Professional Documents

Culture Documents

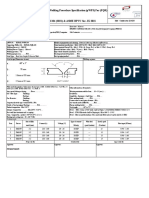

Filling Ointment Jars

Uploaded by

Amit SinghOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filling Ointment Jars

Uploaded by

Amit SinghCopyright:

Available Formats

Filling ointment jars

Ointment jars are filled on a small scale in the pharmacy by carefully

transferring the weighed amount of ointment in to the jar with a spatula .the

ointment is packed on the bottom and along the sides of the jar,avoiding

entrapment of air . the jar size should allow the ointment to reach near the

top of the jar but not so high as to touch the lid when closed . through the

adept use of spatula , some pharmacists place a curl in the center of the

surface of the ointment. Ointments prepared by fusion may be poured

directly in to ointment jar to congeal in it . this must be done cautiously to

prevent stratification of the components. In large- scale manufacture of

ointments , pressure fillers force the specified amount of ointment in to the

jars .

Filling ointment tubes

Tubes are filled from the open back end of the tube , opposite from the cap

end .

Ointments prepared by fusion may be poured while still soft but viscous

directly in to the tubes with caution to prevent stratification of the

components . on a small scale , as in the extemporaneous filling of an

ointment in the pharmacy , the tube may be filled manually or with a small –

scale filling machine .the filled tube is closed and sealed .

Tubes May Be Filled (manual filling ) By The Following Steps

1. The prepared ointment is rolled into a cylinder shape of a piece of parchment

paper, the diameter is smaller than that of the tube.

2. With cap of the tube off to permit escape of air, the cylinder of ointment with the

paper is inserted into the open bottom of the tube

3. The piece of paper covering the ointments is grasped in one hand, the other hand

forces a heavy spatula down on the extreme end of the tube, collapsing it and

retaining the ointment while the paper is slowly pulled from the tube. About one half

(1/2) inch of the bottom is then flattened with the spatula.

4. About 1/8 folds are made from the flattened end of the tube and sealed by pliers

or sealing clip on foot operated “crimper” machine.

Note: Ointments made by fusion may be poured directly into the tubes. Stored

at temperatures below 30oC to prevent softening.

Industrially , automatic filling , closing , crimping , and labeling machines are used for large –

scale tube packaging of semisolid pharmaceuticals . depending on the model , machines have the

capacity to fill about 1000 to 6000 tubes per hour ( 5, 7 ). Rotary machines have four stations for

tube feeding , cleaning , filling and closing .

Sealing of tubes

plastics and laminate tubes are closed and sealed by heat and crimping . metal tubes are sealed by

folding and crimping with or without a vinyl, latex , or lacquer sealant ( 5 ) .

You might also like

- Pharmaceutical Dosage Form Laboratory ManualDocument9 pagesPharmaceutical Dosage Form Laboratory ManualChristian Paulo D. PichayNo ratings yet

- Preparation #16: Simple Syrup Post Lab QuestionsDocument1 pagePreparation #16: Simple Syrup Post Lab QuestionsJANNIE BELLE RODRIGUEZNo ratings yet

- DDS Laboratory Activities - Prep 5-13Document32 pagesDDS Laboratory Activities - Prep 5-13ja_QuinineNo ratings yet

- Pharmaceutical Dosage Forms Lab ReviewDocument7 pagesPharmaceutical Dosage Forms Lab ReviewJana EncaboNo ratings yet

- How to make simple syrupDocument2 pagesHow to make simple syrupSebastian Moron100% (2)

- Phar DoseDocument3 pagesPhar DoseCharm MatiasNo ratings yet

- Cinnamon water preparation methodDocument1 pageCinnamon water preparation methodJANNIE BELLE RODRIGUEZNo ratings yet

- Preparation of Paracetamol and Effervescent PowdersDocument4 pagesPreparation of Paracetamol and Effervescent PowdersJames AzurinNo ratings yet

- Preparation No 12 - 15 PharLabDocument4 pagesPreparation No 12 - 15 PharLabKim Manlangit100% (4)

- Preparation 21Document14 pagesPreparation 21Khael100% (1)

