Professional Documents

Culture Documents

Nawapactor Vsi

Uploaded by

chand_yel100%(2)100% found this document useful (2 votes)

499 views4 pagesRock to be crushed is fed through a Feed Tube onto the center of a closed rotor. The rotor spinning at high speed throws the material with a great centrifugal force. When the accelerated rock hits the stationary rock-box, it breaks by impact along the natural fault lines resulting in a cubical shaped product.

Original Description:

Original Title

NAWAPACTOR VSI

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRock to be crushed is fed through a Feed Tube onto the center of a closed rotor. The rotor spinning at high speed throws the material with a great centrifugal force. When the accelerated rock hits the stationary rock-box, it breaks by impact along the natural fault lines resulting in a cubical shaped product.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

499 views4 pagesNawapactor Vsi

Uploaded by

chand_yelRock to be crushed is fed through a Feed Tube onto the center of a closed rotor. The rotor spinning at high speed throws the material with a great centrifugal force. When the accelerated rock hits the stationary rock-box, it breaks by impact along the natural fault lines resulting in a cubical shaped product.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

WE PARTNER YOUR NEEDS

VERTICAL SHAFT IMPACT CRUSHER

We offer you a comprehensive range of equipment and services. Wherever you do crushing, screening and

conveying, either hard rocks or mineral ores, with NAWA machines and systems, you can rely on our An Ideal Tertiary Machine for

uncompromising quality, workmanship, and unflinching support. You will find NAWA a competent and reliable

! Concrete Aggregates

partner in all your project tasks.

! Manufactured Sand

ROCK SOLID RELIABILITY

NAWA PRODUCT RANGE ! Asphalt Mixing

! Road Base Materials

Single Toggle Primary Jaw Crusher Vibrating Screen

Models PST7550 (30”x20”), ‘MaxFlow’ & ‘HiFlow’ series inclined

PST9060 (36”x24”), PST1108 screens and ‘Tripleks series

(44”x32”) and PST1209 (50”x38”); horizontal screens of 2-Deck,

Capacity range: 70-600 TPH 3-Deck & 4-Deck Models of varying

sizes

Secondary Gyratory Cone Crusher Spiral Classifier

Model 3000 GLH for secondary Spiral sizes from 600 to 2100 mm

crushing, feed opening suitable for dia for raking capacity from 15 TPH

coarse and extra coarse crushing; to 300 TPH for washing-classifying-

Capacity range: 250-350 TPH dewatering plants

Roller Bearing Cone Crusher Mobile Plants

Model 3000 RBC for secondary & Ty r e - m o u n t e d P r i m a r y J a w

tertiary crushing, feed openings St a t i o n s M o d e l N M 7 5 5 0 J ,

suitable for fine, medium, coarse N M 9 0 6 0 J , N M 11 0 8 J a n d

and extra coarse crushing from 60- NM1209J; Secondary Cone

200 TPH Stations Model NM3000RBC and

NM3000GLH/RBC-TC; Tertiary VSI

Sta t i o n M o d e l N M 3 0 0 3 V S I ,

NM3503VSI, NM4003VSI and

NM4503VSI-TD; Capacity range:

90-300 TPH

‘DuraCone SRM’ Crusher Stationary Plants

Models SRM400 and SRM500 for Turnkey crushing & screening and

Secondary & Tertiary Crushing, bulk handling plants from 70-500

feed opening suitable for fine, TPH for aggregates and mineral

medium, coarse and extra coarse ores, and manufactured sand

crushing from 250-700 TPH of hard plants

stones.

VSI Crusher Belt Conveyors

Models NP2503, NP3003, NP3503, All sizes and capacities for cement

NP4003 & NP4503; Capacity plants, thermal power stations,

range: 40-550 TPH mining and process plants.

ENGINEERS CRUSHING-SCREENING-MATERIAL HANDLING-AGGREGATE PLANTS

FEATURES

Vibrating Grizzly Feeder Concrete Delivery Systems

! Easy portability and quick installation with minimum support

800 mm, 1000 mm, 1200 mm, 1350 Belt conveying and placement of

structures.

mm and 1500 mm width and concrete in dam projects; capacity

different lengths to suit; Capacity 1000 TPH and above ! Variable capacity models for tertiary applications.

range: 50-1000 TPH

! Rock-on-Rock technology minimizes wearing of parts, hence

minimum operating and wear costs.

