, which will in turn require

extra operational analysis of the connections

among modules. If the consultants take the

Chan-Hsing Lo, Chih-Hung Tsa & Rong-Kwei Li

26

leading role in implementation, the best

result is limited to introducing a set of new

rules and system not necessarily applicable

to the specific industry.

Solution: When applying the system to a

specific industry, a comprehensive

consulting team should be selected. It could

be comprised of either the experts in various

fields from the same consulting firm or the

comprehensive experts well trained by the

software company. The consultants are

mainly responsible for integrating software

system into enterprise culture. The job

responsibility requires full communication

with the client’s senior management since

the senior management understands their

own company’s process and structure as well

as the company’s future needs. Software

only plays the role of a tool in enterprise

resource planning. Enterprises are

specialized in various professional fields and

have the know-how particular to individual

industries. Therefore, if the consultants can

build up the solid foundation of mutual trust

with clients and are willing to solve

problems for clients, they can finally become

the client’s most trustworthy partners.

Consultants should be the enterprises’

partners but not the brokers wasting client’s

money.

5.2 Thoughts on Several Misconceptions

about Enterprise Software

Implementation

Enterprises usually have several

misconceptions in implementing software,

which causes some disappointment from

unrealistic expectation.

5.2.1 Misconception 1: Can computerization

save labor?

Problem Description: When implementing

ERP system, many enterprises expect the

system to save labor in complicated and

tedious statistics and calculation jobs. In fact,

the system can reduce human errors in

computation and conveniently generate some

statistics reports for management purposes.

However, introducing an ERP system will

not necessarily cut labor, possibly due to

original operators’ inability to produce

statistics or output reports in a timely fashion

as a result of lack of information.

Solution: As a matter of fact, after ERP

software is installed, when all the factors

mentioned above are excluded, users may

feel their workload has been increased.

However, on the other hand, the company’s

overall profitability has been improved

significantly. Take sales for example, sales is

the frontline work and the starting point of

many information systems: receive order –

produce – sell – accounting. The workload of

the frontline operators is not reduced but

increased to include some managerial

parameters. In addition, the process seems

like nothing quite different from handling

other document software, which thus causes

doubts about the benefits that ERP system

can bring to the operation. However, by

means of ERP system, other departments or

management can easily check or manage the

most updated status of the orders received,

then arrange enterprise resources accordingly.

Therefore, the management should certainly

correct any misconception of

computerization can save all labor.

5.2.2 Misconception 2: Can computers

cure all?

Problem Description: Many things cannot

possibly be done without computers, but can

computers cure all? A common

misconception in implementing ERP system

is that the software system can do everything.

However, after all, human brain is superior

to computer. As many enterprise cultures

take quite some time to evolve, many

enterprise-operating processes finally get on

A Case Study of ERP Implementation for Opto-Electronics Industry

International Journal of The Computer, the Internet and Management Vol. 13#1 (January – April, 2005) pp 13 - 30

27

track only after several reforms and

renovations. Many problems and issues

occurred in implementing ERP software still

require human beings to make the judgment.

Solution: ERP software provides enterprises

multiple options of system application. So

selection is a judgment. Whether the choice

is correct or not is determined by the policies

or strategies taken on by the enterprise at the

specific point of time but not the jobs that

ERP system can replace.

5.3 Enterprise-User Unable to Describe

Needs or Requirements Correctly

Problem Description: At operation analysis

stage, the common problem is that most of

the time the Key-User cannot accurately

describe the needs or requirements in full

detail or falls into the so-called “interview

trap”. “Interview Trap” refers to the dilemma

that the needs or requirements are brought up

only when related questions are asked by

ERP system implementation consultants.

Otherwise, the problems are hidden and later

become obstacles to satisfying enterprise

needs in the course of application

implementation. Even some would not be

revealed until the project is being closed.

Solution: ERP system implementation

consultants must bring out the enterprise

needs or requirements completely when

conducting operation analysis and identify

all the problems.

5.4 The Timing of Education and Training

Problem Description: In general, software

companies provide training before transition

happens. However, the training result is

usually the worst before the users can get

their hands on the software.