- Method of Preparation for Muscle and Joint Pain Relief CreamDocument1 pageMethod of Preparation for Muscle and Joint Pain Relief CreamLyanlie MinamotoNo ratings yet

- Phardose Lab (Prep 6-10)Document3 pagesPhardose Lab (Prep 6-10)Jan Aira Almazan100% (1)

- PH 107 DDS Lab Midterm NotesDocument11 pagesPH 107 DDS Lab Midterm NotesKrsna NaveraNo ratings yet

- Phar Dose Lab Prep 19-22Document2 pagesPhar Dose Lab Prep 19-22Alyana Dizon100% (2)

- Peppermint Water Preparation MethodDocument1 pagePeppermint Water Preparation MethodJANNIE BELLE RODRIGUEZNo ratings yet

- Acacia Mucilage Uses for Emulsions & SuspensionsDocument4 pagesAcacia Mucilage Uses for Emulsions & SuspensionsMeah Pacheco0% (1)

- Sugar and Starch Sources for Medicinal and Industrial UsesDocument8 pagesSugar and Starch Sources for Medicinal and Industrial UsesAlexandra Venice ChuaNo ratings yet

- Dispensing2 Lab - Therapeutic IncompatibilitiesDocument2 pagesDispensing2 Lab - Therapeutic IncompatibilitiesAlyssa Erika Azores100% (1)

- White Wax 50 G White Petrolatum 950 G To Make 1000 GDocument3 pagesWhite Wax 50 G White Petrolatum 950 G To Make 1000 GRoseanne Legaspi CasayuranNo ratings yet

- Pha6111 Dispensing Lab Customer Service PDFDocument5 pagesPha6111 Dispensing Lab Customer Service PDFKATHLEEN CALALANGNo ratings yet

- Preparation #13: Calcium Hydroxide Topical Solution Post Lab QuestionsDocument1 pagePreparation #13: Calcium Hydroxide Topical Solution Post Lab QuestionsJANNIE BELLE RODRIGUEZ50% (2)

- Pharmaceutical Microbiology Lab Worksheet ProceduresDocument3 pagesPharmaceutical Microbiology Lab Worksheet ProceduresPRINCESS JULIENNE YUNo ratings yet

- Preparation 19Document3 pagesPreparation 19Kimberley Anne See100% (1)

- Acacia Mucilage Lab ReportDocument1 pageAcacia Mucilage Lab ReportJANNIE BELLE RODRIGUEZNo ratings yet

- Classification Tests For Hydroxyl and Carbonyl Containing Compounds AutosavedDocument9 pagesClassification Tests For Hydroxyl and Carbonyl Containing Compounds AutosavedCamille OngchuanNo ratings yet

- PHARDOSE LAB Preparation 21-31Document2 pagesPHARDOSE LAB Preparation 21-31Czarina Barcelon Daos75% (4)

- Formal Report Experiment 3 EnzymesDocument4 pagesFormal Report Experiment 3 Enzymesliezl_alvarez_1No ratings yet

- Assay of Aromatic Spirit of Ammonia For Ammonium CarbonateDocument18 pagesAssay of Aromatic Spirit of Ammonia For Ammonium CarbonateBj LarracasNo ratings yet

- Isolation and Characterization of CarbohydratesDocument4 pagesIsolation and Characterization of CarbohydratesJearweine FormaranNo ratings yet

- Phardose 19 31 DiscussionDocument8 pagesPhardose 19 31 DiscussionAnna Patricia Berza100% (1)

- Dispensing Post LabDocument3 pagesDispensing Post LabYanni Bryan RegaladoNo ratings yet

- Mineral Oil Emulsion: Dispersed System Official Title Category SynonymsDocument4 pagesMineral Oil Emulsion: Dispersed System Official Title Category SynonymsKate MendozaNo ratings yet

- Prep 9 White Ointment-PharcenDocument7 pagesPrep 9 White Ointment-PharcenKate MendozaNo ratings yet

- Extemporaneous Compounding of PowdersDocument7 pagesExtemporaneous Compounding of PowdersMarie Eloise BugayongNo ratings yet

- Exercise 23 - Sulfur OintmentDocument4 pagesExercise 23 - Sulfur OintmentmaimaiNo ratings yet