! Excellent cubicle shape product.

! Consistent product gradation.

Cat # NE-121-OCT10/VSI

! Low investment.

For more information, contact:

ENGINEERS & CONSULTANTS (P) LTD. ! Simple maintenance.

‘NAWAHOUSE’, Phone Web

! Quicker replacement of worn out parts -lesser downtime.

House No. 8-2-334/3&4, 91.40.2355 4071 http://www.nawaengineers.com

Road No.5, Banjara Hills, 91.40.2355 4072 ! Retro-fit for conversion to Rock-on-Steel for less abrasive

Hyderabad - 500 034 Fax Email rocks

ISO 9001:2000 CERTIFIED COMPANY

Andhra Pradesh, INDIA 91.40.2355 6706 info@nawaengineers.com

CRUSHING-SCREENING-MATERIAL HANDLING-AGGREGATE PLANTS

SOLVE YOUR AGGREGATES SHAPE PROBLEM BY ADDING A PRODUCE QUALITY MANUFACTURED SAND BY INSTALLING A

High Performance Quick and Vibration Free Installation

NAWAPACTOR is a marvel of solid A great care has been taken in

dynamics with high velocity impact developing a factory made crusher

crushing. support frame for quick installation. The

dynamically balanced machine is

The closed rotor is a high technology completely shop-assembled on an

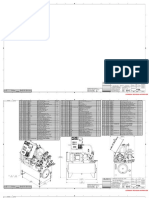

How It Works piece of work to give a greater durability integral base-frame with a motor mount.

in a high abrasion causing environment The whole assembly is placed on a

The mechanism involved is very simple. The of speeding material. The crushing sturdily designed steel skid for a

rock to be crushed is fed through the hopper and chamber with rock-box is skillfully vibration free installation and less

a feed tube onto the center of a closed rotor. The engineered to provide a high amount of foundation costs.

rotor spinning at high speed throws the material attrition coupled with free impact, and to

with a great centrifugal force. When the handle high volumes per kW of power. Our Standard Supply

accelerated rock hits the stationary rock-box,

known as Rock-on-Rock High Performance System Support The machine will be delivered as a

principle, it breaks by impact along the natural complete and stand alone unit reducing

fault lines resulting in a cubical shaped product, Our application engineers will analyze the burden on the user to look for any

which falls freely by gravity on to a conveyor belt your crushing tasks. They develop add-ons before installation. The

below. alternative configurations and assist you standard supply includes:

in arriving at an economical solution.

The Rock-on-Rock principle simulates the ! Feed Spout

Using their in-depth knowledge they will

nature's way of impact and grinding that occurs

select appropriate equipment including ! Discharge chute

in generation of particle shape in natural sand.

the NAWAPACTOR VSI that would

! Main machine with integral base-

The VSI crusher thus comes out a winner as guarantee you the highest quality end

frame

producer of quality aggregates as well as product.

Manufactured Sand, which is very close to the ! Motor mount

natural sand in particle shape and gradation. The crushers are manufactured to

! Machine pulley, motor pulley and

stringent quality standards. Each

V-belts

machine is vigorously tested on the shop

floor before shipment to the user. ! Skid frame

! Electric motor (optional)

Our commissioning engineers will help

you to a smooth integration of the ! Control panel (optional)

machine into your plant.

Spare Parts and Service

Our designers are constantly innovating

the methods and metallurgy vis-à-vis

Hopper Information Required for VSI

different rock characteristics to improve

Selection

the life of wear components. We are

committed to assist all our users to

Feed Tube ! Material Type, Abrasive Index, Feed

optimise the operating cost per ton of

Size and Gradation, Bulk Density

production in their crushing task.

and Hardness

Retro-Fits for Rock-on-Steel As your long-standing and reliable ! Capacity in TPH

partner, we guarantee delivery of original

NAWA offers anvil rings and rock box ! Product Fractions Required

quality spare parts. Our service

combinations to convert the Rock-on-Rock to Anvil Assembly

(Optional) engineers do professional change of ! Proposed Plant Configuration

Rock-on-Steel models for lesser abrasive rocks

parts that are subject to wear and tear.

to get higher product yield. The retro-fits can be

Rotor They train your operators on the job.

quickly installed in the existing Rock-on-Rock

They do periodic inspection of the

models with minimum changes in the machine,

machine to ensure its high efficiency and

which can be conveniently done at site. The

Bearing Catridge output.

retro-fits give the flexibility to change-over

between Rock-on-Rock and Rock-on-Steel

applications to meet the differing product needs.