Solution: In the course of ERP system

implementation, users should be allowed to

continuously test software functions. In this

way, they can get themselves familiar with

the software and raise many operational

questions. Then the consultants can focus the

training on those questions. Thus, a better

effect can be achieved in official transition.

5.5 Defining System Variation

Generally speaking, when purchasing

software, most of the time only the

functional completeness can be evaluated. It

is not quite possible to conduct a complete

evaluation specific to enterprise operational

details. When actually implementing the

software, those functions that cannot be

provided by the software system due to

industrial variance are listed as system

variation items and will cost customization

charge. However, some variations may not

be attributable to industrial variance but

rather incomplete functionality. In this case,

the consultants should list the problem for

modification but not as a part of the client’s

requirements for customization.

6. Conclusions

In the present highly competitive market,

enterprise resource integration and planning

are very critical, especially to those

companies in existence for a long time.

When companies expand their hierarchy and

scale as needed by business growth, lack of

integrated planning always causes duplicate

functions and ambiguously defined

responsibilities. The resulting enterprise

internal discord will affect enterprise

operating efficiency, and even enterprise

normal operation when accompanied by

Y2K effect on enterprise resource utilization.

It therefore requires computer software and

hardware updates. This is a great opportunity

for enterprise restructuring. Enterprise

resource integration involves a wide range of

activities including selection of ERP

Chan-Hsing Lo, Chih-Hung Tsa & Rong-Kwei Li

28

provider, communication equipment,

resource management planning, system

implementation, senior management’s vision,

human resource coordination, system

transition, and continuous renovation, which

are all determinants of the success of

implementing enterprise resource planning

system. Hence, the evaluation before

implementation is rather important. Due to

the consideration of industrial characteristics,

scale, degree of urgency, and software

applicability, not many enterprises have

currently officially implemented ERP

software, among which, the majorities are

from information/semi-conductor industry.

However, without complete preparation

beforehand, the huge investment of money,

time, and human resource usually cannot

generate the expected results because ERP

system implementation involves too many

resources and parties, is very timeconsuming

and capital-intensive. In addition

to their own advance planning, concept

education and promotion among employees,

another more important and essential job for

enterprises is to select well-fit and very

experienced software suppliers and

consulting firms. During the course of

implementation, only if enterprise, supplier,

and consulting firm can closely and

comfortably work side by side, can

enterprise effectively apply to ERP system

and thus realize the goal of integrated

resource utilization.

The rapid growth of Internet has

stimulated the development of ERP

application concept. Many new management

ideas and theories have come out as well.

From the overall fundamental development

perspective, ERP system considers the world

a single market and aims to build a global

operation management system ultimately.

Global operation management system refers

to an overall management process attempting

to economically and effectively plan on and

control raw materials, semi-finished products,

finished products, and related service

information communication from a global

perspective under the premise of satisfying

customer demand. In other words, it aims to

deliver consumers expected services at lower

cost with timely information. Global

operation management includes an extensive

range of contents, for example, the related

important processes in supply chain

including order fulfillment process, customer

service process, and new product

development which are all the necessary

conditions in global operation management

practice. Building a global operation

management and supply chain management

system based on integrated supply chain

management has become a key to enterprise

competitive advantage in globalizing

industrial competition.

The main reason for many enterprises to

introduce e-commerce is to reduce the

inventory cost in supply chain. They hope to

effectively manage the process from raw

materials, parts, semi-finished products,

assembly production, to shipping and

distribution by forecasting demand through

orders received. In this way, customer

satisfaction will be increased while inventory

cost declines. In order to achieve this goal,

the essential measures include order

management function system planning, and

systemizing such process designs as cost

analysis, purchase, production, sales, and

related accounting matters. In global

customer-oriented competition, how to use ecommerce

technology to create such a

structure of economy is very important.

Apparently, this goal can be reached by

external resource integration itself. However,

to build an ERP system effectively

integrating enterprise’s internal and external

resource planning is essential.