- Cold Cream FormDocument2 pagesCold Cream FormsskkaleNo ratings yet

- Phardose Lab Prep 1-6Document4 pagesPhardose Lab Prep 1-6Kimberley Anne SeeNo ratings yet

- Pharmaceutical Dosage Forms Laboratory ManualDocument2 pagesPharmaceutical Dosage Forms Laboratory Manuallalag yanNo ratings yet

- Volatile Oils Resins: Post-Lab Discussion (Experiment 6, 7, & 8)Document30 pagesVolatile Oils Resins: Post-Lab Discussion (Experiment 6, 7, & 8)Christelle GalecioNo ratings yet

- Mg Citrate preparationDocument1 pageMg Citrate preparationJANNIE BELLE RODRIGUEZ100% (1)

- Cold Cream USPDocument4 pagesCold Cream USPRon OlegarioNo ratings yet

- Preparation #19: Iso-Alcoholic Elixir Post Lab QuestionsDocument1 pagePreparation #19: Iso-Alcoholic Elixir Post Lab QuestionsJANNIE BELLE RODRIGUEZNo ratings yet

- Peppermint WaterDocument2 pagesPeppermint WaterJake Frost86% (7)

- 3RD Shifting Phardosage Lab ReviewerDocument14 pages3RD Shifting Phardosage Lab ReviewerMikaela LaoNo ratings yet

- Formal ReportDocument3 pagesFormal ReportRiczen Mae F. Vila33% (3)

- Phardose PreparationsDocument9 pagesPhardose PreparationsMaggie Quinto100% (1)

- Activity #3Document9 pagesActivity #3PrincessNo ratings yet

- Zinc Oxide With Salicylic Acid: University of Perpetual Help System DaltaDocument4 pagesZinc Oxide With Salicylic Acid: University of Perpetual Help System DaltaSittie Fahieda AloyodanNo ratings yet

- Peppermint Spirit Formula PreparationDocument2 pagesPeppermint Spirit Formula PreparationGerard LeeNo ratings yet

- Preparation #17: Chocolate Syrup Post Lab QuestionsDocument1 pagePreparation #17: Chocolate Syrup Post Lab QuestionsJANNIE BELLE RODRIGUEZNo ratings yet

- PHA6111 Lab ACTIVITY 2 HERNANDEZDocument4 pagesPHA6111 Lab ACTIVITY 2 HERNANDEZGrace HernandezNo ratings yet

- Granules and suspensionsDocument4 pagesGranules and suspensionsAlexandra GarciaNo ratings yet

- (Pp.401-411) Dry Method-Ex of Magmas and GelsDocument11 pages(Pp.401-411) Dry Method-Ex of Magmas and GelsJicah Mae LumbaoNo ratings yet

- Enzymes and Effects of PHDocument4 pagesEnzymes and Effects of PHSeph Cordova50% (2)

- Prep 22-27Document2 pagesPrep 22-27soubi_yodi100% (1)

- How To Make AspirinDocument5 pagesHow To Make Aspirincb67No ratings yet

- Capsules Edited ContentDocument11 pagesCapsules Edited ContentTulasee ReddiNo ratings yet

- Introduction of OintmentDocument2 pagesIntroduction of OintmentEbad RazviNo ratings yet

- Capsules:: Hard: Solid Filling Material Soft: Semisolid-Liquid MaterialDocument4 pagesCapsules:: Hard: Solid Filling Material Soft: Semisolid-Liquid MaterialAhmed AldumainiNo ratings yet

- Hard Gelatin CapsulesDocument21 pagesHard Gelatin Capsulesavn6No ratings yet

- Swing Garden SwingDocument7 pagesSwing Garden SwingAlicia MariaNo ratings yet

- Press Working OperationsDocument23 pagesPress Working OperationsKanagaraj Ganesan100% (1)

- Asme Section Ii A Sa-20 Sa-20mDocument42 pagesAsme Section Ii A Sa-20 Sa-20mksd2No ratings yet

- Wave Cyber: Pressure Vessel Lifting, Handling & Installation InstructionsDocument15 pagesWave Cyber: Pressure Vessel Lifting, Handling & Installation InstructionsjayNo ratings yet