Shaft with

Drive Pulley NAWAPACTOR Specifications :

Model No. NP2503 NP3003 NP3503 NP4003 NP4503 NP5003

Max. Size of Feed (mm) 25 40 40 40 40 40

Quality Standards for Aggregates Quality of aggregates produced depends on many factors Rotor Size 600 760 900 1000 1000DR 1200

like: type of stone crushed, reduction ratio, crushing chamber

The aggregate quality specifications for road building under design, choke feeding, comminution properties etc. Power (kW) 45/55 90/110 132/185 200/370 370/450 500/800

Ministry of Road Transport & Highways (MORT&H) and NHAI

calls for a total combined flakiness and elongation index of The best way to get good shape in aggregate is by allowing Capacity (tph) 40 - 50 75 - 110 120-200 200-350 320 - 550 550 - 800

<30%. This specification is considered to be world class by the rock to break on its natural cleavages under free impact Figures given vary with applications. For final selection, refer your requirements to us. The machine is under continuous development. The parameters are subject to vary.

crushing equipment manufacturers and quarry operators. conditions. This is the principle of crushing in a Vertical Shaft For drives more than 200kW, twin drive is recommended.

Impact Crusher.

SOLVE YOUR AGGREGATES SHAPE PROBLEM BY ADDING A PRODUCE QUALITY MANUFACTURED SAND BY INSTALLING A

High Performance Quick and Vibration Free Installation

NAWAPACTOR is a marvel of solid A great care has been taken in

dynamics with high velocity impact developing a factory made crusher

crushing. support frame for quick installation. The

dynamically balanced machine is

The closed rotor is a high technology completely shop-assembled on an

How It Works piece of work to give a greater durability integral base-frame with a motor mount.

in a high abrasion causing environment The whole assembly is placed on a

The mechanism involved is very simple. The of speeding material. The crushing sturdily designed steel skid for a

rock to be crushed is fed through the hopper and chamber with rock-box is skillfully vibration free installation and less

a feed tube onto the center of a closed rotor. The engineered to provide a high amount of foundation costs.

rotor spinning at high speed throws the material attrition coupled with free impact, and to

with a great centrifugal force. When the handle high volumes per kW of power. Our Standard Supply

accelerated rock hits the stationary rock-box,

known as Rock-on-Rock High Performance System Support The machine will be delivered as a

principle, it breaks by impact along the natural complete and stand alone unit reducing

fault lines resulting in a cubical shaped product, Our application engineers will analyze the burden on the user to look for any

which falls freely by gravity on to a conveyor belt your crushing tasks. They develop add-ons before installation. The

below. alternative configurations and assist you standard supply includes:

in arriving at an economical solution.

The Rock-on-Rock principle simulates the ! Feed Spout

Using their in-depth knowledge they will

nature's way of impact and grinding that occurs

select appropriate equipment including ! Discharge chute

in generation of particle shape in natural sand.

the NAWAPACTOR VSI that would

! Main machine with integral base-

The VSI crusher thus comes out a winner as guarantee you the highest quality end

frame

producer of quality aggregates as well as product.

Manufactured Sand, which is very close to the ! Motor mount

natural sand in particle shape and gradation. The crushers are manufactured to

! Machine pulley, motor pulley and

stringent quality standards. Each

V-belts

machine is vigorously tested on the shop

floor before shipment to the user. ! Skid frame

! Electric motor (optional)

Our commissioning engineers will help

you to a smooth integration of the ! Control panel (optional)

machine into your plant.

Spare Parts and Service

Our designers are constantly innovating

the methods and metallurgy vis-à-vis

Hopper Information Required for VSI

different rock characteristics to improve

Selection

the life of wear components. We are

committed to assist all our users to

Feed Tube ! Material Type, Abrasive Index, Feed

optimise the operating cost per ton of

Size and Gradation, Bulk Density

production in their crushing task.

and Hardness

Retro-Fits for Rock-on-Steel As your long-standing and reliable ! Capacity in TPH

partner, we guarantee delivery of original

NAWA offers anvil rings and rock box ! Product Fractions Required

quality spare parts. Our service

combinations to convert the Rock-on-Rock to Anvil Assembly

(Optional) engineers do professional change of ! Proposed Plant Configuration

Rock-on-Steel models for lesser abrasive rocks

parts that are subject to wear and tear.

to get higher product yield. The retro-fits can be

Rotor They train your operators on the job.

quickly installed in the existing Rock-on-Rock

They do periodic inspection of the

models with minimum changes in the machine,

machine to ensure its high efficiency and

which can be conveniently done at site. The

Bearing Catridge output.

retro-fits give the flexibility to change-over

between Rock-on-Rock and Rock-on-Steel

applications to meet the differing product needs.