A Case Study of ERP Implementation for Opto-Electronics Industry

International Journal of The Computer, the Internet and Management Vol. 13#1 (January – April, 2005) pp 13 - 30

29

References

[1] APICS, APICS Dictionary, The 9th edition,

1998.

[2] Bingi, P., Sharma, M.K. and Godla, J.K.,

“Critical Issues Affecting an ERP

Implementation,” Information Systems

Management, Vol. 16, Issue. 5, pp.7-14,

1999.

[3] Holland, C.P. and Light, B., “A Critical

Success Factors Model for ERP

Implementation,” IEEE Software, Vol. 16,

Iss. 3, pp.30-36, 1999.

[4] Mandal, P. and Gunasekaran, A.,

“Application of SAP R/3 in on-line

inventory control,” International Journal of

Production Economics, Vol. 75, pp.47-55,

2002.

[5] Motwani, J., Mirchandani, D., Madan, M.

and Gunasekaran, A., “Successful

implementation of ERP projects: Evidence

from two case studies,” International

Journal of Production Economics, Vol. 75,

pp.83-96, 2002.

[6] Norris, G., Hurley, J.R., Hartley, K.M.,

Dunleavy, J.R. and Balls, J.D., E-Business

and ERP, John Wiley & Suns, 2000.

[7] Summer, M., “Critical success factors in

enterprise wide information manage-ment

system projects,” Proceedings of the

SIGCPR’99, New Orleans, LA, USA,

pp.297-303, 1999.

[8] Welti, Norbert, Successful SAP R/3

Implementation: Practical Management of

ERP Project, Addison Wesley Longman,

1999.

[9] Shen, Yuan-huang and Hsu, Ping-yu, “ERP

Implementation Effect Not Up to

Expectations?,” Data and Computers,

2002/1, pp.52-57.

[10] Chu, Hai-cheng and Lai, Chu-liang, “ERP

Crucial Success Factors (CSF) and Failure

Causes Investigation,” Electronic Business

and Digital Lifestyle Discussion Panel,

Taiwan Electronics Business Institute, Shita

University Data Control Department, 2002.

[11] Hung, Yu-chung, Hsiao, Tsui-chen, and Hsu,

Chun-lin, “ERP Key Success Factor

Analysis—A Case Study of Company P’s

Implementation of SAP,” Electronic

Business and Digital Lifestyle Discussion

Panel, Taiwan Electronics Business

Institute, Shita University Data Control

Department, 2002.

[12] Lien, Ya-hui and Wang, Chiang-liu,

“Surpassing Time Competitiveness,”

Chinese Production Capability Center,

1998.

[13] Chen, Chih-che, “Taiwan Enterprise Data

Operation Requirement Analysis:

Manufacturing Version,” MIC Research

Report, 2001/3.

[14] Chen, Chih-che, “Using Traditional

Industry Electronic Analysis Enterprise

Electronic Strategy,” MIC Research Report,

2001/4.

[15] Lin, Feng-ju, “Research Regarding

Relationship between ERP Package

Software Strategy Target Strategic Targets

and Key Factors,” Taiwan University

Business Research Masters Thesis, Taiwan,

1999.

Chan-Hsing Lo, Chih-Hung Tsa & Rong-Kwei Li

30

[16] Liu, Shih-hao, Wu, Shih-ming, Pi, Shi-ming

and Tsai, Yi-chang, “ERP Strategic

Investigation Research,” 11th Nationwide

Data Control Academic Research

Discussion Thesis, Kaohsiung Chungshan

University, Taiwan, 2000.

[17] Tsai, Yu-in, “Taiwan Electronic Industry

ERP System Key Factors,” Chunghsing

University Business Administration Masters

Thesis, Taiwan, 1999.

[18] Jin, Da-ren, “Eight Bottlenecks of ERP

Applications”, Enterprise Resource

Management Center, 2000.

[19] URL: www.erp.org.tw.

[20] Wang, Er-rui, Introduction to ECommerce,

Hua-Tai Bookstore, Taiwan,

2000.

[21] Zeng, Huan-zhao, “Arthur Management

Consulting Communication 29th Edition”,

2000.