- NUBERG General TradingDocument1 pageNUBERG General TradingNexus Inspectorate Private LimitedNo ratings yet

- RT Report For CastingDocument1 pageRT Report For CastingSwarup mishraNo ratings yet

- TIEIG 2023 - Twin Washers & Disc SpringsDocument24 pagesTIEIG 2023 - Twin Washers & Disc SpringsHülya Kula ÇİÇEKÇİNo ratings yet

- Win a FREE Trip to Italy! Contest Runs Sept 15 - Jan 15Document84 pagesWin a FREE Trip to Italy! Contest Runs Sept 15 - Jan 15mvb100% (2)

- Technical Data Sheet - RELY PAINTS PRIVATE LIMITED - 2Document5 pagesTechnical Data Sheet - RELY PAINTS PRIVATE LIMITED - 2iR DesignNo ratings yet

- 1 Exam Chapter 1 CSA Level 2 InspectorDocument29 pages1 Exam Chapter 1 CSA Level 2 InspectorEyyEychNo ratings yet

- Surface Cladding and Hardfacing MethodsDocument6 pagesSurface Cladding and Hardfacing MethodsEduardo GonzálezNo ratings yet

- Nisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)Document3 pagesNisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)pejman.imaniNo ratings yet

- TM0172 2015 Determining CorrosiveDocument16 pagesTM0172 2015 Determining Corrosiveahmed sobhyNo ratings yet

- Combustion - Related Fuel PropertiesDocument57 pagesCombustion - Related Fuel PropertiesNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET0194No ratings yet

- Method of Statement For Wrapping and Coating of Underground PipingDocument4 pagesMethod of Statement For Wrapping and Coating of Underground PipingKarthikNo ratings yet

- TUV India PIPING InspectionDocument26 pagesTUV India PIPING InspectionParthiban NCNo ratings yet

- Welding TechnologyDocument390 pagesWelding Technologygueess100% (2)

- JIS G 3141 (2005) Cold-Reduced Carbon Steel Sheets and Strip (SPCC SPCD SPEC)Document15 pagesJIS G 3141 (2005) Cold-Reduced Carbon Steel Sheets and Strip (SPCC SPCD SPEC)Robert SumińskiNo ratings yet

- Check List Blasting & Painting Inspection Tools: Tripatra-Samsung ConsortiumDocument1 pageCheck List Blasting & Painting Inspection Tools: Tripatra-Samsung ConsortiumHeri FebriyantoNo ratings yet

- ZN ExtractionDocument73 pagesZN ExtractionKola PattabhiNo ratings yet

- Lack of Fusion in Welded Joints: Pretty Long and Narrow and RejectableDocument20 pagesLack of Fusion in Welded Joints: Pretty Long and Narrow and RejectableSamira MahmoodiNo ratings yet

- 4LH ST PDFDocument101 pages4LH ST PDFAshley CampbellNo ratings yet

- Brazing: Brazing Is A Metal-Joining Process in Which Two or More Metal Items Are JoinedDocument20 pagesBrazing: Brazing Is A Metal-Joining Process in Which Two or More Metal Items Are JoinedAaquil RaziNo ratings yet

- BW Cleaner+401 en 2022 GL 151 PreviewDocument2 pagesBW Cleaner+401 en 2022 GL 151 PreviewDeivid MiquelinoNo ratings yet

- Good Mornin G: Prepared byDocument19 pagesGood Mornin G: Prepared byElaine Clarise AGBUYA100% (1)

- Plastic Welding TechniquesDocument33 pagesPlastic Welding TechniquesFaiz SabianNo ratings yet

- Aluminium Profile Catalogue 2020Document156 pagesAluminium Profile Catalogue 2020febri antoNo ratings yet

- Bench WorkDocument8 pagesBench WorkAl Fredo94% (17)

- Din 1691 - 1985Document12 pagesDin 1691 - 1985a.n.87711990No ratings yet

- CERT SAE 4340 180mm 8.195mtDocument1 pageCERT SAE 4340 180mm 8.195mtMiguel AychasiNo ratings yet