Shaft with

Drive Pulley NAWAPACTOR Specifications :

Model No. NP2503 NP3003 NP3503 NP4003 NP4503 NP5003

Max. Size of Feed (mm) 25 40 40 40 40 40

Quality Standards for Aggregates Quality of aggregates produced depends on many factors Rotor Size 600 760 900 1000 1000DR 1200

like: type of stone crushed, reduction ratio, crushing chamber

The aggregate quality specifications for road building under design, choke feeding, comminution properties etc. Power (kW) 45/55 90/110 132/185 200/370 370/450 500/800

Ministry of Road Transport & Highways (MORT&H) and NHAI

calls for a total combined flakiness and elongation index of The best way to get good shape in aggregate is by allowing Capacity (tph) 40 - 50 75 - 110 120-200 200-350 320 - 550 550 - 800

<30%. This specification is considered to be world class by the rock to break on its natural cleavages under free impact Figures given vary with applications. For final selection, refer your requirements to us. The machine is under continuous development. The parameters are subject to vary.

crushing equipment manufacturers and quarry operators. conditions. This is the principle of crushing in a Vertical Shaft For drives more than 200kW, twin drive is recommended.

Impact Crusher.

WE PARTNER YOUR NEEDS

VERTICAL SHAFT IMPACT CRUSHER

We offer you a comprehensive range of equipment and services. Wherever you do crushing, screening and

conveying, either hard rocks or mineral ores, with NAWA machines and systems, you can rely on our An Ideal Tertiary Machine for

uncompromising quality, workmanship, and unflinching support. You will find NAWA a competent and reliable

! Concrete Aggregates

partner in all your project tasks.

! Manufactured Sand

ROCK SOLID RELIABILITY

NAWA PRODUCT RANGE ! Asphalt Mixing

! Road Base Materials

Single Toggle Primary Jaw Crusher Vibrating Screen

Models PST7550 (30”x20”), ‘MaxFlow’ & ‘HiFlow’ series inclined

PST9060 (36”x24”), PST1108 screens and ‘Tripleks series

(44”x32”) and PST1209 (50”x38”); horizontal screens of 2-Deck,

Capacity range: 70-600 TPH 3-Deck & 4-Deck Models of varying

sizes

Secondary Gyratory Cone Crusher Spiral Classifier

Model 3000 GLH for secondary Spiral sizes from 600 to 2100 mm

crushing, feed opening suitable for dia for raking capacity from 15 TPH

coarse and extra coarse crushing; to 300 TPH for washing-classifying-

Capacity range: 250-350 TPH dewatering plants

Roller Bearing Cone Crusher Mobile Plants

Model 3000 RBC for secondary & Ty r e - m o u n t e d P r i m a r y J a w

tertiary crushing, feed openings St a t i o n s M o d e l N M 7 5 5 0 J ,

suitable for fine, medium, coarse N M 9 0 6 0 J , N M 11 0 8 J a n d

and extra coarse crushing from 60- NM1209J; Secondary Cone

200 TPH Stations Model NM3000RBC and

NM3000GLH/RBC-TC; Tertiary VSI

Sta t i o n M o d e l N M 3 0 0 3 V S I ,

NM3503VSI, NM4003VSI and

NM4503VSI-TD; Capacity range:

90-300 TPH

‘DuraCone SRM’ Crusher Stationary Plants

Models SRM400 and SRM500 for Turnkey crushing & screening and

Secondary & Tertiary Crushing, bulk handling plants from 70-500

feed opening suitable for fine, TPH for aggregates and mineral

medium, coarse and extra coarse ores, and manufactured sand

crushing from 250-700 TPH of hard plants

stones.

VSI Crusher Belt Conveyors

Models NP2503, NP3003, NP3503, All sizes and capacities for cement

NP4003 & NP4503; Capacity plants, thermal power stations,

range: 40-550 TPH mining and process plants.