[22] URL: www1.trdi.edu.tw/~875115/erp.htm.__

You might also like

- ERP Case Study FINALDocument5 pagesERP Case Study FINALibn_uae100% (1)

- Change Management For Human in Enterprise Resource Planning SystemDocument5 pagesChange Management For Human in Enterprise Resource Planning SystemseventhsensegroupNo ratings yet

- ERP and SCMDocument34 pagesERP and SCMRasika DeshpandeNo ratings yet

- Recent Developments in ERP SystemsDocument7 pagesRecent Developments in ERP SystemsShilpa MukeshNo ratings yet

- Erp CRM Case Studies Failures PDFDocument2 pagesErp CRM Case Studies Failures PDFAmberNo ratings yet

- ERP Implementation Failure CaseDocument8 pagesERP Implementation Failure Casepf shahidNo ratings yet

- Recent Developments in The Field of ERPDocument8 pagesRecent Developments in The Field of ERPNimishaNandan100% (1)

- Erp Pliva Case Study FinalERP System Implementation and Business Process Change: Case Study of A Pharmaceutical CompanyDocument13 pagesErp Pliva Case Study FinalERP System Implementation and Business Process Change: Case Study of A Pharmaceutical CompanyNota Razi100% (13)

- Chapter 5 - ERP Selection NewDocument28 pagesChapter 5 - ERP Selection NewKLASDJAKLNo ratings yet

- Erp Keda Sap ImplementationDocument28 pagesErp Keda Sap ImplementationAksa DindeNo ratings yet

- ERP Implementation Drives Change at PantaloonsDocument38 pagesERP Implementation Drives Change at PantaloonsAnshulBhatiaNo ratings yet

- Enterprise Resource Planning, 1st Edition by Mary SumnerDocument23 pagesEnterprise Resource Planning, 1st Edition by Mary SumnerSneha ShreeNo ratings yet

- Public Cloud ERP for Small or Midsize Businesses A Complete Guide - 2019 EditionFrom EverandPublic Cloud ERP for Small or Midsize Businesses A Complete Guide - 2019 EditionNo ratings yet

- ERP Case StudiesDocument10 pagesERP Case StudiesSAIMA VRNo ratings yet

- Erp Case StudyDocument10 pagesErp Case StudyGaurav KadamNo ratings yet

- Integrated Business Planning A Complete Guide - 2020 EditionFrom EverandIntegrated Business Planning A Complete Guide - 2020 EditionNo ratings yet

- Markiv CRMDocument485 pagesMarkiv CRMravikumarreddytNo ratings yet

- The Development of Enterprise Resource Planning SystemsDocument9 pagesThe Development of Enterprise Resource Planning SystemsNeha SharmaNo ratings yet

- Enterprise Wide Resource PlanningDocument20 pagesEnterprise Wide Resource PlanningmeghagoyalNo ratings yet

- Erp Functional ArchitectureDocument12 pagesErp Functional ArchitectureKarthika SasikumarNo ratings yet

- Challenges in Implementing ERPDocument9 pagesChallenges in Implementing ERPMano Billi100% (4)

- Table of Content: by Kunal ChadhaDocument19 pagesTable of Content: by Kunal ChadhaNicolette BrownNo ratings yet

- Warid Telecom's History, Services and PartnershipDocument30 pagesWarid Telecom's History, Services and PartnershipMakkia ShaheenNo ratings yet

- ERP Package Selection and Implementation ProcessDocument33 pagesERP Package Selection and Implementation ProcessSonali AgrawalNo ratings yet

- Enterprise Resource Planning: Made by - Pavan Mathur Prateek KediaDocument25 pagesEnterprise Resource Planning: Made by - Pavan Mathur Prateek Kediaprateek_kedia_1No ratings yet

- ERP HCM ROLLS Royce CaseDocument3 pagesERP HCM ROLLS Royce CaseAmrita MishraNo ratings yet

- Analysis of ERP System ImplementationDocument2 pagesAnalysis of ERP System Implementationarchana_motagiNo ratings yet