ENGINEERS CRUSHING-SCREENING-MATERIAL HANDLING-AGGREGATE PLANTS

FEATURES

Vibrating Grizzly Feeder Concrete Delivery Systems

! Easy portability and quick installation with minimum support

800 mm, 1000 mm, 1200 mm, 1350 Belt conveying and placement of

structures.

mm and 1500 mm width and concrete in dam projects; capacity

different lengths to suit; Capacity 1000 TPH and above ! Variable capacity models for tertiary applications.

range: 50-1000 TPH

! Rock-on-Rock technology minimizes wearing of parts, hence

minimum operating and wear costs.

! Excellent cubicle shape product.

! Consistent product gradation.

Cat # NE-121-OCT10/VSI

! Low investment.

For more information, contact:

ENGINEERS & CONSULTANTS (P) LTD. ! Simple maintenance.

‘NAWAHOUSE’, Phone Web

! Quicker replacement of worn out parts -lesser downtime.

House No. 8-2-334/3&4, 91.40.2355 4071 http://www.nawaengineers.com

Road No.5, Banjara Hills, 91.40.2355 4072 ! Retro-fit for conversion to Rock-on-Steel for less abrasive

Hyderabad - 500 034 Fax Email rocks

ISO 9001:2000 CERTIFIED COMPANY

Andhra Pradesh, INDIA 91.40.2355 6706 info@nawaengineers.com

CRUSHING-SCREENING-MATERIAL HANDLING-AGGREGATE PLANTS

You might also like

- Descriptive Pamphlet of the Richmond Mill Furnishing WorksFrom EverandDescriptive Pamphlet of the Richmond Mill Furnishing WorksNo ratings yet

- TV Series Vertical Impact Crushers: Highly Efficient Crushing SolutionsDocument8 pagesTV Series Vertical Impact Crushers: Highly Efficient Crushing SolutionsShawn ChenNo ratings yet

- Wmd0976 Trio Tc66 Series Cone Crusher Spec SheetDocument2 pagesWmd0976 Trio Tc66 Series Cone Crusher Spec SheetYang Wan100% (1)

- Size Control: - Screening Using A Geometrical Pattern For Size ControlDocument5 pagesSize Control: - Screening Using A Geometrical Pattern For Size ControlSergei DumrovaNo ratings yet

- Vsi 2Document9 pagesVsi 2Vivek AgrawalNo ratings yet

- 8r77r-Cybas I ConeDocument6 pages8r77r-Cybas I Coneturkishdjem100% (1)

- Barmac Sales Manual April2011Document66 pagesBarmac Sales Manual April2011NelsonNo ratings yet

- UH320 ClassicDocument2 pagesUH320 ClassicRicardo E Andrea RachelNo ratings yet

- Purchased Part Specification: Current Revision ApprovedDocument9 pagesPurchased Part Specification: Current Revision ApprovedJavier Pineda GalvisNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFมนต์ชัย บุญธนลาภNo ratings yet

- Sandvik HSI EN PDFDocument8 pagesSandvik HSI EN PDFkranthiNo ratings yet

- Jaw Crusher Broch 2Document12 pagesJaw Crusher Broch 2Nanjappa K NuchumaniandaNo ratings yet

- Hydraulic Diagram MM0346835 - 1Document4 pagesHydraulic Diagram MM0346835 - 1miguel. montañoNo ratings yet

- Vertical Shaft Impactor - Sand Making MachineDocument37 pagesVertical Shaft Impactor - Sand Making Machineaaronshakti100% (1)

- 05.CH660-04 Installation Instructions S223.1257-04 enDocument78 pages05.CH660-04 Installation Instructions S223.1257-04 enMichael adu-boahen100% (1)

- Jaw CrusherDocument4 pagesJaw CrusherRebekah HaleNo ratings yet

- Sandvik S6800 Crusher Parts ManualDocument3 pagesSandvik S6800 Crusher Parts ManualTomas Chien100% (1)

- The MP2500: The Largest Cone Crusher Ever Built: Materials Handling and LogisticsDocument1 pageThe MP2500: The Largest Cone Crusher Ever Built: Materials Handling and LogisticsDiegoAlvarezHuguezNo ratings yet

- Mobile Jaw Crusher PDFDocument7 pagesMobile Jaw Crusher PDFNguyễn LinhNo ratings yet

- Dynamic Study and Balances Cone Crusher Small Crushing Environment in Solidworks MotionDocument3 pagesDynamic Study and Balances Cone Crusher Small Crushing Environment in Solidworks MotionlandagoNo ratings yet

- Deepak Project On Jaw CrusherDocument96 pagesDeepak Project On Jaw CrusherAnil Kumar KnNo ratings yet

- Project Case - CT4254 JAW PLATESDocument4 pagesProject Case - CT4254 JAW PLATESNicole WuNo ratings yet

- Uranium Corporation of India Limited P.O: Jaduguda Mines, Jharkhand - 832102Document4 pagesUranium Corporation of India Limited P.O: Jaduguda Mines, Jharkhand - 832102arsanioseNo ratings yet

- QMS - General BrochureDocument6 pagesQMS - General BrochureArpit VermaNo ratings yet

- Screen in The Middle Position (27DEG, 5480MM) : Drawing ST4.8Document2 pagesScreen in The Middle Position (27DEG, 5480MM) : Drawing ST4.8Dorin IlasNo ratings yet

- Excel Tramp Release System Upgrade For HP700 and HP800 Cone CrushersDocument2 pagesExcel Tramp Release System Upgrade For HP700 and HP800 Cone CrushersCarlos Andres Maldonado ArdilesNo ratings yet

- Excel Gears and Pinions For Cone CrushersDocument2 pagesExcel Gears and Pinions For Cone CrushersJohnDim100% (2)

- NW-FH NW106 GA Drawing R002-1Document2 pagesNW-FH NW106 GA Drawing R002-1Zoran Djurdjevic100% (1)

- Excel Certified Eye Bolts For Symons Cone CrushersDocument2 pagesExcel Certified Eye Bolts For Symons Cone CrushersJohnDimNo ratings yet

- MANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFDocument27 pagesMANUAL DE CONO SYMONS DESDE EMCC - Archivo PDFGuillermo BalarinniNo ratings yet

- Mantos A Pedir para El Cono k200Document1 pageMantos A Pedir para El Cono k200Vladimir Illich Pinzon BallenNo ratings yet

- Trio TC51 Series Cone Crusher.Document2 pagesTrio TC51 Series Cone Crusher.Enso E Rosales FNo ratings yet

- Sandvik S4800 Crusher Parts ManualDocument5 pagesSandvik S4800 Crusher Parts ManualTomas ChienNo ratings yet

- Sandvik CA Series Folder 8sid A4 LowDocument8 pagesSandvik CA Series Folder 8sid A4 LowRelining MineralsNo ratings yet

- Book1 11Document38 pagesBook1 11chandradeep yadavNo ratings yet

- Washing and Classifying Brochure EnglishDocument24 pagesWashing and Classifying Brochure EnglishMohammed Alshami GeologistNo ratings yet

- Gyratory Mill: EccentricDocument10 pagesGyratory Mill: EccentricAbhishek Kumar100% (1)

- Bulletin 1047Document2 pagesBulletin 1047Cesar Casachagua DavilaNo ratings yet

- Dynamic Modeling and Simulation of Cone Crushing Circuits PDFDocument7 pagesDynamic Modeling and Simulation of Cone Crushing Circuits PDFmarceladeveraNo ratings yet

- Hazemag Hpi HPC EngDocument16 pagesHazemag Hpi HPC EngMohammed ElhayloufiNo ratings yet

- JW Series Jaw Crushers: Terex Minerals Processing SystemsDocument16 pagesJW Series Jaw Crushers: Terex Minerals Processing SystemsKarin Anderson100% (1)

- WO 2014/075722 Al: International BureauDocument17 pagesWO 2014/075722 Al: International BureauneusonNo ratings yet

- KEESTRACK Productoverview - 5.17 - Eng - Web - 11Document43 pagesKEESTRACK Productoverview - 5.17 - Eng - Web - 11Антон ЛазаровNo ratings yet

- Terex Jaques - Apron FeederDocument12 pagesTerex Jaques - Apron FeederJoseph Amoateng Appiah-kubi WadaadaNo ratings yet

- ) Mets: Iqdilution BookDocument106 pages) Mets: Iqdilution BookDanilNo ratings yet

- HP - CONICA General-Introduction PDFDocument25 pagesHP - CONICA General-Introduction PDFluisantonio2No ratings yet

- Hazemag Hpi-H EngDocument16 pagesHazemag Hpi-H Engekrem0867100% (1)