- Supply Chain Integration, Advanced Manufacturing Technology, and Strategic PDFDocument109 pagesSupply Chain Integration, Advanced Manufacturing Technology, and Strategic PDFAdelina RomanNo ratings yet

- Erp Implementation Case Studies PDFDocument2 pagesErp Implementation Case Studies PDFKarlieNo ratings yet

- Oracle vs. SapDocument10 pagesOracle vs. SapRose Siena Simon AntioquiaNo ratings yet

- ERP SelectionDocument35 pagesERP SelectionNeha SinghNo ratings yet

- Erp Selection Survival Guide Erpfocus ComDocument15 pagesErp Selection Survival Guide Erpfocus ComSaad Yacoubi SahliNo ratings yet

- GTU MCA Semester-I Enterprise Resources Planning (ERPDocument2 pagesGTU MCA Semester-I Enterprise Resources Planning (ERPVirendra Arekar100% (1)

- MIS 480 FinalDocument21 pagesMIS 480 Finalnetflix buff100% (1)

- Agilent ERP FailureDocument2 pagesAgilent ERP FailureIshita JainNo ratings yet

- Critical Success Factors For The Implementation of Enterprise Resource Planning (Erp) : Empirical ValidationDocument10 pagesCritical Success Factors For The Implementation of Enterprise Resource Planning (Erp) : Empirical ValidationiacikgozNo ratings yet

- Assessing ERP Post-Implementation SuccessDocument25 pagesAssessing ERP Post-Implementation SuccessAkshay UpwanshiNo ratings yet

- ERP Selection Process Survival Guide PDFDocument20 pagesERP Selection Process Survival Guide PDFasaNo ratings yet

- Coca Cola Personal StatementDocument4 pagesCoca Cola Personal Statementsalman_schon100% (1)

- An Approach To ERP ImplementationDocument16 pagesAn Approach To ERP ImplementationAvijit RoyNo ratings yet

- ERP Implementation in TISCODocument8 pagesERP Implementation in TISCObhauwaladeepakNo ratings yet

- ERP in Furniture Manufacturing IndustryDocument5 pagesERP in Furniture Manufacturing IndustryJyotindra Zaveri E-LibraryNo ratings yet

- Customer Relationship Management: Mms at IesDocument49 pagesCustomer Relationship Management: Mms at Iesnimi210No ratings yet

- Erp Case Study 1 & 2Document18 pagesErp Case Study 1 & 2Darshan Shah100% (1)

- Erp and Supply Chain Management PDFDocument2 pagesErp and Supply Chain Management PDFChris0% (1)

- Erp Implementation Life Cycle and FrameworkDocument31 pagesErp Implementation Life Cycle and FrameworkabuNo ratings yet

- Enterprise Information Systems Project Implementation: A Case Study of ERP in Rolls-RoyceDocument21 pagesEnterprise Information Systems Project Implementation: A Case Study of ERP in Rolls-Roycesandyjbs100% (1)

- Selecting ERP System 2016Document24 pagesSelecting ERP System 2016manee4uNo ratings yet

- CSF For ERP ImplementationDocument66 pagesCSF For ERP ImplementationSandeep SinghNo ratings yet

- State of the art ERP technologies in the 21st centuryDocument21 pagesState of the art ERP technologies in the 21st centuryEric KamaraNo ratings yet

- SFADocument23 pagesSFAUsha RadhakrishnanNo ratings yet

- ERP, CRM, SCM & BI: Understanding Key Business SystemsDocument11 pagesERP, CRM, SCM & BI: Understanding Key Business SystemsAnnie NguyenNo ratings yet

- Service Quality in Institutions of Higher Learning With Reference To Vits.Document65 pagesService Quality in Institutions of Higher Learning With Reference To Vits.Abhay JainNo ratings yet

- Architect's Role in Construction Quality ManagementDocument26 pagesArchitect's Role in Construction Quality ManagementBing XinNo ratings yet

- Wan - Davi Journal 2015.pdf 856218388Document33 pagesWan - Davi Journal 2015.pdf 856218388Wan Desti TariniNo ratings yet

- Receiving Copy For RaincoatsDocument19 pagesReceiving Copy For RaincoatsJeca BellsNo ratings yet