- EXCEL High Performance Parts For HP-Cone-Crushers - MetsoDocument7 pagesEXCEL High Performance Parts For HP-Cone-Crushers - MetsoabcNo ratings yet

- Technical Bulletin: Bleeding Air From The Hydroset SystemDocument5 pagesTechnical Bulletin: Bleeding Air From The Hydroset SystemMf Lui100% (1)

- Cone Crusher SBMDocument3 pagesCone Crusher SBMOrlando Melipillan100% (1)

- TBK 80 (Ø850) Rock-On-Rock Vsi Crusher Operation and Maintenance ManualDocument44 pagesTBK 80 (Ø850) Rock-On-Rock Vsi Crusher Operation and Maintenance ManualIruna HupaloNo ratings yet

- Vibratory Feeders and Conveyors PDFDocument14 pagesVibratory Feeders and Conveyors PDFArnaldo BenitezNo ratings yet

- Cone Crusher Metso Nordberg gp220 en 2816Document3 pagesCone Crusher Metso Nordberg gp220 en 2816Binu VarkeyNo ratings yet

- Technical Specifications: Original InstructionsDocument34 pagesTechnical Specifications: Original InstructionsEduardoNo ratings yet

- Rocksledger: Primary Jaw CrushersDocument2 pagesRocksledger: Primary Jaw CrushersMechanical department100% (2)

- Jaw Crusher ThyssenkruppDocument12 pagesJaw Crusher ThyssenkrupplucasmaltaNo ratings yet

- Cone Crusher RBC3000Document4 pagesCone Crusher RBC3000chand_yel100% (2)

- Somani Industries: Complete Rock Mining SolutionDocument8 pagesSomani Industries: Complete Rock Mining SolutionLeonardo Da-vinciNo ratings yet

- Magnum: Rock BitsDocument1 pageMagnum: Rock Bitsmohammad teimuriNo ratings yet

- E Broch-VSI (3) - Compressed-CompressedDocument10 pagesE Broch-VSI (3) - Compressed-CompressedPradeep SambhusNo ratings yet

- BHS RPMDocument16 pagesBHS RPMchand_yelNo ratings yet

- M.S Flats Dimension and Properties - Weight in KG / Metre As Per Isi Specfication Is: 2062-1999Document11 pagesM.S Flats Dimension and Properties - Weight in KG / Metre As Per Isi Specfication Is: 2062-1999chand_yelNo ratings yet

- Egg Omlet Nutrition InformationDocument2 pagesEgg Omlet Nutrition Informationchand_yelNo ratings yet

- NAWA Spiral ClassifierDocument2 pagesNAWA Spiral ClassifierChandra ShekarNo ratings yet

- Paneer Cooked in Cashew Sauce / Shahi PaneerDocument9 pagesPaneer Cooked in Cashew Sauce / Shahi Paneerchand_yelNo ratings yet

- Elec Grs Pumps 203seriesDocument5 pagesElec Grs Pumps 203serieschand_yelNo ratings yet

- Mobile Jaw Crusher NM1209JDocument2 pagesMobile Jaw Crusher NM1209Jchand_yelNo ratings yet

- Hazardous Duty Motors: Data, Facts and DetailsDocument2 pagesHazardous Duty Motors: Data, Facts and Detailschand_yelNo ratings yet

- Sites Process Steelcastings Pages MaterialsDocument9 pagesSites Process Steelcastings Pages Materialschand_yelNo ratings yet

- Rotary Seal Design GuideDocument434 pagesRotary Seal Design GuideBhargav Suvagiya100% (3)

- Personal GrowthDocument17 pagesPersonal Growthchand_yelNo ratings yet

- WwwDocument1 pageWwwchand_yelNo ratings yet

- Cone Crusher RBC3000Document4 pagesCone Crusher RBC3000chand_yel100% (2)

- Cone CrusherDocument3 pagesCone Crusherchand_yelNo ratings yet

- B.Tech. (CCC) IV Year (NR) Results - March, 2012: HTNO:07063A3651 Name: S Jayakumar Father Name: YYYDocument1 pageB.Tech. (CCC) IV Year (NR) Results - March, 2012: HTNO:07063A3651 Name: S Jayakumar Father Name: YYYchand_yelNo ratings yet

- Sandvik ASRi ENGDocument8 pagesSandvik ASRi ENGchand_yel50% (2)