- Balanced Scorecard Sections Louw Venter Strategic ManagementDocument6 pagesBalanced Scorecard Sections Louw Venter Strategic ManagementThuba MahlanguNo ratings yet

- IPO Performance: Nykaa's 89% RiseDocument2 pagesIPO Performance: Nykaa's 89% RiseKunal JunejaNo ratings yet

- Apo-Ppds Cookbook - 2Document40 pagesApo-Ppds Cookbook - 2Rajanish MaddesiyaNo ratings yet

- Warehouse Report Division BRD WebsiteDocument7 pagesWarehouse Report Division BRD Websiteapi-292355526No ratings yet

- 2023 AnimatorDocument1 page2023 Animatorapi-483886860No ratings yet

- Grinding Technical Questions of Producing Composite CementDocument10 pagesGrinding Technical Questions of Producing Composite CementAziz MalkiNo ratings yet

- Paper+13+ (2021 3 2) +Effect+of+Promotional+Mix+on+the+Marketing+of+Insurance+ServicesDocument10 pagesPaper+13+ (2021 3 2) +Effect+of+Promotional+Mix+on+the+Marketing+of+Insurance+ServicesAnvesh Pulishetty -BNo ratings yet

- Department Store PrjectDocument65 pagesDepartment Store PrjectRaj Kumar75% (4)

- CHANNEL MANAGEMENT STRATEGIESDocument54 pagesCHANNEL MANAGEMENT STRATEGIESPratik PatilNo ratings yet

- B2B Marketing ProjectDocument13 pagesB2B Marketing ProjectRishabh HajelaNo ratings yet

- Materials Management Two MarksDocument7 pagesMaterials Management Two Marksmarimuthu96No ratings yet

- Hospital IsocertificationDocument18 pagesHospital IsocertificationPing KyNo ratings yet

- Toyota Production SystemDocument2 pagesToyota Production SystemDiwakar BishtNo ratings yet

- Ch183 Process Cost Systemsdocx PDF FreeDocument52 pagesCh183 Process Cost Systemsdocx PDF FreeROLANDO II EVANGELISTANo ratings yet

- Executive SummaryDocument31 pagesExecutive Summaryanon_9534584080% (2)

- Create Excel and XML Data Servers in ODIDocument51 pagesCreate Excel and XML Data Servers in ODIRamu PentapatiNo ratings yet

- Sales & Distribution Management Project ReportDocument53 pagesSales & Distribution Management Project ReportPriyanshu Prajapati (Pp)No ratings yet

- Checksheet Mixing PaintDocument1 pageChecksheet Mixing PaintRizqy Fadry LazimNo ratings yet

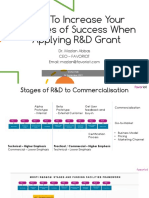

- How To Increase Your Chances of Success When Applying R&D GrantDocument19 pagesHow To Increase Your Chances of Success When Applying R&D GrantMazlan AbbasNo ratings yet

- AA164 Fasson ®: PP NG Top White - Ts8000-Bg50Wh BssDocument2 pagesAA164 Fasson ®: PP NG Top White - Ts8000-Bg50Wh BssHASAN AYDINNo ratings yet

- Offshore Outsourcing ChecklistDocument23 pagesOffshore Outsourcing Checklistapi-3826263100% (1)

- Restaurant PitchDocument21 pagesRestaurant PitchyollaNo ratings yet

- Leadership Competencies - Passion for Guest ExperienceDocument10 pagesLeadership Competencies - Passion for Guest ExperienceMohab Mohamed El GazzarNo ratings yet

- EJSR 152 4 10hamedDocument13 pagesEJSR 152 4 10hamedLuay JumaaNo ratings yet

- Moulding MCS FactoryDocument21 pagesMoulding MCS Factorymeet dodhiwalaNo ratings yet

- Weygandt J (2019) - Accounting Principles IFRS Version c06Document46 pagesWeygandt J (2019) - Accounting Principles IFRS Version c06Kirsten Rae SuaverdezNo ratings yet