- H SeriesDocument2 pagesH Serieschand_yelNo ratings yet

- Aumund - StakerDocument24 pagesAumund - Stakerchand_yelNo ratings yet

- Twin Cone MobileDocument2 pagesTwin Cone Mobilechand_yelNo ratings yet

- 1108 Jaw Crusher MobileDocument2 pages1108 Jaw Crusher Mobilechand_yelNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument15 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- Exam Flashcards: by Jonathan DonadoDocument520 pagesExam Flashcards: by Jonathan Donadosolarstuff100% (1)

- State ManagementDocument16 pagesState Managementnegikamal703No ratings yet

- Capstone Documentation RevisedDocument5 pagesCapstone Documentation RevisedMary Joy BolinaNo ratings yet

- Electronic Dice Using LEDs Electrical Engineering ProjectDocument16 pagesElectronic Dice Using LEDs Electrical Engineering Projectprakhar agarwal33% (3)

- AHRLACDocument18 pagesAHRLACVictor Pileggi100% (1)

- Final Reporting GuidelinesDocument183 pagesFinal Reporting GuidelinesAkhmad NuzulNo ratings yet

- 20 Site SummaryDocument2 pages20 Site SummaryMuzammil WepukuluNo ratings yet

- Teaching Finite Element Analysis For Design Engineers: August 2011Document7 pagesTeaching Finite Element Analysis For Design Engineers: August 2011Nelu CheluNo ratings yet

- Feasibility Study of Solar Photovoltaic (PV) Energy Systems For Rural Villages of Ethiopian Somali Region (A Case Study of Jigjiga Zone)Document7 pagesFeasibility Study of Solar Photovoltaic (PV) Energy Systems For Rural Villages of Ethiopian Somali Region (A Case Study of Jigjiga Zone)ollata kalanoNo ratings yet

- 4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSDocument3 pages4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSPaulo PiresNo ratings yet

- Rational Suite ToolsDocument47 pagesRational Suite ToolsZatin GuptaNo ratings yet

- Apqp - DR SHFTDocument60 pagesApqp - DR SHFTrajesh5000100% (2)

- Hot Air Oven Or Dry Oven: نﺎﺸﻄﻋ ﻦﻴﺴﺣ ﻲﻠﻋ G @a - nv19Document2 pagesHot Air Oven Or Dry Oven: نﺎﺸﻄﻋ ﻦﻴﺴﺣ ﻲﻠﻋ G @a - nv19حسين محمد مطرود كاظمNo ratings yet

- 03-1 Synchronous Machines 1 DNDocument25 pages03-1 Synchronous Machines 1 DNsaif thuraonNo ratings yet

- Alloys DensityDocument4 pagesAlloys DensityArnold Melissa CollettNo ratings yet

- Web 2.0: Dynamic Web PagesDocument12 pagesWeb 2.0: Dynamic Web PagesAra PantaleonNo ratings yet

- EN 1991-1-4 NA enDocument4 pagesEN 1991-1-4 NA enanuj3936100% (1)

- Eramus Bridge PDFDocument10 pagesEramus Bridge PDFBabaO.Riley100% (1)

- Q3 NSP - SLP - RLPDocument41 pagesQ3 NSP - SLP - RLPRushi RavalNo ratings yet

- Siemens Engineering Manual V7Document338 pagesSiemens Engineering Manual V7Jeremy Branch100% (2)

- Jacky Smith Resume Project ManagerDocument1 pageJacky Smith Resume Project ManagerGrey GrayNo ratings yet

- SIM BoxingDocument2 pagesSIM Boxingkrishnakant_75No ratings yet

- Cisco Network DiagramDocument1 pageCisco Network DiagramĐỗ DuyNo ratings yet

- Triaxial Test Systems enDocument10 pagesTriaxial Test Systems enDetjan JuniorNo ratings yet

- DT NotesDocument117 pagesDT NotestessNo ratings yet

- Asgmnt HECRASDocument7 pagesAsgmnt HECRASShahruzi MahadzirNo ratings yet

- MILL Series GB-1007 01Document20 pagesMILL Series GB-1007 01Ady IonutNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Fast, Accurate Data Management Across The Enterprise: Fact Sheet: File-Aid / MvsDocument4 pagesFast, Accurate Data Management Across The Enterprise: Fact Sheet: File-Aid / MvsLuis RamirezNo ratings yet